Beruflich Dokumente

Kultur Dokumente

Mekanisme Red Scale PDF

Hochgeladen von

Agustine SetiawanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mekanisme Red Scale PDF

Hochgeladen von

Agustine SetiawanCopyright:

Verfügbare Formate

ISIJ International. Vol.

34

(1

994). No.

11

,

pp.

906-91

1

Mechanism

of

Steel Sheets

RedScale Defect Formation

in

Si-added Hot-rolled

Tomoki

FUKAGAWA.

Hikaru OKADA1)

and Yasuhiro MAEHARA2)

lron

and

Steel Research Laboratories,

SumitomoMetal Industries, Ltd..

Fuso-cho, Amagasaki, Hyogo-ken. 660 Japan.

1

)

Iron

andSteel ResearchLaboratories.

SumitomoMetal Industries, Ltd.,

Kashima-cho, Kashima-gun, Ibaragi-ken. 31

4

Japan.

2)

AdvancedTechnology Research Laboratories.

SumitomoMetal Industries, Ltd.,

Fuso-cho. Amagasaki. Hyogo-ken. 660

Ja

pan.

(Received

on

June

7.

l994; accepted

in final form

on

September

l6. 1994)

The

red scale,

which

is

one

of the major defects

on

hot-rolled Si

added steel sheets,

is

reproduced

6xperimentally.

On

the basis of detailed observation of the scale properties,

we

propose

the mechanism

of

formation of the red scale. Imcompletedescaling of

FeO

prior

to hot rolling

causes

red scale formation

even

in Si-free steels, since the reaction from FeOto Fe304and red Fe203

is largely accelerated by the breakage

of the FeO

scale, In

Si-added

steels, descaling

is quite difficult

to perform, becausethe eutectic

compound

of FeO/Fe.SiO*

is

formed at the scale/steel interface and penetrates

irregularly into both

upper

FeOand

lower steel sides. auite high strength of the eutectic

compound,

even

just

below the solidus

temperature

of

11

73'C,

can

also

make

it

difficult

to

descale.

KEYWORDS:

scale; descaling: Si-added

steelj red scale; hot rolling.

1. Introduction

Recently, for examplein the automobile industry, the

demand

for high strength steel sheets has increased for

the

purpose

of

energy

saving dueto the weight reduction.

Although

there

are

some

methods to strengthen the

materials,

among

them

solid solution hardening

is the

best

way,

becausethe other properties hardly be affected

by

this

method. For example, the precipitation harden-

ing affects significantly other properties such

as

forma-

bility

or

ductility.

The

ductility of hot rolled sheets

is

considerably reduced by the precipitation, since the

precipitates

act

as

initiation sites for ductile fracture.

In

case

of cold rolled sheets, since the formability

determined by

recrystallization behavior in the final

annealing will largely be affected by the precipitation,

drastic change

will

become

necessary

in order to keep

the original formability. Silicon is

a

reasonable alloying

element for the solid solution hardening

not

only from

the above-described view point but also

from the cost

performance aspect. In addition, the ductility is

not

largely affected by the small addition of

Si.

However,

on

the hot-rolled sheets of the Si-added

steel,

defects of heterogeneous red scale,

which reduce the

conunercial value,

are

often formed.1)

This

is

the

main

reason

why

the spread of this kind of steel sheet has been

limited. In addition, these defects

are

often inherited to

the cold rolled sheets, resulting in the plating defects in

the subsequent

process.

It is said that the red scale defect

on

the hot-rolled

sheets originates from the eutectic

compoundof

FeO/Fe2Si04with relatively

low solidus

temperature

of

l

173'C, which

is

generated in the furnace before hot

rolling.

The mechanismof the red scale formation,

however, has

not been

fully

undetstood

so

far.

Thus, the objective of this study

is

to

clarify the

mechanismof the red scale fornration in order to prevent

the scale defects in Si-added

steels.

2. Experimental Procedure

First,

we

investigated the actual state of the red scale

formed

on

the commercial hot strips of Si-added

steels.

Next,

we

tried

to reproduce the red scale

by the laboratory

hot

rolling.

Thechemical composition of the steels used

in the laboratory reproduction tests

is

given in Table

1.

Although there

is

a

significant difference of

Mn

content

between

Steels

I

and

2, it is well

known

that

Mn

does

Table

1. Chemical composition of the steel

used (massolo).

