Beruflich Dokumente

Kultur Dokumente

Manual Pajero 4x4 Intake and Exhaust

Hochgeladen von

GIAN CARLO MAMANI GILES.Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual Pajero 4x4 Intake and Exhaust

Hochgeladen von

GIAN CARLO MAMANI GILES.Copyright:

Verfügbare Formate

15-1

INTAKE AND

EXHAUST

CONTENTS 15109000311

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . 2 INTERCOOLER AND INTERCOOLER

FAN-ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTAKE MANIFOLD <6G7> . . . . . . . . . . . . . . . . . 8

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 2

Intake Manifold Vacuum Check <6G7> . . . . . . . . . 2

Turbocharger Supercharging Check <4D5> . . . . . 2

Waste Gate Actuator Check <4D5> . . . . . . . . . . 3

Power Relay Check . . . . . . . . . . . . . . . . . . . . . . . . . . 3

TURBOCHARGER AND EXHAUST

MANIFOLD <4D5> . . . . . . . . . . . . . . . . . . . . . . 12

TURBOCHARGER . . . . . . . . . . . . . . . . . . . . . . . . 15

EXHAUST MANIFOLD <6G7> . . . . . . . . . . . . . 18

AIR CLEANER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

EXHAUST PIPE AND MAIN MUFFLER . . . . 19

Service Specifications/

15-2

INTAKE AND EXHAUST Special Tool/On-vehicle Service

SERVICE SPECIFICATIONS 15100030128

SPECIAL TOOL 15100060172

ON-VEHICLE SERVICE

INTAKE MANIFOLD VACUUM CHECK

15100180236

<6G7>

Refer to GROUP 11A

TURBOCHARGER

<4D5>

Caution

On-vehicle Service

SUPERCHARGING CHECK

15100100102

Conduct the driving test in a location where driving at

full acceleration can be done with safety. Two person

should be in the vehicle when the test is conducted; the

person in the passenger seat should read the indications

shown by the pressure meter.

1. Remove the boost compensator hose from the fuel

injection pump, and install a pressure gauge as shown

in the illustration.

Drive at full-throttle acceleration in second gear and then

measure the supercharging when the engine speed in

about 3,000 r/min.

When the indicated supercharging does not become

positive pressure, check the following items.

2.

3.

Malfunction of the waste gate actuator.

Leakage of supercharging pressure.

Malfunction of the turbocharger.

4. When the indicated supercharging is 84 kPa or more,

supercharging control may be faulty, therefore check the

followings.

Disconnection or cracks of the waste gate actuator

rubber hose.

Malfunction of the waste gate actuator.

Malfunction of the waste gate valve.

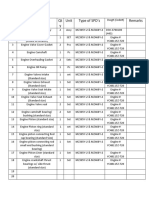

Tool Number Name Use

MD998770

Oxygen sensor

wrench

Removal/Installation of oxygen sensor

<6G7>

Items Standard value Limit

Waste gate actuator activation pressure kPa Approx. 83

Intake air temperature switch C

OFF (no continuity) 55 or less

ON (continuity) 57 or more

Manifold distortion of the installation surface mm 0.15 or less 0.20

15-3 INTAKE AND EXHAUST On-vehicle Service

WASTE GATE ACTUATOR CHECK <4D5>

15100120078

1. Connect a manual pump (pressure-application type) to

nipple.

While gradually applying pressure, check the pressure

that begins to activate (approx. 1 mm stroke) the waste

gate actuator rod.

Standard value: Approx. 83 kPa

Caution

In order to avoid damage to the diaphragm, do not

apply a pressure of 91 kPa or higher.

If there is a significant deviation from the standard value,

check the actuator or the waste gate valve: replace if

necessary.

2.

3.

POWER RELAY CHECK 15100620011

INTERCOOLER FAN MOTOR RELAY CONTINUITY CHECK

Battery voltage

Terminal No.

