Beruflich Dokumente

Kultur Dokumente

Management of Change of Chemical Process Control Systems

Hochgeladen von

Vinh Do Thanh0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

135 Ansichten7 SeitenManagement of Change of Chemical Process Control Systems

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenManagement of Change of Chemical Process Control Systems

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

135 Ansichten7 SeitenManagement of Change of Chemical Process Control Systems

Hochgeladen von

Vinh Do ThanhManagement of Change of Chemical Process Control Systems

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

Paper # H-15

Management of Change of Chemical Process Control Systems

M. Sam Mannan and Harry H. West*

Mary Kay !Connor Process Safety Center

Chemical "ngineering #epartment

$e%as &'M (ni)ersity System

College Station* $e%as ++,-.-.1//* (S&

01+12 ,-5-.-,1* hh3est4che.tam5.ed5

&6S$7&C$

Management of Change (MOC) has been recommended to be an important part of chemical

process safety since the British Inquiry Boards investigation report of the 1!" #li$borough %&

incident' (he %)* Occupational )afety and +ealth *dministration (O)+*) regulation

formali,ed MOC as one of the 1" elements of its process safety management regulation in 1-'

+o.ever/ most facilities focused their MOC program on equipment changes/ particularly

changes that .ould change the 01I2s or equipment specifications' 0rocedural changes/

organi,ational changes and computer control system changes are not universally considered

.ithin the scope of the MOC program'

3ven though formal MOC is also a part of the I)O 444 and I)O 1"444 global management

standards/ the need for controlling changes to plant computer soft.are is not generally

ac5no.ledged'

)everal recent incidents/ in .hich a degraded control system has been identified as one of the

contributing factors/ most notably as alarm floods or bypassed safeguards/ have put the spot light

on the need to maintain the control system effectiveness'

(he gaining recognition of the functional safety instrumented system standards/ I)* 6"'41 and

I)O 71811/ .ith MOC as a part of its safety life cycle concept/ has helped' (he *bnormal

)ituation Management consortium/ the .or5 of the British +ealth and )afety 3$ecutive on

*larm Management and the recommendation of )C*2* system assessment by the %)* Office

0ipeline )afety are among the positive indicators that regulators and safety professionals are

attempting to add soft.are changes to the very important MOC program'

K"8W7#S

Management of Change/ MOC/ )C*2*/ 2C)/ )I)/ O)+*/ *bnormal )ituation Management/

*larm Management

9:$7#(C$9:

Management of Change (MOC) procedures .ere first formali,ed in the fledgling nuclear po.er

industry 9:est/ 1-; and quic5ly spread to the defense industry 9Mil )td !<;' )everal different

names .ere used to describe MOC/ including concurrent engineering/ process change control/

and configuration management'

MOC procedures have received increased attention due to the introduction of requirements

.ithin the ne. O)+* and 30* process safety management regulations 9O)+* 1-= 30*/

16; in the %)*' (he more recent I)O 444 quality initiatives 9I)O 444; have provided

further significance to the need for process change control management'

+o.ever/ many firms applied MOC only to equipment and field operational procedure changes'

(he intent of all MOC standards and regulations clearly includes process control systems'

MC SP&7K"# 68 C&$&S$7PH9C 9:C9#":$S

*bsence of management control over process changes has resulted in several catastrophic

failures' One of the first catastrophic incidents to have identified MOC as a root cause .as the

#li$borough accident in 1!"' (he %& royal commission 9#li$borough/ 1!8; recommended that

chemical plants institute MOC procedures to avoid such devastating accidents' *lmost every

ma>or incident can be lin5ed to a change that .as not sub>ected to a proper safety revie. as

required by MOC 9)anders/ 1<= &let,/ 166;'

#ollo.ing the Bhopal incident/ the formation of the Center for Chemical 0rocess )afety by the

*merican Institute of Chemical 3ngineers (*ICh3) lead eventually to the publication of the

ma>or principles of 0rocess )afety/ including MOC' (he *ICh3 definition 9*ICh3 1-; of

MOC is?

