Beruflich Dokumente

Kultur Dokumente

Iso 9001 Audit Preparation Sheet

Hochgeladen von

SUBODHHCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Iso 9001 Audit Preparation Sheet

Hochgeladen von

SUBODHHCopyright:

Verfügbare Formate

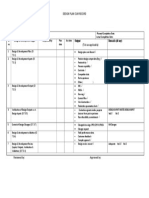

ISO AUDIT PREPARATION SHEET

QUALITY POLICY-STATEMENT

QUALITY OBJECTIVES STATEMENT

----------------is Management Representative (Internal coordinator for ISO 9001 related activities)

Key Processes for ISO are Sales, Design, Purchase, Production, Quality, Stores, HR and Admin; MR

and Top Management

The ISO 9001 documentation generally comprise of:

Quality Manual (which mentions Quality Policy, Quality Objectives, organization structure, job

description and how We fulfill ISO 9001 requirements)

Six mandatory Procedures

QSP-01 Control of Documents

QSP-02 Control of Quality Records

QSP-03 Control of Non conforming Product

QSP-04 Corrective Action

QSP-05 Preventive Action

QSP-06 Internal Audit

Work instructions:

Quality Plans: Checklist for incoming inspection, stage-wise inspection, jobwork inspection and final

inspection

Department-wise Records

Internal audits Internal review of the documented systems by trained auditors

Internal audit NC-

--------------------------------------------------------------------------------------------------------------------------------------

Management review- Review of achievement of Quality objectives as well as Departmental

objectives by core team (The core team consists of MD and heads of all departments)- -------------------

-----------------------------------------------------

There are 8 Clauses in ISO:

Main Clauses-Area-wise are as follows:

Top Management-Management Responsibility (5.1, 5.2, 5.3, 5.4 , 5.5, 5.6), Resource Provision (6.1)

Sales and Marketing-Customer related process (7.2), Customer satisfaction (8.2.1)

Purchase-7.4

Design and development-7.3

Production-Control of production (7.5.1); Validation of process (7.5.2); Identification and

traceability (7.5.3); Customer property(7.5.4); Work environment (6.4)

Control of nonconforming Product (8.2.3)

Stores- Preservation of product (7.5.5) ; Customer property(7.5.4); Work environment (6.4)

Control of nonconforming Product (8.2.3)

Quality: Verification of Purchased Product (7.4.3); Monitoring and measurement of Product

(8.2.4); Calibration (7.6); Corrective, preventive action and continual improvement (8.5)

Control of nonconforming Product (8.2.3)

HR and Admin- Human resources (6.2); Infrastructure-(6.3); Work environment (6.4); Corrective,

preventive action and continual improvement (8.5)

Machine maintenance-Infrastructure-6.3;

MR- Control of documents (4.2.3); Control of records (4.2.4); Internal audit(8.2.2); Management

review (5.6); Corrective, preventive action and continual improvement (8.5); Analysis of data (8.4)

General- Control of documents (4.2.3); Control of records (4.2.4); Corrective, preventive action and

continual improvement (8.5); Planning (7.1)

External audits are done by certification agency

Eight Principles of Quality Management:

1. Customer focus

2. Leadership

3. Involvement of people

4. Process Approach

5. System approach to Management

6. Continual Improvement

7. Factual approach to decision making

8. Mutually beneficial supplier relationships

Das könnte Ihnen auch gefallen

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19Von EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19Noch keine Bewertungen

- Cracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsVon EverandCracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsNoch keine Bewertungen

- Internal QMS Auditor (IRCA Certified Course - Reg. NoDokument2 SeitenInternal QMS Auditor (IRCA Certified Course - Reg. NoSubramanian SaravananNoch keine Bewertungen

- Risk-Based Auditing - To SendDokument67 SeitenRisk-Based Auditing - To SendThùy GiangNoch keine Bewertungen

- 03 - Exercises - Participant HandoutDokument33 Seiten03 - Exercises - Participant Handoutnandhu sampathNoch keine Bewertungen

- Certified ISO 9001 Lead Auditor - Two Page BrochureDokument2 SeitenCertified ISO 9001 Lead Auditor - Two Page BrochurePECBCERTIFICATIONNoch keine Bewertungen

- CQI-IRCA LA Online Exam Guide5Dokument8 SeitenCQI-IRCA LA Online Exam Guide5shams aliNoch keine Bewertungen

