Beruflich Dokumente

Kultur Dokumente

Mech Engg Syllabus Modified (R10) 11.3.2012

Hochgeladen von

Srimanthula Srikanth0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

186 Ansichten57 Seitenjntuk

Originaltitel

Mech Engg Syllabus Modified(R10) 11.3.2012

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenjntuk

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

186 Ansichten57 SeitenMech Engg Syllabus Modified (R10) 11.3.2012

Hochgeladen von

Srimanthula Srikanthjntuk

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 57

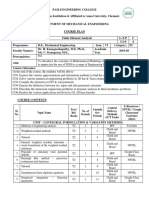

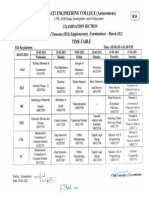

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

1

III Year B.Tech I Sem.

DYNAMICS OF MACHINERY

UNIT I

PRECESSION: Gyroscopes, effect of precession motion on the stability of moving vehicles such as

motor car, motor cycle, aero planes and ships, static and dynamic force analysis of planar mechanisms,

(Demonstration of models in video show).

UNIT II

FRICTION: Inclined plane, friction of screw and nuts, pivot and collar, uniform pressure, uniform wear,

friction circle and friction axis: lubricated surfaces, boundary friction, film lubrication.

UNIT III

CLUTCHES: Friction clutches- single disc or plate clutch, multiple disc clutch, cone clutch, centrifugal

clutch.

BRAKES AND DYNAMOMETERS: Simple block brakes, internal expanding brake, band brake of

vehicle. General description and operation of dynamometers: Prony, Rope brake, Epicyclic, Bevis

Gibson and belt transmission,

UNIT IV

TURNING MOMENT DIAGRAMS: Dynamic force analysis of slider crank mechanism, inertia

torque, angular velocity and acceleration of connecting rod, crank effort and turning moment diagrams

fluctuation of energy fly wheels and their design.

UNIT-V

GOVERNERS: Watt, porter and proell governors, spring loaded governors Hartnell and Hartung with

auxiliary springs. sensitiveness, isochronism and hunting.

UNIT VI

BALANCING: Balancing of rotating masses single and multiple single and different planes, use

analytical and graphical methods.

UNIT VII

BALANCING OF RECIPROCATING MASSES: Primary, secondary, and higher balancing of

reciprocating masses. analytical and graphical methods, unbalanced forces and couples examination of

V multi cylinder in line and radial engines for primary and secondary balancing, locomotive balancing,

hammer blow, swaying couple, variation of tractive effort.

UNIT VIII

VIBRATIONS: Free Vibration of spring mass system oscillation of pendulums, centers of oscillation

and suspension. transverse loads, vibrations of beams with concentrated and distributed loads. Dunkerlys

methods, Raleighs method, whirling of shafts, critical speeds, torsional vibrations, two and three rotor

systems, Simple problems on forced damped vibration, vibration isolation and transmissibility.

TEXT BOOKS :

1. Theory of Machines / S.S Ratan/ Mc. Graw Hill Publ.

2. Mechanism and machine theory by Ashok G. Ambedkar, PHI Publications.

REFERENCES :

1. Mechanism and Machine Theory / JS Rao and RV Dukkipati / New Age

2. Theory of Machines / Shiegly / MGH

3. Theory of Machines / Thomas Bevan / CBS Publishers

4. Theory of machines / Khurmi/S.Chand.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

2

III Year B.Tech I Sem.

METAL CUTTING & MACHINE TOOLS

UNIT I

Elementary treatment of metal cutting theory element of cutting process geometry of single point tool

angles, chip formation and types of chips built up edge and its effects chip breakers, mechanics of

orthogonal cutting Merchants force diagram, cutting forces, cutting speeds, feed, depth of cut, tool life,

coolants, tool materials, constructional features of speed gear box and feed gear box.

UNIT II

Engine lathe principle of working, specification of lathe types of lathe work holders tool holders

box tools taper turning, thread turning for lathes and attachments, turret and capstan lathes collet

chucks other work holders tool holding devices box and tool layout.

Principal features of automatic lathes classification single spindle and multi-spindle automatic lathes

tool layout and cam design.

UNIT III

Shaping, Slotting and Planning Machines: Principles of working principal parts specifications,

operations performed, machining time calculations.

UNIT IV

Drilling & boring Machines: Principles of working, specifications, types, operations performed tool

holding devices twist drill Boring Machines fine Boring Machines jig boring machine, deep hole

Drilling Machine.

UNIT V

Milling machine: Principles of working specifications classification of Milling Machines principal

features of horizontal, vertical and universal Milling Machine, machining operations, types of cutters,

geometry of milling cutters methods of indexing, accessories to milling machines.

UNIT VI

Grinding: Theory of grinding classification of grinding machines, cylindrical and surface grinding

machines, tool and cutter grinding machines, different types of abrasives, bonds, specification and

selection of a grinding wheel. Lapping, Honing & Broaching operations, comparison to grinding.

UNIT - VII

Jigs & Fixtures: Principles of design of jigs and fixtures and uses, classification of jigs & fixtures,

principles of location and clamping, types of clamping & work holding devices, typical examples of jigs

and fixtures.

UNIT VIII

CNC Machine Tools: CNC Machines, working principle, classification, constructional features of CNC

machines, CNC controller, types of motion controls in CNC machines, applications of CNC machines.

TEXT BOOKS :

1. Production Technology by R.K. Jain and S.C. Gupta.

2. Workshop Technology B.S.Raghu Vamshi Vol II

REFERENCES:

1. Metal cutting Principles by M.C. Shaw

2. Metal cutting and machine tools by Boothroyd

3. Production Technology by H.M.T. (Hindustan Machine Tools).

4. Production Engineering, K.C Jain & A.K Chitaley, PHI Publishers

5. Manufacturing technology II, P.N Rao,

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

3

III Year B.Tech. I Sem.

DESIGN OF MACHINE MEMBERS - I

UNIT I

INTRODUCTION: General considerations in the design of Engineering Materials and their properties

selection Manufacturing consideration in design, tolerances and fits BIS codes of steels.

STRESSES IN MACHINE MEMBERS : Simple stresses combined stresses torsional and bending

stresses impact stresses stress strain relation various theories of failure factor of safety design

for strength and rigidity preferred numbers. the concept of stiffness in tension, bending, torsion and

combined situations static strength design based on fracture toughness.

UNIT II

STRENGTH OF MACHINE ELEMENTS: Stress concentration theoretical stress concentration

factor fatigue stress concentration factor notch sensitivity design for fluctuating stresses endurance

limit estimation of endurance strength goodmans line soderbergs line modified goodmans line.

UNIT III

Riveted and welded joints design of joints with initial stresses eccentric loading

UNIT IV

Bolted joints design of bolts with pre-stresses design of joints under eccentric loading locking

devices both of uniform strength, different seals.

UNIT V

KEYS, COTTERS AND KNUCKLE JOINTS:

Design of keys-stresses in keys-cotter joints-spigot and socket, sleeve and cotter, jib and cotter joints-

knuckle joints.

UNIT VI

SHAFTS: Design of solid and hollow shafts for strength and rigidity design of shafts for combined

bending and axial loads shaft sizes BIS code. Use of internal and external circlips, gaskets and seals

(stationary & rotary).

UNIT VII

SHAFT COUPLING : Rigid couplings muff, split muff and flange couplings. flexible couplings

flange coupling (modified).

UNIT VIII

Mechanical Springs :

Stresses and deflections of helical springs extension -compression springs springs for fatigue loading,

energy storage capacity helical torsion springs co-axial springs, leaf springs.

TEXT BOOKS:

1. Machine Design, V.Bandari, TMH Publishers

2. Machine design Pandya & Shah

3. Machine Design PSG Data hand book

REFERENCES:

1. Design of Machine Elements / V.M. Faires

2. Machine design / Schaum Series.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

4

III Year B.Tech. I Sem.

FINITE ELEMENT METHODS

UNIT-I

Introduction to finite element method, stress and equilibrium, strain displacement relations, stress

strain relations, plane stress and plane strain conditions, variational and weighted residual methods,

concept of potential energy, one dimensional problems.

UNIT II

Discretization of domain, element shapes, discretization procedures, assembly of stiffness matrix, band

width, node numbering, mesh generation, interpolation functions, local and global coordinates, convergence

requirements, treatment of boundary conditions.