* temporary or permanent substitution/ alteration/ replacement (not in 5ind)/

modification by addition or deletion of critical process equipment/ applicable codes/

process control/ catalysts or chemicals/ feed stoc5s/ operating limits/ mechanical

procedures/ electrical procedures/ safety procedures/ emergency response equipment from

the present configuration of the critical process equipment/ procedures/ or operating

limits'

In the aftermath of the 16 0hillips polyethylene plant disaster/ O)+* published the 0rocess

)afety Management regulation .ith the follo.ing e$cerpt defining MOC in - C#@ 114'11

section (l)=

(1) (he employer shall establish and implement .ritten procedures to manage changes

(e$cept for Areplacements in 5indA) to process chemicals/ technology/ equipment/ and

procedures? and/ changes to facilities that affect a covered process'

(-) (he procedures shall assure that the follo.ing considerations are addressed prior to

any change?

(i) (he technical basis for the proposed change=

(ii) Impact of change on safety and health=

(iii) Modifications to operating procedures=

(iv) Becessary time period for the change= and

(v)*uthori,ation requirements for the proposed change

(<) 3mployees involved in operating a process and maintenance 1 contract employees

.hose >ob tas5s .ill be affected by a change in the process shall be informed of/ and

trained in/ the change prior to startCup of the process or affected part of the process'

(") If a change covered by this paragraph results in a change in the process safety

information required by paragraph (d)/ such information shall be updated accordingly'

(8) If a change covered by this paragraph results in a change in the operating procedures

or practices required by paragraph (f)/ such procedures or practices shall be updated

accordingly

(he tenets of quality management also contain a management element essentially identical in

philosophy as the process safety MOC' )ection 6'6 of the I)O 44" *B)ID*)EC E" 9I)O

444; is entitled Fdesign change control (configuration management)G' )ection 11'7 is entitled

Fprocess change controlG' (herefore/ the total quality management initiative has a change

management requirement e$tremely similar to the MOC principles defined herein

(he first specific mention of MOC concepts in the petroleum production safety and loss

prevention literature .as the *0I @ecommended 0ractice/ Management of 0rocess +a,ardsH

9*0I 14;' (he Cullen report 9Cullen 166; recommendations led to British regulations in the

north sea that also included MOC requirements'

MC &PP;9"S $ C:$7; S8S$"MS

Bote that paragraph (") of the O)+* regulation above lin5s MOC to Fprocess safety

informationG/ .hich in turn mentions safety systems and control systems' +ence/ O)+* includes

the entire control system .ithin the >urisdiction of process safety regulations' Many O)+*

official interpretation letters also reinforce vie.point'

(he *ICh3 definition above clearly defines process control .ithin the areas to be .ithin MOC

control procedures'

(he safety instrumented systems ()I)) standards/ such as I)* 6" and I3C 71811 9*ICh3 1<=

I)* 17= I3C 71811; define a safety life cycle concept for safety control system components in

.hich MOC is highlighted' Many other recently updated or revised standards crossCreference the

need for MOC' (he 3uropean *(3I rules on ha,ardous area classification are but one e$ample'

(he %) Office of 0ipeline )afety issued an advisory that strongly suggests pipeline )C*2*

systems be sub>ected to MOC procedures' (his recommendation resulted from the analysis of the

Billingham pipeline catastrophic accident/ .hich listed reduced control system response time as

a root cause of the incident'

(herefore/ MOC must be applied to all changes in the process control system'

";"M":$S < P7C"SS C:$7; S8S$"MS

)ome of the ma>or elements of a typical modern process control systems include=

Hardware

#ield instrumentation

2ata high.ay

Jogic solvers (computers/ electronic devices)

0o.er supplies

Software

Operating )ystem

2C)D)CK*2*D 0JC system soft.are

*pplication soft.are

*larm system

*pplying MOC to hard.are changes is similar to the equivalent practices for changes to other

process equipment' (hree areas have proved to be more difficult to bring .ithin MOC

>urisdiction

Configuration

Jimit values

Operating systems

Changes to the process control configuration/ such as adding alarms/ appears to be a benign

change/ +o.ever/ the cumulative effect of adding too many alarms can cause alarm floods'

Changes to limit values/ even temporary changes/ can lead to safety problems' )everal incidents

have been attributed to temporary changes that have not been restored to their original interloc5

limit values'

Changes to operating systems are even more challenging/ since minor soft.are patches/ larger

system upgrades/ or even ma>or version upgrades are possible' (he only .ay to be sure that no

impact on the control system has been made is to conduct another site acceptance test'

P;&: <7 C:$7; S8S$"MS CH&:="

:hile process equipment is typically designed for a -4C<4 year pro>ect life/ )C*2*/ )I) and