Steel

C

Si

Mn P S

Cu Ni Cr

Mo

A1

N

1

2

0.09

0.05

0.54

0.005

1

.46

0.15

0.009

0.009

0.0014

0.013

O

.O

l

0.01

0.02

0.02

o.02

o.02

0.01

0.01

0.019

0.024

0.0023

O.O016

C

1

994 ISIJ 906

ISIJ International. Vol.

34

(1

994), No.

11

Test A(Rol

I

ing without scale)

Weating the slab

(covered

with

)

SS sheet

Table 2.

Summary

of hot ductility and constituent ofscale

in Tests

A

and B.

Test B(Rol

I

ing with secondary scale)

Deformation of

FeO

Final constituent

Test Before rolling

by rolling of scale

Heating the slab

-

Scale forRlation

(covered ,vith

)

(exposed in air for 40s)

SS sheet

A

Thin scale Apparently ductile

FeO

+

Fe304

B

Thick scale Brittle fracture

FeO

+

Fe304

+

(Impressron

mto

steel)

ocFe203(red)

Test C(Rol

I

ing with primary scale

)

Heating the siab

-

r~~~~

r~~:~~1TT~~I

Descalln9

-

(without cover) Ll~li~Li

~

2-ndary scale formation

~rl~~:~~lTT~l

Desca

I[ng

(exposed in air for 40

s)

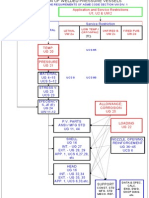

Fig. l. Block diagramofreproducing test ofscale before final

3-pass rolling.

The

slabs

were

heated at

1

220"C

for

2h

in

an

atmo-

sphere of 77.1"/oN2+ 14.30/0H20+8.201*C02with

or

without the stainless steel

cover.

After the Tests, the

slabs

were

cooled by water spray

in order to

suppress

the further changeof scale structure.

not

affect the red scale defect formation. In fact, the

red scale defects have

not

been reported in Si-free high-

Mn

hot-rolled steel sheets, in which considerable high

amount

of

Mnmore

than

I

wt"/* has been used for the

strengthening

purpose.

The30

mm

thick plates

cut from

continuously cast (CC) slabs

were

heated at

1

220'C for

2h

in

an

atmosphere of 77.10/0N2-14.30/0H208.60/0

C02, which simulated that of the actual combustion type

furnace, and hot rolled into

5

mm

thick hot bands by

3

passes.

Figure

I

showsschematically the three kinds of

tests employed

in this study. In Tests

A

and B, the slabs

were

covered with stainless steel sheets which prevented

the primary

scale

from forming in the furnace. In Test

A, the formation of the secondary scale

was

also

prevented by immediate hot rolling after

removing the

stainless steel sheet

cover.

Whereas,

in Test B, the slabs

were

exposedfor 40

s

in air after removing the

cover

in

order to form the secondary

scale. In Test C, the slabs

were

heated in the furnace without the

cover

to form the

primary

scale. After descaling, they

were

rolled

to 25

mm

by

I pass

and exposed for 40

s

in air for the secondary

scale formation. After being descaled again they

were

hot rolled

by

3passes

to bands with given thickness of

5

mm.

In

all the tests, after the final rolling the hot bands

were

cooled immediately by water

spray

in order to

suppress

further changeof scale structure.

On

these hot strips

and hot bands,

a

few

scale

properties

were

investigated by

means

of surface

roughness measurement,

optical microscopy, scanning

electron microscopy and

EPMA

analysis.

3.

Experimental Results

3.1.

Red

Scale

on

CommercialHot

Strips

Figure

2

shows

an appearance

of

a

red scale

on

the

commercial hot

strip,

which

was

hot-rolled from about

300

mm

thick

CC

slab to

6

mm

hot

strip.

Thechemical

907

composition

is

almost the

same

as

that of Steel

I

given

in Table

I.

Abnormal

red scale islands

are

elongated in

the rolling direction within the normal black scale matrix.

Figure

3

shows

a

surface roughness

profile in

a

transverse

direction after complete descaling.

Comparedwith the

relatively

smoothsurface after

removing the black scale,

the interface under the red scale

caves

irregularly in the

steel substrate.

3.2. Effect of SecondaryScale

on

the Final Structure

Here

the results of Tests

A

and

B

without primary

scale will be explained. In the Test

A

without the

secondary scale before rolling, the hot rolled hot bands

were

covered uniformly with black

~cale,

independent of

the kind of

steel.

