Beruflich Dokumente

Kultur Dokumente

1 s2.0 S0920586113004586 Main PDF

Hochgeladen von

Jenny CórdobaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 S0920586113004586 Main PDF

Hochgeladen von

Jenny CórdobaCopyright:

Verfügbare Formate

Catalysis Today 218219 (2013) 5156

Contents lists available at ScienceDirect

Catalysis Today

j our nal homepage: www. el sevi er . com/ l ocat e/ cat t od

Carbon as a catalyst: Esterication of acetic acid with ethanol

Raquel P. Rocha, Manuel F.R. Pereira, Jos L. Figueiredo

LCM Laboratory of Catalysis and Materials Associate Laboratory LSRE/LCM, Faculdade de Engenharia, Universidade do Porto, Rua Dr. Roberto Frias,

4200-465 Porto, Portugal

a r t i c l e i n f o

Article history:

Received 14 December 2012

Received in revised form27 March 2013

Accepted 29 September 2013

Available online 25 October 2013

Keywords:

Carbon nanotubes

Carbon xerogels

Sulphonic acid groups

Carbon catalyst

Esterication

Acetic acid

a b s t r a c t

Multiwalled carbon nanotubes (CNTs) and carbon xerogels prepared by the solgel process (CXs) were

modied by different chemical and thermal treatments with sulphuric and nitric acid in order to produce

materials with different textural properties and acidic nature. The presence of sulphonic acid groups was

identied by X-ray photoelectron spectroscopy on the sulphuric acid treated samples. Carboxylic acids

and anhydrides, phenol groups, some lactones and carbonyl-quinone groups were incorporated during

the nitric acid treatment, as shown by temperature programmed desorption. Oxidation with nitric acid

affects more the textural properties (the effect is more pronounced in the case of CNTs than in CXs)

promoting an increase of surface area and a decrease of total pore volume, while a decrease of surface area

was observed with the sulphuric acid treatment. The prepared materials were tested in the esterication

of acetic acid with ethanol as a model acid-catalyzed reaction. The rate of formation of ethyl acetate was

found to depend strongly on the chemical properties of the carbon materials, the presence of sulphonic

acid groups being more adequate for this reaction. A good correlation was obtained between the rate of

formation of ethyl acetate and the concentration of sulphonic groups.

2013 Elsevier B.V. All rights reserved.

1. Introduction

The versatility of carbon as a catalyst was recognized long

time ago [1]. In fact, carbon materials can perform well in

reactions which are typically catalyzed by metals (such as dehy-

drogenations), non-stoichiometric oxides (such as oxidations and

reductions) and acids (such as alkylation and dehydration) as dis-

cussed in a recent review [2]. The performance of any catalyst

depends on the availability of suitable active sites, capable of

chemisorbing the reactants and forming surface intermediates of

adequate strength. Therefore, the catalytic properties of carbon

materials are mostly determined by their surface chemistry [3].

The presence of heteroatoms (O, N, H, Cl, S, etc.) bound to the edges

of the graphene layers in the carbon material originates a variety

of surface functional groups. The concentration of these groups can

be further tuned in order to suit specic requirements [2,4]. Acidic

groups include carboxylic acids and anhydrides, lactones or lactols,

and phenols, and can be easily incorporated by oxidative treat-

ments with nitric acid, oxygen peroxide and oxygen [58]. Carbon

materials can also be functionalized with sulphonic acid groups,

providing efcient acid catalysts [913].

Suitable methods of analysis of the carbon functional groups

are now available, including TPD-MS and XPS [4,14]. Therefore, it

Corresponding author. Tel.: +351 225081663.

E-mail address: jlg@fe.up.pt (J.L. Figueiredo).

shouldbe possible tocorrelate the catalytic properties of the carbon

materials withtheir surfacechemistry. However, this is not thegen-

eral case, quantitative relationships being published only in a few

cases [16]. The present work explores the effect of different surface

chemistry of carbon nanotubes and carbon xerogels in the esteri-

cation of acetic acid, as a model acid-catalyzed reaction. Carbon

materials with sulphonic acid groups ( SO

3

H) have been reported

as excellent solid acid catalysts for this reaction [10,12,1517].

2. Experimental

2.1. Materials

Different chemical andthermal treatments wereappliedtomul-

tiwalled carbon nanotubes (CNTs) and carbon xerogels (CXs) in

order to produce materials with different textural and chemical

properties. The pristine CNTs (CNT-O) with an average diameter

of 9.5nm, average length of 1.5mand carbon purity higher than

95% were purchased from NANOCYL

TM

(NC3100 series). The CXs

were produced by polycondensation of resorcinol with formalde-

hyde, adaptingtheproceduredescribedelsewhere[18]. Briey, 25g

of resorcinol were added to 40mL of distilled water under stir-

ring and 34mL of formaldehyde were introduced after complete

dissolution. The pHwas adjustedto6.0(inorder toproduce a meso-

porous structure [18]) by dropwise addition of a sodiumhydroxide

solution. The gelation step was completed after 3 days at 85

C in a

parafn bath. Once nished, the material was dried in an oven from

0920-5861/$ see front matter 2013 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.cattod.2013.09.049

52 R.P. Rocha et al. / Catalysis Today 218219 (2013) 5156

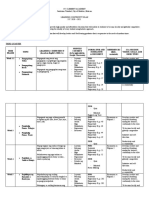

Table 1

Textural properties of the original carbon nanotube and xerogel samples and selected modied samples.