1 3 4 5

Power is not supplied

Power is supplied

15-4 INTAKE AND EXHAUST Air Cleaner

AIR CLEANER

REMOVAL AND INSTALLATION

<6G7>

15100210126

8.8 Nm

4 Nm

5

<Vehicles without pre-cleaner>

7

8.8 Nm

9

10

13

1

2

<Vehicles with

11

pre-cleaner>

4

with

3

8.8 Nm

8.8 Nm

<Vehicles pre-cleaner>

4 Nm

12

14

<4D5>

8.8 Nm

13 8 9

2 Nm

7

4 Nm

8.8 Nm

1

8.8 Nm

4 Nm

8.8 Nm

6

11

2

14

Removal steps

1. Breather hose connection

2. Air intake hose

3. Resonator

<6G7-Vehicles with pre-cleaner>

4. Resonator <6G7>

5. Air frow sensor assembly <6G7>

6. Air intake hose <4D56>

7. Air cleaner cover

8. Bolt <4D5>

9. Air cleaner element

10. Air duct

<6G7-Vehicles without pre-cleaner>

11. Air duct

<6G7-Vehicles with pre-cleaner>

12. Pre-cleaner assembly

<6G7-Vehicles with pre-cleaner>

13. Air cleaner body

14. Air cleaner bracket

15-5 INTAKE AND EXHAUST Intercooler and Intercooler Fan-ECU

INTERCOOLER AND INTERCOOLER FAN-ECU 15100420079

REMOVAL AND INSTALLATION

3

9 Nm

6

4

1

7 2

9 Nm

5

9

9 Nm

Intercooler fan-ECU removal steps

1. Scuff plate

2. Cowl side trim

3. Intercooler fan-ECU

Intercooler removal steps

4. Intake air temperature switch

connector

5. Intercooler fan motor connector

6. Air hose B connection (Intake

manifold side)

7. Air hose A-2 connection (Turbochar-

ger side)

8. Intercooler and bracket assembly

15-6 INTAKE AND EXHAUST Intercooler and Intercooler Fan-ECU

DISASSEMBLY AND REASSEMBLY 15100660020

6

4

9 Nm

1

6 Nm

10

5

6 Nm

7

9 Nm

3

2

9 Nm

9

8

Disassembly steps

1. Air hose A-2

2. Blanch tube

3. Blanch tube bracket

4. Intercooler cover

5. Air hose A-1

6. Air hose B

7. Intake air temperature switch

8. Intercooler bracket

9. Fan and motor assembly

10. Intercooler

INSPECTION 15100430027

Check the intercooler fins for bending damage or foreign

matter.

Check the intercooler hoses for cracking, damage or wear.

15-7 INTAKE AND EXHAUST Intercooler and Intercooler Fan-ECU

INTAKE AIR TEMPERATURE SWITCH CHECK

15100630014

1. Immerse the intake air temperature switch in the hot water

shown in the figure.

2. When changing the water temperature, check for

continuity between the terminals with the circuit tester.

Standard value:

(Temperature at point B)

Temperature Continuity

Less than 55 C

(Temperature at point A)

OFF (No continuity)

More than 57 C

ON (Continuity)

B

ON

OFF

Water

temperature

A

15-8 INTAKE AND EXHAUST Intake Manifold <6G7>

INTAKE MANIFOLD <6G7> 15100300663

REMOVAL AND INSTALLATION

18 Nm

22 Nm 9 Nm

10 12 Nm

10 12 Nm

17 20 Nm

4

12

11

18 Nm

5

17 20 Nm

7

9 Nm

6

16

9

1

15

18 Nm

2

18

24 Nm

17

8

13

19

18 Nm

18 Nm

14

10

3

35 Nm

Removal steps

1. Ignition coils

2. Brake booster vacuum hose

connection

3. PCV hose connection

4. Crankshaft position sensor and

cam position sensor connector

5. Accelerator cable bracket

6. Ignition power transistor

7. Water outlet fitting bracket

8. Water pump stay

9. Vacuum hose connection

10. Fuel pipe connection

11. Solenoid valve and vacuum hose

assembly

12. EGR valve

13. EGR pipe connection

14. Surge tank stay

15. Throttle cable connection

16. Air intake fitting

17. Air intake fitting gasket

18. Upper intake manifold

}D] 19. Surge tank gasket

Post-installation Operation

Throttle Body installation (Refer to GROUP 13A

Throttle Body.)

Pre-removal Operation

Fuel Discharge Prevention (Refer to GROUP 13A

On-vehicle Service.)