UNIT III

Analysis of Trusses: Finite element modeling, coordinates and shape functions, assembly of global

stiffness matrix and load vector, finite element equations, treatment of boundary conditions, stress, strain

and support reaction calculations.

UNIT IV

Analysis of Beams: Element stiffness matrix for Hermite beam element, derivation of load vector for

concentrated and UDL, simple problems on beams.

UNIT V

Finite element modeling of two dimensional stress analysis with constant strain triangles and treatment of

boundary conditions, formulation of axisymmetric problems.

UNIT-VI

Higher order and isoparametric elements: One dimensional quadratic and cubic elements in natural

coordinates, two dimensional four noded isoparametric elements and numerical integration.

UNIT VII

Steady state heat transfer analysis : one dimensional analysis of a fin and two dimensional analysis of thin

plate, analysis of a uniform shaft subjected to torsion.

UNIT-VIII

Dynamic Analysis: Formulation of finite element model, element consistent and lumped mass matrices,

evaluation of eigen values and eigen vectors, free vibration analysis.

TEXT BOOKS:

1. Introduction to Finite Elements in Engineering / Chandraputla, Ashok and Belegundu /

Prentice Hall.

2. The Finite Element Methods in Engineering / SS Rao / Pergamon.

REFERENCES:

1. An introduction to Finite Element Method / JN Reddy / McGrawHill

2. The Finite Element Method for Engineers Kenneth H. Huebner, Donald L. Dewhirst, Douglas E.

Smith and Ted G. Byrom / John Wiley & sons (ASIA) Pte Ltd.

3. Finite Element Analysis: Theory and Application with Ansys, Saeed Moaveniu, Pearson

Education

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

5

III Year B.Tech. I Sem.

THERMAL ENGINEERING II

(Use of steam tables and Mollier chart is allowed)

UNIT I

Basic Concepts: Rankine cycle - schematic layout, thermodynamic analysis, concept of mean

temperature of heat addition, methods to improve cycle performance regeneration & reheating.

combustion: fuels and combustion, concepts of heat of reaction, adiabatic flame temperature,

stoichiometry, flue gas analysis.

UNIT II

Boilers : Classification working principles with sketches including H.P.Boilers mountings and

accessories working principles, boiler horse power, equivalent evaporation, efficiency and heat balance

draught, classification height of chimney for given draught and discharge, condition for maximum

discharge, efficiency of chimney artificial draught, induced and forced.

UNIT III

Steam Nozzles: Function of a nozzle applications - types, flow through nozzles, thermodynamic

analysis assumptions -velocity of fluid at nozzle exit-Ideal and actual expansion in a nozzle, velocity

coefficient, condition for maximum discharge, critical pressure ratio, criteria to decide nozzle shape:

Super saturated flow, its effects, degree of super saturation and degree of under cooling - Wilson line.

UNIT IV

Steam Turbines: Classification impulse turbine; mechanical details velocity diagram effect of

friction power developed, axial thrust, blade or diagram efficiency condition for maximum efficiency.

De-laval turbine - methods to reduce rotor speed-velocity compounding, pressure compounding and

velocity & pressure compounding, velocity and pressure variation along the flow combined velocity

diagram for a velocity compounded impulse turbine, condition for maximum efficiency

UNIT V

Reaction Turbine: Mechanical details principle of operation, thermodynamic analysis of a stage,

degree of reaction velocity diagram Parsons reaction turbine condition for maximum efficiency

calculation of blade height.

UNIT VI

Steam Condensers: Requirements of steam condensing plant classification of condensers working

principle of different types vacuum efficiency and condenser efficiency air leakage, sources and its

affects, air pump- cooling water requirement.

UNIT VII

Gas Turbines: Simple gas turbine plant ideal cycle, essential components parameters of performance

actual cycle regeneration, inter cooling and reheating closed and semi-closed cycles merits and

demerits, types of combustion chambers.

UNIT VIII

Jet Propulsion : Principle of operation classification of jet propulsive engines working principles

with schematic diagrams and representation on t-s diagram - thrust, thrust power and propulsion

efficiency turbo jet engines needs and demands met by turbo jet schematic diagram, thermodynamic

cycle, performance evaluation, thrust augmentation methods.

Rockets : Application working principle classification propellant type thrust, propulsive

efficiency specific impulse solid and liquid propellant rocket engines.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

6

TEXT BOOKS:

1. Thermodynamics and Heat Engines- R.Yadav- Central book depot.

2. Gas Turbines V.Ganesan /TMH

3. Heat Engineering V.P Vasandani and D.S Kumar- Metropolitan Book Company, New Delhi

REFERENCES:

1. Gas Turbines and Propulsive Systems P.Khajuria & S.P.Dubey - /Dhanpatrai

2. Gas Turbines / Cohen, Rogers and Saravana Muttoo / Addison Wesley Longman

3. Thermal Engineering-R.S Khurmi/JS Gupta/S.Chand.

4. Thermal Engineering-P.L.Bellaney/ Khanna publishers.

5. Thermal Engineering-M.L.Marthur & Mehta/Jain bros.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

7

III Year B.Tech. I Sem.

OPERATIONS RESEARCH

UNIT I

Development definition characteristics and phases types of models operation research models

applications.

ALLOCATION: Linear programming problem formulation graphical solution simplex method

artificial variables techniques -twophase method, big-m method duality principle.

UNIT II

TRANSPORTATION PROBLEM: Formulation optimal solution, unbalanced transportation problem

degeneracy, assignment problem formulation optimal solution - variants of assignment problem-

traveling salesman problem.

SEQUENCING Introduction flow shop sequencing n jobs through two machines n jobs through

three machines job shop sequencing two jobs through m machines.

UNIT III

REPLACEMENT: Introduction replacement of items that deteriorate with time when money value

is not counted and counted replacement of items that fail completely, group replacement.

UNIT IV

THEORY OF GAMES: Introduction mini. max (max. mini) criterion and optimal strategy

solution of games with saddle points rectangular games without saddle points 2 x 2 games

dominance principle m x 2 & 2 x n games -graphical method.

UNIT V

WAITING LINES: Introduction single channel poison arrivals exponential service times with

infinite population and finite population models multichannel poison arrivals exponential service

times with infinite population single channel poison arrivals.

UNIT VI

INVENTORY : Introduction single item deterministic models purchase inventory models with one

price break and multiple price breaks shortages are not allowed stochastic models demand may be

discrete variable or continuous variable instantaneous production. Instantaneous demand and

continuous demand and no set up cost.

UNIT VII

DYNAMIC PROGRAMMING: Introduction Bellmans principle of optimality applications of

dynamic programming- capital budgeting problem shortest path problem linear programming

problem.

UNIT VIII

SIMULATION: Definition types of simulation models phases of simulation applications of

simulation inventory and queuing problems advantages and disadvantages simulation languages.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

8

TEXT BOOKS:

1. Operations Research / S.D.Sharma-Kedarnath

2. Introduction to O.R/Hiller & Libermann (TMH).

REFERENCES:

1. Operations Research /A.M.Natarajan,P.Balasubramani, A. Tamilarasi/Pearson Education.

2. Operations Research: Methods & Problems / Maurice Saseini, Arhur Yaspan & Lawrence

Friedman

3. Operations Research / R.Pannerselvam,PHI Publications.

4. Operations Research / Wagner/ PHI Publications.

5. Operation Research /J.K.Sharma/MacMilan.

6. O.R/Wayne L.Winston/Thomson Brooks/cole

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

9

III Year B.Tech. I Sem.

THERMAL ENGINEERING LAB

1. I.C. Engines valve / port timing diagrams

2. I.C. Engines performance test (4 -stroke diesel engines)

3. I.C. Engines performance test on 2-stroke petrol

4. Evaluation of engine friction by conducting morse test on 4-stroke multi cylinder petrol engine

5. Determination of FHP by retardation and motoring test on IC engine

6. I.C. Engines heat balance.

7. Economical speed test of an IC engine

8. Performance test on variable compression ratio engines.

9. Performance test on reciprocating air compressor unit

10. Study of boilers

11. Dis-assembly / assembly of engines.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

10

III Year B.Tech. I Sem.

MACHINE TOOLS LAB

1. Introduction of general purpose machines -lathe, drilling machine, milling machine, shaper,

planing machine, slotting machine, cylindrical grinder, surface grinder and tool and cutter grinder.

