Beruflich Dokumente

Kultur Dokumente

GEMI Equations Tool

Hochgeladen von

jnmanivannanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GEMI Equations Tool

Hochgeladen von

jnmanivannanCopyright:

Verfügbare Formate

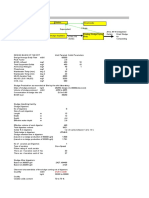

Head = 100.

00 ft

Flow Rate = 200.00 gpm

Specific Gravity = 50.00

HP = 252.78

KW = 187.06

HP = 5.00 HP

Pump Efficiency = 60.00%

Brake Horsepower = 8.33

Brake KW = 6.17

Pressure = 30.48 meters

Flow Rate = 12.60

L

/

S

KW = 3.77

HP = 5.05

User Input

Calculated Result

Head (ft) x Flow Rate (gpm) x (specific gravity)

3956

(9.81) x Head (meters) x Flow Rate (

L

/

S

) x (specific gravity)

1000

Hydraulic Power

Pump Efficiency

Head (ft) x Flow Rate (gpm) x (specific gravity)

3956

Pump Discharge Pressure = 100 ft

Measured Flow Rate = 200 gpm

Sample Horsepower Calculations

Once the hydraulic horsepower is known, the brake horsepower can be determined based on the pump efficiency. A

pump efficiency of 60% can be used as a conservative estimate for a basic calculation to provide a general

approximation.

Many technical references are available that can provide guidance on the use of these equations and the user should

refer to these references.

GEMI Water Sustainability Tool Draft (9/21/05)

Hydraulic HP =

Hydraulic Kilowatts =

Brake Horsepower and Motor Efficiency

Horsepower Calculator

Estimating Pump Hydraulic Horsepower

Hydraulic Horsepower and Kilowatt Equations

Horsepower is the unit of power to define hydraulic or water horsepower. In System International System (SI) it is in

kilowatts (kw).

The hydraulic power is the next energy transferred to the water per unit time. The input power delivered by the motor

to the pump is called bare horsepower (bHp). The difference between the brake horsepower and hydraulic power is

the pump efficiency.

The horsepower of a pump can be determined once basic information is known about the pumping station.

Brake Horsepower =

Question: Determine the estimated pump horsepower based on the 200 gpm flow rate and 100 ft discharge pressure

at the pump.

HP =

Multiply HP by 0.746 to obtain kilowatts

Multiply kilowatts by 1.341 to obtain horsepower

Inputs

Brake Horsepower Calculator

Inputs

SI Calculator

Inputs

Calculate Horsepower

100 ft x 200 gpm x 1.0

3956

HP = 5

5

0.6

= 8.3

Pump Discharge Pressure = 30.48 meter

Measured Flow Rate =

12.6

L

/

S

9.81 x 30.48 m x 12.6

L

/

S

x 1.0

1000

Kilowatts = 3.76

L

/

S

Liters per Second

gpm Gallons per minute

HP Horespower

KW Kilowatt

m/s Meters per Second

m

3

Cubic Meters

m

2

Square Meters

ft

2

Square Feet

ft

3

Cubic Feet

Kilowatts =

HP

SI Units

=

Brake Horsepower =

Legend

Calculate Brake Horsepower

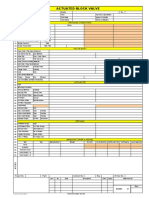

Velocity = 5 ft/sec

Cross Sectional Area = 0.196 ft

2

Flow Rate = 440.02 gpm

Velocity = 1.52 m/sec

Cross Sectional Area = 0.018 m

2

Flow Rate = 27.36

L

/

S

User Input

Calculated Result

Cross Sectional Area

Flow rate (cfs) = Velocity (ft/sec) x Pipe Cross Sectional Area (ft

2

)

Flow rate (cfs) =

5 ft/sec x .196 ft

2

0.98 ft

3

sec

0.98 ft

3

sec

Flow (gpm) = 0.98 x 449

= 440 gpm

Flow M

3

/ S = Velocity (m/s) x Pipe Cross Sectional Area (m

2

)

Flow M

3

/ S = 1.52 m/s x .018 m

2

= .028 m

3

/sec

Multiply 0.028 m

3

/sec by 1000 to get

L

/

S

Flow Rate Calculator

Inputs

SI Units

Flow rate (cfs)

Fluid Flow Fundamentals

Water systems involve the movement of water from one point to another. Examples are transferring water from one process to

another or from one production facility or building to a packaging plant or final product shipping area.