2C) systems are more li5ely to be replaced or seriously upgraded on a 14 year cycle or less'

(herefore/ ma>or future changeout of the control system must also be considered in the original

pro>ect plan'

:hereas/ for.ard thin5ing pro>ect designers planned for future changeout by specifying po.er

supplies .ith additional parallel load capability/ >unction bo$es .ith large spare capacity/ 0JC=s

.ith additional spare contact capability/ and telemetry .ith additional frequency pairs/ the

evolving e$pansion of operations over the years sometimes scavenges the changeout capability'

If the original pro>ect documentation has identified the spare capacity as reserved for future

changeout/ then the Management of Change system should 5eep operations management a.are

of encroachments on the ne$t control system upgrade pro>ect'

#9=9$&; 6&6";

In his letter to the editor of the I)* Intech monthly maga,ine/ internationally noted control

system author Bela Jipta5 9Jipta5/ -44"; .arned of the safety implications of the chaotic state of

the currently 6 different digital data high.ays .ith the concomitant problems of message

translation' +e also deplored the control system vendor practice of BO( including tested

.or5ing control soft.are/ leaving the users to select among many independent soft.are

suppliers

&PP;89:= MC ;"SS:S ;"&7:"# $ P7C"SS C:$7;

(he most important lesson learned in applying MOC procedures in the earlier e$periences .as to

categori,e facilities into safety critical and nonCsafety critical systems' If nonCsafety critical

equipment are sub>ected to safety revie. at the level of detail required by safety critical items/

then the MOC system bogs do.n in itLs o.n paper.or5' :hile this may .or5 for process areas

that are not safety critical or instrument loops that are controlling non ha,ardous systems/ there

may be many control subsystems (data high.ay/ operating systems/ etc) .hich coCmingle safety

and non safety critical systems

It is interesting to note that each recommended practice or regulation delegates the level of safety

revie. detail to the applicable facility management' :hile some of the management practices

espoused in the recent MOC standards have long been practiced by many firms/ it is the

formali,ation of MOC and the ability to audit the program that is relatively ne. to the petroleum

and chemical industry' (his translates into paper.or5 D documentation of changes applied to the

control system operators and engineers'

C:C;(S9:S

Management of Change is required to maintain the safety integrity of the chemical process

facility' *dministration of a cost C effective Management of Change program requires careful

planning' )ince the brunt of Management of Change operational effectiveness is dependent on

the first and second line process supervisors/ a simple Management of Change procedural

.or5flo. and a document management system are practical necessities'

#urthermore/ various screening techniques have been used to optimi,e scarce technical

resources/ particularly by allo.ing small ha,ard D lo. ris5 changes to be analy,ed and authori,ed

.ithout the need for unnecessary red tape' #requent verification of actual practice is particularly

critical until Management of Change becomes part of the corporate culture'

&CK:W;"#=M":$S

(he authors .ould li5e to than5 our colleagues for the many discussions and pro>ects/ .hich

assisted in the evolution of the ideas and concepts presented herein'

696;9=7&PH8

0rocess )afety Management of +ighly +a,ardous Chemical= 3$plosives and Blasting *gents=

#inal @ule/ - C#@ 0art 114/ 2epartment of Jabor/ Occupational )afety and +ealth

*dministration/ :ashington/ 2C/ #ebruary -"/ 1-/ #ederal @egister/ Kolume 8!/ Bo' <7'

(he #li$borough Cyclohe$ane 2isaster/ +er Ma>estyLs )tationery Office/ Jondon/ 1!8'

('*' &let,/ 0lant Operations 0rogress/ vol 8/ M </ *merican Institute of Chemical 3ngineers/ Nuly

167/ p'1<7'

0lant Ouidelines for (echnical Management of Chemical 0rocess )afety/ Center for Chemical

0rocess )afety of the *merican Institute of Chemical 3ngineers/ Be. Por5/ 1-'

I)O 444/ Euality Management of Industrial #acilities/ Jondon/ %&/ latest edition'

@evie. )afety Euestions in the Buclear 0o.er Industry/ 14 C#@ 84'8/ 2epartment of 3nergy/

Buclear @egulatory Commission/ :ashington/ 2C'

Military )tandard !</ Configuration Management at Oovernment #acilities/ (MIJC)(2 !<)/

2epartment of 2efense/ :ashington/ 2'C'