Throttle Body Removal (Refer to GROUP 13A

Throttle Body.)

m

15-9

INTAKE AND EXHAUST Intake Manifold <6G7>

22

12 Nm

23

21

9 N

22

20 23 Nm

5 Nm

20

24

26

24

25

}C] 20. High-pressure fuel hose

}C] 21. Fuel pressure regulator

22. Injector connector

23. Injector and delivery pipe assembly ]A}

24. Water hose connection

}B] 25. Intake manifold

}A] 26. Intake manifold gasket

REMOVAL SERVICE POINT

]A} INJECTOR AND DELIVERY PIPE

REMOVAL

ASSEMBLY

Remove the fuel rail (with the injectors attached to it.)

Caution

Care must be taken when removing the fuel rail not to

drop the injector.

O-ring 23

20

23 21

Engine oil

15-10

INTAKE AND EXHAUST Intake Manifold <6G7>

INSTALLATION SERVICE POINTS

}A] INTAKE MANIFOLD GASKET INSTALLATION

Install the gasket with the protrusions in the position illustrated.

}B] INTAKE MANIFOLD INSTALLATION

Tighten the nuts by the following procedure.

}C] FUEL PRESSURE REGULATOR/HIGH-PRESSURE

FUEL HOSE INSTALLATION

When connecting the fuel pressure regulator and the high-

pressure fuel hose to the fuel rail, apply a small amount of

new engine oil to the O-ring. Then insert the high-pressure

fuel hose, being careful not to damage the O-ring.

Caution

Be careful not to let any engine oil get into the fuel rail.

}D]SURGE TANK GASKET INSTALLATION

Install the gasket with the protrusion in the position illustrated.

Front

Protrusion

Fuel pressure

regulator

Fuel rail

High-pressure

fuel hose

Fuel rail

Order Mounting Nuts Tightening Torque

1 Right-bank nuts 7 Nm

2 Left-bank nuts 2023 Nm

3 Right-bank nuts 2023 Nm

4 Left-bank nuts 2023 Nm

5 Right-bank nuts 2023 Nm

Right bank

Left bank

Front

Intake manifold

Protrusion

Front

Protrusion

15-11

INTAKE AND EXHAUST Intake Manifold <6G7>

INSPECTION 15100370039

Check the following points; replace the part if a problem is

found.

INTAKE MANIFOLD CHECK

1.

2.

Check for damage or cracking of any part.

Clogging of the negative pressure (vacuum) outlet port,

or clogging of the gas passages.

Check deflection of installation surface with straight edge

and feeler gauge.

Standard value: 0.15 mm or less

Limit: 0.20 mm

3.

Turbocharger and Exhaust

Manifold <4D5>

15-12

INTAKE AND EXHAUST

TURBOCHARGER AND EXHAUST

REMOVAL AND INSTALLATION

MANIFOLD <4D5> 15100450061

19 Nm

3

4

5

18 Nm

9 Nm

25 Nm

18 Nm

7

9 Nm

9 Nm

6

42 Nm

17 Nm

8

12

1 18 Nm

14

10

11

2

9 Nm 30 Nm

9

13 43 Nm

15

Removal steps

1. Front exhaust pipe connection

2. Boost hose

3. Waste gate actuator

4. Vacuum hose

5. EGR valve

6. EGR pipe

7. Heat protector A

8. Intake manifold

9. Heat protector

10. Water pipe B

11. Water pipe A

12. Oil pipe

13. Oil return hose connection

14. Exhaust manifold and turbocharger

assembly

15. Intake and exhaust manifold gasket

Pre-removal and Post-installation Operation

Engine Coolant Draining and Supplying Intercooler Removal and Installation (Refer to P. 15-5.)

Air Cleaner Cover and Air Intake Hose Removal and

Installation (Refer to P. 15-4.)

Turbocharger and Exhaust

15-13

INTAKE AND EXHAUST Manifold <4D5>

60 Nm

17

22

16

20

23

19

9 Nm

21

18 60 Nm

12 15 Nm

16. Exhaust fitting

17. Exhaust fitting gasket

18. Oil-return pipe

19. Oil-return pipe gasket

20. Exhaust manifold

21. Turbocharger gasket

}A] 22. Turbocharger assembly

23. Heat protector

INSTALLATION SERVICE POINT

}A] TURBOCHARGER ASSEMBLY INSTALLATION

1. Clean the alignment surfaces shown in the illustration.

2. Supply clean engine oil from the oil pipe mounting hole

of the turbocharger assembly.