Water usage is typically expressed as a volumetric flow rate (volume/time). If the water flowing though a cylindrical pipe is

represented by the shaded area shown below (perpendicular to flow direction) and the velocity of the water is known, then the

flow rate of the water can be determined through the pipe as gal/min or m

3

/sec.

SI Calculator

Inputs

GEMI Water Sustainability Tool Draft (9/21/05)

By 449 to get gpm

Flow Rate Equations

Flow rate (Q) = Area x velocity

Sample Calculation: Determine the quantity of water flowing through a 6-inch diameter pipe that has a velocity of 5 ft/sec.

=

Multiply

The flow rates of process pipes are very important to know to complete water balances and usage and measuring volumetric

flow rates are easy using common flow meters. See "Types of Flow Meters" tab for various types of flow measurement

devices.

Flow

L

/

S

= 0.028 x 1000

Flow

L

/

S

=

28

L

/

S

L

/

S

Liters per Second

gpm Gallons per minute

HP Horespower

KW Kilowatt

m/s Meters per Second

m

3

Cubic Meters

m

2

Square Meters

ft

2

Square Feet

ft

3

Cubic Feet

Legend

Pipe Length = 1000.00 ft

Pipe Diameter = 0.33 ft

Cross Sectional Area = 0.09 ft

2

Flow Rate = 300 gpm

Pipe Velocity = 7.02 ft/sec

Friction Factor = 0.02

Friction Loss = 46.36

User Input

Calculated Result

L

V

2

d 2g

h

f =

f = Friction Loss Factor

L = d = Pipe Diameter (ft)

v =

g = (acceleration of gravity factor)

Cross-sectional areas = x (pipe radius)

2

Where = 3.14

Pipe diameter = 4-inch = .33 ft

Pipe radius = 2-inch = .16 ft

Cross-sectional area = 3.14 x (.16) = .08 ft

300 gpm x .002 =

0.60 ft

3

/sec

Calculate pipe velocity

0.60

0.08

Velocity ft/sec = 7.5 ft/sec

L

V

2

d 2g

Pipe velocity (V) =

Determine the friction loss of water pumped through 1,000 ft. of 4-inch diameter pipe at a 300 gpm flow rate.

Flowrate can be determined using a flowmeter or the drum and stop watch method.

The first step is to determine the velocity based on the pipes cross-sectional area.

Velocity ft/sec =

Friction Loss (h

f

)

Multiply the 300 gpm flow rate by .002 to convert to ft

3

/sec

Using a .02 friction factor calculate the friction loss

lb f - sec

2

GEMI Water Sustainability Tool Draft (9/21/05)

Friction Loss Calculator

Inputs

= f

Friction loss (ft)

Pipe length (ft)

Pipe velocity (ft/sec)

32.2 lb m - ft

The second step is to determine the pipe velocity

= f x

Flow rate

Cross sectional area

Friction Loss/Flow Calculations

Several methods are available to determine the friction losses and estimated water flow rates in pipes. In this

section one of the most widely used formulas for friction loss, the Darcy-Weisback equation will be presented so

the user can have an understanding of the use of these formulas and the information they can provide.