Sample SBET (m

2

g

1

) Vp (cm

3

g

1

) SMeso (m

2

g

1

) V

Micro

(cm

3

g

1

) dp (nm)

CNT-O 302 2.90

CNT-N7 358 1.62

CNT-N10 330 1.32

CNT-Nc 312 0.54

CX-O 672 1.16 244 0.173 17.4

CX-N7 697 1.14 234 0.188 17.5

CX-S1 416 0.95 213 0.084 17.3

CX-S2 528 1.04 222 0.125 17.4

60 to 120

C during 4 days, increasing the temperature 20

C/day.

After drying, the material was further subjected to a carbonization

procedure: using a heating ramp of 2

Cmin

1

under nitrogen ow

(100cm

3

min

1

), the material was heated until 150, 400, 600 and

800

C holding each temperature between 1 and 6h (higher tem-

perature), resulting ina carbonxerogel henceforwardreferredto as

CX-O. Nitric acidoxidationandsulphuric acidtreatments were per-

formed in order to introduce different types and amounts of acidic

functional groups on the surface of the distinct carbon structures.

In a typical liquid-phase oxidation, CNT-O was treated with nitric

acid (ratio 1:75 (w/v)) at boiling temperature during 3h, using dif-

ferent acidconcentrations (7, 10Mandconcentrated). The oxidized

material was washed several times with distilled water until neu-

tral pHwas reachedandnally driedat 110

Cinanovenovernight.

The resulting samples were designated in terms of the nitric acid

concentration as CNT-N7, CNT-N10 and CNT-Nc. The same proce-

dure was repeated using the CX-O sample; however, in this case,

only the 7M solution of nitric acid was tested (CX-N7 sample).

The liquid-phase chemical treatment with concentrated sulphuric

acid (H

2

SO

4

) was performed in a round-bottomask immersed in

a parafn bath at 150

C during 6h. Using the CX-O sample two

treatments were done using different ratios of catalyst weight/acid

volume: 1g:150mL H

2

SO

4

(CX-S1) and 1g:20mL H

2

SO

4

(CX-S2).

The samples were washed withdistilled water until neutral pHwas

reached, and nally dried at 110

C in an oven during the night.

Lastly, one portion of the CX-S1 sample was subjected to a nal

thermal treatment up to 250

C using helium as inert gas (heated

at 10

Cmin

1

; He ow of 25cm

3

min

1

) with the aim of remov-

ing part of the surface groups incorporated during the sulphuric

treatment, sample CX-S1-250. Representative samples of CNTs and

CXs were subjected to a thorough characterization and tested in

the catalytic esterication of acetic acid with ethanol.

2.2. Catalyst characterization

The textural characterization of the carbon materials was based

on the nitrogen adsorption-desorption isotherms. The samples

were pre-degassed at 150

C for 5h and the analysis performed in

a Quantachrome NOVA 4200e multi-station apparatus at 196

C.

Surface areas of the carbon samples were determined according

to the Brunauer, Emmett and Teller (BET) method and the aver-

age mesoporous diameters (d

p

) of the CX samples were obtained

by the method of Barrett, Joyner and Halenda (BJH). The mesopore

surface area (S

meso

), andmicropore volume (V

micro

) were calculated

using t-method, as described elsewhere [4]. The surface chemistry

of the samples was characterized by temperature programmed

desorption (TPD) analysis in a fully automated AMI-300 Catalyst

Characterization apparatus (Altamira Instruments) connected to a

Dycor Dymaxion Mass Spectrometer. The samples (0.100g) were

placed in a U-shaped quartz tube located inside an electrical fur-

nace and heated up to 1100

C at 5

Cmin

1

using a constant ow

rate of helium equal to 25cm

3

min

1

. The CO and CO

2

released

during TPD were monitored, and calibration with the respective

gases was carried out at the end of each analysis. SO and SO

2

signals were also followed in the case of sulphuric-treated sam-

ples. Elemental analysis was performed in a Carlo Erba EA 1108

Elemental Analyser. X-ray photoelectron spectroscopy (XPS) anal-

ysis was performed in a VG Scientic ESCALAB 200A spectrometer

using a non-monochromatized Mg K radiation (1253.6eV), the

binding energies being calibrated with the respect to the C1s peak

at 285.0eV. The characterizationwas completedwiththermogravi-

metric analysis (TGA), by heating the samples at 10

Cmin

1

under

nitrogen ow (50cm

3

min

1

) up to 900

C using a STA 490 PC/4/H

Luxx Netzsch thermal analyzer.