@is5 Management 0rograms for Chemical *ccidental @elease 0revention/ (itle "4 C#@ 0art 76

)ection 76'<7 0revention 0rogram C Management of Change/ 3nvironmental 0rotection

*dministration/ :ashington/ 2'C'

@ecommended 0ractices for 2evelopment of a )afety and 3nvironmental 0rogram for Outer

Continental )helf (OC)) Operations and #acilities/ *0I @ecommended 0ractice !8/ *merican

0etroleum Institute/ :ashington 2'C' latest edition/ 1<'

)' B' &ovach/ 0ractical Method for Management of Change/ *ICh3 0rocess 0lant )afety

)ymposium/ +ouston/ (e$as/ -6 #ebruary 1"'

British )tandard 7"66 Configuration Management/ Jondon/ 3ngland'

+'+' :est and @' 2anna/ Course te$t for the *ICh3 Continuing 3ducation Course= Management

of Change/ *merican Institute of Chemical 3ngineers/ Be. Por5/ 1-'

@' 3' )anders/ Management of Change in Chemical 0lant; Butter.orthC+einemann/ O$ford/

1<'

Jord Cullen/ A(he 0ublic Inquiry into the 0iper *lpha 2isaster/A Kolumes 1 1 -/ +is Ma>estyLs

)tationary Office/ Jondon/ Bovember 14

('*' &let,/ :hat :ent :rongQ Case +istories of 0rocess 0lant 2isasters/ Oulf 0ublishing

Company/ +ouston/ 166'

+'+' :est/ M')' Mannan/ @' 2anna 1 3'M' )tafford/ Ma5e 0lants )afer .ith a 0roper

Management of Change 0rogram/ Chemical 3ngineering 0rogress/ *merican Institute of

Chemical 3ngineering/ 16'

+'+ :est/ 3'M' )tafford/ Management of Change * @equirement for Joss 0revention )uccess/

0rocess 0lant )ymposium/ Kol' -/ *merican Institute of Chemical 3ngineering/ 17'

Bela Jipta5/ 2igital Babel/ I)* Intech/ page / Nune -44"

*ICh3/ Ouidelines for )afe *utomation of Chemical 0rocesses American Institute of Chemical

3ngineers/ Center for Chemical 0rocess )afety (CC0))/ 1<

*B)IDI)* )6"'41C17/ *pp lication of )afety Instrumented )ystems ()I)) for the 0rocess

Industries/ I)* @esearch (riangle BC 17'

I3C 71811/ #unctional safety? )afety Instrumented )ystems for the process industry sector/ -44<

Das könnte Ihnen auch gefallen

- MOC GuidanceDokument5 SeitenMOC GuidanceSergiu Lung100% (1)

- 010 - Permit To Work Procedure Feb 2013Dokument61 Seiten010 - Permit To Work Procedure Feb 2013vdeviv100% (1)

- MaintenanceDokument67 SeitenMaintenanceBala M100% (1)

- NAVSEA RCM Handbook DTD 18 April 2007 PDFDokument105 SeitenNAVSEA RCM Handbook DTD 18 April 2007 PDFTiu TonNoch keine Bewertungen

- Trouble Shooting For InternDokument9 SeitenTrouble Shooting For InternSANMINoch keine Bewertungen

- An Alternative Structure For Next Generation Regulatory Controllers Part I Basic Theory For Design Development and Implementation 2006 Journal of ProcDokument11 SeitenAn Alternative Structure For Next Generation Regulatory Controllers Part I Basic Theory For Design Development and Implementation 2006 Journal of ProcLarry LimNoch keine Bewertungen

- Overview of Control System Design: General RequirementsDokument18 SeitenOverview of Control System Design: General RequirementsMaruf KhanNoch keine Bewertungen

- Marsh Risk Engineering Position Paper 05 Management of ChangeDokument24 SeitenMarsh Risk Engineering Position Paper 05 Management of ChangeMathew MammenNoch keine Bewertungen

- Eqix Sg4 2 Mech Cx3 002 r0 Air Balancing MV FansDokument19 SeitenEqix Sg4 2 Mech Cx3 002 r0 Air Balancing MV FansLâm trầnNoch keine Bewertungen

- AC 120-17A - Maintenance Control by Reliability MethodsDokument41 SeitenAC 120-17A - Maintenance Control by Reliability Methodsdedoneza100% (1)