A simple method to estimate flowrate is the drum and stop watch method. Place a drum or container of

sufficient size (30 to 50 gallons) at the end of the pipe and estimate the time to fill the container with a stop

watch. This will provide a good method to determine the flowrate that can be used in these calculations if a

flowmeter is not available.

x

Sample Calculation

Friction Loss (h

f

)

The Darcy-Weisback formula is:

.02 x 1000 ft (7.5 ft/sec)

.33 ft 64.4

Velocity ft/sec = 52.9 ft

L

/

S

Liters per Second

gpm Gallons per minute

HP Horespower

KW Kilowatt

m/s Meters per Second

m

3

Cubic Meters

m

2

Square Meters

ft

2

Square Feet

ft

3

Cubic Feet

Friction loss (ft) = x

Legend

Flowmeter Application Service

Drum and Stop Watch Closed pipe or open channel Simple and inexpensive. Clean or dirty water

Weir Open channel v-notch, rectangular

or cipolletti weirs

Simple and inexpensive. Clean or dirty water

Flume Open channel, Parshall, Palmer-

Bowlus Flumes

Frequently used in sewers and wastewater treatment plants

dirty water

Orifice Closed pipe, round flat metal disc

plate with specific hole size

Clean and dirty water

Venture Closed pipe. Section of pipe with

tampered entrance straight throat

and tampered exit

Can be used with most liquids. Clean and dirty water. No

moving parts

Positive Displacement Closed pipe. Piston gear rotary or

disk type meters

Clean water applications. Good for low flow measurement

Turbine Closed pipe. Flow passes a

shedder bar creating vortices

Clean and dirty water

Magnetic Closed pipe. Magnetic field is

created to measure conductive

liquid

Difficult and corrosive liquids, slurries and sludges

Ultrasonic Closed pipe. Doppler and time of

travel meters

Clean and dirty water

Mass Closed pipe. Coriolis principal

meter

Clean and dirty water. Mass related processes. Chemical

reactions, heat transfer applications

Pitot Tube Closed pipe. Pressure sensing

taps measure differential pressure

Clean water. Low cost. Susceptible to plugging

GEMI Water Sustainability Tool Draft (9/21/05)

Flowmeter Reference Guide

Selecting a Flowmeter

Types of Flowmeters for Flow Measurement

There are many types of flowmeters available for flow measurement applications. This section provides the user with an

overview of the types of uses.

Flowmeter selection is based on location, (open pipe versus closed pipe), service (dirty water versus clean water) and

accuracy of the flow measurement. The following table summarizes the most common flowmeters on the market today.

Is the water conductive?

What are the operating temperatures?

Does the existing piping accommodate the flowmeter installation requirements?

It is important to understand the capabilities of the flowmeter you are selecting because each one has different advantage

and disadvantages. The flowmeter performance will vary and it may not be necessary to install an expensive flowmeter if

only a simple flow measure is needed with little concern for high accuracy. Most suppliers can assist with the right flowmeter

for a specific application.

The first step in selecting a flow meter is to determine exactly what the meter is supposed to do. The following lists several

questions that the user should ask when selecting a meter:

How accurate of flow measurement is needed?

Is local or remote indication necessary because the flowmeter will be difficult to access?

Is the water dirty, viscous or corrosive?

GEMI Water Sustainability Tool Draft (9/21/05)

Das könnte Ihnen auch gefallen

- Electrical - BB International PDFDokument480 SeitenElectrical - BB International PDFedelmolina100% (3)

- Bernoulli Lab ReportDokument18 SeitenBernoulli Lab ReportRam Krishna Singh80% (15)

- Pump SizingDokument3 SeitenPump Sizingtimayaa1000Noch keine Bewertungen

- Raft Slab DesignDokument5 SeitenRaft Slab DesignLekins Sefiu Yekini100% (2)

- DFMEA analysis of Sand Bed Turnover Monitor projectDokument2 SeitenDFMEA analysis of Sand Bed Turnover Monitor projectjnmanivannanNoch keine Bewertungen

- Horizontal Cylindrical Tank Volume and Level CalculatorDokument5 SeitenHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNoch keine Bewertungen

- Swimming Pool Ric TayatayDokument39 SeitenSwimming Pool Ric TayatayRENZZ IRVIN DELA TORRENoch keine Bewertungen