2.3. Experimental procedure

The catalytic activity of the prepared materials was tested on

the esterication of acetic acid with ethanol. The experiments were

carried in a round-bottom ask with necks for sample extraction

and for coupling a condenser, immersed in a parafn bath. 0.1mol

of acetic acid, 1mol of ethanol and 0.20g of catalyst were placed

inside the reactor and nally the temperature was set at 70

C. The

carbon material was recovered at the end of each run for further

characterization, or for reutilization in cyclic experiments. A blank

experiment without catalyst was also performed in the same con-

ditions. For comparison, homogeneous catalysis using H

2

SO

4

as

catalyst was also studied.

2.4. Analytical techniques

Samples periodicallywithdrawnfromthereactor wereanalyzed

by high performance liquid chromatography (HPLC) with a Hitachi

Elite LaChrom system equipped with ultraviolet (=210nm) and

refractive index detectors in series. A Bio-Rad Aminex HPX-87H

column (300mm7.8mm) and a 4mM sulphuric acid solution as

mobile phase (owrate of 0.8mL min

1

) were used.

3. Results and discussion

3.1. Carbon materials characterization

Table 1 summarizes the textural properties of the original and

modied CNT and CX samples determined from the N

2

adsorp-

tion isotherms. In the case of the CNT samples treated with nitric

acid, the differences between the S

BET

surface areas are smaller

than 100m

2

g

1

. However, the total pore volume (V

p

, determined

fromthe N

2

uptake at p/p

0

=0.99) decreases byincreasingthe HNO

3

concentration.

According to IUPAC, the isotherms of the CNT samples (Fig. 1a)

can be classied as type II, characteristic of nonporous materi-

als such as CNTs. On this carbon material, the pore volume is

mostly associated to the free space occurring in CNT bundles [19],

therefore, the decrease of the pore volume could be related to the

combinedeffect of de-agglomerationof CNTs, promotedby the oxi-

dation treatment [20,21], and the incorporation of oxygen surface

groups. On the other hand, the changes in S

BET

may be connected

R.P. Rocha et al. / Catalysis Today 218219 (2013) 5156 53

0.0 0.5 1.0

0

400

800

1200

1600

2000

0.0 0.5 1.00.0 0.5 1.0

CNT-N10 CNT-O CNT-N7

V

a

d

s

(

c

m

3

g

-

1

,

S

T

P

)

a.

p/p

0

0.0 0.5 1.0

0

400

800

1200

0.0 0.5 1.00.0 0.5 1.0

p/p

0

V

a

d

s

(

c

m

3

g

-

1

,

S

T

P

)

b.

CX-S1 CX-N7 CX-O

Fig. 1. N

2

adsorptiondesorption isotherms at 196

C for original and selected

modied carbon samples: (a) CNT samples; (b) CX samples.

to changes in length and perfection of the nanotubes, as a result of

the applied treatments [22] or by opening the tips of the tubes [23].

Regarding the CX samples, they presented type IV isotherms

(Fig. 1b), characteristic of mesoporous solids, with average pore

diameter around 20nm (determined by BJH method). Likewise,

the BET surface of the sample treated with nitric acid increased,

in comparison with the original carbon xerogel, while it decreased

in the case of samples treated with sulphuric acid. On the latter

samples (CX-S1 and CX-S2), both the surface area and the micro-

pore volume decrease, indicating that the sulphuric acid treatment

contributes to reduce the microporosity of the surface, contrary to

what happens with nitric acid [24].

Elemental and XPS analyses were done for selected samples,

mainly in the case of sulphuric acid treated samples, in order to

identifytheamount andthenatureof thesurfacegroups introduced

during the treatment. Table 2 shows the results obtained.

Table 2

Elemental and XPS analyses of original and sulphuric acid treated CX samples.

Sample Elemental analysis XPS

%C %N %H %S %O

a

%C %N %O %S

CX-O 92.4 0.75 0.39 7.23 n.d.

CX-S1 74.7 0.16 1.26 2.10 22.0 79.9% 0.71% 16.2% 3.18%

CX-S2 75.5 0.08 0.89 1.59 22.0 81.0% 0.55% 16.6% 1.89%

CX-S1-250 74.6 0.14 0.28 0.17 24.8 89.4% 0.25% 9.7% 0.60%

a

Oxygen determined by difference; n.d. not determined.

160 164 168 172 176

a.

CX-S1

I

n

t

e

n

s

i

t

y

(

a

.

u

.

