Beruflich Dokumente

Kultur Dokumente

Heat Transfer and Heat - Exchangers

Hochgeladen von

Vinh Do ThanhOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Transfer and Heat - Exchangers

Hochgeladen von

Vinh Do ThanhCopyright:

Verfügbare Formate

HEAT TRANSFER AND HEAT EXCHANGERS

INTRODUCTION

The engineer is frequently called upon to transfer energy from one fluid to another. The

transfer is most often effected by a heat exchanger. A steam power plant, for example, includes

several major heat exchangers: boiler, superheater, economizer, and condenser. t also includes

minor heat exchangers such as the gland exhaust condenser and the lube oil cooler. The principal

heat exchangers in an air conditioning system are the evaporator and the condenser. !ther

applications abound throughout the mechanical industry.

THEORETICAL CONSIDERATIONS AND THE HEAT TRANSFER PROBLEM

The typical heat transfer problem involves energy transfer from a fluid stream at an

assumed average temperature, through a series of "resistances#, to a destination fluid stream also

at an assumed average temperature. $or transfer through a pipe wall, the resistances consist of,

in order, a thermal boundary layer %T&'(, a scale or soot layer, the pipe wall, another scale layer,

and the destination T&'.

)ach T&' is characterized by a convection %or film( coefficient designated h. *ewton+s

'aw of ,ooling models heat transfer through the T&':

( )

s

T T h q

where:

- q

. heat flux or rate of heat transfer per unit area ( )

/

0 Btu h ft

h . convection %film( coefficient ( )

/ 1

0 Btu h ft R

T

. average temperature of the fluid stream

Ts . surface temperature of the pipe

$ourier+s 'aw governs transfer by conduction through the pipe wall:

dr

dT

k q

where: 2 . thermal conductivity %

1

0 Btu ft h R (

The negative sign results from the decreasing temperature gradient. ntegration yields:

3

( )

( )

3 /

/ 3

ln

/

r r

T T kL

q

where: q . heat transfer rate ( ) 0 Btu h

L . length of pipe through which heat transfer occurs ( ) ft

An experimentally determined fouling factor

( )

44 / 1

0

f

R ft h R Btu

accounts for scale resistance.

3

THE OVERALL HEAT TRANSFER COEFFICIENT

5eat transfer through the various layers can be represented by an overall heat transfer

coefficient, U, such that:

q UAD

where: A . heat transfer surface area based on either the inside or outside pipe surface

U . overall heat transfer coefficient (Btu/h-ft

2

-R

D . log mean temperature difference, derived below

n analogy with electrical resistance, we can express the *ewton and $ourier laws as:

conv

conv

R

T T

q

/ 3

where:

hA

R

conv

3

cond

cond

R

T T

q

/ 3

( )

kL

r r

R

cond

/

ln

3 /

6e can then write:

( )

/ / /

/

3 /

3

3

3 3

/ 3 / 3

3

/

ln 3

h A A

R

kL

r r

A

R

h A

T T

R

T T

q

f f

total

+

+ +

+

7electing either the inside or outside area as a basis, factoring out !/A! %for example(, and letting

A! " 2r!L, we have:

3

#ee, e$g$, ncropera, p 898, for representative fouling factors.

/

( )

3

3 / 3

3 3

3 /

3 / / /

ln

3

f f

q AUD

r r r

r r

U R R

h k r r h

1

+ + + +

1

]

LOG MEAN TEMPERATURE DIFFERENCE

6hat temperature difference is to be used for :; &ecause the temperature varies on each

side of the heat exchanger as heat transfer occurs, we must derive a sort of average temperature

difference. ,onsider a counterflow heat exchanger, which we represent as shown in the figure

below:

'et: T . temperature of the hot fluid

t . temperature of the cold fluid

h . hot fluid

c. cold fluid

,. heat capacity rate

%c &

i . entrance condition

o . outlet condition

: . log mean temperature difference

C

h

T dq T+dT

t+dt t C

c

x

T

1

T

2

dq

dt

dT

T

i

t

o

t

i

T

o

h c

q q q ( )

i o h h

T T & q ( )

i o c c

t t & q TdA U dt & dT & dq

c h

<

( )

,

_

,

_

+

c h c h

& &

TdA U

&

dq

&

dq

dt dT T d

3 3

( )