- Brown Field Pipe Rack Design ForcesDokument7 SeitenBrown Field Pipe Rack Design ForcesjnmanivannanNoch keine Bewertungen

- Mechanical Calculations - Plumbing PDFDokument43 SeitenMechanical Calculations - Plumbing PDFRaoof0% (1)

- Five Nights at Freddy's The Ultimate Guide Five Nights at Freddy's Wiki FandomDokument1 SeiteFive Nights at Freddy's The Ultimate Guide Five Nights at Freddy's Wiki FandomAmto Hosima0% (1)

- Emiss Calc HotmixDokument37 SeitenEmiss Calc HotmixjnmanivannanNoch keine Bewertungen

- Norgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)Dokument5 SeitenNorgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)navneetNoch keine Bewertungen

- Long Span PrattDokument36 SeitenLong Span PrattCarmel Buniel SabadoNoch keine Bewertungen

- Project Management ProcessDokument23 SeitenProject Management ProcessMuhammad Sajid Saeed100% (2)

- Cooling Tower ComparisonDokument4 SeitenCooling Tower ComparisonKiran DasNoch keine Bewertungen

- Plumbing Calculation For BMWDokument9 SeitenPlumbing Calculation For BMWSenghy MaoNoch keine Bewertungen

- ParalDokument9 SeitenParalTahirJabbarNoch keine Bewertungen

- Curtiss SO3C-1 Seamew Recon PlaneDokument11 SeitenCurtiss SO3C-1 Seamew Recon PlaneAdrian Rosero Bautista100% (1)

- Cent PumpDokument1 SeiteCent PumpChem.EnggNoch keine Bewertungen

- GEMI Equations ToolDokument10 SeitenGEMI Equations TooljnmanivannanNoch keine Bewertungen

- FEMA Equip ScheduleDokument14 SeitenFEMA Equip SchedulejnmanivannanNoch keine Bewertungen

- Structural Sections SpreadsheetDokument74 SeitenStructural Sections Spreadsheetpiper1985Noch keine Bewertungen

- Line Size Calculation For Cooling Water Pipes: Pipe Size Provided Is OKDokument40 SeitenLine Size Calculation For Cooling Water Pipes: Pipe Size Provided Is OKjitendra shindeNoch keine Bewertungen

- Calculation of time needed to mix liquids with pitch blade impellersDokument10 SeitenCalculation of time needed to mix liquids with pitch blade impellershadiNoch keine Bewertungen

- Drawing Assignment Ii Ce 2211 - Civil Engineering MethodsDokument2 SeitenDrawing Assignment Ii Ce 2211 - Civil Engineering MethodsFearless HeroNoch keine Bewertungen

- Rms B C HesaplamaDokument21 SeitenRms B C HesaplamayilmazerolNoch keine Bewertungen

- Tank or Silo - Volume and Level Calculations-D1.9SDokument24 SeitenTank or Silo - Volume and Level Calculations-D1.9SJacques J PienaarNoch keine Bewertungen

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDokument7 SeitenQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- No Item: I/D CR KR SF THKDokument30 SeitenNo Item: I/D CR KR SF THKnil100% (1)

- SHELL AND TUBE HEAT EXCHANGER DESIGNDokument16 SeitenSHELL AND TUBE HEAT EXCHANGER DESIGNSarvagyaNoch keine Bewertungen

- FIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFDokument63 SeitenFIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFamrefat77100% (1)

- CH - Mates PH II - Boiler QuestionsDokument13 SeitenCH - Mates PH II - Boiler QuestionsArun GeorgeNoch keine Bewertungen

- Properties of liquid hydrocarbons in pumpsDokument1 SeiteProperties of liquid hydrocarbons in pumpsmahesh_eilNoch keine Bewertungen

- Axial ThrustDokument2 SeitenAxial ThrustGerman ToledoNoch keine Bewertungen

- VSD Calculator for Fan Energy SavingsDokument10 SeitenVSD Calculator for Fan Energy SavingsCésar Christian JankoNoch keine Bewertungen