)

Binding Energy (eV)

160 164 168 172 176

b.

CX-S2

I

n

t

e

n

s

i

t

y

(

a

.

u

.

)

Binding Energy (eV)

160 164 168 172 176

CX-S1-250

I

n

t

e

n

s

i

t

y

(

a

.

u

.

)

Binding Energy (eV)

c.

Fig. 2. S2p XPS spectra for the sulphuric acid treated carbon xerogel samples.

The CX-S1 sample presented the highest sulphur content

(3.18%), as expected, since it was prepared with a higher ratio of

sulphuric acid (1:150), contrary to the CX-S2 sample that has 1.89%

(ratio of 1:20). The thermally treatedsample, CX-S1-250, presents a

residual amount of sulphur (only 0.60%) which shows that most of

the incorporated S-containing groups are released fromthe surface

of the carbon structure at lowtemperatures (below250

C).

The S2p spectra of CX-S1, CX-S2 and CX-S1-250 samples (Fig. 2)

show a common peak around 169eV which is the BE typically

attributed to sulphonic groups ( SO

3

H) [25,26]. The absence of

other peaks, especially at lower BE, allows to conclude that other

S-containinggroups (suchas the thiol groups, 163eV) are not incor-

porated during the treatment applied [27].

The amounts of CO and CO

2

released during the TPD analyses

(Table 3) indicate that the oxygen content incorporated during

sulphuric acid treatment is much lower than during nitric acid

oxidation, suggesting that the formation of oxygen-containing

functional groups is more favoured by nitric acid oxidation. This

is in agreement with what was demonstrated in a previous work

[28]. Considering samples CNT-N7 and CX-N7, larger amounts of

54 R.P. Rocha et al. / Catalysis Today 218219 (2013) 5156

Table 3

Concentration of the CO and CO

2

groups released during TPD of the carbon mate-

rials subjected to different liquid phase treatments compared with the amount of

volatiles released by TGA.

Sample CO (mol g

1

) CO

2

(mol g

1

) %Volatiles

a

CNT-O 299 105 2.3

CNT-N7 1453 1008 9.3

CNT-Nc 1592 1422 15.7

CX-S1 732 330 16.4

CX-S2 657 191 15.0

CX-N7 2414 1715 35.1

a

Determined by TGA in a dry ash free basis.

CO and CO

2

are released during TPD, indicating that carboxylic

acids and phenol groups, as well as some anhydrides, lactones and

carbonyl-quinones, are incorporated on the surface of the carbon

materials upon nitric acid treatment [2,4]. However, samples con-

tainingsulphonic groups (CX-S1andCX-S2) present lower amounts

of evolved CO and CO

2

, as shown in Table 3. The global amount

of groups incorporated during the distinct treatments can be esti-

mated by the amount of volatiles released during the TGA analyses

(Table 3). Those results show that, in spite of the smaller amounts

of CO and CO

2

releasing groups incorporated with the sulphuric

acid treatment, the sulphonic groups represent a large percentage

(by weight) of the total surface groups.

The MS signal of SO

2

(m/z =64) was followed during the TPD

analyses of the CX-S samples (Fig. 3c). The spectra reveal desorption

of S-containing groups from the surface in a specic temperature

range (200400

C) mainly due to the decomposition of sulphonic

groups intoSO

2

species [29]. Inagreement withtheprevious results

of XPS analyses, the amounts of SO

2

released decrease in the same

order as the S content, as follows: CX-S1, CX-S2 and CX-S1-250.

3.2. Catalytic activity for the esterication of acetic acid

The catalytic activity of the samples was evaluated in the ester-

ication of acetic acid with ethanol, as described above. Under the

operating conditions employed, the homogeneous non-catalytic

reaction can be neglected (Blank). Fig. 4a shows the ethyl acetate

formation during the reaction time using selected samples. The

sample functionalized with sulphuric acid (CX-S1) was the most

active, with a yield of 52% after 6h, followed by the CX-S2 and CNT-

Nc samples. For comparison purposes, the homogeneous catalysis

reaction using H

2

SO

4

was also performed using an amount of acid

density equivalent to that of the CX-S1 sample (1.80mmol g

1

,

determined by titration). However, it should be noted that the acid

density in the case of CX-S1 represents all acidic groups (including

carboxylic acids, that are measurable by the titration technique)

reason why the catalytic performance of the sample is lower than

the homogenous catalyst.

Since acidic groups of different nature were incorporated into

two different types of carbon structures, the samples were divided

in two groups for a better understanding of their catalytic per-

formance: S containing samples (S-samples) (CX-S1, CX-S2, and

CX-S1-250, in decreasing order of the S content) and nitric acid

functionalized samples (CNT-Nc, CX-N7, CNT-N10 and CNT-N7, in

decreasing order of the carboxylic acid groups, released as CO

2

).