,

_

/

3

/

3

3 3

dA

& &

U

T

T d

c h

( ) ( ) [ ] [ ]

3 /

3

/

ln T T

q

UA

t T t T

q

UA

q

t t

q

T T

UA

T

T

o i i o

c

i o

h

i o

,

_

,

_

,

_

3

/

3 /

ln

T

T

T T

D

$or multipass and cross=flow heat exchangers, the expression for D is modified by a

multiple ', which depends upon heat exchange geometry, number of tube passes and whether the

fluid is mixed %flow transverse to the fluid direction is not prevented( or unmixed %transverse

flow ix prevented by fins or separate tubes(. The '-factor can be found in the technical

literature.

/

EXTENDED SURFACES (FINS)

)xtended surfaces, or fins, are frequently used to increase the heat transfer rate. $ins can

be justified economically when fin effectiveness, defined by the below approximate equation, is

greater than about /.

/

/

3

,

_

c

f

hA

k(

where: k . thermal conductivity

( . perimeter of fin

h . convection coefficient

Ac . cross sectional area of fin

&ecause the temperature varies from the base of the fin to its tip, an adjustment is made to the

total heat transfer surface area, which consists of the uncovered base area plus the fin area.

>ultiplying the total area, At, by an overall surface efficiency, o,

<

which is less than unity, gives:

/

#ee, e$g$, , ncropera and :e6itt, ? ed, pp. 8@/=@?.

<

7ee ncropera, 7ection <.A.8.

?

( )

f

t

f

) t

t t

o

A

*A

hA

q

q

q

3 3

max

where: * . number of fins

Af . area of a single fin

At . total area including base

f . fin efficiency

qt . total heat transfer rate from At

h . convection coefficient

. Tb = T

T) . base temperature

T

. bul2 temperature

$in efficiency is a function of fin geometry, convection coefficient and thermal

conductivity. Balues of fin efficiency for various shapes can be found in the technical literature.

?

5aving found both fin and overall surface efficiency, the overall heat transfer coefficient

is modified by multiplying each area %fin plus uncovered base( by the overall surface efficiency.

This step results in the following relation for C:

( )

3

3 / 3 / 3 3 3

3 3 3 / / / / /

ln 3

f f

o o o o

R R r r r r r

U

h k r r h

1

+ + + +

1

]

$rom the definition of fin effectiveness, it is deduced that fins with a high thermal

conductivity, low ratio of perimeter to cross=sectional area and small convection coefficient are

desirable. &ecause a small convection coefficient improves fin performance, fins are frequently

placed on the gas side of a gas=to=liquid heat exchanger. Automobile radiators and air

conditioning evaporators and condensers are common examples. $ins are often placed on

economizers in boiler designs.

THE CONVECTION HEAT TRANSFER COEFFICIENT

(FILM COEFFICIENT)

?

7ee, e.g., ncropera, p 3/<

8

,onvection coefficients are determined from empirical correlations found in the

literature. ncropera, for example, includes summaries of convection coefficients for external

and internal flow in the bac2 of chapters D and 9. The classical correlation for internal flow is the

,olburn equation:

?0 8 30 <

1.1/<Ee Fr

D D

*u

where:

D

hD

*u

k

%the *usselt number( k . thermal conductivity of fluid

Ee

+D

%the Eeynolds number( . 2inematic viscosity

Fr

%the Frandtl number(

,

k

c

%thermal diffusivity(

A cautionary note. The engineer must exercise care in choosing and using a correlation.

Farticular attention must be given to limits of applicability. s the flow fully developed;

'aminar or turbulent; 6hat temperature should be used to find properties; 6hat are the

applicable ranges for the Eeynolds and Frandtl numbers and the length to diameter ratio;

DESIGN PROCEDURE

7elect an appropriate heat exchanger type.

7elect appropriate convection coefficients.

:etermine needed thermal properties.