2. Step turning and taper turning on lathe machine

3. Thread cutting and knurling on -lathe machine.

4. Drilling and tapping

5. Shaping and planning

6. Slotting

7. Milling

8. Cylindrical surface grinding

9. Grinding of tool angles.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

11

III Year B.Tech. I Sem.

IPR & PATENT-I

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

12

III Year B.Tech. II Sem.

METROLOGY

UNIT-I

Systems of limits and fits: Introduction, nominal size, tolerance, limits, deviations, fits and their types-

unilateral and bilateral tolerance system, hole and shaft basis systems- interchangeability, determistic &

statistical tolerancing, selective assembly. British standard system, International standard system,

application of limits and tolerances for correct functioning.

UNIT-II

Linear Measurement: Length standards, end standards, slip gauges- calibration of the slip gauges, dial

indicators, micrometers.

Measurement of Angles and Tapers:

Different methods bevel protractor, angle slip gauges-clinometer angle dekkor- spirit levels- sine bar-

sine table, rollers and spheres used to determine tapers.

Limit Gauges:

Taylors principle design of go and no go gauges; plug, ring, snap, gap, taper, profile and position

gauges.

UNIT-III

Optical Measurement Instruments: Tools makers microscope and uses - collimators, optical projector,

optical flats and their uses.

Interferometry:

Interference of light, Michalesons interferometer, NPL flatness interferometer, and NPL gauge

interferometer.

Flat Surface Measurement:

Measurement of flat surfaces- instruments used- straight edges- surface plates auto collimator.

UNIT-IV

Surface Roughness Measurement: Differences between surface roughness and surface waviness

Numerical assessment of surface finish-CLA, Rt., R.M.S. Rz, R10 values, Method of measurement of

surface finish Profilograph. Talysurf, ISI symbols for indication of surface finish.

UNIT-V

Comparators: Types - mechanical, optical , electrical and electronic, pneumatic comparators and their

uses.

UNIT VI

Gear Measurement: Nomenclature of gear tooth, tooth thickness measurement with gear tooth vernier

& flange micro meter, pitch measurement, total composite error and tooth to tooth composite errors,

rolling gear tester, involute profile checking.

UNIT VII

Screw Thread Measurement: Elements of measurement errors in screw threads- concept of virtual

effective diameter, measurement of effective diameter, angle of thread and thread pitch, and profile

thread gauges.

UNIT VIII

Machine Tool Alignment tests: Machine tool alignment test on lathe, drilling and milling machines.

TEXT BOOKS:

1. Engineering Metrology by R.K.Jain / Khanna Publishers

2. Engineering Metrology by Mahajan / Dhanpat Rai Publishers

3. Dimensional Metrology, Connie Dotson, Cengage Learning

REFERENCE BOOKS:

1. Engineering Metrology by I.C.Gupta / Dhanpat Rai Publishers

2. Precision Engineering in Manufacturing by R.L.Murthy / New Age

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

13

III Year B.Tech. II Sem.

INSTRUMENTATION & CONTROL SYSTEMS

UNIT I

Definition Basic principles of measurement measurement systems, generalized configuration and

functional descriptions of measuring instruments examples. dynamic performance characteristics

sources of error, classification and elimination of error.

UNIT II

Measurement of Displacement: Theory and construction of various transducers to measure

displacement piezo electric, inductive, capacitance, resistance, ionization and photo electric

transducers, calibration procedures.

MEASUREMENT OF TEMPERATURE: Classification ranges various principles of measurement

expansion, electrical resistance thermistor thermocouple pyrometers temperature indicators.

UNIT III

MEASUREMENT OF PRESSURE: Units classification different principles used. manometers,

piston, bourdon pressure gauges, bellows diaphragm gauges. low pressure measurement thermal

conductivity gauges ionization pressure gauges, mcleod pressure gauge.

UNIT IV

MEASUREMENT OF LEVEL : Direct method indirect methods capacitative, ultrasonic, magnetic,

cryogenic fuel level indicators bubler level indicators.

FLOW MEASUREMENT: Rotameter, magnetic, ultrasonic, turbine flow meter, hot wire

anemometer, laser doppler anemometer (LDA).

UNIT V

MEASUREMENT OF SPEED : Mechanical tachometers electrical tachometers stroboscope,

noncontact type of tachometer

Measurement of Acceleration and Vibration: Different simple instruments principles of seismic

instruments vibrometer and accelerometer using this principle.

UNIT VI

STRESS STRAIN MEASUREMENTS : Various types of stress and strain measurements electrical

strain gauge gauge factor method of usage of resistance strain gauge for bending compressive and

tensile strains usage for measuring torque, strain gauge rosettes.

UNIT VII

MEASUREMENT OF HUMIDITY Moisture content of gases, sling psychrometer, Absorption

psychrometer, Dew point meter.

MEASUREMENT OF FORCE, TORQUE AND POWER- Elastic force meters, load cells, torsion

meters, dynamometers.

UNIT VIII

ELEMENTS OF CONTROL SYSTEMS : Introduction, importance classification open and closed

systems, servomechanismsexamples with block diagramstemperature, speed & position control

systems.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

14

TEXT BOOKS:

1. Measurement Systems: Applications & design by D.S Kumar.

2. Mechanical Measurements / BeckWith, Marangoni,Linehard, PHI / PE

REFERENCES:

1. Measurement systems: Application and design, Doeblin Earnest. O. Adaptation by Manik and

Dhanesh/ TMH

2. Experimental Methods for Engineers / Holman.

3. Mechanical and Industrial Measurements / R.K. Jain/ Khanna Publishers.

4. Instrumentation, measurement & analysis by B.C.Nakra & K.K.Choudhary, TMH

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

15

III Year B.Tech. II Sem.

DESIGN OF MACHINE MEMBERS II

UNIT I

BEARINGS: Classification of bearings- applications, types of journal bearings lubrication bearing

modulus full and partial bearings clearance ratio heat dissipation of bearings, bearing materials

journal bearing design ball and roller bearings static loading of ball & roller bearings, bearing life.

UNIT II

ENGINE PARTS : Connecting Rod: Thrust in connecting rod stress due to whipping action on

connecting rod ends cranks and crank shafts, strength and proportions of over hung and center cranks

crank pins, crank shafts.

UNIT III

Pistons, forces acting on piston construction design and proportions of piston, cylinder, cylinder liners,

UNIT IV

Design of curved beams: introduction, stresses in curved beams, expression for radius of neutral axis for

rectangular, circular, trapezoidal and t-section. design of crane hooks, c clamps.

UNIT V

POWER TRANSMISSIONS SYSTEMS, PULLEYS: Transmission of power by belt and rope drives ,

transmission efficiencies, belts flat and v types ropes - pulleys for belt and rope drives, materials,

chain drives

UNIT VI

SPUR & HELICAL GEAR DRIVES: Spur gears- helical gears load concentration factor dynamic

load factor, surface compressive strength bending strength design analysis of spur gears estimation

of centre distance, module and face width, check for plastic deformation, check for dynamic and wear

considerations.

UNIT VII

DESIGN OF POWER SCREWS: Design of screw, square ACME, buttress screws, design of nut,

compound screw, differential screw, ball screw- possible failures.

UNIT VIII

MACHINE TOOL ELEMENTS: Levers and brackets: design of levers hand levers-foot lever

cranked lever lever of a lever loaded safety valve- rocker arm straight angular- design of a crank pin

brackets- hangers- wall boxes.

TEXT BOOKS:

1. Machine Design, V.Bandari, TMH Publishers

2. Machine Design PSG Data hand book

3. Machine Design, Pandya & Shaw, Charotar publishers

REFERENCES:

1. Machine Design / R.N. Norton

2. Data Books : (I) P.S.G. College of Technology (ii) Mahadevan

3. Mech. Engg. Design / JE Shigley

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

16

III Year B.Tech. II Sem.

ROBOTICS

UNIT-I

Introduction: Automation and Robotics, CAD/CAM and Robotics An over view of Robotics

present and future applications classification by coordinate system and control system.

UNIT II

Components of the Industrial Robotics: Function line diagram representation of robot arms,

common types of arms. Components, Architecture, number of degrees of freedom Requirements

and challenges of end effectors, determination of the end effectors, comparison of Electric, Hydraulic

and Pneumatic types of locomotion devices.

UNIT III

Motion Analysis: Homogeneous transformations as applicable to rotation and translation problems.

UNIT IV

Manipulator Kinematics: Specifications of matrices, D-H notation joint coordinates and world

coordinates Forward and inverse kinematics problems.