Caution

When cleaning, take care that no foreign material gets

into the engine coolant or oil passages hole.

Turbocharger and Exhaust

INTAKE AND EXHAUST Manifold <4D5>

15-14

INSPECTION

TURBOCHARGER ASSEMBLY CHECK

15100640017

Visually check the turbine wheel and the compressor

wheel for cracking or other damage.

Check whether the turbine wheel and the compressor

wheel can be easily turned by hand.

Check for oil leakage from the turbocharger assembly.

Check whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK 15100650010

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

15100340108

Compressor

wheel

15-15 INTAKE AND EXHAUST Turbocharger

TURBOCHARGER 15100600039

DISASSEMBLY AND REASSEMBLY

4

3

1

2

5

6

5 Nm

Disassembly steps

1. Coupling

2. Turbine housing

3. Snap ring

4. Turbine wheel assembly

5. Compressor cover

6. O-ring

}E]

}D]

]A} }C]

]B} }B]

}A]

DISASSEMBLY

]A} SNAP RING

SERVICE POINTS

REMOVAL

Lay the unit with the compressor cover side facing down

and using snap ring pliers, remove the compressor cover

attaching snap ring.

Caution

When removing the snap ring, hold it with fingers to

prevent it from springing away.

Snap ring

15-16 INTAKE AND EXHAUST Turbocharger

]B} TURBINE WHEEL ASSEMBLY REMOVAL

Remove the turbine wheel assembly, striking the

circumference of the compressor cover with a plastic hammer.

The turbine wheel assembly may be a little hard to remove

due to an O-ring put on the outer circumference.

CLEANING

1. Use a clean cleaning oil commercially available. Do not

use corrosive cleaning oils as they could damage to some

parts.

2. Use a plastic scraper or hard brush to clean aluminum

parts.

REASSEMBLY SERVICE POINTS

}A] O-RING INSTALLATION

Apply a light coat of engine oil to a new O-ring and fit in

the turbine wheel assembly groove.

Caution

When installing the O-ring, use care not to damage it.

A damaged O-ring causes oil leaks.

}B] TURBINE WHEEL ASSEMBLY

1. Apply a light coat of engine oil to the periphery of the

O-ring.

2. Install the turbine wheel assembly to the compressor cover

in relation to the dowel pin.

Caution

Use care not to damage the blades of turbine wheel

and compressor wheel.

}C] SNAP RING INSTALLATION

Lay the assembly with the compressor cover facing down

and fit the snap ring.

Caution

Fit the snap ring with its chamfered side facing up.

Snap ring edge

Chamfered

Turbine wheel

assembly

Compressor

cover

Dowel pin hole

Dowel pin

O-ring

Turbine

wheel as-

sembly

15-17 INTAKE AND EXHAUST Turbocharger

}D] TURBINE HOUSING INSTALLATION

Install the turbine housing in relation to the dowel pin.

Caution

Use care not to damage the blades of turbine wheel.

}E] COUPLING INSTALLATION

Install the coupling and tighten to specified torque.

INSPECTION

TURBINE HOUSING

1. Check the housing for traces of contact with the turbine

wheel, cracks due to overheating, pitching, deformation

and other damage. Replace with a new turbine housing

if cracked.

2. Operate the waste gate valve lever manually to check

that the gate can be operated and closed smoothly.

15100610018

COMPRESSOR COVER

Check the compressor cover for traces of contact with the

compressor wheel and other damage.

TURBINE WHEEL ASSEMBLY

1. Check the turbine and compressor wheel blades for bend,

burr, damage, corrosion and traces of contact on the

back side and replace if defective.

Check the oil passage of the turbine wheel assembly

for deposit and clogging.

In the case of water cooled type, check also the water

passage for deposit and clogging.

Check the turbine wheel and compressor wheel for light

and smooth turning.

2.

Compressor

3.

4.

OIL PIPE/OIL RETURN PIPE

Correct or replace the oil pipe and oil return pipe if clogged,

collapsed, deformed or otherwise damaged.