7olve the fundamental equations. teration may be required.

h ,

q %c T &

c ,

q %c T &

q UA'D

A

Das könnte Ihnen auch gefallen

- Heat Exchanger-Design and ConstructionDokument46 SeitenHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Application of Finite Element Method in Structural DesignDokument16 SeitenApplication of Finite Element Method in Structural DesignAnil KadbhaneNoch keine Bewertungen

- Modelling of Tube and Fins Coil Working As Evaporator or CondenserDokument6 SeitenModelling of Tube and Fins Coil Working As Evaporator or CondenserAntarip PoddarNoch keine Bewertungen

- Bending ProcessDokument5 SeitenBending ProcessMohamed Esmael ElsayedNoch keine Bewertungen

- Sparger Design GuideDokument5 SeitenSparger Design GuideShooeibNoch keine Bewertungen

- Storage-Tank Heat TransferDokument57 SeitenStorage-Tank Heat Transfervitcon87100% (12)

- Periodical Exam Science 8Dokument5 SeitenPeriodical Exam Science 8Mike Guerzon100% (1)

- 1 Relative MotionDokument26 Seiten1 Relative MotionvvvNoch keine Bewertungen

- Ansi B16-104Dokument1 SeiteAnsi B16-104Monica Suarez100% (1)

- Double Pipe HXDokument67 SeitenDouble Pipe HXKendin Yap Fikirleri Diy0% (1)

- Heat ExchangerDokument27 SeitenHeat ExchangerKashish Mehta75% (4)

- ADP CalculationDokument12 SeitenADP Calculationnim_gourav1997Noch keine Bewertungen

- All DesignDokument45 SeitenAll Designchandan kumar c gNoch keine Bewertungen

- Physically Distanced But Academically EngagedDokument141 SeitenPhysically Distanced But Academically EngagedCeasarEj DiazNoch keine Bewertungen

- Shell & TubeDokument9 SeitenShell & TubeRanjith Kumar PNoch keine Bewertungen

- Calculation of Overall Heat Transfer CoefficientDokument2 SeitenCalculation of Overall Heat Transfer CoefficientSrihari KodimelaNoch keine Bewertungen

- Heat Ex ChangersDokument29 SeitenHeat Ex ChangersveyneeNoch keine Bewertungen

- Natural and Forced Convection ExperimentsDokument12 SeitenNatural and Forced Convection ExperimentsOmar Yamil Sanchez Torres25% (4)

- Heat Transfer Analysis of Corrugated Plate Heat ExchangerDokument6 SeitenHeat Transfer Analysis of Corrugated Plate Heat Exchangerpak1t0Noch keine Bewertungen

- Heat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Dokument15 SeitenHeat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Joli SmithNoch keine Bewertungen

- Review On Development of Polypropylene Manufacturing ProcessDokument11 SeitenReview On Development of Polypropylene Manufacturing ProcessShweta Yadav100% (1)

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Heat Exchanger Part 1 PDFDokument22 SeitenHeat Exchanger Part 1 PDFRyu RyloNoch keine Bewertungen

- Heat Transfer and Heat - ExchangersDokument6 SeitenHeat Transfer and Heat - Exchangershoang vu ngocNoch keine Bewertungen

- Estimation of Over-All Heat TransferDokument10 SeitenEstimation of Over-All Heat TransferAllan Troy SalazarNoch keine Bewertungen

- Fan Heat Sink OptimizationDokument6 SeitenFan Heat Sink Optimizationrobert s wilsonNoch keine Bewertungen

- Heat Chap08 001Dokument30 SeitenHeat Chap08 001Kerem GönceNoch keine Bewertungen

- Lab 2Dokument17 SeitenLab 2Callum BiggsNoch keine Bewertungen

- HEDokument10 SeitenHEMohamed BelallNoch keine Bewertungen

- 11B - Chapter 11, Secs 11.4 - 11.7 BlackDokument15 Seiten11B - Chapter 11, Secs 11.4 - 11.7 BlackrajindoNoch keine Bewertungen

- 08B - Chapter 8, Sec 8.4 - 8.8 BlackDokument18 Seiten08B - Chapter 8, Sec 8.4 - 8.8 BlackAli HazratNoch keine Bewertungen

- Exp 1 Cross Flow Heat ExchangerDokument6 SeitenExp 1 Cross Flow Heat ExchangerChristopher SequeraNoch keine Bewertungen

- Forced ConvectionDokument6 SeitenForced ConvectionTirth VyasNoch keine Bewertungen

- Heat ExchangeDokument10 SeitenHeat ExchangeAhmed GadNoch keine Bewertungen

- Lab 5 Heat ExchangerDokument4 SeitenLab 5 Heat ExchangerJoson ChaiNoch keine Bewertungen

- Experiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural ConvectionDokument6 SeitenExperiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural Convectionpriya3939Noch keine Bewertungen

- Heat Chap13 111Dokument10 SeitenHeat Chap13 111Kerem GönceNoch keine Bewertungen

- HMT Lab 5-1Dokument5 SeitenHMT Lab 5-1Zahoor AhmadNoch keine Bewertungen

- Czasopismo Techniczne Volume 3 (2017) 16Dokument14 SeitenCzasopismo Techniczne Volume 3 (2017) 16nidhul07Noch keine Bewertungen

- Design Validation of Shell and Tube Heat Exchanger by HTRI Xchanger SoftwareDokument5 SeitenDesign Validation of Shell and Tube Heat Exchanger by HTRI Xchanger SoftwareAhmed HassanNoch keine Bewertungen

- Pin Fin Apparatus - UpdatedDokument10 SeitenPin Fin Apparatus - UpdatedVignesh MallyaNoch keine Bewertungen

- Heat and Mass Transfer Calculation of The Intercooler With SprayiDokument6 SeitenHeat and Mass Transfer Calculation of The Intercooler With SprayiBertalan Gyuszi Kristóf0% (1)

- Finned TubeDokument4 SeitenFinned Tubeknife2008Noch keine Bewertungen

- HjjooDokument28 SeitenHjjooJohn Patrick DagleNoch keine Bewertungen

- Heat5 (Convection II)Dokument48 SeitenHeat5 (Convection II)ابو الجعل0% (1)

- Heat Transfer Tutorial For Heat ExchangersDokument0 SeitenHeat Transfer Tutorial For Heat ExchangersvicopipNoch keine Bewertungen

- Design of Heat ExchangersDokument20 SeitenDesign of Heat ExchangersSudhir JadhavNoch keine Bewertungen

- Heat TransferDokument7 SeitenHeat TransferEngr. AbdullahNoch keine Bewertungen

- Effect of Inclination of Impinging Jets On Flow and Heat Transfer CharacteristicsDokument6 SeitenEffect of Inclination of Impinging Jets On Flow and Heat Transfer CharacteristicsInternational Journal of Science and Engineering InvestigationsNoch keine Bewertungen

- Internal Flow: General ConsiderationsDokument18 SeitenInternal Flow: General ConsiderationsAhmad Arif SaktiNoch keine Bewertungen

- Pin Fin Apparatus EditedDokument10 SeitenPin Fin Apparatus EditedS S S REDDYNoch keine Bewertungen

- P2Dokument55 SeitenP2Abdulla BaderNoch keine Bewertungen

- Flare Sweep GasDokument5 SeitenFlare Sweep GasChem.EnggNoch keine Bewertungen

- MCL Assignment - 3&4 Application of Entropy Generation Concepts in Design and Operation of Electronic Devices or Electrical MachinesDokument7 SeitenMCL Assignment - 3&4 Application of Entropy Generation Concepts in Design and Operation of Electronic Devices or Electrical Machinesastute kidNoch keine Bewertungen

- Cost Optimization Using Genetic Algorithm: Steam Surface Condenser Design Based OnDokument6 SeitenCost Optimization Using Genetic Algorithm: Steam Surface Condenser Design Based Onaliscribd46Noch keine Bewertungen

- ME 315 - Heat Transfer Laboratory Experiment No. 8 Forced Convection From A Circular Cylinder Subjected To Cross FlowDokument11 SeitenME 315 - Heat Transfer Laboratory Experiment No. 8 Forced Convection From A Circular Cylinder Subjected To Cross FlowSharath SharuNoch keine Bewertungen

- 6 Heat TransferDokument19 Seiten6 Heat TransferPrecious Mae Cuerquis BarbosaNoch keine Bewertungen

- Heat ExchangersDokument7 SeitenHeat Exchangersonezero111Noch keine Bewertungen

- Vertical ConderDokument9 SeitenVertical Condermanoj kumarNoch keine Bewertungen

- Thermal Analysis of Water Cooled Charge Air Cooler in Turbo Charged Diesel EngineDokument5 SeitenThermal Analysis of Water Cooled Charge Air Cooler in Turbo Charged Diesel EngineesatjournalsNoch keine Bewertungen