- 7 Key Benefits of IATF 16949 Implementation: "What Is IATF 16949?" Are You Looking For A Simple Answer To This Question?Dokument7 Seiten7 Key Benefits of IATF 16949 Implementation: "What Is IATF 16949?" Are You Looking For A Simple Answer To This Question?alejandro galvanNoch keine Bewertungen

- Management Review Meeting Report - 03Dokument2 SeitenManagement Review Meeting Report - 03Claire TanNoch keine Bewertungen

- Why ISO 9001:2015? Awareness Presentation: Subtitle or PresenterDokument15 SeitenWhy ISO 9001:2015? Awareness Presentation: Subtitle or PresenterMarusia TirmicanNoch keine Bewertungen

- Clause 8 ReqmntsDokument48 SeitenClause 8 ReqmntsAkhil GuptaNoch keine Bewertungen

- Summary of Iso 90091Dokument3 SeitenSummary of Iso 90091Ihuhwa Marta TauNoch keine Bewertungen

- Iso 9001 Awareness Part 02-StructureDokument9 SeitenIso 9001 Awareness Part 02-StructureMohd DaudNoch keine Bewertungen

- Iso 14000Dokument13 SeitenIso 14000Rangothri Sreenivasa SubramanyamNoch keine Bewertungen

- Enc 13 Iso Audit ReportsDokument82 SeitenEnc 13 Iso Audit ReportsTaufiq KSSBNoch keine Bewertungen

- ISO 19011-2018 Terms and DefinitionsDokument4 SeitenISO 19011-2018 Terms and DefinitionsredaNoch keine Bewertungen

- ISO 9001:2015 - Client Transition ChecklistDokument8 SeitenISO 9001:2015 - Client Transition ChecklistYulissaPazNoch keine Bewertungen

- Iso 9000 2015Dokument15 SeitenIso 9000 2015Vasudevan GovindarajNoch keine Bewertungen

- All ExercisesDokument13 SeitenAll ExercisesMeenal Dutt100% (1)

- Sample - Management Review MeetingDokument9 SeitenSample - Management Review MeetingClaire TanNoch keine Bewertungen

- ISO 9001 2015 Bill Mizak PDFDokument35 SeitenISO 9001 2015 Bill Mizak PDFblitzkrigNoch keine Bewertungen

- Preview - Iso9001-2015.checklist For ISO 9001-2015Dokument6 SeitenPreview - Iso9001-2015.checklist For ISO 9001-2015Jones RNoch keine Bewertungen

- Integrated Management Systems (2013!02!18) - IsODokument7 SeitenIntegrated Management Systems (2013!02!18) - IsOrwillestoneNoch keine Bewertungen

- ISO 9001 & 14001 AwarenessDokument11 SeitenISO 9001 & 14001 AwarenessSundar_1975100% (1)

- QMS ISO 9001 2008 OverviewDokument16 SeitenQMS ISO 9001 2008 Overviewvipul_gupta1835100% (1)

- RESUME CV Tabeti Abdelkader English 2017Dokument11 SeitenRESUME CV Tabeti Abdelkader English 2017Habib TabetiNoch keine Bewertungen

- Pt. XXXXX: Internal Auditor Course On Quality Management SystemDokument39 SeitenPt. XXXXX: Internal Auditor Course On Quality Management SystemImam MansyurNoch keine Bewertungen

- Iso 9001 Lead ImplementerDokument7 SeitenIso 9001 Lead ImplementerwircexdjNoch keine Bewertungen

- FR-198 Opening-Closing Meeting Form Rev01 3Dokument1 SeiteFR-198 Opening-Closing Meeting Form Rev01 3Erkan DilekNoch keine Bewertungen

- Project Plan For ISO 14001:2015 Implementation: Subtitle or PresenterDokument11 SeitenProject Plan For ISO 14001:2015 Implementation: Subtitle or PresenterWashington coaquira ccahuaNoch keine Bewertungen

- ISO 45001 2018 PresentationDokument18 SeitenISO 45001 2018 PresentationHEMA SANTOSH KUMAR REDDY KARRINoch keine Bewertungen

- P5 - Anrpod - Productivity CycleDokument19 SeitenP5 - Anrpod - Productivity CycleNicko Nur RakhmaddianNoch keine Bewertungen