Whereas, in Test

B

with the secondary

scale,

a

red scale

was

observed in both

steels.

X-ray

diffraction analysis revealed that the black scale

after Test

A

consisted of

FeOand Fe304,

as

shown

in

Fig. 4. After Test B, Fe203

was

also detected in addition

to FeOand Fe304.

It

should be noted that the

con-

stituents

were

independent of the kind of

steel.

Figure

5

shows

scale

structures

in the

transverse

cross

sections

of both

steels. After Test

A

without the secondary scale,

thin double layer

structure of FeO/Fe304

was

observed

to form

tightly in the both

Steels,

as

shown

in Figs. 5(a)

and

5(b). Whereas,after Test

B

with the secondary

scale,

the scale

structures

were very

complicated and

were

different from each other.

That

is,

in addition to

the

irregular double layer structure,

upper

layer of Fe304

was

broken by the rolling.

On

the broken Fe304

red

Fe203

Was

observed,

as

shown

in Figs. 5(c)

and

5(d).

The

results of Tests

A

and

Bcan

be summarized

as

Table

2. In Test A, the thin scale

can

bedeformedwithout

fracture during rolling,

and the scale constituent

is

preserved without

any

change. Whereas,

in

Test

B

with

the secondary

scale, the thick oxide layer

is

broken by

the shear deformation during rolling.

By

the increase of

surface

area

through the breakage supply of

oxygencan

be accelerated, Ieading to the formation of O-rich red

Fe203,

as

discussed later.

3.3. Effect of Primary Scale

on

the Final Scale Structure

Although

any

difference

between Steels

I

and

2

did

not

appear

in Tests

A

and B, marked

difference between

the both Steels

was

observed in Test

C

with the primary

scale,

as

shown

in Fig. 6.

The

colors of the hot bandsof

low

Si Steel

2

and high Si Steel

I were

black and

red,

respectively. Figure

7

showsback scattered electron and

SiK* X-ray image

on

transverse

cross

section of

Steel

1.

Zig-zag interface of steel/oxide

was

observed, and

oxide

particles

were

also formed

inside the steel,

as

shown

in

Fig. 7(a).

EPMA

analysis revealed that Si

atoms were

C

1994

ISIJ

ISIJ International, Vol.

34

(1

994), No.

11

2.

Appearanceofred scale defect in

a

Si-added hot rolled

steel sheet.

Thechemical composition

is

almost the

same

as

that

of Steel

I

shown

in Table

I.

R B R B R

45

.

OO

(

p

m)

O.

OO

45.

OO

o,

oo

7.

50 15,

Fig.

45 oo

Fig. 3.

O.

OO

7.

50

15.

OO

(

mm

)

Surface roughness profile after pickling in

a

transverse

direction of the sheet shown

in Fig. 2.

R: Red

scale

area

before pickling

B: Black scale

area

before pickling

(a)SteeJ

1

,

Test

A

(b)Steel

2

,

Test

A

FeO

a

Fe

FeO Fe304 a

Fe

Fe304

(c)Steel

1

,

Test

B (

d)

Stee

l 2

,

Test

B

a

Fe

FeO

a

Fe203

Fe304

a

Fe

FeO

Fe203

Fe304

47 48 50 52 54 48

26

(deg)

50 52 54

Fig. 4.

X-ray diffraction

patterns of the scales after Tests

A

and B.

(a) Steel l,

Test A; starting

temperature of rolling:

l I

18'C

(b) Steel 2,

Test A; starting

temperature of rolling:

I

122'C

(c) Steel l,

Test B; pre-oxidized from

1

184 to

I

OOO"C

for 30s before rolling

(d) Steel 2, Test B; pre-oxidized from

I

090 to 929'C

for 33

s

before rolling

Fe

1Opm

'

10

PrT,j~

~

f~TT~~i

~ 10Hm

Fig. 5.

Optical micrographs

on

transverse

cross

sections showing scale

struc-

tures.

(a) Steel

I

i

Test A; starting

tempera-

ture of rolling:

I I

18"C

(b) Steel 2,

Test A; starting

tempera-

ture of rolling:

I

122'C

(c) Steel

I

,

Test B; pre-oxidized from

1

184 to

I

OOO'Cfor 30s before

rolling

(d) Steel 2. Test B; pre-oxidized from

l

090 to 929'C for 33

s

before

rolling

Fig. 6.

Appearanceof the sheet after Test C.