UNIT V

Differential transformation and manipulators, Jacobians problems

Dynamics: Lagrange Euler and Newton Euler formulations Problems.

UNIT VI

General considerations in path description and generation. Trajectory planning and avoidance of

obstacles, path planning, Skew motion, joint integrated motion straight line motion Robot

programming, languages and software packages-description of paths with a robot programming

language..

UNIT VII

Robot actuators and Feed back components:

Actuators: Pneumatic, Hydraulic actuators, electric & stepper motors.

Feedback components: position sensors potentiometers, resolvers, encoders Velocity sensors.

UNIT VIII

Robot Applications in Manufacturing: Material Transfer - Material handling, loading and

unloading- Processing - spot and continuous arc welding & spray painting - Assembly and

Inspection.

TEXT BOOKS:

1. Industrial Robotics / Groover M P /Pearson Edu.

2. Robotics and Control / Mittal R K & Nagrath I J / TMH.

REFERENCES:

1. Robotics / Fu K S/ McGraw Hill.

2. Robotic Engineering / Richard D. Klafter, Prentice Hall

3. Robot Analysis and Intelligence / Asada and Slow time / Wiley Inter-Science.

4. Introduction to Robotics / John J Craig / Pearson Edu.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

17

III Year B.Tech. II Sem.

HEAT TRANSFER

(Heat transfer data book allowed)

UNIT I

Introduction: Modes and mechanisms of heat transfer Basic laws of heat transfer General discussion

about applications of heat transfer.

Conduction Heat Transfer: Fourier rate equation General heat conduction equation in Cartesian,

Cylindrical and Spherical coordinates.

UNIT II

Steady, unsteady and periodic heat transfer Initial and boundary conditions.

One Dimensional Steady State Conduction Heat Transfer : Homogeneous slabs, hollow cylinders and

spheres overall heat transfer coefficient electrical analogy Critical radius of insulation-

Variable Thermal conductivity systems with heat sources or Heat generation. Extended surface (fins)

Heat Transfer Long Fin, Fin with insulated tip and Short Fin, Application to error measurement of

Temperature.

UNIT III

One Dimensional Transient Conduction Heat Transfer : Systems with negligible internal resistance

Significance of Biot and Fourier Numbers - Chart solutions of transient conduction systems

UNIT IV

Convective Heat Transfer : Classification of convective heat transfer Dimensional analysis as a tool

for experimental investigation Buckingham Pi Theorem for forced and free convection, application for

developing semi empirical non- dimensional correlation for convective heat transfer Significance of

non-dimensional numbers concepts of continuity, momentum and Energy Equations.

UNIT V

Forced convection

External Flows : Concepts about hydrodynamic and thermal boundary layer and use of empirical

correlations for convective heat transfer -Flat plates and Cylinders.

Internal Flows : Concepts about Hydrodynamic and Thermal Entry Lengths Division of internal flow

based on this Use of empirical relations for Horizontal Pipe Flow and annulus flow.

Free Convection : Development of Hydrodynamic and thermal boundary layer along a vertical plate

Use of empirical relations for Vertical plates and pipes.

UNIT VI

Heat Transfer with Phase Change

Boiling: Pool boiling Regimes- Calculations on Nucleate boiling, Critical Heat flux and Film boiling.

Condensation: Film wise and drop wise condensation Nusselts theory of condensation on a vertical

plate - Film condensation on vertical and horizontal cylinders using empirical correlations.

UNIT VII

Heat Exchangers:

Classification of heat exchangers overall heat transfer Coefficient and fouling factor Concepts of

LMTD and NTU methods Problems.

UNIT VIII

Radiation Heat Transfer :

Emission characteristics and laws of black-body radiation Irradiation total and monochromatic

quantities laws of Planck, Wien, Kirchoff, Lambert, Stefan and Boltzmann heat exchange between

two black bodies concepts of shape factor Emissivity heat exchange between grey bodies

radiation shields electrical analogy for radiation networks.

TEXT BOOKS :

1. Heat Transfer / HOLMAN/TMH

2. Heat Transfer P.K.Nag/ TMH

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

18

REFERENCE BOOKS:

1. Heat and Mass Transfer Arora and Domkundwar, Dhanpatrai & sons

2. Fundamentals of Engg. Heat and Mass Transfer / R.C.SACHDEVA / New Age International

3. Heat and Mass Transfer Cengel- McGraw Hill.

4. Heat and Mass Transfer D.S.Kumar / S.K.Kataria & Sons

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

19

III Year B.Tech. II Sem.

INDUSTRIAL ENGG. & MANAGEMENT

Unit I

Introduction: Definition of industrial engineering (I.E), Development, applications, role of an industrial

engineer, differences between production management and industrial engineering, quantitative tools of IE

and productivity measurement. Concepts of Management, Importance, functions of management,

scientific management, Taylors principles, theory X and theory Y, Fayols principles of management.

Unit II

Plant layout: Factors governing plant location, types of production layouts, advantages and disadvantages

of process layout and product layout, applications, quantitative techniques for optimal design of layouts,

Plant maintenance, preventive and breakdown maintenance.

Unit III

Operations Management: Importance, types of production, applications, workstudy, method study and

time study, work sampling, PMTS, micro-motion study, rating techniques, MTM, work factor system,

principles of Ergonomics, flow process charts, string diagrams and Therbligs,

Unit IV

Statistical Quality Control: Quality control, its importance, SQC, sampling inspection, types, Control

charts X and R charts X AND S charts and their applications, numerical examples.

Unit V

Resource management: Concept of human resource management, personnel management and industrial

relations, functions of personnel management, Job-evaluation, its importance and types, merit rating,

quantitative methods, wage incentive plans, types.

Unit VI

Total quality management: zero defect concept, quality circles, implementation, applications, ISO quality

systems. Six sigma definition, basic concepts.

Unit - VII

Value analysis: value engineering, implementation procedure, enterprise resource planning and supply

chain management.

Unit - VIII

Project management: PERT, CPM differences & applications, Critical path, determination of floats,

importance, project crashing, smoothing and numerical examples.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

20

TEXT BOOKS:

1. Industrial Engineering and management by O.P Khanna, Khanna Publishers.

2. Industrial Engineering and Production Management, Martand Telsang, S.Chand & Company Ltd. New

Delhi

Reference Books:

1. Operations Management by J.G Monks, McGrawHill Publishers.

2. Industrial Engineering by Banga & Sharma.

3. Principles of Management by Koontz O Donnel, McGraw Hill Publishers.

4. Statistical Quality Control by Gupta.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

21

III Year B.Tech. II Sem.

METROLOGY & INSTRUMENTATION LAB

Note: Minimum of 6 experiments from each section

METROLOGY LAB

1. Measurement of lengths, heights, diameters by Vernier calipers, micrometers etc.

2. Measurement of bores by internal micrometers and dial bore indicators.

3. Use of gear tooth Vernier calipers and checking the chordal thickness of spur gear.

4. Machine tool alignment test on the lathe.

5. Machine tool alignment test on milling machine.

6. Angle and taper measurements by Bevel protractor, Sine bars, etc.

7. Use of spirit level in finding the straightness of a bed and flatness of a surface.

8. Thread measurement by two wire/ three wire method & Tool makers microscope.

9. Surface roughness measurement by Talysurf.

INSTRUMENTATION LAB

1. Calibration of Pressure Gauges

2. Calibration of transducer for temperature measurement.

3. Study and calibration of LVDT transducer for displacement measurement.

4. Calibration of strain gauge for temperature measurement.

5. Calibration of thermocouple for temperature measurement.

6. Calibration of capacitive transducer for angular displacement.

7. Study and calibration of photo and magnetic speed pickups for the measurement of speed.

8. Calibration of resistance temperature detector for temperature measurement.

9. Study and calibration of a Rotameter for flow measurement.

10. Study and use of a Seismic pickup for the measurement of vibration amplitude of an engine bed

at various loads.

11. Study and calibration of Mcleod gauge for low pressure.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

22

III Year B.Tech. II Sem.

HEAT TRANSFER LAB

1. Determination of overall heat transfer co-efficient of a composite slab

2. Determination of heat transfer rate through a lagged pipe.

3. Determination of heat transfer rate through a concentric sphere

4. Determination of thermal conductivity of a metal rod.

5. Determination of efficiency of a pin-fin

6. Determination of heat transfer coefficient in forced convection

7. Determination of heat transfer coefficient in natural convection.

8. Determination of effectiveness of parallel and counter flow heat exchangers.

9. Determination of emissivity of a given surface.

10. Determination of Stefan Boltzman constant.

11. Determination of heat transfer rate in drop and film wise condensation.

12. Determination of critical heat flux.

13. Demonstration of heat pipe.

14. Study of two phase flow.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

23

III Year B.Tech. II Sem.