- Introduction To ISO 14001 ImplementationDokument118 SeitenIntroduction To ISO 14001 ImplementationrobbiejfergussonNoch keine Bewertungen

- IMS Internal Auditing - Refresher WorkshopDokument52 SeitenIMS Internal Auditing - Refresher WorkshopTedy MTNoch keine Bewertungen

- TQM Unit 5 - IsO 14000 SystemDokument62 SeitenTQM Unit 5 - IsO 14000 SystemBabin DhasNoch keine Bewertungen

- ISO 14001 Pre-Course QuestionnaireDokument3 SeitenISO 14001 Pre-Course Questionnairecivil engineerNoch keine Bewertungen

- Integrated Management System (Ims) : Internal Auditor For Iso 9001, ISO 14000 AND OHSAS 18001 (COURSE CODE: IMS/1)Dokument6 SeitenIntegrated Management System (Ims) : Internal Auditor For Iso 9001, ISO 14000 AND OHSAS 18001 (COURSE CODE: IMS/1)bawcockNoch keine Bewertungen

- ISO 9001 2015 GAP Analysis ReviewDokument58 SeitenISO 9001 2015 GAP Analysis ReviewabcNoch keine Bewertungen

- ISO 9001 Evidence ChecklistDokument40 SeitenISO 9001 Evidence ChecklistsanrexiNoch keine Bewertungen

- EMS APG Risks and OpportunitiesDokument3 SeitenEMS APG Risks and Opportunitiesdio39saiNoch keine Bewertungen

- TPL Internal Auditor Training Programme ISO 19011 - 2002 Guidelines For Quality and /or Environmental Management Systems AuditingDokument25 SeitenTPL Internal Auditor Training Programme ISO 19011 - 2002 Guidelines For Quality and /or Environmental Management Systems Auditingshabbir626Noch keine Bewertungen

- IRCA Scheme Brand Terms of UseDokument9 SeitenIRCA Scheme Brand Terms of UseGovindan PerumalNoch keine Bewertungen

- IRCA 9152-QMS Internal Auditor Training (A 17962) - 2Dokument1 SeiteIRCA 9152-QMS Internal Auditor Training (A 17962) - 2silswal1988Noch keine Bewertungen

- 14k Gap GridDokument13 Seiten14k Gap GridMansoor AliNoch keine Bewertungen

- Internal Quality Audit - Training For AuditorsDokument56 SeitenInternal Quality Audit - Training For AuditorsRizaldi Djamil100% (3)

- Integrated Management System (IMS) Internal Auditing (Process Risk & Performance Based Approach) (ISO 9001:2015, ISO 14001:2015 and OHSMS 45001:2018)Dokument4 SeitenIntegrated Management System (IMS) Internal Auditing (Process Risk & Performance Based Approach) (ISO 9001:2015, ISO 14001:2015 and OHSMS 45001:2018)AnkurNoch keine Bewertungen

- Audit Plan (07-09 Nov 2022)Dokument2 SeitenAudit Plan (07-09 Nov 2022)hrd cave sumber berkat 3Noch keine Bewertungen

- Qms/Quality Manual: Student: José Raúl Martínez Lara Teacher: Ricardo Ramirez AguilarDokument6 SeitenQms/Quality Manual: Student: José Raúl Martínez Lara Teacher: Ricardo Ramirez AguilarJosé MartínezNoch keine Bewertungen

- ISO TC 176 Quality Management and Quality AssuranceDokument7 SeitenISO TC 176 Quality Management and Quality AssuranceJMauricio SalgadoNoch keine Bewertungen

- Audit Duration IAF GuidelinesDokument18 SeitenAudit Duration IAF GuidelineselangotvmNoch keine Bewertungen

- Certified ISO 14001 Lead Auditor - Four Page BrochureDokument4 SeitenCertified ISO 14001 Lead Auditor - Four Page BrochurePECBCERTIFICATIONNoch keine Bewertungen

- ISO9001 The Ultimate GuideDokument20 SeitenISO9001 The Ultimate GuideAymen Badreddine BouderbalaNoch keine Bewertungen

- SLCP Verification ProtocolDokument62 SeitenSLCP Verification ProtocolWILFREDO SSOCONSULTORESNoch keine Bewertungen

- Iso 9001 Sample ProceduresDokument11 SeitenIso 9001 Sample ProceduresNick Palma Jr.100% (2)