Oil passage

Turbine wheel

Water passage

wheel

Traces for

contact

Coupling

Dower pin

Dower pin hole

15-18 INTAKE AND EXHAUST Exhaust Manifold <6G7>

EXHAUST MANIFOLD <6G7> 15100330587

REMOVAL AND INSTALLATION

1

12 15 Nm

4

2

18 Nm

44 Nm

59 Nm

3

44 Nm

5

7

6

12 15 Nm

Removal steps

1. Heat protector (R.H.)

2. Exhaust manifold (R.H.)

3. Exhaust manifold gasket (R.H.)

4. EGR pipe

5. Heat protector (L.H.)

6. Exhaust manifold (L.H.)

7. Exhaust manifold gasket (L.H.)

INSPECTION 15100340160

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD CHECK

1. Check for damage or cracking of any part.

2. Using a straight edge and a feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

Pre-removal and Post-installation Operation

Front Exhaust Pipe Removal and Installation

(Refer to P.15-19.)

Air Cleaner Removal and Installation

(Refer to P.15-4.)

Battery and Battery Tray Removal and Installation

Engine Oil Dipstick Guide Removal and Installation

15-19 INTAKE AND EXHAUST Exhaust Pipe and Main Muffler

EXHAUST PIPE AND MAIN MUFFLER 15100540461

REMOVAL AND INSTALLATION

<6G7> 16

17

13 Nm

2

13 Nm

14

1

15

4 13 Nm

5

10 3

44 Nm

6

13

49 Nm

49 Nm

49 Nm

13 Nm

4 25 Nm

5

10

7 13 Nm

8

13

25 Nm

49 Nm

25 Nm

<4D5>

16

17

13 Nm

2

1

14

13 Nm

15

4 3

5

13 Nm

25 Nm

49 Nm

25 Nm

13 Nm

4

5

7

49 Nm 13 Nm

11

7

8 49 Nm

Main muffler removal steps

1. Tail pipe

2. Hanger

3. Main muffler

4. Hanger

5. Protector

Center exhaust pipe removal steps

6. Center exhaust pipe

7. Hanger

8. Protector

9. Catalytic converter <6G7>

Front exhaust pipe removal steps

]A} }A] 10. Oxygen sensor <6G7>

11. Front exhaust pipe <4D5>

12. Front exhaust pipe (R.H.) <6G7>

13. Front exhaust pipe (L.H.) <6G7>

14. Hanger

15. Protector

16. Front floor heat protector B

17. Front floor heat protector A

Pre-removal and Post-installation Operation

Front Under Cover Removal and Installation

15-20 INTAKE AND EXHAUST Exhaust Pipe and Main Muffler

REMOVAL SERVICE POINT

]A} OXYGEN SENSOR REMOVAL

Use special tool to remove the oxygen sensor.

INSTALLATION SERVICE POINT

}A] OXYGEN SENSOR INSTALLATION

Use special tool to install the oxygen sensor.

MD998770

Das könnte Ihnen auch gefallen

- 1 Mitsubishi Lancer Evo IX.Dokument1.000 Seiten1 Mitsubishi Lancer Evo IX.seregap84100% (2)

- GR00002000 15 PDFDokument12 SeitenGR00002000 15 PDFNicu PascalutaNoch keine Bewertungen

- Intake and Exhaust System Service GuideDokument8 SeitenIntake and Exhaust System Service GuideAlexandre Da Silva PintoNoch keine Bewertungen

- General Information: Intake and ExhaustDokument8 SeitenGeneral Information: Intake and ExhaustاحمدميدوNoch keine Bewertungen

- Engine Cooling Guide for 6G7 and 4D5 ModelsDokument18 SeitenEngine Cooling Guide for 6G7 and 4D5 ModelsGIAN CARLO MAMANI GILES.100% (1)

- 17 Engine and Emission ControlDokument38 Seiten17 Engine and Emission ControlJoaoBorgesNoch keine Bewertungen

- 15sPACE WAGONDokument8 Seiten15sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Intake and Exhaust Specifications for 2.6L and 3.0L EnginesDokument16 SeitenIntake and Exhaust Specifications for 2.6L and 3.0L EnginesGonzalez RubenNoch keine Bewertungen

- Engine Cooling: Group 14Dokument28 SeitenEngine Cooling: Group 14jagjitemir6014Noch keine Bewertungen