- Comprehensive analysis of salt composition and propertiesDokument188 SeitenComprehensive analysis of salt composition and propertiesBurhanudin MuizNoch keine Bewertungen

- Al Ain Sludge Status - BwiDokument1 SeiteAl Ain Sludge Status - BwiHRK65Noch keine Bewertungen

- GEMI Equations ToolDokument12 SeitenGEMI Equations ToolalexnomitaNoch keine Bewertungen

- How To Read Basic Pump CurvesDokument5 SeitenHow To Read Basic Pump CurvesGauravNoch keine Bewertungen

- Design HeatexchangerDokument15 SeitenDesign HeatexchangerMayurMahajan100% (1)

- Pump Filter SizingDokument3 SeitenPump Filter SizingkavjoNoch keine Bewertungen

- PDS Ga-401Dokument1 SeitePDS Ga-401wahyuNoch keine Bewertungen

- Nss CalculatorDokument4 SeitenNss CalculatorZoebair100% (1)

- (EDITED-FINAL) Sludge - Storage CalculationDokument16 Seiten(EDITED-FINAL) Sludge - Storage CalculationAmro Ahmad AliNoch keine Bewertungen

- Sizing Duct Work SheetDokument4 SeitenSizing Duct Work SheetMaulana MaftuhiNoch keine Bewertungen

- C - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Dokument4 SeitenC - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Padma Raju0% (1)

- 5 Calculation Compressed Air System Principal DimensionDokument16 Seiten5 Calculation Compressed Air System Principal DimensionAtandho Gama MagwasyarNoch keine Bewertungen

- 11.3 KernDokument78 Seiten11.3 KernChou ChouNoch keine Bewertungen

- Pump NPSH CalculationDokument18 SeitenPump NPSH CalculationDarwinNoch keine Bewertungen

- Estimating Pump Horsepower and Flow Rate Using Common CalculatorsDokument10 SeitenEstimating Pump Horsepower and Flow Rate Using Common CalculatorsggdgdfgdfgdfgdgddddNoch keine Bewertungen

- Valve Sizing CalculationDokument7 SeitenValve Sizing CalculationSteve Wan100% (1)

- Design FMR HighDensityDokument2 SeitenDesign FMR HighDensityPandiaraj MkNoch keine Bewertungen

- PUMP DESIGNDokument2 SeitenPUMP DESIGNmoh. rusli bahtiarNoch keine Bewertungen

- COAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISDokument5 SeitenCOAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISDenny ThomasNoch keine Bewertungen

- Bab Iv Hasil Pengamatan Dan PerhitunganDokument9 SeitenBab Iv Hasil Pengamatan Dan PerhitunganAhmad NurilNoch keine Bewertungen

- Siemens Compressor PackageDokument8 SeitenSiemens Compressor PackageMilos ObrenovicNoch keine Bewertungen

- Centrifugal Pump CurvesDokument2 SeitenCentrifugal Pump CurvesBesan LaduNoch keine Bewertungen

- Bilge System DesignDokument40 SeitenBilge System DesignTegar LanangNoch keine Bewertungen

- Pump Horsepower CalculationDokument4 SeitenPump Horsepower CalculationAbigail RuedaNoch keine Bewertungen

- Doc. No. 01 - 42 10 002 - OCSDokument36 SeitenDoc. No. 01 - 42 10 002 - OCSHerlambang sNoch keine Bewertungen

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpDokument11 SeitenCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumpthanh_79Noch keine Bewertungen

- Compressor SizeDokument3 SeitenCompressor SizeSubhash KumarNoch keine Bewertungen

- Water HammerDokument3 SeitenWater HammerSrinivas ReddyNoch keine Bewertungen

- ATFE Installation Costing for Xylene Distillation ProjectDokument27 SeitenATFE Installation Costing for Xylene Distillation ProjectPrathmesh GujaratiNoch keine Bewertungen