- Operational Control SampleDokument19 SeitenOperational Control Sampleeduardog1972Noch keine Bewertungen

- 27 Feb 2019 - Auditor TrainingDokument30 Seiten27 Feb 2019 - Auditor TrainingbojaNoch keine Bewertungen

- Process Validation ReportDokument4 SeitenProcess Validation ReportSUBODHH100% (1)

- Mould Trial ReportDokument5 SeitenMould Trial ReportSUBODHH0% (1)

- Process Validation ReportDokument4 SeitenProcess Validation ReportSUBODHH0% (1)

- Electric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderDokument7 SeitenElectric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderSUBODHHNoch keine Bewertungen

- LABELS SmallDokument6 SeitenLABELS SmallSUBODHHNoch keine Bewertungen

- Performance Assessment and Review Admin and Accounts ManagersDokument3 SeitenPerformance Assessment and Review Admin and Accounts ManagersSUBODHHNoch keine Bewertungen

- Process Validation ReportDokument4 SeitenProcess Validation ReportSUBODHHNoch keine Bewertungen

- Name of Company: Sub: Application For LeaveDokument2 SeitenName of Company: Sub: Application For LeaveSUBODHHNoch keine Bewertungen

- Mobile Policy: When Sim + Mobile Allotted To EmployeeDokument5 SeitenMobile Policy: When Sim + Mobile Allotted To EmployeeSUBODHHNoch keine Bewertungen

- Performance Appraisal Managers-Performance LinkedDokument1 SeitePerformance Appraisal Managers-Performance LinkedSUBODHHNoch keine Bewertungen

- Performance Appraisal ManagersDokument1 SeitePerformance Appraisal ManagersSUBODHHNoch keine Bewertungen

- Leave Application Form: SL CL Half Day LeaveDokument1 SeiteLeave Application Form: SL CL Half Day LeaveSUBODHHNoch keine Bewertungen

- Process Change NoteDokument1 SeiteProcess Change NoteSUBODHHNoch keine Bewertungen

- Enquiry Register Cum Job Tracker: Page No.Dokument1 SeiteEnquiry Register Cum Job Tracker: Page No.SUBODHHNoch keine Bewertungen

- Fire Response PlanDokument1 SeiteFire Response PlanSUBODHHNoch keine Bewertungen

- Leave Travel Allowance Claim LTADokument1 SeiteLeave Travel Allowance Claim LTASUBODHHNoch keine Bewertungen

- Kaizen ReportDokument1 SeiteKaizen ReportSUBODHHNoch keine Bewertungen

- Customer Feedback SummaryDokument1 SeiteCustomer Feedback SummarySUBODHHNoch keine Bewertungen

- Vision MissionDokument1 SeiteVision MissionSUBODHHNoch keine Bewertungen

- 4M Change Management FormatDokument1 Seite4M Change Management FormatSUBODHH100% (2)

- Design Plan Cum Record: Output Remarks (If Any)Dokument1 SeiteDesign Plan Cum Record: Output Remarks (If Any)SUBODHHNoch keine Bewertungen

- Manpower PlanningDokument7 SeitenManpower PlanningSUBODHHNoch keine Bewertungen

- Iso 9001 Clause ChartDokument2 SeitenIso 9001 Clause ChartSUBODHHNoch keine Bewertungen

- PDE Lecture 3Dokument48 SeitenPDE Lecture 3fanusNoch keine Bewertungen

- 17th Century Crisis DocxDokument6 Seiten17th Century Crisis DocxRenuNoch keine Bewertungen

- chp:10.1007/978 94 017 8727 7 - 3 PDFDokument21 Seitenchp:10.1007/978 94 017 8727 7 - 3 PDFKelly MillsNoch keine Bewertungen

- Kra KpiDokument2 SeitenKra Kpiimport_shakti100% (1)

- Fundamentals of Political EconomyDokument208 SeitenFundamentals of Political Economypsyops008Noch keine Bewertungen

- Space and Spatiality. What The Built Environment Needs From Social TheoryDokument16 SeitenSpace and Spatiality. What The Built Environment Needs From Social TheorypaolinocostaNoch keine Bewertungen

- 12th Economics Full Study Materials 2022 2023 English Medium PDF DownloadDokument53 Seiten12th Economics Full Study Materials 2022 2023 English Medium PDF DownloadSenthil KathirNoch keine Bewertungen