- 4D56 Engine CoolingDokument26 Seiten4D56 Engine CoolingmpvfolloscoNoch keine Bewertungen

- Isx 870 IfsmDokument20 SeitenIsx 870 IfsmhaviettuanNoch keine Bewertungen

- Isx 870 IfsmDokument20 SeitenIsx 870 IfsmhaviettuanNoch keine Bewertungen

- Engine PDFDokument0 SeitenEngine PDFpie031Noch keine Bewertungen

- Worksheet TurboDokument19 SeitenWorksheet TurboAbdul Al-hadiNoch keine Bewertungen

- Engine Fuel System Troubleshooting GuideDokument19 SeitenEngine Fuel System Troubleshooting GuidePablo Rojas Valenzuela100% (1)

- ENGINE INSPECTION AND TEST PROCEDURES (2AZ-FEDokument4 SeitenENGINE INSPECTION AND TEST PROCEDURES (2AZ-FEOlatunde OnakoyaNoch keine Bewertungen

- GR00000700 11C PDFDokument52 SeitenGR00000700 11C PDFNicu PascalutaNoch keine Bewertungen

- Mitsubishi 4 g63 Turbo PDFDokument48 SeitenMitsubishi 4 g63 Turbo PDFAlexandru UngureanuNoch keine Bewertungen

- GR00001900 14 PDFDokument36 SeitenGR00001900 14 PDFNicu PascalutaNoch keine Bewertungen

- CVT Pressure TestsDokument18 SeitenCVT Pressure TestsاحمدميدوNoch keine Bewertungen

- Sect 10 CH 05Dokument16 SeitenSect 10 CH 05deniden2013100% (1)

- 14sPACE WAGONDokument20 Seiten14sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Chapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesDokument6 SeitenChapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesmohhizbarNoch keine Bewertungen

- R90/E LPG Reducer Maintenance GuideDokument15 SeitenR90/E LPG Reducer Maintenance GuideBen MuisNoch keine Bewertungen

- 22sPACE WAGONDokument16 Seiten22sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Clutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .Dokument8 SeitenClutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .rafaelcruzgjaNoch keine Bewertungen

- Aaz 1z Ahu Turbocharger SystDokument39 SeitenAaz 1z Ahu Turbocharger Systboschit100% (1)

- Steering System PDFDokument12 SeitenSteering System PDFGeorge Guerrero100% (1)

- Fuel System: SectionDokument15 SeitenFuel System: SectionRonildo GirardiNoch keine Bewertungen

- Engine mechanical section contents and proceduresDokument175 SeitenEngine mechanical section contents and proceduresRolfs Almonte Diaz100% (1)

- 1996 Subaru Legacy Intake Manifold Service ProcedureDokument11 Seiten1996 Subaru Legacy Intake Manifold Service ProcedureJohn CubineNoch keine Bewertungen

- CAT 3412 Air Inlet and Exhaust SystemDokument8 SeitenCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- ACCELERATOR, FUEL & EXHAUST SYSTEMSDokument22 SeitenACCELERATOR, FUEL & EXHAUST SYSTEMSDwight GeorgeNoch keine Bewertungen

- Scania Retarder 3Dokument33 SeitenScania Retarder 3neilevcvr88% (34)

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDokument7 SeitenGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNoch keine Bewertungen

- Audi 100Dokument93 SeitenAudi 100Dalibor Angelovski100% (1)

- Diesel Turbo Direct Injection (TDI) system servicing overviewDokument149 SeitenDiesel Turbo Direct Injection (TDI) system servicing overviewuriiiNoch keine Bewertungen

- Clio Sport Manual 3286aDokument149 SeitenClio Sport Manual 3286aOctavio LópezNoch keine Bewertungen

- NUMBER: 4-10-13 S.M. REF.: Listed in Table ENGINE: EPA07 Series 60 DATE: April 2013Dokument12 SeitenNUMBER: 4-10-13 S.M. REF.: Listed in Table ENGINE: EPA07 Series 60 DATE: April 2013Walter A Gómez de la CruzNoch keine Bewertungen

- GR00001600 17 PDFDokument20 SeitenGR00001600 17 PDFNicu PascalutaNoch keine Bewertungen

