Beruflich Dokumente

Kultur Dokumente

1 s2.0 026378639390047Q Main - 2 PDF

Hochgeladen von

safrancooolOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 026378639390047Q Main - 2 PDF

Hochgeladen von

safrancooolCopyright:

Verfügbare Formate

Dealing with delay claims:

a survey

S Scott

A survey was conducted in which interviews were

carried out with contractors and supervising engineers

to identify the extent to which claims for delay occur on

major contracts, and also to discover how such claims

are prepared and assessed. It appears from the survey

that claims for extensions of time occur on the majority

of major civil-engineering contracts, although acceleration

claims occur much less frequently. The main part of the

survey addressed the means by which contractors attempt

to justify their claims, and the methods of assessment

of these claims used by supervising engineers. This was

approached in a number of ways, and the paper presents

conclusions concerning attitudes towards such claims,

and also the mechanisms which are used to prepare and

evaluate them.

Keywords: delay claims, extensions of time, critical-path

method

Claims are generally considered to be an inevitable

feature of major projects that has to be dealt with on the

majority of contracts let. The project designer's accepted

inability to provide fully for all eventualities means that

changes are made to the contract as it proceeds, and,

where these involve additional work, adjusted payments

are necessary. Disagreements on the level of these pay-

ments are a typical source of claims. As well as causing

changes to the payments made, these variations

also often result in delays to the works. Where these

delays have a knock-on effect on the project as a whole,

they may give rise to extra costs resulting from the

contractor's prolonged presence on site, whereby he/

she incurs additional overhead costs for the extended

period. Not all delays stem from such changes, and it is

generally recognized that delays may be attributed to the

employer/owner, to the contractor, or to neither party.

The contract normally specifies a predetermined time

after which it must be substantially completed and avail-

able for use. In the absence of delays, failure to complete

substantially within this timeframe often means that

liquidated damages are deducted from the contractor.

These are at the level defined in the contract, and are

payable for the period by which the whole project is

delayed. Such damages should aim to compensate the

employer/owner for any lost profits or lost benefits stem-

ming from his/her inability to make use of the project at

the agreed date. Clearly, where delays have occurred dur-

ing the project which can be attributed to the employer/

owner and have delayed the contractor, these should be

taken into account before such damages are deducted.

The opportunities available in many contract conditions

to recognize a contractor' s right to have the time for the

completion of the contract extended reflect this accep-

tance of the more likely state of affairs.

By no means all of the changes to a contract delay the

project. Some involve changes in detail that merely affect

the nature of the work to be done without increasing its

difficulty, requirement for resources or duration. Other

changes actually reduce the work to be carried out. There

are typically, however, changes that do delay, increase

the duration of, or force a change in the sequence of, the

activities that make up the contractor' s programme. The

impact of such amendments on the total project time

cannot be easily predicted at the time at which the events

occur, and consideration must also be given to delays for

which the employer/owner is not responsible.

Delays to parts of the contractor's programme (which

may not necessarily cause delays in the project as a whole,

simply using up available float time) are most helpfully

categorized as those for which

the employer/owner or his/her supervising engineer is

responsible (E),

the contractor is responsible (C),

neither party to the contract is responsible (N).

Department of Civil Engineering, Cassie Building, University of

Newcastle upon Tyne, Newcastle upon Tyne NEI 7RU, UK

In the US literature, these are usually called compensable

(E), nonexcusable (C) and excusable (N), and some of

Vol 11 No 3 August 1993 0263-7863/93/030143-11 1993 Butterworth-Heinemann Ltd 143

Dealing with delay claims: a survey

the main reasons for del ay encount ered under these

subdivisions are, respectively,

changes to the contract document s, failure to provi de

land or information wi t hi n a reasonabl e time, and

failure to approve the cont r act or ' s met hod of worki ng

expeditiously,

inadequate supervision and technical support , late

agreements with subcontractors/suppliers, insufficient

labour/plant,

strikes, riots and exceptional adverse weather.

There appears to be a general consensus as to the rights

to additional time and payment for such delays (where

warranted) in all the cont ract forms encount ered by the

author. These are as follows:

Del ay type E: Award: ext ensi on of time plus ext ended

overhead costs.

Del ay type C: Award: no compensat i on.

Del ay type N: Award: extension of time wi t hout

extended overhead costs.

It should be stressed t hat it is dangerous t o generalize

on cont ract ual matters. For any part i cul ar cont ract , it

is the actual conditions used t hat must be consul t ed to

ascertain the liability for the delays. However, provi di ng

this is underst ood, this met hod of representing the

situation is a useful one.

A realistic delay-claim scenario on a complex project

may well cont ai n a number of delays of each of

these three types, affecting different activities in the

programme at different times. It is also quite likely t hat

a request for an extension of the cont ract time for

completion may be made part of the way t hr ough the

contract. Where the cont r act or has al ready requested

such an extension, and this has been t urned down, he/she

may now say that, as a result of this, he/she is havi ng t o

accelerate to complete on time. The supervising engineer

must consider the cont ract or' s claim in all its complexity,

and, depending on the t ype of claim, make a decision as

to whether an extension of the cont ract time shoul d be

given, or whether the cont r act or has had to accelerate,

and should be recompensed for any addi t i onal costs.

These are particularly difficult si t uat i ons to comprehend

fully and to make j udgment s on, and, in the UK in

particular, there is little gui dance t o assist in the process.

The aim of the survey was to at t empt to underst and how

professionals act ual l y deal with these si t uat i ons in the

absence of such guidance.

MAI N S URVEY

The survey was carried out in organi zat i ons operat i ng

as supervising engineers and cont ract ors on maj or con-

struction projects in the UK. Because of the complexity

of the area studied, it was consi dered to be not feasible

to use a mai l shot approach, and, instead, interviews were

held t hat were based on questionnaires. The question-

naires were piloted by carryi ng out interviews prior to

the mai n survey, and were edited to t ake account of the

findings from these interviews. Two questionnaires were

used: one for the supervising engineers, and one for the

contractors. In some questions, the responses were further

subdi vi ded i nt o the supervising engineer (engineer) and

his/her representative on site (RE), and the cont ract or' s

mai n engineer (agent), and his/her financial assistant

(QS).

The response rate for the mai n survey was 45%, and

this generat ed 22 interviews. Of these, 11 were conducted

with organizations t hat fulfilled the supervising engineer's

role, and 11 with cont ract ors. Some of the companies

appr oached did not respond at all, even after a reminder

was sent out , and one firm replied t hat it would not

become involved as it was its ' . . . policy not to discuss

commerci al mat t ers outside our own organization' .

Despite this viewpoint, which may have been the basis

for a number of nonresponses, those who did take part

did so enthusiastically. The interviews typically t ook 2 h

each to complete, and were conduct ed in the offices and

site hut s of the respondents.

The findings from these interviews clearly relate most

directly to the UK const ruct i on industry, but, because

of the similarities f ound in this area between the contract

condi t i ons used in the UK and those used in other

countries, it is believed t hat t hey have a wider relevance.

It is, however, recognized that more sophisticated systems

for deal i ng with del ay claims exist in the USA, and, for

US readers, it may be interesting to compare the two

approaches.

MAI N F I NDI NGS

For clarity, all the interviews conduct ed with the

quest i onnai re prepared for organi zat i ons fulfilling the

supervising-engineer role (i.e. local authorities and con-

suiting engineers) are referred to as engineer interviews.

Those carried out using the quest i onnai re designed for

cont ract ors are referred to as contractor interviews. The

findings are best considered under the headings (a) delay

claims: frequency of occurrence and award, (b) prep-

arat i on/ assessment of claims.

Delay claims: frequency of occurrence and award

The mai n quest i ons in this section follow a simple

pat t ern. Fi rst , the frequency of the extension of time

claims is addressed; this is t hen followed by questions

to det ermi ne the ext ent of awards for such claims. This

procedure is t hen repeated with acceleration claims.

The quant i t at i ve i nf or mat i on t hat resulted from these

questions is present ed in Table 1, and it is discussed in

detail below.