Regarding the S-samples, a good correlation is obtained between

the rate of formation of ethyl acetate after 1h and the concentra-

tion of SO

3

H groups determined from XPS data (Fig. 4b). With

respect to the nitric treated samples, the lower rates observed can

be partiallyexplainedbythe lowacidityof the incorporatedgroups.

The catalytic activity relates well with the amount of carboxylic

acids determined by deconvolution of CO

2

spectra during the TPD

analysis, as also shown in Fig. 4b.

A brief comparison with published results shows that the

turnover frequency(TOF) of theCX-S1samplepreparedinthis work

(1.9min

1

) is competitive with similar catalytic performances

published in the literature, as single walled carbon nanotubes

(TOF =1.9min

1

) [12], and with conventional strong solid acid cat-

alysts (such as the protonated Naon resin NR50, TOF =1.5min

1

[15]). Thus, carbon xerogels with a strong acid character can be

used as catalysts for the esterication of acetic acid, and the cat-

alytic activity can be correlated with the amount of the strong

acid sites. This methodology is being extended to other types of

acid-catalyzed reactions.

The catalytic stability of the sample CX-S1 was studied in three

consecutive runs in order to evaluate the catalyst lifetime of the

900 800 700 600 500 400 300 200 100

0.0

0.4

0.8

1.2

CX-N7

a.

[

C

O

]

(

m

o

l

g

-

1

s

-

1

)

Temperature (C)

CX-S1

CNT-N7

900 800 700 600 500 400 300 200 100

0.0

0.4

0.8

1.2

b.

Temperature (C)

[

C

O

2

]

(

m

o

l

g

-

1

s

-

1

)

CX-S1

CNT-N7

CX-N7

900 800 700 600 500 400 300 200 100

0.00E+000

2.00E-008

4.00E-008

6.00E-008

S

O

2

,

M

S

S

i

g

n

a

l

(

t

o

r

r

g

-

1

)

c.

Temperature (C)

CX-S2

CX-S1

Fig. 3. TPD spectra of some CX and CNT samples treated with nitric or sulphuric acid: (a) CO release; (b) CO

2

release; (c) MS signal of groups released as SO

2

(m/z =64).

R.P. Rocha et al. / Catalysis Today 218219 (2013) 5156 55

0 400 800 1200

0.0

0.3

0.6

0.9

1.2

1.5

1.8

2.1

Sulphuric treated samples

Nitric treated samples

(Solid Symbols - CXs)

(Open Symbols - CNTs)

b.

a.

E

t

A

c

F

o

r

m

a

t

i

o

n

(

m

m

o

l

g

-

1

m

i

n

-

1

)

[SO

3

H] or [CarbAcid] (mol g

-1

)

0.0 0.5 1.0 1.5 2.0 2.5 3.0

6 4 2 0

0

25

50

75

100

E

t

h

y

l

A

c

e

t

a

t

e

(

m

m

o

l

)

Time (h)

1st Run

2nd Run

3rd Run

c.

1st Run

2nd Run

Ethyl Acetate Formation (mmol g

-1

min

-1

)

3rd Run

0 2 4 6

0

25

50

75

100

Blank

CX-N7

CNT-Nc

CX-S2

CX-S1

H

2

SO

4

E

t

h

y

l

A

c

e

t

a

t

e

(

m

m

o

l

)

Time (h)

Fig. 4. (a) Ethyl acetate formation during the reaction time (T =70

C; molar ratio:

ethanol/acetic acid=10; 0.2g of catalyst); (b) ethyl acetate formation rate after 1h

usingtreatedCXandCNTsamples as functionof therespectivesurfaceconcentration

of sulphonic/carboxylic acid groups; (c) rate of formation of ethyl acetate using the

CX-S1 sample in the cyclic experiments (inset: Ethyl acetate formation during the

reaction time).

sample, which is an important factor when a newcatalyst is being

tested. Fig. 4c shows the consecutive runs with fresh acetic acid

and with the materials recovered after each run, as well as the

rate of ethyl acetate formation for the rst hour of reaction. In

spite of the high activity shown in the 1st run, the catalytic perfor-

mance of CX-S1 markedly decreases when reused in consecutive

runs, more pronounced from the 1st to the 2nd runs. After the

3rd cycle, the material was characterized by TPD. The amount of

SO

2

released, corresponding to the desorption of sulphonic groups,

had decreased from1623mol g

1

to 1024mol g

1

, which could

explain the decrease in catalytic activity. On the other hand, the

decrease in catalytic performance can also be explained by forma-

tion of sulphonic esters, as reported by Fraile et al. [30]. According

to their work, the formation of sulphonate esters accounts for

the deactivation behaviour in reactions taking place in alcohol

solvents.