- Appendix C: Examples of Moc System Procedure Work Flow Charts and Moc Review Documentation FormsDokument8 SeitenAppendix C: Examples of Moc System Procedure Work Flow Charts and Moc Review Documentation FormsAmna KhalidNoch keine Bewertungen

- Trouble Shooting PrinciplesDokument6 SeitenTrouble Shooting PrinciplesSANMINoch keine Bewertungen

- Workplace Safety RuleDokument2 SeitenWorkplace Safety RuleMohamedNoch keine Bewertungen

- OGDCL Safety Critical Elements Handbook Final PDFDokument106 SeitenOGDCL Safety Critical Elements Handbook Final PDFSyed Muhmmad Hussain Shah100% (1)

- Data Analysis Report 2650788-DAS-C1Dokument72 SeitenData Analysis Report 2650788-DAS-C1chirag.rathiNoch keine Bewertungen

- Management of Change - 2013 - Rev 3Dokument24 SeitenManagement of Change - 2013 - Rev 3hvananthNoch keine Bewertungen

- Loop Checking A Technicians GuideDokument24 SeitenLoop Checking A Technicians GuideJ Mohamed UvaisNoch keine Bewertungen

- ISA Transactions: Flavio ManentiDokument8 SeitenISA Transactions: Flavio ManentiwhoismeNoch keine Bewertungen

- Basics of Pumps TechnologyDokument25 SeitenBasics of Pumps TechnologySANMINoch keine Bewertungen

- 2.331 - Employee Participation & Consultantion.Dokument4 Seiten2.331 - Employee Participation & Consultantion.kirandevi1981Noch keine Bewertungen

- COMAH and Safety Case RegulationsDokument16 SeitenCOMAH and Safety Case RegulationsAdeel RazaNoch keine Bewertungen

- The WORKPLACE SAFETY RULE On Safety and Environmental Management Systems SEMSDokument2 SeitenThe WORKPLACE SAFETY RULE On Safety and Environmental Management Systems SEMSJason Belts KauffmanNoch keine Bewertungen

- DNV RP 116 SchemeDokument13 SeitenDNV RP 116 SchemePasquale CutriNoch keine Bewertungen

- Reguratory Control StabilizationDokument2 SeitenReguratory Control StabilizationChi PhamNoch keine Bewertungen

- Project Constraints: Safety RegulationsDokument4 SeitenProject Constraints: Safety RegulationsDonna Mae Ramos GalaezNoch keine Bewertungen

- Overview of Undergraduate Control PDFDokument48 SeitenOverview of Undergraduate Control PDFboban_mikicNoch keine Bewertungen

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneVon EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNoch keine Bewertungen

- AcuTech White Paper SEMSDokument8 SeitenAcuTech White Paper SEMSFihawango0% (1)

- Sop Maintenance Final - Part1Dokument57 SeitenSop Maintenance Final - Part1Ashfaque Hussain0% (2)

- Accident Management in VVER-1000Dokument5 SeitenAccident Management in VVER-1000Jeyakrishnan CNoch keine Bewertungen

- The Offshore Structural Integrity Management Inspection GuideDokument25 SeitenThe Offshore Structural Integrity Management Inspection GuideTomasPavlovic100% (2)

- Ed Loss of ContainmentDokument47 SeitenEd Loss of Containmentliamo88880Noch keine Bewertungen

- Well OpsDokument27 SeitenWell Opsdosetiadi67% (3)

- 09 - Management of ChangeDokument19 Seiten09 - Management of ChangeDave CNoch keine Bewertungen

- Introduction To Structural Health Monitoring: January 2006Dokument26 SeitenIntroduction To Structural Health Monitoring: January 2006shahriar satil martinNoch keine Bewertungen

- Ench 617 Notes I (2021)Dokument20 SeitenEnch 617 Notes I (2021)Mohan kumar0% (1)

- CDCCL PTCDokument82 SeitenCDCCL PTCrizcst9759100% (7)

- Maintenance SolarDokument17 SeitenMaintenance Solardilo001100% (3)

- Commissioning and Start-Up: EM 1110-1-4001 3 Jun 02Dokument24 SeitenCommissioning and Start-Up: EM 1110-1-4001 3 Jun 02André OliveiraNoch keine Bewertungen

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationVon EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNoch keine Bewertungen

- Applied Ocean Research: Bernard Kamsu-FoguemDokument11 SeitenApplied Ocean Research: Bernard Kamsu-FoguemApriyan Tri KusumaNoch keine Bewertungen