IPR & PATENT -II

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

24

IV Year B.Tech. I Sem.

REFRIGERATION & AIR CONDITIONING

(Refrigeration and Psychrometric tables and charts allowed)

UNIT I

Introduction to Refrigeration : Necessity and applications Unit of refrigeration and C.O.P.

Mechanical Refrigeration Types of ideal cycles of refrigeration. Air Refrigeration: Bell Coleman cycle

open and dense air systems refrigeration systems used in air crafts and problems.

UNIT II

Vapour compression refrigeration working principle and essential components of the plant simple

vapour compression refrigeration cycle COP Representation of cycle on T-S and p-h charts effect of

sub cooling and super heating cycle analysis Actual cycle Influence of various parameters on system

performance Use of p-h charts numerical problems.

UNIT III

System Components : Compressors general classification comparison Advantages and

Disadvantages. Condensers classification Working Principles Evaporators classification Working

Principles Expansion devices Types Working Principles

Refrigerants Desirable properties classification refrigerants used Nomenclature Ozone Depletion

Global Warming .

UNIT IV

Vapor Absorption System Calculation of max COP description and working of NH3 water system

and Li Br water ( Two shell & Four shell) System. Principle of operation Three Fluid absorption system,

salient features.

UNIT V

Steam Jet Refrigeration System Working Principle and Basic Components. Principle and operation of

(i) Thermoelectric refrigerator (ii) Vortex tube.

UNIT VI

Introduction to Air Conditioning: Psychometric Properties & Processes Characterization of Sensible

and latent heat loads Need for Ventilation, Consideration of Infiltration Load concepts of RSHF,

GSHF- Problems, Concept of ESHF and ADP temperature.

UNIT VII

Requirements of human comfort and concept of effective temperature- Comfort chart Comfort Air

conditioning Requirements of Industrial air conditioning, Air conditioning Load Calculations.

UNIT VIII

Air Conditioning systems - Classification of equipment, cooling, heating humidification and

dehumidification, filters, grills and registers, fans and blowers. Heat Pump Heat sources different heat

pump circuits.

TEXT BOOKS :

1. A Course in Refrigeration and Air conditioning / SC Arora & Domkundwar / Dhanpatrai

2. Refrigeration and Air Conditioning / CP Arora / TMH.

REFERENCES :

1. Refrigeration and Air Conditioning / Manohar Prasad / New Age.

2. Principles of Refrigeration - Dossat / Pearson Education.

3. Basic Refrigeration and Air-Conditioning Ananthanarayanan / TMH

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

25

IV Year B.Tech. I Sem.

CAD/CAM

UNIT I

Computers in Industrial Manufacturing, Product cycle, CAD / CAM Hardware, Basic structure, CPU,

Memory types, input devices, display devices, hard copy devices, storage devices.

UNIT II

Computer Graphics : Raster scan graphics coordinate system, database structure for graphics modeling,

transformation of geometry, 3D transformations, mathematics of projections, clipping, hidden surface

removal.

UNIT III

Geometric modeling : Requirements, geometric models, geometric construction models, curve

representation methods, surface representation methods, modeling facilities desired.

UNIT IV

Drafting and Modeling systems : Basic geometric commands, layers, display control commands,

editing, dimensioning, solid modeling.

UNIT V

Part programming for NC Machines : NC, NC modes, NC elements, CNC machine tools, structure of

CNC machine tools, features of Machining center, turning center, CNC Part Programming :

fundamentals, manual part programming methods, Computer Aided Part Programming.

UNIT VI

Group Tech : Part family, coding and classification, production flow analysis, advantages and

limitations, Computer Aided Processes Planning, Retrieval type and Generative type.

UNIT VII

Computer aided Quality Control: Terminology in quality control, the computer in QC, contact

inspection methods, noncontact inspection methods-optical, noncontact inspection methods-nonoptical,

computer aided testing, integration of C AQC with CAD/CAM.

UNIT VIII

Computer integrated manufacturing systems: Types of Manufacturing systems, Machine tools and

related equipment, material handling systems, computer control systems, human labor in the

manufacturing systems, CIMS benefits.

TEXT BOOK :

1. CAD / CAM A Zimmers & P.Groover/PE/PHI

2. Automation, Production systems & Computer integrated Manufacturing/ Groover/P.E

REFERENCES :

1. CAD / CAM Theory and Practice / Ibrahim Zeid / TMH

2. Principles of Computer Aided Design and Manufacturing / Farid Amirouche / Pearson

3. Computer Numerical Control Concepts and programming / Warren S Seames / Thomson.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

26

IV Year B.Tech. I Sem.

ALTERNATIVE SOURCES OF ENERGY

UNIT-I

SOLAR RADIATION : Role and potential of new and renewable sources, the solar energy option,

Environmental impact of solar power, structure of the sun, the solar constant, sun-earth

relationships, coordinate systems and coordinates of the sun, extraterrestrial and terrestrial solar

radiation, solar radiation on titled surface, instruments for measuring solar radiation and sun shine,

solar radiation data, numerical problems.

UNIT-II

SOLAR ENERGY COLLECTION: Flat plate and concentrating collectors, classification of

concentrating collectors, orientation and thermal analysis, advanced collectors.

UNIT-III

SOLAR ENERGY STORAGE AND APPLICATIONS : Different methods, sensible, latent heat

and stratified storage, solar ponds. Solar applications- solar heating/cooling technique, solar

distillation and drying, solar cookers, central power tower concept and solar chimney.

UNIT-IV

WIND ENERGY: Sources and potentials, horizontal and vertical axis windmills, performance

characteristics, Betz criteria, types of winds, wind data measurement.

UNIT-V

BIO-MASS : Principles of Bio-Conversion, Anaerobic/aerobic digestion, types of Bio-gas

digesters, gas yield, combustion characteristics of bio-gas, utilization for cooking, bio fuels,

I.C.Engine operation and economic aspects.

UNIT-VI

GEOTHERMAL ENERGY: Resources, types of wells, methods of harnessing the energy, potential in

India.

UNIT-VII

OCEAN ENERGY: OTEC, Principles utilization, setting of OTEC plants, thermodynamic

cycles. Tidal and wave energy: Potential and conversion techniques, mini-hydel power plants, and

their economics.

UNIT-VIII

DIRECT ENERGY CONVERSION : Need for DEC, Carnot cycle, limitations, principles of DEC.

Thermo-electric generators, See-beck, Peltier and Joul Thomson effects, Figure of merit, materials,

applications, MHD generators, principles, dissociation and ionization, hall effect, magnetic flux, MHD

accelerator, MHD Engine, power generation systems, electron gas dynamic conversion, economic aspects.

Fuel cells, principles, faradays laws, thermodynamic aspects, selection of fuels and operating conditions,

photo voltaic energy conversion types of PV cells, I-V characteristics.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

27

TEXT BOOKS:

1. Sukhatme S.P. and J.K.Nayak, Solar Energy Principles of Thermal Collection and Storage,

Tata- McGraw Hill, New Delhi, 2008

2. Khan B.H., Non-Conventional Energy Resources, Tata McGraw Hill, New Delhi, 2006

REFERENCES:

1. Solar Power Engineering / B.S Magal Frank Kreith & J.F Kreith.

2. Principles of Solar Energy / Frank Krieth & John F Kreider.

3. Non-Conventional Energy / Ashok V Desai /Wiley Eastern.

4. Renewable Energy Technologies /Ramesh & Kumar /Narosa

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

28

IV Year B.Tech. I Sem.

UN CONVENTIONAL MACHINING PROCESSES

UNIT I

INTRODUCTION Need for non-traditional machining methods-Classification of modern machining

processes considerations in process selection, applications.

UNIT II

Ultrasonic machining Elements of the process, mechanics of material removal, MRR process

parameters, economic considerations, applications and limitations.

UNIT III

Abrasive jet machining, Water jet machining and abrasive water jet machining : Basic principles,

equipments, process variables, mechanics of material removal, MRR, application and limitations.