- Sis 631 PRTDokument15 SeitenSis 631 PRTAshraf m aliNoch keine Bewertungen

- Engine Mechanical PDFDokument115 SeitenEngine Mechanical PDFAndrey GladyshevNoch keine Bewertungen

- ME Manual AppendixDokument641 SeitenME Manual AppendixAnonymous uTO1WI0% (1)

- V40232 Clark C270 Torque ConverterDokument44 SeitenV40232 Clark C270 Torque ConverterRemHenry100% (4)

- VW Passat B5 21 (38) Charge Air SystemDokument47 SeitenVW Passat B5 21 (38) Charge Air SystemJosé Luis OrmeñoNoch keine Bewertungen

- Additions, Revisions, or Updates: Subject DateDokument5 SeitenAdditions, Revisions, or Updates: Subject DateKevinCalderonNoch keine Bewertungen

- Manual Eclipse 06Dokument68 SeitenManual Eclipse 06Ángel PastranaNoch keine Bewertungen

- R32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettDokument580 SeitenR32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettNick Viccajee100% (1)

- 1z Ahu Diesel Tdi ServicingDokument149 Seiten1z Ahu Diesel Tdi ServicingAleksandar VeberovicNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineVon EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineBewertung: 5 von 5 Sternen5/5 (1)

- Diesel Engine Care and Repair: A Captain's Quick GuideVon EverandDiesel Engine Care and Repair: A Captain's Quick GuideBewertung: 5 von 5 Sternen5/5 (1)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesVon EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesBewertung: 1 von 5 Sternen1/5 (2)

- Testing SoftwareDokument54 SeitenTesting SoftwareGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- UK (Euro) Air Burner BrochureDokument6 SeitenUK (Euro) Air Burner BrochureGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Mitsubishi Pajero 4x4 Interior and SuplyDokument62 SeitenManual Mitsubishi Pajero 4x4 Interior and SuplyGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 Engine and Emision ControlDokument48 SeitenManual Pajero 4x4 Engine and Emision ControlGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 ExteriorDokument32 SeitenManual Pajero 4x4 ExteriorGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 Service BrakesDokument70 SeitenManual Pajero 4x4 Service BrakesGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 Front SuspentionDokument16 SeitenManual Pajero 4x4 Front SuspentionGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Mitsubishi Pajero 4x4 Propeler ShaftDokument8 SeitenManual Mitsubishi Pajero 4x4 Propeler ShaftGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 ClutchDokument8 SeitenManual Pajero 4x4 ClutchGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 Rear AxleDokument32 SeitenManual Pajero 4x4 Rear AxleGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 Rear AxleDokument32 SeitenManual Pajero 4x4 Rear AxleGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 Power PlantDokument10 SeitenManual Pajero 4x4 Power PlantGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual - Pajero4x4wheel and TyreDokument6 SeitenManual - Pajero4x4wheel and TyreGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual - Pajero4x4rear SuspentionsDokument8 SeitenManual - Pajero4x4rear SuspentionsGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Steering System Maintenance GuideDokument42 SeitenSteering System Maintenance GuideGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 GeneralDokument30 SeitenManual Pajero 4x4 GeneralGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 BodyDokument58 SeitenManual Pajero 4x4 BodyGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Instructions For Chemical Kinetics SimulatorDokument11 SeitenInstructions For Chemical Kinetics SimulatorGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Toyota 22R-Manual de Motor 1983-1995Dokument339 SeitenToyota 22R-Manual de Motor 1983-1995Anthonio LezcanoNoch keine Bewertungen

- Pinout 2 F150Dokument1 SeitePinout 2 F150Vicent JesusNoch keine Bewertungen

- Harlan Gasoline Towing Tractor Parts ManualDokument174 SeitenHarlan Gasoline Towing Tractor Parts ManualCLO CRM100% (2)

- Mitsubishi Galant 4g63 Engine Repair ManualDokument29 SeitenMitsubishi Galant 4g63 Engine Repair ManualMoaed Kanbar100% (1)

- Cylinder Head and Guide ValvesDokument12 SeitenCylinder Head and Guide ValvesSamiran BuragohainNoch keine Bewertungen