- Chapter 12 - Changes Related: (Clause Description-Paraphrase)Dokument11 SeitenChapter 12 - Changes Related: (Clause Description-Paraphrase)mahesh KhatalNoch keine Bewertungen

- CIP Cycle Development Sep04Dokument7 SeitenCIP Cycle Development Sep04John HigginsNoch keine Bewertungen

- Development of A Condition Based Maintenance Architecture For Optimal Maintainability of Mine ExcavatorsDokument5 SeitenDevelopment of A Condition Based Maintenance Architecture For Optimal Maintainability of Mine ExcavatorsInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- Standard HVAC Control SystemsDokument127 SeitenStandard HVAC Control Systemsdash_caddiesNoch keine Bewertungen

- 09.0 Pre StartupDokument13 Seiten09.0 Pre StartupChandraSekaranBm100% (1)

- SPE/IADC-189403-MS Well Integrity - Next DevelopmentsDokument15 SeitenSPE/IADC-189403-MS Well Integrity - Next DevelopmentsMahfoud AMMOURNoch keine Bewertungen

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceVon EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceBewertung: 5 von 5 Sternen5/5 (2)

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeDokument24 SeitenJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaNoch keine Bewertungen

- Recommandation-Omcl 16 122 R Change Control Web PublicationDokument3 SeitenRecommandation-Omcl 16 122 R Change Control Web PublicationPornphanNoch keine Bewertungen

- Pre Commissioning ManualDokument44 SeitenPre Commissioning ManualMahmoud Tobala83% (24)

- Reliability-Centered Maintenance Planning Based On Computer-Aided FMEADokument7 SeitenReliability-Centered Maintenance Planning Based On Computer-Aided FMEAAhmed El-FayoomiNoch keine Bewertungen

- Condition Based MaintenanceDokument18 SeitenCondition Based Maintenancedshalev8694Noch keine Bewertungen

- 00 Saip 72Dokument6 Seiten00 Saip 72Erin JohnsonNoch keine Bewertungen

- Maint Philsp N Devlp ProgrDokument47 SeitenMaint Philsp N Devlp Progrhatach100% (1)

- ENQ-SEL-EG-0000-PRC-0001 RevB - (Signature)Dokument26 SeitenENQ-SEL-EG-0000-PRC-0001 RevB - (Signature)dandiar1Noch keine Bewertungen

- Applying Reliability Centered Maintenance RCM To Sampling Subsystem in Continuous Emission Monitoring SystemDokument9 SeitenApplying Reliability Centered Maintenance RCM To Sampling Subsystem in Continuous Emission Monitoring SystemteguhNoch keine Bewertungen

- Roles and Responsibilities of Plant Pre-Commissioning, Commissioning and Acceptance Test RunDokument11 SeitenRoles and Responsibilities of Plant Pre-Commissioning, Commissioning and Acceptance Test RunArsalan QadirNoch keine Bewertungen

- Design Plant-Wide Control To Waste Heat Recovery Generation On Cement Industry Based HYSYSDokument9 SeitenDesign Plant-Wide Control To Waste Heat Recovery Generation On Cement Industry Based HYSYSDHe Vic'zNoch keine Bewertungen

- Effects of Drying Parameters On Heat Transfer During DryingDokument13 SeitenEffects of Drying Parameters On Heat Transfer During DryingVinh Do ThanhNoch keine Bewertungen

- Tỷ số air-fuel lý tưởng (14.7)Dokument9 SeitenTỷ số air-fuel lý tưởng (14.7)Vinh Do ThanhNoch keine Bewertungen

- Modeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsDokument8 SeitenModeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsVinh Do ThanhNoch keine Bewertungen

- Studies On Drying Kinetics of Solids in A Rotary DryerDokument6 SeitenStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNoch keine Bewertungen

- Modelling and Simulation of A Direct Contact Rotary DryerDokument16 SeitenModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhNoch keine Bewertungen

- Air-Fuel Ratio, Lambda and Engine Performance: AFR M MDokument12 SeitenAir-Fuel Ratio, Lambda and Engine Performance: AFR M MVinh Do ThanhNoch keine Bewertungen

- E. E.' " (75 Ion Agent of Firm Rope-Mckay & AssociatesDokument7 SeitenE. E.' " (75 Ion Agent of Firm Rope-Mckay & AssociatesVinh Do ThanhNoch keine Bewertungen