UNIT - IV

ELECTRO CHEMICAL MACHINING : Fundamentals of electro chemical machining,

electrochemical grinding, electro chemical honing and deburring process, metal removal rate in ECM,

Tool design, Surface finish and accuracy, economic aspects of ECM Simple problems for estimation of

metal removal rate. Fundamentals of chemical, machining, advantages and applications.

UNIT - V

THERMAL METAL REMOVAL PROCESSES : General principle and applications of Electric

Discharge Machining, Electric Discharge Grinding and wire EDM Power circuits for EDM, Mechanics

of metal removal in EDM, Process parameters, selection of tool electrode and dielectric fluids, surface

finish and machining accuracy, characteristics of spark eroded surface

UNIT VI

EBM, LBM, basic principle and theory, process parameters, efficiency & accuracy, applications

UNIT-VII

Application of plasma for machining, metal removal mechanism, process parameters, accuracy and

surface finish and other applications of plasma in manufacturing industries.

UNIT VIII

Magnetic abrasive finishing, Abrasive flow finishing, Electrostream drilling, Shaped tube electrolytic

machining.

TEXT BOOK :

1. Advanced machining processes/ VK Jain/ Allied publishers.

REFERENCES :

1. Modern Machining Process / Pandey P.C. and Shah H.S./ TMH.

2. New Technology / Bhattacharya A/ The Institution of Engineers, India 1984.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

29

IV Year B.Tech. I Sem.

OPEN ELECTIVE

MICRO ELECTRO MECHANICAL SYSTEMS (MEMS)

Unit I

Introduction: Definition of MEMS, MEMS history and development, micro machining, lithography

principles & methods, structural and sacrificial materials, thin film deposition, impurity doping, etching,

surface micro machining, wafer bonding, LIGA.

Unit II

Mechanical sensors and actuators: Principles of sensing and actuation: beam and cantilever,

capacitive, piezo electric, strain, pressure, flow, pressure measurement by micro phone, MEMS

gyroscopes, shear mode piezo actuator, gripping piezo actuator, Inchworm technology.

Unit III

Thermal sensors and actuators: Thermal energy basics and heat transfer processes, thermisters, thermo

devices, thermo couple, micro machined thermo couple probe, peltier effect heat pumps, thermal flow

sensors, micro hot plate gas sensors, MEMS thermo vessels, pyro electricity, shape memory alloys

(SMA), U-shaped horizontal and vertical electro thermal actuator, thermally activated MEMS relay,

micro spring thermal actuator, data storage cantilever.

Unit IV

Micro-Opto-electro mechanical systems: Principle of MOEMS technology, properties of light, light

modulators, beam splitter, micro lens, micro mirrors, digital micro mirror device (DMD), light detectors,

grating light valve (GLV), optical switch, wave guide and tuning, shear stress measurement.

Unit V

Magnetic sensors and actuators: Magnetic materials for MEMS and properties, magnetic sensing and

detection, magneto resistive sensor, more on hall effect, magneto diodes, magneto transistor, MEMS

magnetic sensor, pressure sensor utilizing MOKE, mag MEMS actuators, by directional micro actuator,

feedback circuit integrated magnetic actuator, large force reluctance actuator, magnetic probe based

storage device.

Unit VI

Radio frequency (RF) MEMS: RF based communication systems, RF MEMS, MEMS inductors,

varactors, tuner/filter, resonator, clarification of tuner, filter, resonator, MEMS switches, phase shifter.

Unit VII

Micro fluidic systems: Applications, considerations on micro scale fluid, fluid actuation methods,

dielectro phoresis (DEP), electro wetting, electro thermal flow, thermo capillary effect, electro osmosis

flow, opto electro wetting (OEW), tuning using micro fluidics, typical micro fluidic channel, microfluid

dispenser, micro needle, molecular gate, micro pumps.

Unit - VIII

Chemical and Bio Medical Micro systems: Sensing mechanism & principle, membrane-transducer

materials, chem.-lab-on-a-chip (CLOC) chemoresistors, chemocapacitors, chemotransistors, electronic

nose (E-nose), mass sensitive chemosensors, fluroscence detection, calorimetric spectroscopy.

TEXT BOOK:

1. MEMS, Nitaigour Premchand Mahalik, TMH Publishing co.

REFERENCE BOOKS:

1. Foundation of MEMS, Chang Liu, Prentice Hall Ltd.

2. Bio-MEMS (Micro systems), Gerald Urban, Springer.

3. MEMS and Micro Systems: Design and Manufacture, Tai-Ran Hsu, TMH Publishers.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

30

IV Year B.Tech. I Sem.

OPEN ELECTIVE

INDUSTRIAL ROBOTICS

UNIT I

Automation and Robots-Technology of Robots-Economics and social issues-General characteristics of

Robots-Basic components-Robot configuration-Robot selection.

UNIT-II

Robot classification-Arm Geometry-Degree of Freedom-Power Sources-Types of Motion-Path control-

Intelligence Level. Robot System Analysis-Robot Operation-Hierarchical Control Structure-Line

Tracking-Dynamic Properties of Robots-Modular Robot Components. Robot End Effectors-Types of End

Effectors-Mechanical Grippers-Gripper Force AnalysisOther Types of Grippers.

UNIT-III

Sensors-Robot sensors-Sensor Classification-Micro switches-Solid-State Switches-Proximity Sensors-

Photoelectric Sensors-Rotary Position Sensors-Usage and Selection of Sensors-Signal Processing.

Vision-Visual Sensing-Machine Vision-Machine Vision Applications.

UNIT-IV

Control Systems-Control System Correlation-Control System Requirements-Programmable Logic

Controller-PLC Programming Terminals-Proportional-Integral-Derivative-Computer Numerical Control-

Microprocessor Unit-Work cell Control.

UNIT-V

Programming-Robot Programming-Programming Methods-Programming Languages-Levels of Robot

Programming-Motion Interpolation-Sample Programs.

UNIT-VI

Artificial Intelligence-Intelligent Systems-Elements of Artificial Intelligence-System Architecture-

Applications of Advanced Robots-Fuzzy Logic controls- Advanced Concepts and Procedures-Future

Developments.

UNIT-VII

Safety-Robot Safety-Safety standards-System Reliability-Human Factor Issues-Safety Sensors and

Monitoring-SafeguardingTraining-Safety Guide lines-Definitions.

UNIT-VIII

Industrial Applications-Automation in Manufacturing-Robot Applications-Material-Handling

Applications-Processing Operations-Assembly Operations-Inspection Operations-Evaluating The

Potential of a Robot Application-Future Applications-Innovations.

Text Books: 1. Robot Technology Fundamentals by James G.Keramas, Cengage Learning.

2. Industrial Robotics by Mikell P.Groover, Weiss, Nagel, Odrey/McGrawHill

Reference Book:

1. Robotics, K.S Fu/McGrawHill

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

31

IV Year B.Tech. I Sem.

DEPARTMENTAL ELECTIVE I

AUTOMOBILE ENGINEERING

UNIT I

Introduction : Components of four wheeler automobile chassis and body power unit power

transmission rear wheel drive, front wheel drive, 4 wheel drive types of automobile engines, engine

construction, turbo charging and super charging engine lubrication, splash and pressure lubrication

systems, oil filters, oil pumps crank case ventilation engine service, reboring, decarbonisation,

Nitriding of crank shaft..

UNIT II

Transmission System : Clutches, principle, types, cone clutch, single plate clutch, multi plate clutch,

magnetic and centrifugal clutches, fluid fly wheel gear boxes, types, sliding mesh, construct mesh,

synchro mesh gear boxes, epicyclic gear box , over drive torque converter. propeller shaft Hotch Kiss

drive, Torque tube drive, universal joint, differential rear axles types wheels and tyres.

UNIT III

Steering System : Steering geometry camber, castor, king pin rake, combined angle toein, center point

steering. types of steering mechanism Ackerman steering mechanism, Davis steering mechanism,

steering gears types, steering linkages.

UNIT IV

Suspension System : Objects of suspension systems rigid axle suspension system, torsion bar, shock

absorber, Independent suspension system.

Braking System : Mechanical brake system, hydraulic brake system, master cylinder, wheel cylinder

tandem master cylinder requirement of brake fluid, pneumatic and vacuum brakes.

UNIT V

Electrical System : Charging circuit, generator, current voltage regulator starting system, bendix

drive mechanism solenoid switch, lighting systems, horn, wiper, fuel gauge oil pressure gauge, engine

temperature indicator etc.