(a) Steel

1

(b) Steel

2

C

1994 ISIJ

908

ISIJ International, Vol. 34 (1994). No. 11

20, p,=m,

Fig. 7. (a)

Backscattered electron and

(b) Si-Kc( X-ray image

in the vicinity of the primary scale/steel interface of

Steel

I

in Test C.

a

Fe

(1

10)

W

F

(200)

F

F

(231)

(112)(221)

W

=

FeO

w

F

=

Fe2S

i

0+

(111)

F F

F F

(1

31

X220)(031

)(

200)

55 50 45 40 35

2O

(deg)

Fig. 8.

X-ray diffraction pattern of Steel

I

in Test C, showing

the existence of

FeOandFe2Si04

in the primary

scale.

Back scattered electron image in the vicinity of the

primary scale/steel interface of Steel

2

in Test C.

Frg 10. Backscattered electron imageofremained

scale after

descaling the primary scale in Test C.

(a) Steel

I

(b) Steel

2

Fig. 9.

enriched in the oxide adjacent to the steel,

as

shown

in

Fig. 7(b).

Thecontent

ratio of Fe/Si in this region

was

2: I

in ato/o

.

Figure

8

shows

an

X-ray

diffraction

pattern

of the specimen shown

in Fig. 7(a) after

removing the

upper

oxide layers. Obviously diffraction peaks from

Fe2Si04

Were

detected,

as

indicated by mark

F.

From

these results, it

can

be

seen

that the oxide adjacent tQ

the steel is

a

eutectic product of FeO/Fe2Si04and the

upper

oxide

is

FeO. Figure

9

is

a

back

scattered. electron

image

on

the

transverse

cross

section of low

Si Steel

2

after Test C. The oxide layer consists of only FeO,

al-

though the interface of oxide/steel

was

complicated and

internal oxidation occurred samely

as

in high Si Steel

I.

Figure 10

illustrates

a

back scattered electron image

of the specimens after descaling the primary scale in

Test C, showing rema:ined scale

structure before hot

r.olling.

In high Si Steel

1,

a

large

amount

of oxide

re-

mains,

as shown

in Fig. lO(a).

The

eutectic

compound

of FeO/Fe2Si04

exists

between

steel

and FeO, and

is

penetrating irregularly into both

sides. In addition, the

eutectic

compound

entered into grain boundaries of the

upper

FeO. In

some

cases FeO

grains

are

enveloped by

the eutectic

compound. Such

very

complicated scale

909

Fig.

n.

Effect of rolhng temperature

on

the FeO/Fe2Si04

eutectic

structure of Steel

I

in Test C.

(a) Starting

temperature ofroning:

I

163"c

(b) Starting

temperature or

rolling:

I

ro7'C

structure

can

make

it difficult

to

descale.

On

the

contrary,

the primary scale in

low

Si Steel

2was

descaled

easily.

The

very

thin

FeO

film in Fig, lO(b)

seems

to be

formed by the oxidation after descaling.

Figure 11 showsthe effect of hot rolling

temperature

on

the scale

structure of high Si Steel

I

in Test C. In

this experiment, the primary scale

formed at

1

300'C

was

rolled directly without descaling at

different

tempera-

C

1994 ISIJ

ISIJ International, Vol.

tures

in order to

investigate the deformation behavior of

oxide layer during hot rolling.

When

hot rolling

tem-

perature

was

high enough, the oxide layer

was

deformed

plastically without

any

cracking,

as

shown

in Fig.

1

1(a).

In

case

of lower temperature

rolling, the eutectic

com-

pound of FeO/Fe2Si04remains with their

lammelar

structure, showing that these particles did

not deform

after the solidification. Instead,

FeO

surrounding the

eutectic

compounddeformed

largely, resulting in ductile

fracture,

as shown

in Fig.

1

1(b). This result

showsthat

the high

temperature

strength of FeO/Fe2Si04

is

much

higher than that of FeO.

4. Discussion

*

4.1.

Mechanismof

Red

Scale Formation

First

we

discuss

how

the red

Fe203forms through the

breakageof

an FeO

scale.

Figure 12 showsschematically

the

mechanismof red scale formation by fracture of

FeO

layer during rolling.

The kinds of oxides formed by

heating Fe

in air

are

FeO, Fe304and Fe203with the

volume

ratio of about 95

: 4:

l,

around

I

OOO'C.2)

That

is,

the scale consists mainly of

FeOunder normal

conditions without deformation. If the scale is

fractured

by hot rolling, the

area

of

FeO

particles exposedto

air

increases considerably.