- 4.4 Heat Ex ChangersDokument7 Seiten4.4 Heat Ex Changersmukesh kaushikNoch keine Bewertungen

- PIPE LOSS CALCULATION FOR FIRE PROTECTION SYSTEMDokument8 SeitenPIPE LOSS CALCULATION FOR FIRE PROTECTION SYSTEMsaraNoch keine Bewertungen

- TOP For Water SystemDokument35 SeitenTOP For Water SystemNaresh PattanaikNoch keine Bewertungen

- Pump motor power capacity chart for 120 m3/hr dischargeDokument2 SeitenPump motor power capacity chart for 120 m3/hr dischargeMangesh MandgeNoch keine Bewertungen

- Air Duct CalculatorDokument1 SeiteAir Duct Calculatoraravoof84Noch keine Bewertungen

- Calc-Plum Fire IrtankDokument6 SeitenCalc-Plum Fire IrtankAmro Metwally El HendawyNoch keine Bewertungen

- Perhitungan Compressed Air System Untuk KapalDokument30 SeitenPerhitungan Compressed Air System Untuk KapaldhearNoch keine Bewertungen

- Weil Pump Flow and Basin Sizing Calculator (EDocFind - Com)Dokument15 SeitenWeil Pump Flow and Basin Sizing Calculator (EDocFind - Com)mohdnazirNoch keine Bewertungen

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDokument6 SeitenSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNoch keine Bewertungen

- Yazd-System Description For Clean Drain System PDFDokument7 SeitenYazd-System Description For Clean Drain System PDFace-winnieNoch keine Bewertungen

- Density of WaterDokument5 SeitenDensity of WaterJean Pajuelo0% (1)

- Pump VFD ES EstimatorDokument2 SeitenPump VFD ES EstimatorVeeresh MustapureNoch keine Bewertungen

- Vapor Line Sizing-Mpp6Dokument10 SeitenVapor Line Sizing-Mpp6Nitin KurupNoch keine Bewertungen

- Hydro Design & ConstructionDokument81 SeitenHydro Design & ConstructionSamNoch keine Bewertungen

- Pump Filter SizingDokument3 SeitenPump Filter SizingxrosspointNoch keine Bewertungen

- Steam Trap EstimatorDokument9 SeitenSteam Trap EstimatorjnmanivannanNoch keine Bewertungen

- Dola Char AnalysisDokument3 SeitenDola Char AnalysisS V NAGESHNoch keine Bewertungen

- Larsen and Toubro Cement Plant Equipment ListDokument14 SeitenLarsen and Toubro Cement Plant Equipment ListjnmanivannanNoch keine Bewertungen

- Average values and data qualifiers from literature on wastewater constituentsDokument46 SeitenAverage values and data qualifiers from literature on wastewater constituentsjnmanivannanNoch keine Bewertungen

- Chimney Qty ReinforcementDokument25 SeitenChimney Qty ReinforcementjnmanivannanNoch keine Bewertungen

- 22268Dokument290 Seiten22268jnmanivannanNoch keine Bewertungen

- Soil Resistivity1Dokument12 SeitenSoil Resistivity1jnmanivannanNoch keine Bewertungen

- AHU Supply Front PackageDokument10 SeitenAHU Supply Front PackagejnmanivannanNoch keine Bewertungen

- EI2009Dokument717 SeitenEI2009jnmanivannanNoch keine Bewertungen

- Plant SpecificationsDokument4 SeitenPlant SpecificationsjnmanivannanNoch keine Bewertungen

- EH GPR Checklist v1-2Dokument8 SeitenEH GPR Checklist v1-2jnmanivannanNoch keine Bewertungen

- Journal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesDokument5 SeitenJournal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesjnmanivannanNoch keine Bewertungen

- Normality Acid, N Sample Vol: ML PHDokument10 SeitenNormality Acid, N Sample Vol: ML PHjnmanivannanNoch keine Bewertungen