- Ford Motor Company Group Diagnostic Trouble CodesDokument5 SeitenFord Motor Company Group Diagnostic Trouble Codeslester100% (40)

- VW 1.4L TSI Engine - SSP - 359Dokument64 SeitenVW 1.4L TSI Engine - SSP - 359freefly286% (7)

- Engine coolant temperature sensor and related component locationsDokument12 SeitenEngine coolant temperature sensor and related component locationsMaya OlmecaNoch keine Bewertungen

- Zukio Offroad Engine Removal and Overhaul GuideDokument58 SeitenZukio Offroad Engine Removal and Overhaul Guideahmad zainiNoch keine Bewertungen

- Spark Plug Trouble TracerDokument1 SeiteSpark Plug Trouble TracerVash SamNoch keine Bewertungen

- Control Parts List for BW 332 WZDokument12 SeitenControl Parts List for BW 332 WZNidya Wardah JuhanaNoch keine Bewertungen

- C-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDokument4 SeitenC-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDamien LEGRANDNoch keine Bewertungen

- Solar Pile Drive Spare PartsDokument2 SeitenSolar Pile Drive Spare PartsFrancis SalongaNoch keine Bewertungen

- PERKINS 1506 SERIES 1506A-E88TA, 1506-E88TA AND 1506D-E88TA INDUSTRIAL ENGINES Model PK9 Service Repair Manual PDFDokument23 SeitenPERKINS 1506 SERIES 1506A-E88TA, 1506-E88TA AND 1506D-E88TA INDUSTRIAL ENGINES Model PK9 Service Repair Manual PDFfjjskeksemmde100% (12)

- SSP 327 - Audi Engines - Chain Drives - Part 2Dokument47 SeitenSSP 327 - Audi Engines - Chain Drives - Part 2McGiver990100% (2)

- Dtvs Product Awareness Training PPT - Bsiii, Bsiv & BsviDokument52 SeitenDtvs Product Awareness Training PPT - Bsiii, Bsiv & BsviRuhan100% (1)

- Mitsubishi OBDII ProjectDokument2 SeitenMitsubishi OBDII ProjectSamir Ami100% (3)

- 2GR-FE Engine Drive Belt Inspection and ReplacementDokument290 Seiten2GR-FE Engine Drive Belt Inspection and ReplacementDiego Falconi100% (2)

- 2007 LC4 690 LC8 990 Diagnostic Measurements Failure CodesDokument49 Seiten2007 LC4 690 LC8 990 Diagnostic Measurements Failure Codeschili_s16Noch keine Bewertungen

- SSP 522 - The 2.0-Liter 162 KW 169 KW TSI EngineDokument56 SeitenSSP 522 - The 2.0-Liter 162 KW 169 KW TSI Engineotandreto100% (4)

- 2013-g2.0 Dohc Mfi #1pdfDokument1 Seite2013-g2.0 Dohc Mfi #1pdfautocomputerNoch keine Bewertungen

- Coleman Powermate 6520-Subaru Robins EX300D52010 Service ManualDokument78 SeitenColeman Powermate 6520-Subaru Robins EX300D52010 Service ManualAKsentinel100% (1)

- Engine Timing MarksDokument3 SeitenEngine Timing MarksNorberto IglesiasNoch keine Bewertungen

- 2015 Creta G 1.6 Mpi A-T-DiagramDokument1 Seite2015 Creta G 1.6 Mpi A-T-DiagramJimmy Durand LunaNoch keine Bewertungen

- 10 PP T235 Fuel InjDokument22 Seiten10 PP T235 Fuel InjShankara SubramanianNoch keine Bewertungen

- Heavybaski PDFDokument80 SeitenHeavybaski PDFCATNoch keine Bewertungen

- VM 2.5 ManualDokument49 SeitenVM 2.5 Manualjeepfreak212185% (20)

- 64l Power StrokeDokument103 Seiten64l Power StrokeMathias ChamorroNoch keine Bewertungen

- Operation Manual: ENGLISCH - Kapitel 00 - Seite 1Dokument104 SeitenOperation Manual: ENGLISCH - Kapitel 00 - Seite 1Victor PinedoNoch keine Bewertungen

- CVVT System CVVT SystemDokument15 SeitenCVVT System CVVT SystemSubbu Kannappan SrinivasanNoch keine Bewertungen