UNIT VI

Engine specification and safety systems: Introduction- engine specifications with regard to power,

speed, torque, no. of cylinders and arrangement, lubrication and cooling etc.

Safety: Introduction, safety systems - seat belt, air bags, bumper, anti lock brake system (ABS), wind

shield, suspension sensors, traction control, mirrors, central locking and electric windows, speed control.

UNIT VII

Engine Emission Control: Introduction types of pollutants, mechanism of formation, concentration

measurement, methods of controlling-engine modification, exhaust gas treatment-thermal and catalytic

converters-use of alternative fuels for emission control National and International pollution standards

UNIT VIII

Engine Service: Introduction, service details of engine cylinder head, valves and valve mechanism,

piston-connecting rod assembly, cylinder block, crank shaft and main bearings, engine reassembly-

precautions.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

32

TEXT BOOKS :

1. Automotive Mechanics Vol. 1 & Vol. 2 / Kripal Sing, standard publishers

2. Automobile Engineering / William Crouse, TMH Distributors

3. Automobile Engineering- P.S Gill, S.K. Kataria & Sons, New Delhi.

REFERENCES :

1. Automotive Engines Theory and Servicing, James D. Halderman and Chase D. Mitchell Jr.,

Pearson education inc.

2. Automotive Engineering / Newton Steeds & Garrett

3. Automotive Mechanics / G.B.S. Narang

4. Automotive Mechanics / Heitner

5. Automotive Engines / Srinivasan

6. Automobile Engineering K.K. Ramalingam / Scitech Publications (India) PVT. LTD.

7. A system approach to Automotive Technology, Jack Erjavec, India Edition

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

33

IV Year B.Tech. I Sem.

DEPARTMENTAL ELECTIVE I

COMPUTATIONAL FLUID DYNAMICS

UNIT-I

Elementary details in numerical Techniques: Number system and errors, Representation of

integers, Fractions, Floating point Arithmetic, loss of significance and error propagation, condition

and instability, computational methods for error estimation, Convergence of Sequences.

UNIT II

Applied Numerical Methods: Solution of a system of simultaneous Linear Algebraic Equations,

iterative schemes of Matrix Inversion, Direct Methods for Matrix inversion, Direct Methods for

banded matrices.

UNIT III

Review of Equations Governing Fluid Flow and Heat Transfer: Introduction, conservation of mass,

Newtons second law of motion, expanded forms of Navier-stokes equations, conservation of energy

principle, special forms of the Navier-stokes equations.

UNIT - IV

Steady flow, dimensionless form of Momentum and Energy equations, Stokes equation,

conservative body force fields, stream function - Vorticity formulation.

UNIT - V

Finite Difference Applications in Heat conduction and Convention Heat conduction, steady heat

conduction in a rectangular geometry, transient heat conduction, finite difference application in

convective heat transfer, closure.

UNIT - VI

Finite Differences, discretization, consistency, stability, and Fundamentals of fluid flow modeling:

Introduction, elementary finite difference quotients, implementation aspects of finite-difference

equations, consistency, explicit and implicit methods.

UNIT - VII

Introduction to first order wave equation, stability of hyperbolic and elliptic equations, fundamentals of

fluid flow modeling, conservative property, the upwind scheme.

UNIT -VIII

Finite Volume Method: Approximation of surface integrals, volume integrals, interpolation and

differentiation practices, Upwind interpolation, Linear interpolation and Quadratic interpolation.

TEXT BOOKS:

1. Numerical heat transfer and fluid flow / Suhas V. Patankar- Butter-worth Publishers

2. Computational fluid dynamics - Basics with applications - John. D. Anderson / Mc Graw Hill.

REFERENCES:

1. Computational Fluid Flow and Heat Transfer/ Niyogi, Pearson Publications

2. Fundamentals of Computational Fluid Dynamics Tapan K. Sengupta / Universities Press.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

34

IV Year B.Tech. I Sem.

DEPARTMENTAL ELECTIVE I

CONDITION MONITORING

UNIT-I

Basics of Vibration: Basic motion: amplitudes, period, frequency, Basic Parameters: displacement,

velocity, acceleration, Units (including dB scales) and conversions, Mass, spring and damper

concept, Introduction to SDOF and MDOF systems, Natural frequencies and resonance, Forced response

UNIT-II

Vibration Measurements and analysis: Transducers and mounting methods, Data acquisition using

instrumentation recorders/data loggers, Time domain signal analysis, Orbit analysis, Filters, Frequency

domain analysis (Narrow band FFT analysis), Nyquist criteria, Sampling, aliasing, windowing and

averaging,

UNIT-III

Vibration measurement and analysis: Use of phase; Bode, polar and water fall plots, Constant percentage

band width analysis(1/3 and 1/1 Octave analysis), Envelope detection /Spike energy analysis, Cepstral

analysis, Advances in analysis (PC based and portable instruments for vibration analysis)

UNIT-IV

Fault Diagnosis, Interpreting vibration measurements for common machine faults , Imbalance,

Misalignment, Mechanical looseness, Bearing and Gearing faults, Faults in Induction motors,

Resonances, Some case studies, Static and Dynamic Balancing, International Standards for vibration

condition monitoring

UNIT-V

Thermography: The basics of infrared Thermography, Differences in equipment and specific wave length

limitations, Application of IR to: Electrical inspection, Mechanical inspection, Energy conservation, How

to take good thermal images, Hands-on demonstrations focusing on proper camera settings and image

interpretation, Analysis of Thermal Images and Report Generation, Study of thermo graphy applications

UNIT-VI

Oil and Wear debris analysis: Basics of oil analysis, Monitoring condition of oil, Lubricant analysis,

Physio Chemical properties, Moisture, TAN TBN, Wear Debris analysis, Particle counting,

Spectroscopy, uses & limitations, Ferrography wear particle analysis, Concept of Ferrography, Principle

particle classification, Size, Shape, Composition, Concentration, Analysis procedure, Sampling &

Analytical Ferrography Equipments, Severity rating.

UNIT-VII

Condition Monitoring of Electric Machines and Motor Current Signature Analysis: Basics of Electric

Motors, Types of Electric Motors and operation, Synchronous Motors, Induction Motors, Constructional

features of Squirrel Cage Induction Motors, Common faults in Induction Motors, Motor Current

Signature Analysis, Electric Motor Current Waveform and its characteristics, Motor current harmonics,

Stator motor current wave pattern and reflection of rotor current harmonics, Rotor bar condition analysis,

Estimation of rotor bar condition

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

35

UNIT-VIII

Ultrasonic Monitoring and Analysis: Ultrasonic Monitoring (Leak, Crack and Thickness) Basics of

Ultrasonic Monitoring , Ultrasonic theory, Test taking philosophy, Ultrasonic theory, Mathematics of

Ultrasound, Equipment and transducers, Inspection parameters and calibration, Immersion theory,

Equipment quality control, Flaw origins and inspection methods, UT Procedure familiarization, and

Study recommendations, Application of ultrasound to: Air leaks, Steam trap testing, Bearing lubrication,

Electrical inspection, case studies.

TEXT BOOKS:

1. The Vibration Analysis Handbook, J I Taylor (1994)

2. Machinery Vibration Condition Monitoring, Lynn, Butterworth(1989)

REFERENCE BOOKS:

1. Machinery Vibration: Measurement And Analysis. Victor Wowk(1991)

2. Mechanical fault diagnosis and condition monitoring, RA Collacott(1977)

3. The Vibration Monitoring Handbook (Coxmoor's Machine & Systems Condition Monitoring) (1998)

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

36

IV Year B.Tech. I Sem.

DEPARTMENTAL ELECTIVE I

RAPID PROTOTYPING

UNIT I

Introduction: Prototyping fundamentals, Historical development, Fundamentals of Rapid Prototyping,

Advantages and Limitations of Rapid Prototyping, Commonly used Terms, Classification of RP process,

Rapid Prototyping Process Chain: Fundamental Automated Processes, Process Chain.

UNIT II

Liquid-based Rapid Prototyping Systems: Stereo lithography Apparatus (SLA): Models and

specifications, Process, working principle, photopolymers, photo polymerization, Layering technology,

laser and laser scanning, Applications, Advantages and Disadvantages, Case studies. Solid ground curing

(SGC): Models and specifications, Process, working principle, Applications, Advantages and

Disadvantages, Case studies.

UNIT-III

Solid-based Rapid Prototyping Systems: Laminated Object Manufacturing (LOM): Models and

specifications, Process, working principle, Applications, Advantages and Disadvantages, Case studies.