- Ansi B16-104Dokument1 SeiteAnsi B16-104Monica Suarez100% (1)

- Dryer CalculationsDokument4 SeitenDryer CalculationsVinh Do Thanh0% (1)

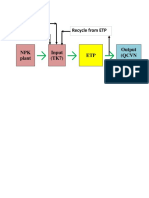

- Recycle From ETP Make Up H2O DAP, UreaDokument1 SeiteRecycle From ETP Make Up H2O DAP, UreaVinh Do ThanhNoch keine Bewertungen

- NPK-15 8 15Dokument5 SeitenNPK-15 8 15Vinh Do ThanhNoch keine Bewertungen

- Estimating Evaporation From Water SurfacesDokument27 SeitenEstimating Evaporation From Water SurfacesVinh Do ThanhNoch keine Bewertungen

- The Heart of Operations - World Cement - 02-2015Dokument4 SeitenThe Heart of Operations - World Cement - 02-2015fetniNoch keine Bewertungen

- Aoac - Methods.1.1990. MoistureDokument2 SeitenAoac - Methods.1.1990. MoistureVinh Do ThanhNoch keine Bewertungen

- Review On Development of Polypropylene Manufacturing ProcessDokument11 SeitenReview On Development of Polypropylene Manufacturing ProcessShweta Yadav100% (1)

- 4244 12672 1 PB PDFDokument15 Seiten4244 12672 1 PB PDFVinh Do ThanhNoch keine Bewertungen

- PEP Report 267A: Ihs ChemicalDokument8 SeitenPEP Report 267A: Ihs ChemicalVinh Do ThanhNoch keine Bewertungen

- Equivalent Grades of Cast IronsDokument2 SeitenEquivalent Grades of Cast IronsVinh Do Thanh100% (1)

- Natural Evaporation RateDokument16 SeitenNatural Evaporation RateVinh Do ThanhNoch keine Bewertungen

- Tinh Luong Nuoc Bay HoiDokument22 SeitenTinh Luong Nuoc Bay HoiVinh Do ThanhNoch keine Bewertungen

- CRACKER A PC Based Simulator For Industr PDFDokument6 SeitenCRACKER A PC Based Simulator For Industr PDFVinh Do ThanhNoch keine Bewertungen

- 1 0ProjectManagementProceduresDokument8 Seiten1 0ProjectManagementProceduresRamiesRahmanNoch keine Bewertungen

- Mau Giay Uy Quyen Bang Tieng AnhDokument3 SeitenMau Giay Uy Quyen Bang Tieng AnhVinh Do ThanhNoch keine Bewertungen

- 4244 12672 1 PB PDFDokument15 Seiten4244 12672 1 PB PDFVinh Do ThanhNoch keine Bewertungen

- Metal Price IndexDokument1 SeiteMetal Price IndexVinh Do ThanhNoch keine Bewertungen

- How To Calculate Heat Load - 5 StepsDokument1 SeiteHow To Calculate Heat Load - 5 StepsVinh Do ThanhNoch keine Bewertungen

- DRS 279-2015 Organic Fertilizer - SpecificationDokument17 SeitenDRS 279-2015 Organic Fertilizer - SpecificationVinh Do ThanhNoch keine Bewertungen

- Investigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyDokument5 SeitenInvestigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyradanpetricaNoch keine Bewertungen

- How To Calculate Heat Load - 5 StepsDokument1 SeiteHow To Calculate Heat Load - 5 StepsVinh Do ThanhNoch keine Bewertungen

- Optimization of Wall Thickness For Minimum Heat LossesDokument9 SeitenOptimization of Wall Thickness For Minimum Heat LossesVinh Do ThanhNoch keine Bewertungen

- Active Magnetic Bearing PDFDokument11 SeitenActive Magnetic Bearing PDFSujan KumarNoch keine Bewertungen

- EM ReleasenoteDokument24 SeitenEM ReleasenoteJanosi ParaNoch keine Bewertungen

- x86 Disassembly Exploring The Relationship Between C, x86 Assembly, and Machine CodeDokument142 Seitenx86 Disassembly Exploring The Relationship Between C, x86 Assembly, and Machine CodePhilip Ngem100% (1)

- Epson EcoTank L3110 L3150 August2018 PDFDokument2 SeitenEpson EcoTank L3110 L3150 August2018 PDFbagasNoch keine Bewertungen