In trying to identify the frequency with which extension

of time claims are made, it was felt necessary to stipulate

t hat such claims shoul d only be recognized i f t hey are

submitted with supporting evidence. Often, letters are sent

by the cont r act or t hat state t hat an extension of time

may be needed as a result of some delay caused by the

empl oyer or supervising engineer, but t hat never act ual l y

lead to a claim. Instances such as these are not considered

to be real claims, and the use of the phrase ' . . . with

support i ng evidence' was i nt ended to make this clear t o

respondents. To elicit sensible i nformat i on regarding the

frequency of ext ensi on of time claims, two questions

were used. These were as follows:

144 I nt er nat i onal Journal of Project Management

S SCOTT

Ta b l e 1. Delay cl ai ms: f requency of oc c ur r e nc e and a wa r d

Short description of question Average responses

Engineer Cont r act or

Percentage of contracts on which extension-of-time claims wi t h support i ng

evidence are submitted 60 70

On these contracts, average number of extension-of-time claims made Two, may be rolled i nt o One claim, delays lumped

one claim t oget her

Percentage of extension-of-time claims made wi t hout subsequent at t empt

to recover overheads 10% or less Very few

How often extension-of-time claims granted: Time, % Cost, % Time, % Cost, %

In full 13 6 10 0

In part 71 76 70 95

How often are acceleration claims with support i ng evidence presented? Rare 26%

How often are such claims granted? Mor e t han 50% 70%

How frequently, if ever, are liquidated damages deducted? Rare Rare

Please state on what percentage of cont r act s ext ensi on

of time claims with supporting evi dence are submi t t ed.

On these cont ract s, what is t he aver age number of

ext ensi on of time claims made?

For the first question, most responses f r om bot h engineers

and cont r act or s indicated a figure of 50% or mor e, and,

f r om Tabl e 1, it can be seen t hat t he aver age per cent age

was 60% and 70%, respectively. On t he second quest i on,

bot h cont r act or s and engineers said t hat di fferent causes

of del ay were oft en lumped t oget her i nt o one claim,

al t hough the engineers also gave an average figure of t wo

causes of claim per cont ract .

To identify t he frequency wi t h whi ch claims are

paid, t wo quest i ons were again used. The first quest i on

addresses the possibility t hat some ext ensi on of t i me

claims may be submitted without any subsequent at t empt

to recover overheads, t hat is, t hat t he cont r act or request s

an ext ensi on of t i me purel y to del ay t he poi nt at whi ch

l i qui dat ed damages may be deduct ed. Thi s quest i on was

phr ased as follows:

Do you ever submi t claims for ext ensi on of time onl y,

i.e. wi t hout t hen or l at er following up wi t h a cl ai m f or

over head costs?

Responses f r om bot h engineers and cont r act or s were

in agr eement in recordi ng t hat this si t uat i on occurs at

best i nfrequent l y. Cont r act or s al most al ways back up

these claims with a request f or t he cost of financing t he

ext ensi on claimed. Gi ven t hat t he claims general l y

consi st of t wo elements: a claim f or t i me and a cl ai m

f or over head costs, the second quest i on was f r amed t o

i dent i fy t he ext ent t o whi ch these were accept ed. The

quest i on was as follows:

Of t he claims f or ext ensi on of t i me and over head cost s

submi t t ed with suppor t i ng evidence, how of t en are these

grant ed:

t i me cost s

in full

in par t

The average figures quot ed by bot h engi neers and

cont r act or s on this quest i on were fairly consistent. I t

appear s t hat the l i kel i hood t hat all t he cost s cited in such

claims will be pai d is ver y small ( 0- 6%) . The l i kel i hood

t hat all t he time demanded will be awar ded is slightly

higher, but is still onl y in t he r ange 10- 13%. Part i al

payment , or the accept ance of a ri ght t o an extension,

was set much hi gher t han this, wi t h figures of 70- 95%.

It seems t hat most claims t hat are t aken seriously by

the cont r act or and submi t t ed wi t h backup are likely t o

succeed, at least in part .

How oft en are accel er at i on claims wi t h suppor t i ng

evidence present ed?

Thi s quest i on pr oduced a numbe r of comment s, mai nl y

f r om cont r act or s. These were as follows:

' Accel erat i on claims are mai nl y t he resul t of liability

l at er accept ed by t he supervi si ng engi neer' (i.e. an

initial claim f or an ext ensi on of t i me is refused, and

accept ed at a l at er dat e, by whi ch t i me t he cont r act or

has accel erat ed hi s/ her wor k) .

' We don' t vol unt ari l y accelerate even t hough instructed

t o do so by the supervi si ng engi neer ( most cont r act or s

i gnore such i nst ruct i ons) - - we onl y vol unt ar i l y

accel erat e i f it is our own pr obl em' .

' The as-built pr ogr amme is t he accelerated programme;

t he supervising engi neer coul d i nst ruct accel erat i on' .

The onl y comment made in an engi neer' s interview

was t hat it woul d be necessary t o change the name of

the cl ai m t o a di sr upt i on cl ai m f or the supervising

engi neer t o pay it. Ther e appear s t o be some uncer t ai nt y

as t o the gr ound rules f or such claims, and this is

possibly a result of t he fact t hat t hey may be qui t e rare.

Indeed, t hat is what t he maj or i t y of t he engi neers said

in answer t o this quest i on. The cont r act or s' responses

pr oduced a mean val ue of 26%. Coul d t here be some

di sagreement as t o exact l y what const i t ut es an acceler-

at i on claim in the mi nds of supervising engineers and

cont r act or s?

When asked t o say how of t en accel erat i on claims are

grant ed, most r espondent s relied on experi ence of a ver y

few such claims, and some had never been i nvol ved in

one. The general feeling was t hat t hese claims woul d be

grant ed in most cases. One engi neer r espondent said t hat

t he cont r act or woul d not submi t such a claim unless he/

she had a good case. He/ she woul d find some al t ernat i ve

met hod of claiming.

Vol 11 No 3 August 1993 145

Dealing with delay claims: a survey

If the contractor on a project fails to complete within

the original or extended time for completion, the

employer typically has the right to deduct liquidated

damages for each day/week for which the project is late.

Such damages are usually written into a construction

contract, but it is not generally known to what extent

this right is ever invoked. A question put to both

engineers and contractors to determine this information

met with a similar response. The question was as follows.

How frequently, if ever, are liquidated damages deducted?

Some interviewees had never had any experience of

liquidated damages being deducted, but others confirmed

that it did happen, albeit very rarely. In all but one

instance, figures quoted to define the frequency of deduc-

tion were 10% or lower. It is not surprising, then, that

some sections of the industry are under the impression

that these damages are never collected.

Preparation/assessment of cl ai ms

A review of the literature of this area of contract

administration shows that much of what has been

written concerns the difficulty of assessing a contractor' s

claims for delay and disruption. In the USA, an under-

standing has developed of a generalized approach to

dealing with such problems, as reported by Wickwire

and Smith ~, but there appears to be no comparable

approach in the UK that is detailed in UK texts. The US

approach involves the preparation of full 'as-built' records

of exactly when the various activities in the project took

place, and when delays were effective. From this inform-

ation, a judgment is made on the right to extensions of

time by pulling out the delays for which the employer

is responsible, and assessing how long the contractor

would have taken to complete the job in the absence of

these delays.

Under the UK Institution of Civil Engineers Condi-

tions of Contract 2 regarding claims for extensions of

time, the supervising engineer is required to ' . . . make

an assessment of the extension of time (if any) to which

he considers the contractor entitled for the completion

of the works. . . ' . He/she must do this in a fair manner.

Exactly how this is to be done, however, is left to the

supervising engineer to decide. Texts relating to the UK

experience suggest that the application of the critical-

path method makes for a more just solution, but they

usually only give very simplistic examples to back this

u p .

The supervising engineer thus has little supporting

material to guide him/her in his/her deliberations on

such problems. In the absence of any substantial legal

precedent or recognized procedures, it is suggested that

the views of other professionals working in this field may

be the most useful guide that can be provided here. With

this in mind, those questions addressed to both con-

tractors and engineers specifically concerning the prep-

aration and assessment of claims are analysed. If general

areas of common agreement between these two main

parties can be recognized and accepted, this may help to

simplify the deliberations on some of these complicated

claims situations that have been found to occur so

frequently.