Fused Deposition Modeling (FDM): Models and specifications, Process, working principle, Applications,

Advantages and Disadvantages, Case studies.

UNIT IV

Powder Based Rapid Prototyping Systems: Selective laser sintering (SLS): Models and specifications,

Process, working principle, Applications, Advantages and Disadvantages, Case studies. Three

dimensional Printing (3DP): Models and specifications, Process, working principle, Applications,

Advantages and Disadvantages, Case studies.

UNIT-V

Rapid Tooling: Introduction to Rapid Tooling (RT), Conventional Tooling Vs RT, Need for RT. Rapid

Tooling Classification: Indirect Rapid Tooling Methods: Spray Metal Deposition, RTV Epoxy

Tools,Ceramic tools, Investment Casting, Spin Casting, Die casting, Sand Casting, 3D Keltool process.

Direct Rapid Tooling: Direct AIM, LOM Tools, DTM Rapid Tool Process, EOS Direct Tool Process and

Direct Metal Tooling using 3DP.

UNIT VI

Rapid Prototyping Data Formats: STL Format, STL File Problems, Consequence of Building Valid

and Invalid Tessellated Models, STL file Repairs: Generic Solution, Other Translators, Newly Proposed

Formats.

UNIT-VII

Rapid Prototyping Softwares: Features of various RP softwares like Magics, Mimics, Solid View,

View Expert, 3 D View, Velocity 2, Rhino, STL View 3 Data Expert and 3 D doctor.

UNIT VIII

RP Applications: Application Material Relationship, Application in Design, Application in

Engineering, Analysis and Planning, Aerospace Industry, Automotive Industry, Jewelry Industry, Coin

Industry, GIS application, Arts and Architecture. RP Medical and Bioengineering Applications: Planning

and simulation of complex surgery, Customized Implants & Prosthesis, Design and Production of

Medical Devices, Forensic Science and Anthropology, Visualization of Bimolecular.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

37

TEXT BOOK:

1. Rapid prototyping: Principles and Applications - Chua C.K., Leong K.F. and LIM

C.S, World Scientific publications

REFERENCE BOOKS:

1. Rapid Manufacturing D.T. Pham and S.S. Dimov, Springer

2. Wholers Report 2000 Terry Wohlers, Wohlers Associates

3. Rapid Prototyping & Manufacturing Paul F.Jacobs, ASME Press

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

38

IV Year B.Tech. I Sem.

SIMULATION LAB

1. Drafting: Development of part drawings for various components in the form of orthographic

andisometric. Representation of Dimensioning and tolerances scanning and plotting. Study of

script, DXE and IGES files.

2. Part Modeling : Generation of various 3D Models through Protrusion, revolve, shell

sweep.Creation of various features. Study of parent child relation. Feature based and Boolean

based modeling surface and Assembly Modeling. Study of various standard Translators. Design

simple components.

3. a). Determination of deflection and stresses in 2D and 3D trusses and beams.

b). Determination of deflections component and principal and Von-mises stresses in plane

stress, plane strain and Axisymmetric components.

c). Determination of stresses in 3D and shell structures (at least one example in each case)

d). Estimation of natural frequencies and mode shapes, Harmonic response of 2D beam.

e). Steady state heat transfer Analysis of plane and Axisymmetric components.

4. a). Development of process sheets for various components based on tooling Machines.

b). Development of manufacturing and tool management systems.

c). Study of various post processors used in NC Machines.

d). Development of NC code for free form and sculptured surfaces using CAM packages.

e). Machining of simple components on NC lathe and Mill by transferring NC Code / from a

CAM package. Through RS 232.

f) Quality Control and inspection.

Any Six Software Packages from the following:

Use of Auto CAD, Micro Station, CATIA, Pro-E, I-DEAS, ANSYS, NISA, CAEFEM, Gibbs

CAM, Master CAM etc,

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

39

IV Year B.Tech. I Sem.

ADVANCED COMMUNICATION SKILLS LAB

1. Introduction

The introduction of the English Language Lab is considered essential at 3

rd

year level. At this stage the

students need to prepare themselves for their careers which may require them to listen to, read, speak and

write in English both for their professional and interpersonal communication in the globalised context.

The proposed course should be an integrated theory and lab course to enable students to use good

English and perform the following:

Gather ideas and information, to organise ideas relevantly and coherently.

Engage in debates.

Participate in group discussions.

Face interviews.

Write project/research reports/technical reports.

Make oral presentations.

Write formal letters.

Transfer information from non-verbal to verbal texts and vice versa.

To take part in social and professional communication.

2. Objectives:

This Lab focuses on using computer-aided multimedia instruction for language development to meet

the following targets:

To improve the students fluency in English, through a well-developed vocabulary and enable

them to listen to English spoken at normal conversational speed by educated English speakers

and respond appropriately in different socio-cultural and professional contexts.

Further, they would be required to communicate their ideas relevantly and coherently in writing.

3. Syllabus:

The following course content is prescribed for the Advanced Communication Skills Lab:

UNIT I

Fundamentals of interpersonal communication starting a conversation responding appropriately and

relevantly using the right body language role play in different situations.

UNIT II

Vocabulary building synonyms and antonyms, word roots, one-word substitutes, prefixes and

suffixes, study of word origin, analogy, idioms and phrases.

UNIT III

Group Discussion dynamics of group discussion , intervention, summarizing, modulation of voice,

body language, relevance, fluency and coherence.

UNIT IV

Interview Skills concept and process, pre-interview planning, opening strategies, answering strategies,

interview through tele and video-conferencing.

UNIT V

e-Mail content, formats formal/informal. Structure, etiquette, structure and presentation.

2010-11

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KAKINADA

B.TECH (MECHANICAL ENGINEERING)

40

UNIT VI

Resume writing structure and presentation, planning, defining the career objective, projecting ones

strengths and skill-sets, summary, formats and styles, letter-writing.

UNIT VII

Reading comprehension reading for facts, guessing meanings from context, scanning, skimming,

inferring meaning, critical reading.

UNIT VIII

Technical Report writing Types of formats and styles, subject matter organization, clarity, coherence

and style, planning, data-collection, tools, analysis.

4. Minimum Requirement:

Computer aided multimedia language lab with 60 systems with LAN facility with speakers, head

phones and a teacher console to accommodate 60 students.

5. Suggested Software:

The software consisting of the prescribed topics elaborated above should be procured and used.

6. Books Recommended:

1. Effective Technical Communication, M. Ashraf Rizvi, Tata Mc. Graw-Hill Publishing Company

Ltd.

2. A course in English communication by Madhavi Apte, Prentice-Hall of India, 2007.

3. Communication Skills by Leena Sen, Prentice-Hall of India, 2005.

4. Academic Writing- A Practical guide for students by Stephen Bailey, Rontledge Falmer, London

& New York, 2004.

5. Body Language- Your Success Mantra by Dr. Shalini Verma, S. Chand, 2006.

6. Deltas Key to the Next Generation TOEFL Test by Nancy Gallagher.

7. IELTS series with CDs by Cambridge University Press.

8. Technical Report Writing Today by Daniel G. Riordan & Steven E. Pauley, Biztantra Publishers,

2005.

9. Basic Communication Skills for Technology by Andra J. Rutherford, 2

nd

Edition, Pearson

Education, 2007.

10. Communication Skills for Engineers by Sunita Mishra & C. Muralikrishna, Pearson Education,

2007.

11. Objective English by Edgar Thorpe & Showick Thorpe, 2

nd

edition, Pearson Education, 2007.

12. Objective IELTS by Michal Black & Wendy Sharp, Cambridge University Press.

13. Objective IELTS by Michal Black & Annette Capel, Cambridge University Press.

14. Cambridge Preparation for the TOEFL Test by Jolene Gear & Robert Gear, 4

th

Edition.

15. Technical Communication by Meenakshi Raman & Sangeeta Sharma, Oxford University Press.

16. TOEFL Test- IBT Edition- Thompson India Ltd.

DISTRIBUTION AND WEIGHTAGE OF MARKS:

Advanced Communication Skills Lab Practicals:

1. The practical examinations for the English Language Laboratory practice shall be conducted as per the

University norms prescribed for the core engineering practical sessions.

2. For the English Language lab sessions, there shall be a continuous evaluation during the year for 25

sessional marks and 50 End Examination marks. Of the 25 marks, 15 marks shall be awarded for day-