To

these particles separated from

the

FeO

matrix, Iess

Featomsare

supplied.

Thus

oxygen

becomesoversupplied comparedwith the supplement of

Fe atoms from

steel, resulting in the

much

accelerated

reaction of FeO-Fe304-Fe203'This

final

product of

Fe203Iooks red. Asai et

al.3)

investigated the relationship

betweenthe color and

particle size of Fe203, andreported

that the depth of red color could be determined by the

fraction of fine

Fe203

particle~ of less

than

2

pm

in

diameter. Therefore,

it

can

beconcluded that the residual

scale before rolling

becomesthe

cause

of the, red scale.

In fact,

a

fractured scale

was

observed in the

part of the

red scale

on

the commercial hot rolled sheets.

4.2.

Mechanismof Red Scale Formation

in Si-added

Steel

In the

present experiment, the red scale

on

Si-added

steel

was

reproduced only by Test

C

wherethe primary

scale

was

formed

in the furnace and

was

not

reproduced

by Tests

A

and

B

without the primary scale. This result

showsthat the

cause

of the red scale defect

is closely

related

to the primary

scale.

The

cause

of

poor

descaling in Si-added steel has been

explained

so

far in

terms

of the fact that the impact by

high

pressure water

spray

is

reduced by the existence of

molten eutectic

compound

bctween

steel

and

scale.4)

According to Morita et

al.,5)

on

the contrary,

the

existence of FeO/FeS

eutectic

compound

with lower

melting point of 950'C, which

is

formed between

steel

and the FeO/Fe2Si04 compound

in high

S

steels,

accelerates descaling, in conflict with the previous

explanation. Okita et

al.6)

reported that the grain

boundary

eutectic

compoundmade

it difficult

to descale

by the anchor

effect,

bywhichthe scale is

firmly connected

with

steel.

Furthermore, Tuckand

Barlow7) pointed

out

that the depth of invasion of FeO/Fe2Si04

eutectic

C

1994

ISIJ 91

O

34

(1

994).

(a)

(b)

Fig.

1

800

l

600

1

400

1

200

Si

02

No.

11

a

Fe203

Fe304

Fe2~

_

FeO

g5:4:

I

(at 1000'C

)

~,.~~..

~

Fracture of FeOby rol

I

ing

OOO

~

~~

Powdered-aFe203(red)

Fe304

~.~.e_

~

PowderedFeO

~>

Fe304

~F

a

Fe2

3

(

red~

12. Mechanismof red scale formation by fracture of

FeO

layer during rolling.

(a) Scale structure before rolling

(b) Scale structure after rolling

2Liquids

Cr istbal

i

te +

Liquid

Fayal ite

+

Liquid

Tr

i

dyma

i

te +

Liquid

W~st

i e+

Li(

Tr

i

dym

i

te +

Faya

Ii

te Faya

Ii

te +

Wtist

i

tc

02 10 20 30 40 50 60 80 90 FeO

Fig. 13.

Fe2S

i

04

FeC~Si02phase

diagram.8)

Liquid

Wtist

i

te

compound

into

FeO

grain boundaries deteriorated

descalability

very

much.

Here

we

discuss the mechanismof penetration of

eutectic

compound

into

FeO

grain boundaries.

As

can

be

seen

from

a

FeO-Si02phase

diagram8) in Fig. 13, the

fraction of

FeO

is

much

larger than that of Fe2Si04

in

the

neighborhood of the scale/steel interface.

The state

of thermal equilibrium in this

system at oxidation

temperature of

1

220'C

is

"FeO(Wtistite)

+

Liquid". The

liquid phaseenclosing

FeO

grains becomesFeO/Fe2Si04

eutectic

compound

with the morphology

like "anchor"

after solidification.

In drder

to confirm the validity of such anchor

effect

on

the

poor

descaling ability, relation of descaling with

high

temperature

mechanical

property

of the Fe2Si04

should be also discussed in addition to

the morphology

effect.

That

is, if the eutectic

compoundhasgood

ductility

or

strength lowenough

for deformation, the anchor

effect

will be diminished. The

eutectic

compound

can

be

deformedwithout failure

by rolling

at

I

163'C

just below

the melting point (Fig.

I

l(a)).