Tabl e 2. Assessment o f claims: general principles

Deci si on Engi neer Cont r a c t or

All Engi neer RE All Agent QS

There is no point in maki ng a claim f o r ext ended overhead costs unless

the time f o r completion is likely to be exceeded

Agr ee

Di sagr ee 11 7 4 11 5 6

Ot her

I f the contract programme (clause 14) shows completion in 18 months,

and the contractor actually completes in 18 months, no extended overhead

costs can ever be j ust i f i ed

Agr ee 2 1 I

Di sagr ee 8 5 3 11 5 6

Ot her 1 1

I f the engineer awards an extension o f time without costs f o r a delay

at t ri but ed to exceptional adverse weather, this prevents the contractor

f r o m j ust i f yi ng an extension o f time w#h recovery o f overhead costs f or

the same period

Agr ee 4 3 1 2 2

Di sagr ee 6 3 3 9 5 4

Ot her 1 1

Providing the engineer never actually instructs the contractor to accelerate,

no acceleration claim can be j ust i f i ed

Agr ee 3 3 3 2 1

Di sagr ee 7 4 3 7 2 5

Ot her I 1 1 1

General principles

As a first and rather crude attempt to determine attitudes

in this area, four statements were presented to the inter-

viewees. They were asked to say whether they agreed or

disagreed with the statements, and invited to comment

as they wished. The statements were selected, in part

to check whether certain principles discussed and

pronounced on in the literature were generally accepted

by the profession, but also to test out attitudes on

matters that have not been so widely considered. The

aim here, as in other parts of this section, is not only to

record and analyse decisions, but also to try to ascertain

on what basis such decisions are made. The results and

comments made on each statement are considered in

turn, and, to assist this process, the statements and

results have been tabulated in Table 2.

The first question suggests that a claim for extended

overhead costs should not succeed unless the time for

completion is likely to be exceeded. Opposing viewpoints

may be found in the literature. Support for the view

is recorded by Powell-Smith and Stephenson 3, although

the view is rejected by Abrahamson 4. The interviewees,

both engineers and contractors, were unequivocal in their

disagreement with this statement. Only two comments

were made: one by an engineer, who stated that a con-

tractor may be due an extension of time even if he/she

can still finish on time, and the other by a contractor,

stating that the time for completion affects only liquidated

damages. Whatever the views of writers and commenta-

tors on this issue, the industry appears to be quite clear

as to its opinion.

In the second statement, if a contractor's programme

shows completion in 18 months, and he/she actually com-

pletes in that time, the statement says that no extended

overhead costs can ever be justified. The supposition

behind this statement is that, having expected to pay

146 International Journal of Project Management

S SCOTT

overheads for the 18-month period, even if he/she could

have completed in (say) 16 months, but was delayed by

two months by the employer, the contractor has suffered

no loss. He/she has only had to pay overheads for the

time he/she expected to have to pay them. All the con-

tractor responses disagreed with this view. This might

have been expected, but a majority of the engineer

responses were against it too. Some of the comments

made show that some respondents would have con-

sidered not extended overhead costs, but additional

overhead costs for the 18-month period occasioned by

any additional work instructed by the supervising engin-

eer. There still, however, seems to be a general distrust

of the logic supporting this statement. A similar scenario

is shown in Figure 1.

The suggestion contained in the third statement

resulted from a discussion with a resident supervising

engineer during a visit to one of the sites on which the

preparatory work for the questionnaires was being con-

ducted. He related that, in the past, he had been involved

in a contract on which the supervising engineer had taken

the initiative to award an extension of time without costs

as a result of exceptionally adverse weather. This had

been done specifically to prevent the contractor from

claiming an extension of time with costs for some cause

that was the employer's responsibility. Irrespective of the

rights or wrongs of such action, this situation raises the

general issue of alternative critical paths and parallel

delays, and, for this reason, was felt to be worthy of

inclusion. Among the engineers, 60% disagreed, and

made comments suggesting that this would be somehow

underhand, while 40% agreed, some of these believing

that the contractor would find another way to recover

his/her costs. The contractors were much more strongly

opposed to this statement, with 82% disagreeing, and

only 18% agreeing. The comments made, however, did

not particularly attempt to disprove the statement, but

were general accounts of views on dealing with weather

in claims situations. Although the question is a rather

complex one, it was surprising that none of the com-

ments anticipated the possibility that a further extension

of time beyond the first might be awarded, this time with

costs. Also, the chance that another parallel path through

the network, much delayed by the employer, might super-

sede the impact of the path on which the weather delay

occurred was not considered. Is it possible that delays

to the contract are not seen, or perhaps not considered,

in this way?

The final question concerns acceleration claims, and

states that, providing the supervising engineer never

actually instructs the contractor to accelerate, no acceler-

ation claim can be justified. The responses from both

contractors and engineers were identical, with 70% of

the responses disagreeing with the statement, and 30%

agreeing. The comments showed a recognition by the

majority of the possibility of what is sometimes known

as 'constructive acceleration'. That is, if the supervising

engineer fails to award a properly deserved extension of

time during the period of the works, the contractor speeds

up to complete within the original time for completion,

and the supervising engineer later decides that the

extension should actually be awarded. In such a case, the

contractor has no need for the late extension, but may

have suffered additional costs as a result of having to

complete work at a faster rate than was reasonable. Such

costs should be recoverable by the contractor because

he/she had to accelerate, even though no specific order

to accelerate was given. This is a generally recognized

scenario, and perhaps the reason for a number of the

respondents not identifying it results from the fact that

so few acceleration claims are made.

Specific eases

As an alternative means of shedding light on the way in

which professionals in the industry consider delay claims,

it was decided to try to describe fully some particular

outcomes of contracts, and to ask the respondents to

recommend solutions. This was the approach used in

both questions in this section, although different methods

were used. In the first question, the whole scenario was

described in words, while in the second question, four

diagrams were drawn to chronicle the outcomes of four

contracts.

In the first question, the interviewee was asked to

make a decision on extension-of-time matters part of the

way through a contract on the basis of the following

statement.

Six months into the contract, it is clear that the employer

has delayed a part of the works in such a way that the

whole of the contract will be delayed by two months. The

time for completion is 24 months, and the contractor's

original programme showed completion in 20 months.

What should the contractor do?

78% of the engineers said that the contractor should

request an extension of time, and the rest said that he/she

should claim for a delay with costs. Of the contractor

responses, 60% said that the contractor should claim for

an extension of time, and 40% said that he/she should

claim for delay, and not an extension of time.

It is clear from the figures that, at the point of

consideration, no extension of time is needed. However,

if the contractor were to allow his/her programme to slip,

or further delays occurred, the situation would change.

An extension of time might then be necessary to defray

the deduction of liquidated damages. This fact was clearly

understood by the respondents, some of whom added

very interesting comments, as follows:

'Claim extension of time - - 20 months is the new time

for completion (we allow the contractor to decide the

time for completion)' (engineer).

'Ask for extension of time (some contractors make a

statement on their programme pointing to the time

between their early completion and the contract time

for completion and stating this to be a 'period for use

by the contractor for circumstances other than entitle-

ment to extension of time')' (engineer).

In assessing the effects of a delay part of the way through

a contract, the supervising engineer must attempt to

predict how the contract will proceed in the future. For

some delays, where (say) the whole site is brought to a

standstill as a result of the employer's actions, the effect

on the completion of the whole project is undeniable.

However, if the delay is not so wide-ranging, and yet, at

the time, it appears that it will necessarily delay the whole

Vol 11 No 3 August 1993 147

Dealing with delay claims: a survey

project, a later assessment mi ght pr ove t hat anot her pat h

t hr ough the net work has become critical. Thi s second

pat h might then cont rol t he compl et i on of t he proj ect ,

and mi ght onl y contain within it del ays f or whi ch the

cont r act or is responsible. In such a si t uat i on, awar di ng

an extension of time, r at her t han si mpl y recogni zi ng a

delay for which the employer is responsible and t hat coul d

lead to an extension of time, mi ght lose t he empl oyer the

right to deduct liquidated damages. The r ecogni t i on of

a fundament al delay to the proj ect r at her t han the award-

ing of an extension of time, however , was not f avour ed

by most supervising engineers. It appears t hat such delays

t end to be closely linked t o ideas of ext ensi ons of time.

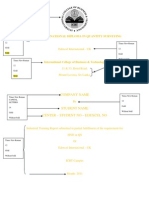

In the second question, t he i nt ent i on was t o illustrate

a few simple yet interesting scenari os t hat mi ght have

to be dealt with in claims si t uat i ons. Ti me-scal ed CPM

diagrams were used f or this pur pose. Al t hough the

simplest cases were chosen, it was still f ound necessary

to clarify a number of points. Fo r this reason, a checklist

was devel oped to help expl ai n t he di agr ams bef or e t hey

were shown to the interviewee. The poi nt s on the checklist

were as follows:

For each case, two di agrams are shown: one showi ng

the cont ract or' s original pr ogr amme (planned), and one

showing the actual ' as-bui l t ' r ecor d of wor k (actual).