- EI2009Dokument717 SeitenEI2009jnmanivannanNoch keine Bewertungen

- 보온재두께계산Dokument2 Seiten보온재두께계산Sharon LambertNoch keine Bewertungen

- Fluid HeatDokument83 SeitenFluid HeatjnmanivannanNoch keine Bewertungen

- GiwlistDokument1 SeiteGiwlistjnmanivannanNoch keine Bewertungen

- H 2 EauDokument4 SeitenH 2 EaujnmanivannanNoch keine Bewertungen

- H 2 EauDokument4 SeitenH 2 EaujnmanivannanNoch keine Bewertungen

- Busbar Size Calculation (22.8.12)Dokument16 SeitenBusbar Size Calculation (22.8.12)Jeya KannanNoch keine Bewertungen

- Calculation Form CombustionDokument2 SeitenCalculation Form CombustionjnmanivannanNoch keine Bewertungen

- Devops Training in Bangalore - Devops Training in Bangalore MarathahalliDokument8 SeitenDevops Training in Bangalore - Devops Training in Bangalore MarathahalliitrainNoch keine Bewertungen

- Resume: Advanced Diploma in Power System Engineering Advanced Diploma in EEEDokument2 SeitenResume: Advanced Diploma in Power System Engineering Advanced Diploma in EEEMozahidul IslamNoch keine Bewertungen

- Dilg Joincircular 2018814 - 80736aa36cDokument10 SeitenDilg Joincircular 2018814 - 80736aa36clexay.mangadosiervoNoch keine Bewertungen

- Adaptive Bit LoadingDokument10 SeitenAdaptive Bit LoadingKrrish BommanaNoch keine Bewertungen

- Aht PQDDokument315 SeitenAht PQDsrinivas raoNoch keine Bewertungen

- User Manual SR 9797HDDokument47 SeitenUser Manual SR 9797HDnavamivbNoch keine Bewertungen

- State Bank of India - Recruitment of Probationary Officers PDFDokument2 SeitenState Bank of India - Recruitment of Probationary Officers PDFTapas Kumar NandiNoch keine Bewertungen

- 0111 Tension Load Cell Datasheet enDokument2 Seiten0111 Tension Load Cell Datasheet enJosipaNoch keine Bewertungen

- RO-BL-005-Mech-XII-2022 Desmi Pump Hose Radiator Clamp Hose Rubber Gasket Air Filter Dust Strip Curtain Spark LighterDokument2 SeitenRO-BL-005-Mech-XII-2022 Desmi Pump Hose Radiator Clamp Hose Rubber Gasket Air Filter Dust Strip Curtain Spark LighterIlyas Rangga RamadhanNoch keine Bewertungen

- Caustic Soda Plant 27 000 Tpy 186Dokument1 SeiteCaustic Soda Plant 27 000 Tpy 186Riddhi SavaliyaNoch keine Bewertungen

- 14.H Out of Specification ResultsDokument10 Seiten14.H Out of Specification Resultsعبدالعزيز بدرNoch keine Bewertungen

- Iwss 31 Win en AgDokument237 SeitenIwss 31 Win en AgmarimiteNoch keine Bewertungen

- R6 Relay ValveDokument2 SeitenR6 Relay ValveveereshNoch keine Bewertungen

- Transmission Lines-Basic Principles 01515900Dokument13 SeitenTransmission Lines-Basic Principles 01515900Sachin1091Noch keine Bewertungen

- Master The Five Remote Function CallDokument25 SeitenMaster The Five Remote Function Callntesla2009Noch keine Bewertungen

- DSS2060D Actuated Block Valve DatasheetDokument1 SeiteDSS2060D Actuated Block Valve Datasheetkrishna kumarNoch keine Bewertungen

- 1.4404 enDokument5 Seiten1.4404 enyraju88Noch keine Bewertungen

- The Significance of Andragogy in Present Day Higher EducationDokument5 SeitenThe Significance of Andragogy in Present Day Higher EducationInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Service QualityDokument11 SeitenService QualityMang Abdul RohmatNoch keine Bewertungen