In

case

of hot rolling at

l

107'C,

it

was

confirmed that the

compound

was

not

deformed and that

FeO

surrounding the compound

was

fractured (Fig,

I I

(b)),

showing that the compound

is

much

harder than FeO. This result does not

conflict

(a)

Fe203-->

Fe304-~~

FeO

FeO-Fe2S

i

04 l~

Fe

Fig. 14.

ISIJ International. Vol.

(b)

Desca

Iing

Rema

i

ned

34

(1

994). No.

11

FeO

FeO-Fe2S

i

04

(b)

Rol

Iing

Impression to steel and

fracture of remained FeO

~

Fe203( red)

Mechanismof red scale formation in Si

addedhot roned steet sheet.

(a) Formation ofthe primary scale (b)

Remainderofthe scale after descaling (c) Red-scale formation

with the

mechanismproposed by Okita et

al., in which not. Since the remained

FeO

scale partially

cut

into the

the

upper

FeO

scale is

strongly connected with

steel

by

steel is

fractured by rolling, the reaction,

FeO-~Fe304

H-

the

strong Fe2Si04 anchors. Fe203,

is largely accelerated by the oversupplement of

From

these results, the mechanismof red scale for-

oxygen.

Resultant fine particles

ofFe203Iooks thick red.

mation

in

Si-addei

steel

can

be depicted schematically (4)

Although the red scale

on

Si-added steels is

also

as

Fig. 14. In the furnace

a

thick scale consisting main- formed by the

same

mechanism

as

described above, the

ly of

FeO

is

formed prior to hot

rolling.

In addition, descaling ofthe primary scaleprior

to hot rolling

becomes

in

case

of Si-added

steel, the eutectic FeO/Fe2Si04 quite difficult

to achieve by the existence of irregularly

compoundformed

on

the FeO/steel interface

runs

shaped lamellar

compoundof FeO/Fe2Si04between

irregularly into both

FeOand

steel sides (Fig. 7).

When

steel

and

upper

FeO

scale.

descaling

is

carried

out at temperatures belowthe melting (5)

The

solidified

FeO/Fe2Si04eutectic

compound

point, since the strength of solidified eutectic

compound has

very

high strength

even

at high

temperatures 60'C

is

high,

it is difficult

to

remove

completely the

upper FeO below the melting point. Cutting into both

upper

FeO

scale

by the anchor

effect.

The remained

FeO

scale is

scale

and

steel sides accelerates the difficulty

of descal-

fractured easily

by the subsequent rolling,

and changed ing, Ieading to the red scale by the above-described

mto

Fe304and

finally into red Fe203 by the

reason

mechanism.

described before.

The molten eutectic FeO/Fe2Si04

compound

is

not

direct

cause

of the red scale defects.

REFE

R.E

NC

ES

l)

K. Onoda. H. Okabe, R. Nomiand N. Hase: SumitomoMet.,

5. Conclusions

20 (1968), 1.

2) S.

Mrowecand K. Przybylski: Oxid. Met.,

n

(1977), 383.

(1)

On

the Si-added hot-rolled steel sheets, scale

3) T. Asai,T. NakamuraandT. Inoue: CAMP-ISIJ,6(1993), 357.

defects consisting of stripe red andblack scales along the 4) S. Takizawa: Iron and steel

Handbook,

ed, by ISIJ, Maruzen,

rolling direction

are

often formed. Tokyo, 37.

(2)

Thered scale layer with

many

cracks

is

normally

5)

M. Morita, M, Nishida and T. Tanaka: Tetsu-to-Hagan~, 68

thicker than the black scale.

The

steel surface under the

(1982), S438.

red scale has

a concave,

because the

upper

surface

6)

M.Okita, A,Nagai,1. SinagawaandK. Horinouchi: CAMP-ISIJ,

2

(1989), 1509.

becomes

flat

by

rolling.

7) C.

W. Tuck and

J. Barlow:

hon

Steel, 45 (1972), 31.

(3)

Thered scale is

formed

easily

by remaining

FeO

8)

N. L.

Brownand

J. F, schairer:

Am.

J. Sci., 5th Ser., 24 (1932),

scale before hot rolling,

whether the steel contains Si

or

200.