The diagrams use time-scaled act i vi t y-on-arrow format ,

in which the following symbol s are used. A rect angl e

with r ounded ends or a circle represent an event. A

double arrow indicates a critical activity, a single arrow

an activity, and a dot t ed line a float. A rect angl e with

a C over it means a del ay t hat is t he cont r act or ' s

responsibility, an E one t hat is t he empl oyer ' s respon-

sibility, and an N one t hat is t he responsi bi l i t y of

nei t her part y.

It is assumed t hroughout t hat t he existence of one delay

has not affected the dur at i on or t i mi ng of subsequent

delays. For instance, i f t he const r uct i on site is not

available at the st art of t he works, any cont r act or

del ay may be a result of t he cont r act or hol di ng back

his preparat i ons. Such effects are assumed not t o have

occurred.

It is t o be assumed t hat no accel erat i on has t aken

place.

In each case, the i nt ervi ewee' s views are sought on

the cont r act or ' s rights t o an ext ensi on of time, the

recovery of overhead costs, and t he empl oyer ' s rights

to deduct l i qui dat ed damages.

The actual di agrams used dur i ng the interviews were

A3-sized. These are shown in Fi gures 1-4. Summari es of

the results are given in Tabl es 3-6.

In Fi gure 1, the time f or compl et i on is f our weeks,

the cont r act or ' s pr ogr amme shows hi m finishing in f our

weeks, and he actually finishes in f our weeks, even t hough

the empl oyer has del ayed hi m f or one week. Ther e is

clearly no need for any l i qui dat ed damages t o be de-

duct ed, and all the r espondent s agreed on this. Al t hough

no ext ensi on of time is requi red t o def r ay t he deduct i on

of damages, al most 50% of t he engineers and 40% of

t he cont r act or s felt t hat one shoul d be awarded. As t o

whet her over head costs shoul d be pai d t o t he cont r act or ,

maj ori t i es of bot h t he engi neers and t he cont r act or s

f avour ed payi ng over head costs f or one week.

Time f or completion

t " 1

( >

2 5 4

; < )

Weeks

a

E

( ) o ;.

b

Figure 1. Delay-claim scenario I; (a) planned, Co)actual

[(a) The whol e pr oj ect consi st s o f one act i vi t y a. (b) At t he end o f the

second week, wor k is s us pended for one week (empl oyer-responsi bl e

del ay), but t he c ont r a c t or still compl et es on time.]

Thi s case has paral l el s with bot h the second st at ement

in t he first section, and wi t h the first quest i on in this

section. In t he second st at ement , even t hough the

cont r act or had al l owed f or t he amount of overheads t hat

Time f or completion )

0 2

( )

4 Weeks

( )

a

b

Figure 2. Delay-claim scenario 2; (a) planned, (b) actual

[(a) The whole project consists of one activity a. (b) Work cannot start

until the end of the second week when the site becomes available.

However, the contractor is not ready to start until the end of the first

week. The project is completed two weeks late.]

)

148 I nt er nat i onal J our nal of Proj ect Management

o 2

T i me f or completion

C

b

3

f - -

Wee ks

5

a

T

b

Figure 3. Delay-claim scenario 3; (a) planned, (b) actual

[(a) The whole project consists of two activities a and b t hat can

proceed simultaneously. When they are bot h complete, the project is

complete. (b) Delays due t o the employer (E) and t he cont ract or (C)

result in the project being completed two weeks late.]

S SCOTT

i T i me f or completion >~

0 I 2 3 4

8

Wee ks

5

J~ C

I

>

Figure 4. Delay-claim scenario 4; (a) planned, (b) actual

[(a) The whole project consists of two activities a and b t hat can

proceed simultaneously. When they are bot h complete, the project is

complete. (b) Delays due t o t he cont r act or (C) and to neither part y (N)

result in the project being completed two weeks late.]

Table 3. Results for delay-claim scenario 1

Number

of weeks Engineers Cont ract ors

All Engineers RE All Agent QS

Liquidated 0 11 7 4 11 5 6

damages 1

2

Extension 0 6 3 3 6 3 3

of time 1 5 4 1 4 2 2

2

Recovery 0 3 2 1 2 2

of overheads 1 8 5 3 9 5 4

2

Tabl e 5. Results for delay-claim scenario 3

Number

of weeks Engineers Cont ract ors

All Engineers RE All Agent QS

Li qui dat ed 0 I 1 7 4 11 5 6

damages 1

2

Extension 0

of time 1 1 1 I 1

2 10 6 4 10 5 5

Recovery 0

of overheads 1 3 2 1 1 1

2 6 3 3 8 5 3

Table 6. Results for delay-claim scenario 4

Number

of weeks Engineers Cont ract ors

All Engineers RE All Agent QS

Table 4. Results for delay-claim scenario 2

Number

of weeks Engineers Cont ract ors

All Engineers RE All Agent QS

Liquidated 0 10 7 3 10 5 5

damages 1 1 1 1 1

2

Extension 0

of time 1 4 2 2 2 2

2 7 5 2 9 5 4

Recovery 0

of overheads 1 8 6 2 5 2 3

2 3 1 2 6 3 3

Liquidated 0 l 1

damages 1 8 6 2 8 4 4

2 3 1 2 2 2

Extension 0 2 2 3 1 2

of time 1 9 7 2 8 4 4

2

Recovery 0 9 6 3 11 5 6

of overheads 1 2 1 I

2

Vo l 11 No 3 Au g u s t 1993 149

Dealing with delay claims: a survey

he/she eventually had to pay, the consensus seemed to be

t hat he/she ought to be rei mbursed the overheads for

any time for which the empl oyer had delayed hi m/ her.

This result is repeated here. In the first quest i on in this

section, most respondents felt t hat an extension of time

should be awarded, rat her t han simply a delay being

recognized for which the empl oyer was responsible. In

somewhat similar circumstances, but where there was

obviously no need for an extension of time, a number

of interviewees still want ed one to be awarded. There

appears to be a linkage in many of the respondent s'

minds between such delays and extensions of time. This

ignores any possibility t hat overheads may be recovered

wi t hout such an extension.

The remaining di agrams show a variety of ways in

which overlapping delays mi ght affect a project' s out-

come. The first of these, shown in Fi gure 2, cont ai ns

two delays of types E and C t hat bot h affect a single

activity a. Al most all of t hose interviewed replied t hat no

liquidated damages shoul d be deduct ed, wi t h majorities

of bot h the engineers and cont ract ors recommendi ng

a 2-week extension of time. The posi t i on on the recovery

of overheads, however, was not so clear-cut. Most

engineers felt t hat overhead costs shoul d be pai d for one

week only, while 60% of the cont ract ors felt t hat two

weeks' overhead costs shoul d be payable. The engineer' s

view in this case is identical to the solution t hat woul d

apply i f the US approach to these mat t ers was adopt ed,

t hat is, a 2-week extension of time shoul d be awarded,

but overhead costs shoul d be payabl e for onl y one of

those weeks. Furt her investigation of the cont ract ors'

response showed t hat the quant i t y surveyors' responses

were equally split between one and two weeks' overhead

recovery, with the agents being bullish about their rights

to two weeks' overheads.

Figure 3 is similar to Fi gure 2, in t hat it cont ai ns two

delays of types E and C, al t hough t hey affect different

activities. The delays are, in fact, on parallel paths. The

response was unani mous t hat no liquidated damages

should be deducted, and nearl y unani mous t hat a two

weeks' extension of time shoul d be awarded. It was less

conclusive in relation to the amount of overheads t hat

should be recovered, but most engineers and cont ract ors

still t hought t hat these shoul d be paid for two weeks.

I f an adjusted schedule were to be const ruct ed for this

situation, in line with the US approach, by removi ng

the employer-responsible delays, it woul d show. t hat the

cont ract or, in the absence of t ype-E delays, woul d not

be able to complete the project on time. He/ she would

be one week beyond the time for compl et i on, and thus

should, on this basis, have one week of liquidated

damages deducted. The ot her week shoul d be covered by

an extension of time, for which overhead costs shoul d be

paid. Bot h supervising engineers and cont ract ors dis-

agreed strongly with this view, and seemed to have simply

identified the critical pat h, and made their decisions on

the basis of the delays on t hat pat h alone.