- Wind-Related Heat Losses of A Flat-Plate Collector: Abstract - TheDokument5 SeitenWind-Related Heat Losses of A Flat-Plate Collector: Abstract - TheJovanJoksicNoch keine Bewertungen

- Tỷ số air-fuel lý tưởng (14.7)Dokument9 SeitenTỷ số air-fuel lý tưởng (14.7)Vinh Do ThanhNoch keine Bewertungen

- Dryer CalculationsDokument4 SeitenDryer CalculationsVinh Do Thanh0% (1)

- Air-Fuel Ratio, Lambda and Engine Performance: AFR M MDokument12 SeitenAir-Fuel Ratio, Lambda and Engine Performance: AFR M MVinh Do ThanhNoch keine Bewertungen

- Studies On Drying Kinetics of Solids in A Rotary DryerDokument6 SeitenStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNoch keine Bewertungen

- Effects of Drying Parameters On Heat Transfer During DryingDokument13 SeitenEffects of Drying Parameters On Heat Transfer During DryingVinh Do ThanhNoch keine Bewertungen

- The Heart of Operations - World Cement - 02-2015Dokument4 SeitenThe Heart of Operations - World Cement - 02-2015fetniNoch keine Bewertungen

- Modeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsDokument8 SeitenModeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsVinh Do ThanhNoch keine Bewertungen

- Modelling and Simulation of A Direct Contact Rotary DryerDokument16 SeitenModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhNoch keine Bewertungen

- Aoac - Methods.1.1990. MoistureDokument2 SeitenAoac - Methods.1.1990. MoistureVinh Do ThanhNoch keine Bewertungen

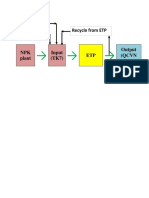

- Recycle From ETP Make Up H2O DAP, UreaDokument1 SeiteRecycle From ETP Make Up H2O DAP, UreaVinh Do ThanhNoch keine Bewertungen

- NPK-15 8 15Dokument5 SeitenNPK-15 8 15Vinh Do ThanhNoch keine Bewertungen

- PEP Report 267A: Ihs ChemicalDokument8 SeitenPEP Report 267A: Ihs ChemicalVinh Do ThanhNoch keine Bewertungen

- E. E.' " (75 Ion Agent of Firm Rope-Mckay & AssociatesDokument7 SeitenE. E.' " (75 Ion Agent of Firm Rope-Mckay & AssociatesVinh Do ThanhNoch keine Bewertungen

- Equivalent Grades of Cast IronsDokument2 SeitenEquivalent Grades of Cast IronsVinh Do Thanh100% (1)

- Metal Price IndexDokument1 SeiteMetal Price IndexVinh Do ThanhNoch keine Bewertungen

- Tinh Luong Nuoc Bay HoiDokument22 SeitenTinh Luong Nuoc Bay HoiVinh Do ThanhNoch keine Bewertungen

- 4244 12672 1 PB PDFDokument15 Seiten4244 12672 1 PB PDFVinh Do ThanhNoch keine Bewertungen

- 4244 12672 1 PB PDFDokument15 Seiten4244 12672 1 PB PDFVinh Do ThanhNoch keine Bewertungen

- Natural Evaporation RateDokument16 SeitenNatural Evaporation RateVinh Do ThanhNoch keine Bewertungen

- Mau Giay Uy Quyen Bang Tieng AnhDokument3 SeitenMau Giay Uy Quyen Bang Tieng AnhVinh Do ThanhNoch keine Bewertungen

- CRACKER A PC Based Simulator For Industr PDFDokument6 SeitenCRACKER A PC Based Simulator For Industr PDFVinh Do ThanhNoch keine Bewertungen

- Estimating Evaporation From Water SurfacesDokument27 SeitenEstimating Evaporation From Water SurfacesVinh Do ThanhNoch keine Bewertungen

- How To Calculate Heat Load - 5 StepsDokument1 SeiteHow To Calculate Heat Load - 5 StepsVinh Do ThanhNoch keine Bewertungen

- 1 0ProjectManagementProceduresDokument8 Seiten1 0ProjectManagementProceduresRamiesRahmanNoch keine Bewertungen

- How To Calculate Heat Load - 5 StepsDokument1 SeiteHow To Calculate Heat Load - 5 StepsVinh Do ThanhNoch keine Bewertungen