91

1

C

1994

ISIJ

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- N9509-Welding Techniques For Tailored BlanksDokument7 SeitenN9509-Welding Techniques For Tailored BlanksAgustine SetiawanNoch keine Bewertungen

- US4026729-Method of Making A Soft Steel Sheet by Continuous AnnealingDokument6 SeitenUS4026729-Method of Making A Soft Steel Sheet by Continuous AnnealingAgustine SetiawanNoch keine Bewertungen

- SM - en - Ar - 2003-ANNUAL REPORT-Nippon SteelDokument56 SeitenSM - en - Ar - 2003-ANNUAL REPORT-Nippon SteelAgustine SetiawanNoch keine Bewertungen

- Nscguide2012 - e - 61-Flow Production Nippon SteelDokument2 SeitenNscguide2012 - e - 61-Flow Production Nippon SteelAgustine SetiawanNoch keine Bewertungen

- NSTR101-13 - Tech - Review-2-2-Change and Development of Steelmaking TechnologyDokument6 SeitenNSTR101-13 - Tech - Review-2-2-Change and Development of Steelmaking TechnologyAgustine SetiawanNoch keine Bewertungen

- US4144379-Drawing Quality Hot-Dip Coated Steel StripDokument5 SeitenUS4144379-Drawing Quality Hot-Dip Coated Steel StripAgustine SetiawanNoch keine Bewertungen

- Ductile Iron and Method of Making SameDokument4 SeitenDuctile Iron and Method of Making SameAgustine SetiawanNoch keine Bewertungen

- NDT-MT TheoryDokument14 SeitenNDT-MT TheoryAgustine SetiawanNoch keine Bewertungen

- NDT-Nondestructive ExaminationDokument103 SeitenNDT-Nondestructive ExaminationAgustine SetiawanNoch keine Bewertungen

- Welding-Basic Study Guide 1997Dokument136 SeitenWelding-Basic Study Guide 1997Agustine SetiawanNoch keine Bewertungen

- Visual Inspection ModulesDokument6 SeitenVisual Inspection ModulesAgustine Setiawan100% (2)

- NDT-PT TheoryDokument22 SeitenNDT-PT TheoryAgustine SetiawanNoch keine Bewertungen

- DNV Os C401Dokument44 SeitenDNV Os C401Mung Duong XuanNoch keine Bewertungen

- Boiler - DFKI PVBOChartDokument10 SeitenBoiler - DFKI PVBOChartAgustine SetiawanNoch keine Bewertungen

- NDT For BoilersDokument9 SeitenNDT For BoilersmjorionNoch keine Bewertungen

- Black SteelDokument2 SeitenBlack SteelAgustine SetiawanNoch keine Bewertungen

- The Metallurgy of Carbon SteelDokument5 SeitenThe Metallurgy of Carbon SteeltsoheilNoch keine Bewertungen

- Hot Dip Galvanizing of Sheet Metal-SpangleDokument6 SeitenHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanNoch keine Bewertungen

- Beda Antara Verifikasi & ValidasiDokument18 SeitenBeda Antara Verifikasi & ValidasiAgustine SetiawanNoch keine Bewertungen

- Trouble Shooting Guide For The Powder CoatingDokument19 SeitenTrouble Shooting Guide For The Powder CoatingAgustine SetiawanNoch keine Bewertungen

- Study of Fork Tube Failure in Motorcycle Using Scanning Electron MicroscopeDokument5 SeitenStudy of Fork Tube Failure in Motorcycle Using Scanning Electron MicroscopeAgustine SetiawanNoch keine Bewertungen

- Metallurgy of Iron and SteelmakingDokument13 SeitenMetallurgy of Iron and SteelmakingAgustine SetiawanNoch keine Bewertungen

- Periodic Table of The ElementsDokument1 SeitePeriodic Table of The Elementsm_tagliaNoch keine Bewertungen

- Cold Work EmbrittlementDokument2 SeitenCold Work EmbrittlementAgustine SetiawanNoch keine Bewertungen

- Cokal Confirms Indonesian Met ResourcesDokument1 SeiteCokal Confirms Indonesian Met ResourcesAgustine SetiawanNoch keine Bewertungen

- Nickel Alloys Applications and ProcessingDokument16 SeitenNickel Alloys Applications and ProcessingAgustine SetiawanNoch keine Bewertungen

- Standard Test Method For Drop Test of Loaded Containers by Free FallDokument8 SeitenStandard Test Method For Drop Test of Loaded Containers by Free FallAgustine SetiawanNoch keine Bewertungen

- Drilling 01Dokument1 SeiteDrilling 01Agustine SetiawanNoch keine Bewertungen

- Metal Ki PehchaanDokument14 SeitenMetal Ki PehchaanParteek GandhiNoch keine Bewertungen