4. Conclusions

Oxidation of carbon nanotubes and xerogels with nitric acid

increases their surface acidity, mainly as a result of the carboxylic

acid groups formed. Sulphonic acid groups are incorporated by

treatment with sulphuric acid, the resulting materials showing a

strong acidic character. These carbon materials exhibited excellent

performances as solid acid catalysts in the esterication of acetic

acid. The sulphonic acid groups seemto be more adequate for this

reaction than the oxygen containing groups incorporated by oxi-

dation with nitric acid. A good correlation was obtained between

the rate of formation of ethyl acetate and the concentration of sul-

phonic acid groups in the case of sulphuric acid treated samples.

Acknowledgments

This work was supported by projects: FREECATS nanced by

the European Union 7th FP (2007-2013), Grant No. 280658; PEst-

C/EQB/LA0020/2011 and PTDC/EQU-ERQ/101456/2008, nanced

by FEDER through COMPETE Programa Operacional Factores de

Competitividade and by FCT Fundac o para a Cincia e a Tecnolo-

gia; and NORTE-01-0162-FEDER-000051 (SAIECT-IEC/2/2010).

References

[1] R.W. Coughlin, Carbon as adsorbent and catalyst, Product R&D 8 (1969) 1223.

[2] J.L. Figueiredo, M.F.R. Pereira, The role of surface chemistry in catalysis with

carbons, Catalysis Today 150 (2010) 27.

[3] P. Serp, J.L. Figueiredo, Carbon Materials for Catalysis, John Wiley &Sons, Hobo-

ken, NJ, 2009.

[4] J.L. Figueiredo, M.F.R. Pereira, M.M.A. Freitas, J.J.M. rfo, Modication of the

surface chemistry of activated carbons, Carbon 37 (1999) 13791389.

[5] N. Mahata, M.F.R. Pereira, F. Surez-Garca, A. Martnez-Alonso, J.M.D. Tascn,

J.L. Figueiredo, Tuning of texture and surface chemistry of carbon xerogels,

Journal of Colloid and Interface Science 324 (2008) 150155.

[6] A.G. Gonc alves, J.L. Figueiredo, J.J.M. rfo, M.F.R. Pereira, Inuence of the sur-

face chemistry of multi-walled carbon nanotubes on their activity as ozonation

catalysts, Carbon 48 (2010) 43694381.

[7] Y.-C. Chiang, W.-H. Lin, Y.-C. Chang, The inuence of treatment duration

on multi-walled carbon nanotubes functionalized by H

2

SO

4

/HNO

3

oxidation,

Applied Surface Science 257 (2011) 24012410.

[8] V. Datsyuk, M. Kalyva, K. Papagelis, J. Parthenios, D. Tasis, A. Siokou, I. Kallitsis,

C. Galiotis, Chemical oxidation of multiwalled carbon nanotubes, Carbon 46

(2008) 833840.

[9] H.T. Gomes, S.M. Miranda, M.J. Sampaio, J.L. Figueiredo, A.M.T. Silva, J.L. Faria,

The role of activated carbons functionalized with thiol and sulfonic acid groups

in catalytic wet peroxide oxidation, Applied Catalysis B: Environmental 106

(2011) 390397.

[10] F. Peng, L. Zhang, H. Wang, P. Lv, H. Yu, Sulfonated carbon nanotubes as a strong

protonic acid catalyst, Carbon 43 (2005) 24052408.

[11] R. Liu, X. Wang, X. Zhao, P. Feng, Sulfonated ordered mesoporous carbon for

catalytic preparation of biodiesel, Carbon 46 (2008) 16641669.

[12] H. Yu, Y. Jin, Z. Li, F. Peng, H. Wang, Synthesis and characterization of sulfonated

single-walled carbon nanotubes and their performance as solid acid catalyst,

Journal of Solid State Chemistry 181 (2008) 432438.

[13] H.T. Gomes, S.M. Miranda, M.J. Sampaio, A.M.T. Silva, J.L. Faria, Activated car-

bons treatedwithsulphuric acid: catalysts for catalytic wet peroxide oxidation,

Catalysis Today 151 (2010) 153158.

[14] J.L. Figueiredo, M.F.R. Pereira, M.M.A. Freitas, J.J.M. rfo, Characterization of

active sites on carbon catalysts, Industrial and Engineering Chemistry Research

46 (2007) 41104115.

[15] M. Hara, T. Yoshida, A. Takagaki, T. Takata, J.N. Kondo, S. Hayashi, K. Domen, A

carbon material as a strong protonic acid, Angewandte Chemie International

Edition 43 (2004) 29552958.

[16] M. Okamura, A. Takagaki, M. Toda, J.N. Kondo, K. Domen, T. Tatsumi, M. Hara,

S. Hayashi, Acid-catalyzed reactions on exible polycyclic aromatic carbon in

amorphous carbon, Chemistry of Materials 18 (2006) 30393045.