The last di agram, shown in Fi gure 4, also cont ai ns

parallel delays, but t hey are of types C and N. Again, a

maj ori t y view can be defined for bot h engineers and

contractors. This is t hat there shoul d be an extension

of time for one week, l i qui dat ed damages shoul d be

deduct ed for one week, and there shoul d be no recovery

of overheads at all. An alternative view is t hat , as the

cont r act or del ayed the cont ract by two weeks by his own

act i ons, and finished two weeks late, he should be totally

responsible for this delay. By this argument , he should

have two weeks' liquidated damages deducted. The

respondent s were, however, more generous t han this.

They clearly felt t hat the cont ract or should benefit from

the fact t hat an ' act - of - God' type of delay would have

prevent ed hi m from compl et i ng on time, had he not been

del ayed himself. Dependi ng on which met hod of dealing

with concur r ent delays were adopt ed, the US response

on such an out come woul d be either t hat recommended

by the maj or i t y of respondents in this survey, or the

al t ernat i ve view expressed.

Compar i ng the responses given by supervising engin-

eers with those given by REs, little difference in their over-

all at t i t udes to these problems could be distinguished.

On the ot her hand, al t hough there was no great gul f

between the opi ni ons of the agents and those of the

quant i t y surveyors, the expectations of the quant i t y

surveyors t ended to be generally lower t han the agents'

expectations.

Claims procedure

This section collects the responses to the questions whose

purpose was t o i dent i fy particular procedures adopt ed

by bot h the cont ract ors and the supervising engineers

in prepari ng and assessing delay claims. Three basic

questions were asked. One was addressed to the engineers

only, one was addressed to bot h the cont ract ors and the

engineers, and the third was addressed onl y to contrac-

tors. The first of these was the mai n question, as follows.

What procedure do you adopt for assessing the validity

of claim for an extension of time on a complex project?

The responses received were varied, and ranged from

Analyse evidence, compare with our records and make a

decision based on those facts.

t o

Require demonstration that delay has occurred, secondly that

delay was critical to completion date; gets very complicated

--anything but straightforward.

There was a general recognition of the need to check the

facts as presented by the cont ract or against the RE' s

records, but ot her points made were as follows:

Just i fy t hat the delays could not have been expected.

Look at the claim as t hough one were maki ng it

oneself.

Try to establish anot her one or two ways to evaluate

the cost of the claim to get a feel for where the

set t l ement figure shoul d lie, and t hen negot i at e with

the cont ract or.

It is difficult t o specify a general procedure; it depends

on how the claim is presented.

Use the pr ogr amme, assess the links between the

activities, and t ake account of float.

Tr y to accept the cont ract or' s approach; i f not , use

one' s own met hods.

In the belief t hat this first question mi ght not elicit

responses t hat directly addressed the actual mechani sm

used to affirm or assess the i mpact of individual delays,

a second, more specific, quest i on was included. Thi s was

150 I nt er nat i onal Jour nal of Project Management

put to both the contractors and the engineers, and it was

as follows.

How do you show that/decide whether a delay to a par-

ticular activity has actually contributed towards delaying

the whole project?

64% of the engineers interviewed mentioned the critical

path or critical activities in their replies, some of them

recognizing that it may not always be easy to identify

this path. Two respondents used the word ' shunting' ,

referring to subsequent activities in the project being

moved along by the effect of the delay in question. There

was certainly a general belief that, where this ' shunting'

occurred on the critical path, an extension of time might

well be justified. Other comments made referred to

the need to check for float on the path affected,

the possibility of stalling to see if the path on which the

delay occurred was actually critical,

the fact that CPM programmes appear when such

claims are being made,

the fact that the programme should be used as a basis,

but then actual activities should be monitored, and

payment should only be agreed if real delay occurs,

the fact that criticality is judged from an understanding

of the sequence of activities,

the fact that, typically, the contractor identifies the

critical path and the engineer checks it.

The importance of critical paths and the shunting effect

of particular delays on activities on such paths were

also recognized by the contractors who answered this

question. Another important element was, however,

reported by 36% of the contractors that was not

mentioned by any of the engineers. This was the concept

of 'plugging' delays into the contract programme to

see their effects on the completion time. Some said that

they would use a software package for this. This is

particularly interesting, as it begins to appear that the

production of an 'as-built' programme is being described.

However, on further examination, this was seen not to

be the case. The contractors who used this approach

admitted that they would use the activity durations from

the original programme for this purpose, and make no

attempt to record the actual durations of the activities.

In fact, it was mentioned by one contractor that he

would extend actual delay durations used in this exercise

to those that would have occurred had he not increased

his resources to improve the situation. The contractors

explained their aim in using this approach as being to

demonstrate to the employer their 'entitlement'. Having

plugged in the delays to the initial contract programme

in this way, they would expect to show a completion time

beyond what they actually needed. They managed to

complete before this time, they would argue, because

they had been particularly expeditious in carrying out the

contract. This would then be followed by the expectation

that the employer would pay their costs, possibly with an

element of profit.

In some circumstances, a large number of site

instructions might cause considerable disruption to a

contractor' s performance. This might happen in such

a way that it was difficult for him/her to isolate and

S SCOTT

deal with each delay individually. A question was posed

to contractors that described this scenario as follows.

How do you formulate claims when the disruption to

progress is due to the effects of a large number of site

instructions and it is not possible to separate individual

causes of delay?

40% of the responses stated that this would be dealt with

as a combination of individual causes of delay, with the

respondents effectively saying that they would be able to

isolate individual delay effects. The others recommended

amassing information on the value of the instructions

together with information on total costs. By showing the

monies spent in comparison with the expected spend-

ing profile, these contractors aimed to show that the

increased expenditure was due to the disruptive effect of

the instructions.

Claims: miscellaneous

At the heart of the critical-path method of planning is the

idea that, a network of activities having been arranged

that represents the construction of a project, a longest

path through this network can be found that dictates

the minimum project time. This, of course, is the critical

path. At the planning stage, it is easy to identify this path

(there may be more than one), and to recognize its/their

significance. As soon as the project begins, this simple

model of progress is likely to be found wanting. Activities

will not always start and continue uninterrupted to com-

pletion, the overlapping of activities not shown on the

plan will occur, and, of course, there will be delays from

the various sources. Can the essential critical path for the

project still be recognized and identified in such circum-

stances? There will obviously be some projects that, by

their nature, consist of one main sequence of activities,

where the critical path is likely to be unchanging. How-

ever, where the network is more complex, with a number

of parallel paths, the identification of any critical path

may well be more difficult.

With this understanding of the real situation con-

fronting site engineers, two questions were put to both

the engineers and the contractors. These were as follows.

Does the critical path through the project usually change

as construction proceeds? (Choice: yes/no/don' t know)

Are you always able to identify the critical path for the

finished project? (Choice: yes/no/don' t know)

The responses to the first question were inconclusive.

33% of the engineers said that the critical path usually

changed, while 56% said that it did not. Comments

varied from 'very rare', to ' often-not unusual'. In com-

plete contrast, 90/0 of the contractors confirmed that

the path did usually change. Their comments were 'often'

and 'sometimes', with one interviewee saying that he

could not think of a job where it had not changed. It is

clearly possible that the engineers and contractors had

been involved in different types of scheme, and that this

was the reason for the mismatch in their replies. How-

ever, as most of them were relying on their experiences

on a number of past schemes in answering the questions,

this is unlikely. Other explanations are possible. It might

Vol 11 No 3 August 1993 151

Dealing with delay claims: a survey

be t hat the two parties have di fferent concept i ons of

what comprises a critical pat h on a live proj ect , or simply

t hat different i nformat i on is avai l abl e t o t hem. I f t he

critical pat h is not identified on t he cont r act pr ogr amme,

as it oft en is not, how is t he engi neer t o know whet her

it has changed?

Wi t h the second quest i on, t here was a r easonabl e

consensus between the cont r act or s and t he engineers.

Majorities of bot h felt t hat t hey woul d be able t o i dent i fy

the critical pat h, and a number of i nt erest i ng comment s

were made, as follows:

Engineer

Yes (I am able to identify the critical path), but it doesn' t

mean to say that I do.

Often with difficulty - - you can never be certain of analysing

the real critical path.