- DRS 279-2015 Organic Fertilizer - SpecificationDokument17 SeitenDRS 279-2015 Organic Fertilizer - SpecificationVinh Do ThanhNoch keine Bewertungen

- Optimization of Wall Thickness For Minimum Heat LossesDokument9 SeitenOptimization of Wall Thickness For Minimum Heat LossesVinh Do ThanhNoch keine Bewertungen

- Investigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyDokument5 SeitenInvestigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyradanpetricaNoch keine Bewertungen

- Mechanical Work: Sub Unit 2.1Dokument9 SeitenMechanical Work: Sub Unit 2.1Carolina PalacioNoch keine Bewertungen

- Y0405 2 md1Dokument6 SeitenY0405 2 md1hthaier4062Noch keine Bewertungen

- Deformation of Straight Beams: Description Learning Objectives/experimentsDokument3 SeitenDeformation of Straight Beams: Description Learning Objectives/experimentsDiego AvendañoNoch keine Bewertungen

- Week 3 Lecture Material - WatermarkDokument53 SeitenWeek 3 Lecture Material - Watermarkchristi SNoch keine Bewertungen

- Design and Fabrication of Cycloidal Gear Box: A Project Report OnDokument25 SeitenDesign and Fabrication of Cycloidal Gear Box: A Project Report OnAjay NishadNoch keine Bewertungen

- AD 251 - Equivalent Uniform Moment Factor, M (Italic)Dokument1 SeiteAD 251 - Equivalent Uniform Moment Factor, M (Italic)symon ellimacNoch keine Bewertungen

- Snist Dom Previous PaperDokument9 SeitenSnist Dom Previous PaperKapil Siddhant DevulapalliNoch keine Bewertungen

- Tides WebquestDokument2 SeitenTides Webquestapi-264150929Noch keine Bewertungen

- 2.1 Duct Design PP 1Dokument42 Seiten2.1 Duct Design PP 1quoc khanh NgoNoch keine Bewertungen

- Study Guide Energy and Chemical Change Student EditableDokument7 SeitenStudy Guide Energy and Chemical Change Student EditableRicki HanNoch keine Bewertungen

- WO Lecture 6Dokument7 SeitenWO Lecture 6RaadNoch keine Bewertungen

- Corrected - Gear - 9 Teeth - ContactAnalysisDokument10 SeitenCorrected - Gear - 9 Teeth - ContactAnalysiskarthikeyan NNoch keine Bewertungen

- Sound Absorption Thermal and Mechanical Behavior of Polyurethane Foam Modified With Nano SilicaDokument8 SeitenSound Absorption Thermal and Mechanical Behavior of Polyurethane Foam Modified With Nano SilicaZarathos SinghNoch keine Bewertungen

- Evaluation Exam 8Dokument8 SeitenEvaluation Exam 8Michael MercadoNoch keine Bewertungen

- Unsteady Friction ModelsDokument32 SeitenUnsteady Friction ModelsWalter F SilvaNoch keine Bewertungen

- EXPT. No. 1 Pressure Measuring DevicesDokument12 SeitenEXPT. No. 1 Pressure Measuring DevicesLowEnd GamerNoch keine Bewertungen

- Dynamic Loading of A Forklift Truck Lifting InstallationDokument4 SeitenDynamic Loading of A Forklift Truck Lifting Installationmiroslav11Noch keine Bewertungen

- 10 Lenoir CycleDokument2 Seiten10 Lenoir Cyclecaptainhass100% (1)

- Wave PowerpointDokument45 SeitenWave PowerpointJoan Rose Ferry0% (1)

- Strut and Tie Approach (Research Thesis)Dokument331 SeitenStrut and Tie Approach (Research Thesis)yyanan1118Noch keine Bewertungen

- Newton's Laws of MotionDokument64 SeitenNewton's Laws of MotionAbhishek PathakNoch keine Bewertungen

- Mechanics of Solids Week 13 LecturesDokument8 SeitenMechanics of Solids Week 13 LecturesFlynn GouldNoch keine Bewertungen

- Chapter 5 - Imperfections in Crystalline SolidsDokument16 SeitenChapter 5 - Imperfections in Crystalline SolidsHậu Trung NguyễnNoch keine Bewertungen

- Brace Force - in Service LoadDokument1 SeiteBrace Force - in Service LoadDhina karanNoch keine Bewertungen