- End of IdeologyDokument1 SeiteEnd of IdeologyNitesh SharmaNoch keine Bewertungen

- John Clarke, Chas Critcher and Richard Johnson - Working-Class Culture. Studies in History and Theory-Hutchinson University Library (1979)Dokument303 SeitenJohn Clarke, Chas Critcher and Richard Johnson - Working-Class Culture. Studies in History and Theory-Hutchinson University Library (1979)mstarcenbaumNoch keine Bewertungen

- Teori Hubungan Internasional I: (Pertemuan 5)Dokument13 SeitenTeori Hubungan Internasional I: (Pertemuan 5)Satrio Bintang PamungkasNoch keine Bewertungen

- Advanatges and Disadvantages of Globalization in The Phil. Economy-Economics ThesisDokument8 SeitenAdvanatges and Disadvantages of Globalization in The Phil. Economy-Economics ThesisAdrian R. Ocampo33% (3)

- Islam and Marxism. Compatible?Dokument4 SeitenIslam and Marxism. Compatible?Mubashir HassanNoch keine Bewertungen

- M.SC CA & IT Wef 2019-20 Sem 1 To 10Dokument173 SeitenM.SC CA & IT Wef 2019-20 Sem 1 To 10hosikin138suggerinNoch keine Bewertungen

- GCWORLDDokument11 SeitenGCWORLDAfanie Mae Romero EstepaNoch keine Bewertungen

- SERF N' TERF: Notes On Some Bad Materialisms - SalvageDokument11 SeitenSERF N' TERF: Notes On Some Bad Materialisms - Salvagegrootvader0% (2)

- Asian American Pan EthnicityDokument11 SeitenAsian American Pan EthnicityTamires Rezende100% (1)

- Disciplines and Ideas in The Social Sciences M13Dokument3 SeitenDisciplines and Ideas in The Social Sciences M13Ericka Rivera SantosNoch keine Bewertungen

- Shanza FaiqDokument21 SeitenShanza FaiqVaqas Taj100% (1)

- MIS Case StudyDokument3 SeitenMIS Case Studycarlo_scribdNoch keine Bewertungen

- Ebook - An Introduction To Selling by GivingDokument36 SeitenEbook - An Introduction To Selling by Givinghans.de.wael8761Noch keine Bewertungen

- Buck Morss, Dreamworld and CatastropheDokument536 SeitenBuck Morss, Dreamworld and CatastropheEvanLitwackNoch keine Bewertungen

- Economic Systems RubricDokument2 SeitenEconomic Systems Rubricapi-493862624Noch keine Bewertungen

- Main Perspectives On Colonialism in IndiaDokument2 SeitenMain Perspectives On Colonialism in IndiaAmvi SwuNoch keine Bewertungen

- Classification of Human Activities: Economic and Non Economic ActivitiesDokument44 SeitenClassification of Human Activities: Economic and Non Economic ActivitiesaQNoch keine Bewertungen

- Capital & Class: State Theory, Regulation, and Autopoiesis: Debates and ControversiesDokument11 SeitenCapital & Class: State Theory, Regulation, and Autopoiesis: Debates and ControversiesD. Silva EscobarNoch keine Bewertungen

- 6.a Paul M. Sweezy and Murice Dobb - Transition Form Feudalism To CapitalismDokument35 Seiten6.a Paul M. Sweezy and Murice Dobb - Transition Form Feudalism To CapitalismPram BayuNoch keine Bewertungen

- Morton, Donald - Return of The CyberqueerDokument14 SeitenMorton, Donald - Return of The Cyberqueerjen-leeNoch keine Bewertungen

- Theories of International Migration - A Review and AppraisalDokument37 SeitenTheories of International Migration - A Review and AppraisalThaysa AndréiaNoch keine Bewertungen

- Question Bank - Multiple Choice Questions (MCQS) : Unit I - Business FinanceDokument45 SeitenQuestion Bank - Multiple Choice Questions (MCQS) : Unit I - Business FinanceABHIJEET SINGH BAGHELNoch keine Bewertungen

- Neoliberalism Is A Political Project: An Interview With David HarveyDokument5 SeitenNeoliberalism Is A Political Project: An Interview With David HarveySocial Scientists' AssociationNoch keine Bewertungen