[17] V.L. Budarin, J.H. Clark, R. Luque, D.J. Macquarrie, Versatile mesoporous car-

bonaceous materials for acid catalysis, Chemical Communications (2007)

634636.

[18] N. Job, R. Pirard, J. Marien, J.-P. Pirard, Porous carbon xerogels with texture

tailored by pH control during solgel process, Carbon 42 (2004) 619628.

[19] R.R.N. Marques, B.F. Machado, J.L. Faria, A.M.T. Silva, Controlled generation of

oxygen functionalities on the surface of single-walled carbon nanotubes by

HNO

3

hydrothermal oxidation, Carbon 48 (2010) 15151523.

[20] I.D. Rosca, F. Watari, M. Uo, T. Akasaka, Oxidation of multiwalled carbon nano-

tubes by nitric acid, Carbon 43 (2005) 31243131.

56 R.P. Rocha et al. / Catalysis Today 218219 (2013) 5156

[21] R.P. Rocha, A.M.T. Silva, G. Dra zi c, M.F.R. Pereira, J.L. Figueiredo, Supported Pt-

particles on multi-walled carbon nanotubes with controlled surface chemistry,

Materials Letters 66 (2012) 6467.

[22] G. Ovejero, J.L. Sotelo, M.D. Romero, A. Rodrguez, M.A. Oca na, G. Rodrguez,

J. Garca, Multiwalled carbon nanotubes for liquid-phase oxidation. Function-

alization, characterization, and catalytic activity, Industrial and Engineering

Chemistry Research 45 (2006) 22062212.

[23] M. Monthioux, B.W. Smith, B. Burteaux, A. Claye, J.E. Fischer, D.E. Luzzi, Sen-

sitivity of single-wall carbon nanotubes to chemical processing: an electron

microscopy investigation, Carbon 39 (2001) 12511272.

[24] A.M.T. Silva, B.F. Machado, J.L. Figueiredo, J.L. Faria, Controlling the surface

chemistry of carbon xerogels using HNO

3

-hydrothermal oxidation, Carbon 47

(2009) 16701679.

[25] E. Cano-Serrano, G. Blanco-Brieva, J.M. Campos-Martin, J.L.G. Fierro, Acid-

functionalized amorphous silica by chemical grafting quantitative oxidation

of thiol groups, Langmuir 19 (2003) 76217627.

[26] J.G.C. Shen, R.G. Herman, K. Klier, Sulfonic acid-functionalized mesoporous sil-

ica: synthesis, characterization, and catalytic reaction of alcohol coupling to

ethers, Journal of Physical Chemistry B 106 (2002) 99759978.

[27] Q. Yang, J. Liu, J. Yang, M.P. Kapoor, S. Inagaki, C. Li, Synthesis, characteriza-

tion, and catalytic activity of sulfonic acid-functionalized periodic mesoporous

organosilicas, Journal of Catalysis 228 (2004) 265272.

[28] R.P. Rocha, J.P.S. Sousa, A.M.T. Silva, M.F.R. Pereira, J.L. Figueiredo, Catalytic

activity and stability of multiwalled carbon nanotubes in catalytic wet air

oxidation of oxalic acid: the role of the basic nature induced by the surface

chemistry, Applied Catalysis B: Environmental 104 (2011) 330336.

[29] A.P. Terzyk, Further insights into the role of carbon surface functionalities in

the mechanism of phenol adsorption, Journal of Colloid and Interface Science

268 (2003) 301329.

[30] J.M. Fraile, E. Garca-Bordej, L. Roldn, Deactivation of sulfonated hydro-

thermal carbons in the presence of alcohols: evidences for sulfonic esters

formation, Journal of Catalysis 289 (2012) 7379.

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 1 s2.0 S0926860X09002981 Main PDFDokument6 Seiten1 s2.0 S0926860X09002981 Main PDFJenny CórdobaNoch keine Bewertungen

- Catalytic Application of Al-MCM-41 in The Esterification of Acetic Acid With Various AlcoholsDokument9 SeitenCatalytic Application of Al-MCM-41 in The Esterification of Acetic Acid With Various AlcoholsJenny CórdobaNoch keine Bewertungen

- Silicotungstic Acid Supported Zirconia: An Effective Catalyst For Esterification ReactionDokument7 SeitenSilicotungstic Acid Supported Zirconia: An Effective Catalyst For Esterification ReactionJenny CórdobaNoch keine Bewertungen

- Problems Analysis and EOS 2011-1Dokument2 SeitenProblems Analysis and EOS 2011-1Jenny CórdobaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cable Subjected To Concentrated Loads CaDokument41 SeitenCable Subjected To Concentrated Loads CaIcy MakerNoch keine Bewertungen

- Basic Rules For Steel ErectionDokument71 SeitenBasic Rules For Steel Erectionfoller2Noch keine Bewertungen