- Online Movie Ticket BookingDokument31 SeitenOnline Movie Ticket BookingRushikesh Pathak55% (11)

- Panduit - FRSPJ2X2LYLDokument2 SeitenPanduit - FRSPJ2X2LYLoscar barrientosNoch keine Bewertungen

- Intel Scalable Io Virtualization Technical SpecificationDokument29 SeitenIntel Scalable Io Virtualization Technical SpecificationDJSNoch keine Bewertungen

- Service Manual Sony Vaio VGN CDokument0 SeitenService Manual Sony Vaio VGN CannaliaxNoch keine Bewertungen

- Comparative Analysis of Different Architectures of CMOS ComparatorDokument4 SeitenComparative Analysis of Different Architectures of CMOS Comparatorj4everNoch keine Bewertungen

- TAC QuickReferenceGuideDokument4 SeitenTAC QuickReferenceGuideAlaa Al-saggafNoch keine Bewertungen

- 072 S VB19 PDFDokument3 Seiten072 S VB19 PDFMauricio CruzNoch keine Bewertungen

- Cordless Sweeper: ALDI IncDokument6 SeitenCordless Sweeper: ALDI IncHarald StephanNoch keine Bewertungen

- Basic of Ethernet CablingDokument13 SeitenBasic of Ethernet CablingtouhedurNoch keine Bewertungen

- Lab GuidelinesDokument10 SeitenLab Guidelineszelin99Noch keine Bewertungen

- Lab Manual Bca 3 Sem Data Structures-IDokument16 SeitenLab Manual Bca 3 Sem Data Structures-IdineshNoch keine Bewertungen

- DPCO Unit 4 2mark Q&ADokument11 SeitenDPCO Unit 4 2mark Q&Akanimozhi rajasekarenNoch keine Bewertungen

- RX-3302 (L) /RX-4303 Manual RX-3302 (L) /RX-4303 Manual RX-3302 (L) /RX-4303 Manual RX-3302 (L) /RX-4303 ManualDokument7 SeitenRX-3302 (L) /RX-4303 Manual RX-3302 (L) /RX-4303 Manual RX-3302 (L) /RX-4303 Manual RX-3302 (L) /RX-4303 Manualtying2005Noch keine Bewertungen

- PRO E LibraryDokument11 SeitenPRO E LibrarygokulahbNoch keine Bewertungen

- Conveyor Systems and Equipment11Dokument6 SeitenConveyor Systems and Equipment11benssjNoch keine Bewertungen

- Doulus SystemC TutorialDokument23 SeitenDoulus SystemC TutorialFrankie LiuNoch keine Bewertungen

- PERKINS (Trobuleshooting)Dokument224 SeitenPERKINS (Trobuleshooting)Iordan Adrian100% (1)

- Care of Computer Electronic PartsDokument5 SeitenCare of Computer Electronic PartsArnold NdukuyuNoch keine Bewertungen

- Robo CellDokument84 SeitenRobo CelldviryNoch keine Bewertungen

- Isilon Data Availability ProtectionDokument38 SeitenIsilon Data Availability Protectionanshuman rahiNoch keine Bewertungen

- COMPAL LS-3803P, 3804P (JBL00, JBL01, JBL02) 2008-05-12, Rev 1.0 (A00) - IO Board PDFDokument5 SeitenCOMPAL LS-3803P, 3804P (JBL00, JBL01, JBL02) 2008-05-12, Rev 1.0 (A00) - IO Board PDFGerman ValenciaNoch keine Bewertungen

- HP Notebook - 17-bs011dx Product Specifications - HP® Customer SupportDokument3 SeitenHP Notebook - 17-bs011dx Product Specifications - HP® Customer SupportJesus PerezNoch keine Bewertungen

- JVM Internals & Runtime Data AreasDokument13 SeitenJVM Internals & Runtime Data AreaskannangceNoch keine Bewertungen

- w1rtc Notes1 PDFDokument8 Seitenw1rtc Notes1 PDFYogesh ThackreyNoch keine Bewertungen

- CS8591 Cloud ComputingDokument29 SeitenCS8591 Cloud Computingsuga1990Noch keine Bewertungen

- Bosch Malaysia Power Tools 2011Dokument118 SeitenBosch Malaysia Power Tools 2011Irwan AliasNoch keine Bewertungen