Contractor

With difficulty - - you are always going to have a critical path

through each structure (when more than one is built at once).

You may have more than one.

The first comment from t he cont r act or s seems t o suggest

a part i cul ar way of l ooki ng at t he real critical pat h.

Rat her t han identifying a pat h t hat is the longest t hr ough

the net work as a whole, this cont r act or appears t o identify

i mpor t ant pat hs t hrough each mai n par t of t he net wor k.

For him, the achi evement of each section is critical to t he

compl et i on of the proj ect as a whole. The fact t hat this

is not in line with our nor mal under st andi ng of t he t erm

' critical pat h' perhaps highlights a need to define bet t er

what is meant by t hat t erm when it relates t o a live

project.

The last question under this heading was also addressed

t o bot h the engineers and the cont r act or s.

Are you aware of the use of as-built CPM schedules

t o validate extension of t i me claims in Amer i can cour t

hearings?

Of all the replies, 77% were uncondi t i onal nos, 18% were

condi t i onal nos, and onl y 5% were yesses. One cont r ac-

t or who replied no added t hat he used as-bui l t pr o-

grammes; this was the same cont r act or whose appr oach

was descri bed above, and who was seen as demonst r at -

ing ' ent i t l ement ' . His view of t he as-built pr ogr amme

was t hat it made no at t empt t o i ncor por at e act ual

activity durat i ons, and simply used the dur at i ons f r om

the initial cont r act pr ogr amme. The responses her e were

a cl ear i ndi cat i on of the fact t hat t he est abl i shed pro-

cedur e adopt ed in the USA is al most unhear d of in the

UK. Fr om t he replies in t he pr evi ous section, it appear s

t hat this may also be t rue of t he phi l osophy t hat

underlies t he US appr oach.

CONCL US I ONS

Fr om t he first section of t he findings, t he mai n

concl usi on is t hat del ay claims have to be deal t with on

the maj or i t y of maj or UK const r uct i on sites. Thi s surely

makes t he val ue of research in this area of par t i cul ar

i mport ance. Two ot her general conclusions can be drawn

f r om this section. The first is t hat i nf or mat i on collected

about the f r equency of accel erat i on claims suggests t hat

t here may be some di screpancy bet ween t he cont r act or ' s

and the supervising engineer' s views of what constitutes

such a claim. Thi s is not at all surprising, as these claims

appear to occur ver y i nfrequent l y, and it is unusual for

any individual engi neer to have had much experience

of t hei r effects. The second concerns t he deduct i on of

l i qui dat ed damages. It is assumed by some t hat they are

never deduct ed. The survey cert ai nl y f ound t hat this

met hod of rest i t ut i on is rarel y i nvoked, but there were

undoubt edl y a number of engineers who had experienced

cont r act s on which t he damages had been taken.

In the second section, the mat eri al is considered in

t erms of t wo mai n themes: (a) the at t i t udes t o part i cul ar

claims situations, and (b) t he mechani sms t hat are used

in pr epar i ng and assessing these claims.

In t erms of t he first t heme, t he pri nci pal conclusions

t hat can be dr awn f r om the st udy are as follows:

Ther e appears to be good agr eement between bot h

t he engineers and the cont r act or s t hat a claim for

ext ended over head costs shoul d be able to succeed

despite t he fact t hat the time f or compl et i on has not

been exceeded. In this situation, however, a number of

t hose i nt ervi ewed woul d award an ext ensi on of time.

A st rong link seems t o exist in t he mi nds of many who

deal with del ay claims bet ween t he awardi ng of an

ext ensi on of time and the accept ance of a claim for

ext ended over head costs.

In t he claims si t uat i ons involving concur r ent delays,

the appr oach adopt ed by the engineers was generally

very fair t o t he cont r act or . No at t empt seemed t o have

been made by ei t her par t y t o r emove delays for which

the cont r act or was not responsible, and t hen to identify

how well t he cont r act or coul d have pr oceeded in the

absence of these delays.

In t erms of the second t heme, the basic appr oach

adopt ed by most engineers in assessing t he claims was as

follows:

Check the facts of the cont r act or ' s submission.

Ident i fy or veri fy the critical pat h.

Check whet her the delays on this pat h have had a

shunt i ng effect on t he activities.

I f some of the delays on t he critical pat h woul d have

caused an ext ensi on of time, t hen an ext ensi on of time

mi ght well be justified.

Similar views were expressed by the cont r act or s in

rel at i on t o t he ways in which t hey woul d t ry t o prove

t hei r rights t o an ext ensi on of time. A few of t hem sought

t o demonst r at e ' ent i t l ement ' , as descri bed above. It is

cl ear t hat , apar t f r om the ' ent i t l ement ' met hod, the inter-

viewees t ended to deal wi t h these pr obl ems on the basis

of the critical pat h alone. Ot her pat hs t hr ough the

net wor k were not likely t o be consi dered.

The f or egoi ng discussion assumes t hat a critical pat h

on a live cont r act can be identified, and t hat t he t erm has

some meani ng in this cont ext . At t he pl anni ng stage of

a proj ect , t he critical pat h is easily identified as t he pat h

with no fl oat when mi ni mum compl et i on time is

enforced. However , even wi t h good, accur at e records of

152 I nt er nat i onal Jour nal of Proj ect Management

S SCOTT

the activities in the contract, the critical path may still be

difficult to identify. When the contractor may start an

activity, stop for a while, and then restart, how is one to

view this gap in the activity's progress? Is it float? If so,

there may be no path through the network that does not

have some element of float within it. The questions in the

questionnaire concerning the critical path produced some

odd results. There was a decided disagreement between

the engineers and the contractors as to whether this path

usually changed during the course of the contract. On

the question of ability to identify the final critical path for

the contract, however, both parties confirmed that they

were able. Other comments expressed while answering

these questions gave the impression that either this was

not always easy to do, or that the respondents might not

have a common understanding of the critical path in these

circumstances. The suggestion, then, is that it might well

be necessary to provide an alternative definition for the

critical path when it relates to a live contract.

For disruption claims caused by a large number of

site instructions, two main responses were given by the

contractors interviewed. One response was that this

was not a special problem, and could be dealt with in

the same way as other delays. The other response was

to amass information on additional costs together with

information on the sources of disruption. By showing

these causes of delay and the purported effects of delay,

the contractors hoped to persuade the employer to pay

their increased costs. The second method is recognized

in the literature, and yet it fails to demonstrate any link

between cause and effect. It could be argued that, if some

contractors are able to cope with these situations, then

others should also be able to manage. The excuse for

adopting a less convincing approach to these problems

is undermined.

As stated above, the issue of delay claims is a difficult

one, and no universal remedies are likely to be found.

However, this does not mean that nothing can be done

to improve the situation. It is hoped that, if information

is made available about how these matters are dealt with

by others, some benefit can be derived. In the absence of

useful legal precedents in this area, the procedures used

by other professionals may be a valuable guide.

R E F E R E N C E S

1 Wickwire, J M and Smith, R F 'The use of critical

path method techniques in contract claims' Public

Contract Law J. Vol 7 No 1 (1974) pp 1-45

2 Conditions of Contract (5th Ed.) Stanhope Press, UK

(1979)

3 Powell-Smith, V and Stephenson, D Civil Engineering

Claims BSP Professional Books, UK (1989)

4 Abrahamson, M W Engineering Law and the I CE

Contracts (4th Ed.) Applied Science Publishers, UK

(1979)

Stephen Scot t graduated f r om the

University o f Manchester Institute

of Science and Technology, UK, in

civil engineering, and later com-

pl et ed an MSc in construction engin-

eering at Leeds University, UK.

Having spent 12 years working on

the design and construction o f major

road and bridge works schemes, he

now lectures on construction man-

agement in the Department o f Civil

Engineering at the University o f

Newcastle upon Tyne, UK. He

gained his doctorate in 1992.