- Development of EIGA Bars For Producing Powder Particles of Ti6Al4V Nanomodified by Gas Atomization (NANOTUN3D European Project)Dokument1 SeiteDevelopment of EIGA Bars For Producing Powder Particles of Ti6Al4V Nanomodified by Gas Atomization (NANOTUN3D European Project)daffaNoch keine Bewertungen

- Cap Bora BrochureDokument8 SeitenCap Bora BrochureMotasim SelićNoch keine Bewertungen

- Lab1 - Kali Linux Overview: 1. ReconnaissanceDokument6 SeitenLab1 - Kali Linux Overview: 1. ReconnaissanceNguyễn Hữu VĩnhNoch keine Bewertungen

- BAGADDokument8 SeitenBAGADMary Ann AbelloNoch keine Bewertungen

- Cost Optimisation of Water Tanks Designed According To The Aci and Euro CodesDokument25 SeitenCost Optimisation of Water Tanks Designed According To The Aci and Euro CodesandysupaNoch keine Bewertungen

- Patient Safety - Examining Every Aspect of Every System To Improve OutcomesDokument3 SeitenPatient Safety - Examining Every Aspect of Every System To Improve OutcomesBeni BolngNoch keine Bewertungen

- Op QuesDokument7 SeitenOp QuessreelakshmiNoch keine Bewertungen

- Hot Mix Asphalt Overlay Splice: (Pavement Termination Detail)Dokument1 SeiteHot Mix Asphalt Overlay Splice: (Pavement Termination Detail)JUAN RULFONoch keine Bewertungen

- Lenovo A516 Maintenance ManualDokument40 SeitenLenovo A516 Maintenance Manualpradipto87Noch keine Bewertungen

- 13-25-551 - 08 - 120121 Compresor Gardern DenverDokument102 Seiten13-25-551 - 08 - 120121 Compresor Gardern DenverArleyTrujillo1224Noch keine Bewertungen

- Boeing, P., Mueller, E., & Sandner, P. (2016)Dokument18 SeitenBoeing, P., Mueller, E., & Sandner, P. (2016)Aby HuzaiNoch keine Bewertungen

- WJ 3 Inch Lift InstallDokument3 SeitenWJ 3 Inch Lift InstallGuilleNoch keine Bewertungen

- Esp32-Wroom-32se Datasheet enDokument26 SeitenEsp32-Wroom-32se Datasheet enWesllen Dias SouzaNoch keine Bewertungen

- Disclaimer of Interest Form PDFDokument2 SeitenDisclaimer of Interest Form PDFSpiritually GiftedNoch keine Bewertungen

- Agesitab OP850: Electronic Operating TableDokument4 SeitenAgesitab OP850: Electronic Operating TableMuhammad NaomanNoch keine Bewertungen

- DR Draw Users Guide 0384Dokument224 SeitenDR Draw Users Guide 0384gottes villainNoch keine Bewertungen

- Esr 2653Dokument9 SeitenEsr 2653Uğur ErdoğanNoch keine Bewertungen

- Approach SlabDokument2 SeitenApproach SlabMahmood Mufti100% (1)

- Paediatrica Indonesiana: Ari Kurniasih, Guslihan Dasa Tjipta, Muhammad Ali, Emil Azlin, Pertin SianturiDokument6 SeitenPaediatrica Indonesiana: Ari Kurniasih, Guslihan Dasa Tjipta, Muhammad Ali, Emil Azlin, Pertin SianturiHarry FebryantoNoch keine Bewertungen

- The Story of MacroeconomicsDokument32 SeitenThe Story of MacroeconomicsMohammadTabbalNoch keine Bewertungen

- FILIPINO 2 LEARNING PLAN 3rd QuarterDokument4 SeitenFILIPINO 2 LEARNING PLAN 3rd QuarterMary Kryss DG SangleNoch keine Bewertungen

- MCT Grade 5 LANGUAGE ARTS 2017 (1)Dokument16 SeitenMCT Grade 5 LANGUAGE ARTS 2017 (1)Boppy VevoNoch keine Bewertungen

- BryophytesDokument18 SeitenBryophytesDiego Andres Moreno GaonaNoch keine Bewertungen

- Minimum Drag Velocity ExplainedDokument4 SeitenMinimum Drag Velocity ExplainedpersesutiNoch keine Bewertungen

- E 1340 - 96 - Rteznda - PDFDokument12 SeitenE 1340 - 96 - Rteznda - PDFsandeepNoch keine Bewertungen

- Chapter 2 - Writing Business MessagesDokument60 SeitenChapter 2 - Writing Business MessagesrenNoch keine Bewertungen

- Tutorial Collection SimpleDokument11 SeitenTutorial Collection SimplerallupymeyraldoNoch keine Bewertungen

- SikaWrap®-900 CDokument4 SeitenSikaWrap®-900 CN.J. PatelNoch keine Bewertungen