- Isstech Studies Paper PDFDokument28 SeitenIsstech Studies Paper PDFAgustine SetiawanNoch keine Bewertungen

- Welding & Material CS & SS From Go WeldingDokument30 SeitenWelding & Material CS & SS From Go WeldingExsan OthmanNoch keine Bewertungen

- Stainless Steel TableDokument4 SeitenStainless Steel Tableerinukafi100% (1)

- Alkaline Leaching of Xenoitme Conc.Dokument6 SeitenAlkaline Leaching of Xenoitme Conc.Ruth LimboNoch keine Bewertungen

- Centrifugal CastingDokument3 SeitenCentrifugal Castingdurim-fcb4435Noch keine Bewertungen

- And Jorge Taipe A.: Geology of This Remarkable Deposit (Yamamura, 1990)Dokument8 SeitenAnd Jorge Taipe A.: Geology of This Remarkable Deposit (Yamamura, 1990)Berthing HerreraNoch keine Bewertungen

- Foundry WorkDokument224 SeitenFoundry WorkMartin Ong100% (1)

- Answers To Chapter 3 Review QuestionsDokument3 SeitenAnswers To Chapter 3 Review Questionsieltstutor100% (1)

- KaolinballclayotherclaysDokument24 SeitenKaolinballclayotherclaysGunjan LalchandaniNoch keine Bewertungen

- Company Profile SBC - BrosurDokument2 SeitenCompany Profile SBC - BrosurTaufan WigunaNoch keine Bewertungen

- Welding CoatingDokument69 SeitenWelding CoatingphillipskincaidNoch keine Bewertungen

- Shaking Table ConcentratorDokument2 SeitenShaking Table ConcentratorMgn SanNoch keine Bewertungen

- Pin HolesDokument4 SeitenPin HolesEr WidodoNoch keine Bewertungen

- Weld and Base Metal DiscontinuitiesDokument69 SeitenWeld and Base Metal Discontinuitiestuvu0% (1)

- MT101 L1 04 Microstucture ExaminationDokument2 SeitenMT101 L1 04 Microstucture ExaminationPasan LiyanaarachchiNoch keine Bewertungen

- 304L MTC Int PDFDokument1 Seite304L MTC Int PDFTanmoy DuttaNoch keine Bewertungen

- Pricing PDFDokument5 SeitenPricing PDFDes MshenguNoch keine Bewertungen

- Jadeite by Kim Be Howard - UsefulDokument85 SeitenJadeite by Kim Be Howard - UsefulPhuong Ngoc VanNoch keine Bewertungen

- Oxo Act02 C3uu cm01 XxaannDokument3 SeitenOxo Act02 C3uu cm01 Xxaannpreeti.2405100% (1)

- Handbook Walter Insert Drill enDokument78 SeitenHandbook Walter Insert Drill enasilka68Noch keine Bewertungen

- Etchant Composition Conc. Conditions Comments Kalling's No. 1Dokument1 SeiteEtchant Composition Conc. Conditions Comments Kalling's No. 1Nick LaveryNoch keine Bewertungen

- Lowell Guilbert On Porphyry Cu (36 Pags)Dokument36 SeitenLowell Guilbert On Porphyry Cu (36 Pags)rmiguelmera4733100% (1)

- Weld AbilityDokument34 SeitenWeld Abilityae1329Noch keine Bewertungen

- Selection of Methods For Separating of Rare Earth MineralsDokument5 SeitenSelection of Methods For Separating of Rare Earth MineralsNatalia PetrovskayaNoch keine Bewertungen

- Welding Book Revised 2012 07 14Dokument15 SeitenWelding Book Revised 2012 07 14surya1960Noch keine Bewertungen

- WTCDokument57 SeitenWTCSarah FrazierNoch keine Bewertungen

- h04 High Sulphidation Epithermal Au Ag CuDokument6 Seitenh04 High Sulphidation Epithermal Au Ag CuErenz Emerald AlexandriteNoch keine Bewertungen

- Assab Steels 709M Machinery SteelDokument3 SeitenAssab Steels 709M Machinery SteelHAFIDZNoch keine Bewertungen

- En 10088 Steel NumberDokument3 SeitenEn 10088 Steel Numberrvieira659Noch keine Bewertungen

- Soldering & WeldingDokument82 SeitenSoldering & WeldingRachita Arora100% (1)

- 4 ESAB Solid Wires Nov 06Dokument84 Seiten4 ESAB Solid Wires Nov 06ananth84Noch keine Bewertungen