Vol 11 No 3 August 1993 153

Das könnte Ihnen auch gefallen

- Delay Claims in U.K. ContractsDokument7 SeitenDelay Claims in U.K. ContractsDalia JarbouNoch keine Bewertungen

- A Legal Analysis of Some ScheduleDokument17 SeitenA Legal Analysis of Some Scheduledrcss5327Noch keine Bewertungen

- A Legal Analysis of Some ClausalDokument13 SeitenA Legal Analysis of Some Clausaldrcss5327Noch keine Bewertungen

- Legal Analysis ScheduleDokument20 SeitenLegal Analysis ScheduleABUAMMAR60100% (1)

- WHY IS QUIT CLAIM NEEDED - How To Prepare A Claim For An Extension of TimeDokument4 SeitenWHY IS QUIT CLAIM NEEDED - How To Prepare A Claim For An Extension of TimeAlberto RebusaNoch keine Bewertungen

- Contract & Claim ManagementDokument30 SeitenContract & Claim Managementrahul nagareNoch keine Bewertungen

- Claims On Construction Projects - Quantification andDokument17 SeitenClaims On Construction Projects - Quantification andmartin.stanekNoch keine Bewertungen

- Accelaration Cost On ProjectsDokument13 SeitenAccelaration Cost On ProjectsWasimuddin SheikhNoch keine Bewertungen

- The Calculation of Acceleration Costs On Construction ProjectsDokument17 SeitenThe Calculation of Acceleration Costs On Construction ProjectsTamrat TadesseNoch keine Bewertungen

- Artificial Intelligence Innovation Report PDFDokument24 SeitenArtificial Intelligence Innovation Report PDFrehmanzidNoch keine Bewertungen

- Lecture 12 Contract IssuesDokument3 SeitenLecture 12 Contract IssuesEric LuuNoch keine Bewertungen

- Delay Analysis in Construction Utilizing CPM SchedulesDokument5 SeitenDelay Analysis in Construction Utilizing CPM Schedulesarmon_terra6220100% (1)

- A Case For Acceleration Rather Than Extension of Time On Construction Projects in UgandaDokument4 SeitenA Case For Acceleration Rather Than Extension of Time On Construction Projects in UgandaShahram FirouzbakhtNoch keine Bewertungen

- Claims On Construction Projects-Quantification and PreventionDokument18 SeitenClaims On Construction Projects-Quantification and PreventionMehmet Kutalmış OkurNoch keine Bewertungen

- The Process of Choosing EOTDokument8 SeitenThe Process of Choosing EOThusam-h2252Noch keine Bewertungen

- Contracts Mng. AssignmntDokument7 SeitenContracts Mng. AssignmntVilayat AliNoch keine Bewertungen

- Construction Delays in Florida A StudyDokument44 SeitenConstruction Delays in Florida A Studypusarath100% (2)

- FIDIC Lecture - 1999Dokument29 SeitenFIDIC Lecture - 1999kamalalifNoch keine Bewertungen

- Project Scheduling: Unit VDokument12 SeitenProject Scheduling: Unit VPoreddy vineelaNoch keine Bewertungen

- Issues During Construction Phase: Acceptance Period/WithdrawalDokument9 SeitenIssues During Construction Phase: Acceptance Period/WithdrawalDavid GaoNoch keine Bewertungen

- SCL Delay and Disruption Protocol in Brief 1689309554Dokument5 SeitenSCL Delay and Disruption Protocol in Brief 1689309554rvsingh17Noch keine Bewertungen

- Module Three: M&E Contract Claims in Construction Projects: PowerDokument9 SeitenModule Three: M&E Contract Claims in Construction Projects: Powernyanzi arthur victor wNoch keine Bewertungen

- Common Mistakes Employers Make That Cause DisputesDokument4 SeitenCommon Mistakes Employers Make That Cause Disputesphuc haNoch keine Bewertungen

- Understanding Claim AnalysisDokument7 SeitenUnderstanding Claim Analysisvenkat6Noch keine Bewertungen

- Claim Analysis of Construction Projects in Oman: January 2012Dokument7 SeitenClaim Analysis of Construction Projects in Oman: January 2012fajar kristantiNoch keine Bewertungen

- Urban Studies Vol 29-5-92Dokument13 SeitenUrban Studies Vol 29-5-92FlyANNoch keine Bewertungen

- Sena Gbedemah-Recovering From Lockdown The Pitfalls of AccelerationDokument3 SeitenSena Gbedemah-Recovering From Lockdown The Pitfalls of AccelerationNebojsa PavlovicNoch keine Bewertungen

- EOT BookletDokument8 SeitenEOT BookletanoopvvvNoch keine Bewertungen

- The Expert Witness April 2022 For WebsiteDokument2 SeitenThe Expert Witness April 2022 For WebsiteSara DessukiNoch keine Bewertungen

- Evaluating Extension of Time ClaimsDokument12 SeitenEvaluating Extension of Time ClaimsRana Muhammad TalhaNoch keine Bewertungen

- Legal Aspects Project Management 0208Dokument4 SeitenLegal Aspects Project Management 0208Faizan Ahmad100% (4)

- Eaint Yadanar Khin (ME - CM - 2) Yoon Mone Mone Khin (ME - CM - 3) Than Zaw Htike (ME - CM - 4) Moe Hein Kyaw (Dip - CM - 1) Shar Lae Win (Dip - CM - 3) Htet Wai Yee Aung (Dip - CM - 4)Dokument16 SeitenEaint Yadanar Khin (ME - CM - 2) Yoon Mone Mone Khin (ME - CM - 3) Than Zaw Htike (ME - CM - 4) Moe Hein Kyaw (Dip - CM - 1) Shar Lae Win (Dip - CM - 3) Htet Wai Yee Aung (Dip - CM - 4)than zawNoch keine Bewertungen

- Dadcic 61972 031Dokument19 SeitenDadcic 61972 031Manuel Alejandro San MartinNoch keine Bewertungen

- PGPM 31 Nicmar AssignmentsDokument29 SeitenPGPM 31 Nicmar Assignmentsvjrana2003Noch keine Bewertungen

- QTS 432 IiDokument8 SeitenQTS 432 Iikathy briggsNoch keine Bewertungen

- Article 12 - Recovery SchedulesDokument9 SeitenArticle 12 - Recovery SchedulesBonas Ponco WijanarkoNoch keine Bewertungen

- A Summarized Study of The Society of Construction Law Delay and Disruption Protocol (2nd Edition)Dokument7 SeitenA Summarized Study of The Society of Construction Law Delay and Disruption Protocol (2nd Edition)Santanu Debnath100% (1)

- Construction ClaimsDokument34 SeitenConstruction ClaimsTent ParkNoch keine Bewertungen

- Construction Claims Disputes and Project ClosureDokument53 SeitenConstruction Claims Disputes and Project ClosureSmit RamaniNoch keine Bewertungen

- Delay Analysis Helping MaterialDokument16 SeitenDelay Analysis Helping Materialsreenath100% (1)

- FIDIC Lecture - Pursuing or Defending Claims Under FIDIC Contracts - Regionally & Internationally - PpsDokument29 SeitenFIDIC Lecture - Pursuing or Defending Claims Under FIDIC Contracts - Regionally & Internationally - PpsteedNoch keine Bewertungen

- Scheduling Claims ProtectionDokument9 SeitenScheduling Claims ProtectionmanikantanNoch keine Bewertungen

- Design & Construction of the Contract Package ConceptVon EverandDesign & Construction of the Contract Package ConceptNoch keine Bewertungen

- Basic Concepts and Principles of Construction Claims - Khuong Do BlogDokument12 SeitenBasic Concepts and Principles of Construction Claims - Khuong Do BlogKhuong DoNoch keine Bewertungen

- Delay and Disruption Claims Martin Waldron BL March 2014 PDFDokument32 SeitenDelay and Disruption Claims Martin Waldron BL March 2014 PDFMumthaz ahamedNoch keine Bewertungen

- Nicmar Nicmar Institute of Construction Management and Research School of Distance EducationDokument11 SeitenNicmar Nicmar Institute of Construction Management and Research School of Distance Educationrahulchauhan7869Noch keine Bewertungen

- Case Study For Contract Management - Hydro Power Projects PDFDokument4 SeitenCase Study For Contract Management - Hydro Power Projects PDFpradeepsharma62100% (1)

- Subcontractor SchedulingDokument11 SeitenSubcontractor SchedulingionesqNoch keine Bewertungen

- ClaimsDokument63 SeitenClaimskian hongNoch keine Bewertungen

- Wa0006.Dokument398 SeitenWa0006.ankushNoch keine Bewertungen

- Project Management For Procurement Management ModuleVon EverandProject Management For Procurement Management ModuleNoch keine Bewertungen

- Textbook of Urgent Care Management: Chapter 4, Building Out Your Urgent Care CenterVon EverandTextbook of Urgent Care Management: Chapter 4, Building Out Your Urgent Care CenterNoch keine Bewertungen

- Contract Administration Pitfalls and Solutions for Architect-Engineering Projects: A JournalVon EverandContract Administration Pitfalls and Solutions for Architect-Engineering Projects: A JournalNoch keine Bewertungen

- Field Guide for Construction Management: Management by Walking AroundVon EverandField Guide for Construction Management: Management by Walking AroundBewertung: 4.5 von 5 Sternen4.5/5 (3)

- A Practical Guide to Disruption and Productivity Loss on Construction and Engineering ProjectsVon EverandA Practical Guide to Disruption and Productivity Loss on Construction and Engineering ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Contracts, Biddings and Tender:Rule of ThumbVon EverandContracts, Biddings and Tender:Rule of ThumbBewertung: 5 von 5 Sternen5/5 (1)

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- Integrated Project Planning and Construction Based on ResultsVon EverandIntegrated Project Planning and Construction Based on ResultsNoch keine Bewertungen

- 3.4 - Food Processing PDFDokument42 Seiten3.4 - Food Processing PDFsafrancooolNoch keine Bewertungen

- Dispute Resolution An Action PlanDokument44 SeitenDispute Resolution An Action PlanrianneNoch keine Bewertungen

- 3 PDFDokument21 Seiten3 PDFsafrancooolNoch keine Bewertungen

- Procurement StandardsDokument13 SeitenProcurement StandardssafrancooolNoch keine Bewertungen

- Brief Should Not Be Modified After This PointDokument2 SeitenBrief Should Not Be Modified After This PointHeshan Raween de SilvaNoch keine Bewertungen

- Handling Prolongation ClaimsDokument18 SeitenHandling Prolongation ClaimssafrancooolNoch keine Bewertungen

- Handling Prolongation ClaimsDokument18 SeitenHandling Prolongation ClaimssafrancooolNoch keine Bewertungen

- Understand Arabic in 12 Coloured TablesDokument36 SeitenUnderstand Arabic in 12 Coloured Tablesspeed2kx100% (1)

- ProcumentDokument28 SeitenProcumentsafrancooolNoch keine Bewertungen

- 1.4a Procurement Issues (Dr. Zhang-TJU)Dokument33 Seiten1.4a Procurement Issues (Dr. Zhang-TJU)safrancooolNoch keine Bewertungen

- Marres 07Dokument17 SeitenMarres 07safrancooolNoch keine Bewertungen

- FIDIC Lecture - EOT & Related Costs in ConstructionDokument39 SeitenFIDIC Lecture - EOT & Related Costs in Constructionsomapala88Noch keine Bewertungen

- 27 Final DelaysDokument22 Seiten27 Final Delaysinitiative1972Noch keine Bewertungen

- FIDIC Lecture - EOT & Related Costs in ConstructionDokument39 SeitenFIDIC Lecture - EOT & Related Costs in Constructionsomapala88Noch keine Bewertungen

- Delays in ProjectDokument44 SeitenDelays in ProjectMohamed El ArabiNoch keine Bewertungen

- Module 5 Hand and Power Tools SeminarDokument38 SeitenModule 5 Hand and Power Tools Seminarsafrancoool100% (1)

- FIDIC Lecture - EOT & Related Costs in ConstructionDokument39 SeitenFIDIC Lecture - EOT & Related Costs in Constructionsomapala88Noch keine Bewertungen

- Attachment 09Dokument1 SeiteAttachment 09safrancooolNoch keine Bewertungen

- Analytical Methods Batch 13 SubmitDokument7 SeitenAnalytical Methods Batch 13 SubmitsafrancooolNoch keine Bewertungen

- Leveling PDFDokument18 SeitenLeveling PDFJGon0% (1)

- Factors Affecting Span of ControlDokument1 SeiteFactors Affecting Span of ControlsafrancooolNoch keine Bewertungen

- 2 1Dokument69 Seiten2 1safrancooolNoch keine Bewertungen

- Land Surveying: Assignment 07Dokument9 SeitenLand Surveying: Assignment 07safrancooolNoch keine Bewertungen

- Concrete LearningDokument2 SeitenConcrete LearningsafrancooolNoch keine Bewertungen

- Chain SurveyingDokument3 SeitenChain SurveyingUlfathbary AB100% (3)

- High Heat Gain Heat GainDokument19 SeitenHigh Heat Gain Heat GainsafrancooolNoch keine Bewertungen

- Concrete LearningDokument2 SeitenConcrete LearningsafrancooolNoch keine Bewertungen

- Housekeeping AgreementDokument6 SeitenHousekeeping Agreementapi-3733759100% (2)

- TOPO Sales Process DesignDokument19 SeitenTOPO Sales Process DesignMax de Freitas100% (1)

- Case ReviewDokument5 SeitenCase ReviewAkmal RahmanNoch keine Bewertungen

- Geraldez v. CA Case DigestDokument5 SeitenGeraldez v. CA Case DigestMoireeG100% (2)

- Lalman Shukla vs. Gauri DuttDokument2 SeitenLalman Shukla vs. Gauri Duttvijay chittiboyinaNoch keine Bewertungen

- Law and EthicsDokument52 SeitenLaw and EthicsJanani PriyaNoch keine Bewertungen

- QBE Technical Claims Brief July 2011Dokument13 SeitenQBE Technical Claims Brief July 2011QBE European Operations Risk ManagementNoch keine Bewertungen

- Application Form - Erection All RiskDokument8 SeitenApplication Form - Erection All RiskKhan NiaziNoch keine Bewertungen

- Obligation and ContractsDokument24 SeitenObligation and ContractsRobert Labe JrNoch keine Bewertungen

- Alternative Funding Application FormDokument9 SeitenAlternative Funding Application Formthobani dludlaNoch keine Bewertungen

- Section 261 of The Omnibus Election Code 1Dokument4 SeitenSection 261 of The Omnibus Election Code 1Aimie Razul-AparecioNoch keine Bewertungen

- (US) SEC v. Glenn W. Turner Enterprises, 474 F.2d 476 (1973) PDFDokument6 Seiten(US) SEC v. Glenn W. Turner Enterprises, 474 F.2d 476 (1973) PDFkathreenmonjeNoch keine Bewertungen

- Pensatory Damages Fall 2014 Prof. George W. ConkFordham Law Schoolgconk@law - Fordham.eduDokument80 SeitenPensatory Damages Fall 2014 Prof. George W. ConkFordham Law Schoolgconk@law - Fordham.eduGeorge ConkNoch keine Bewertungen

- In The Spotlight: IFRS 17 Affects More Than Just Insurance CompaniesDokument14 SeitenIn The Spotlight: IFRS 17 Affects More Than Just Insurance Companiesgir botNoch keine Bewertungen

- Marifosque Vs People 435 SCRA 332Dokument29 SeitenMarifosque Vs People 435 SCRA 332WilfredNoch keine Bewertungen

- Unit 2. Law of ContractDokument29 SeitenUnit 2. Law of Contractste100% (2)

- Deed of Sale Parking Slot 78Dokument2 SeitenDeed of Sale Parking Slot 78tcv.deliveryNoch keine Bewertungen

- Sasan vs. NLRC, G.R. No 176240 (2008)Dokument19 SeitenSasan vs. NLRC, G.R. No 176240 (2008)Christiaan CastilloNoch keine Bewertungen

- Law Firm MemoDokument4 SeitenLaw Firm MemoMark Anthony Ruiz DelmoNoch keine Bewertungen

- Partnership and CorporationDokument12 SeitenPartnership and CorporationPaulyn Marie BathanNoch keine Bewertungen

- Iloilo Dock Vs WCC PDFDokument13 SeitenIloilo Dock Vs WCC PDFSheena ValenzuelaNoch keine Bewertungen

- Birches Investment Brochure - 25% BMVDokument11 SeitenBirches Investment Brochure - 25% BMVMark I'AnsonNoch keine Bewertungen

- Estimating Excavation Revised Book Preview PDFDokument32 SeitenEstimating Excavation Revised Book Preview PDFjose jimenezNoch keine Bewertungen

- Family CodeDokument9 SeitenFamily Codejoel ayonNoch keine Bewertungen

- 2017 08 02 18 49 30 PW2b FINAL DRAFT 010113 - 109 - 109Dokument56 Seiten2017 08 02 18 49 30 PW2b FINAL DRAFT 010113 - 109 - 109sharif uddinNoch keine Bewertungen