Beruflich Dokumente

Kultur Dokumente

01 Introduction PDF

Hochgeladen von

thuythu09h5Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

01 Introduction PDF

Hochgeladen von

thuythu09h5Copyright:

Verfügbare Formate

ProcessLRwject Engineering

Overview

m Project Def"mition

r Precess Engineering

m Project Eagineefing

Ilrztro.du:c&on

a U W s basic engineering dm@ package known as the

I Engi~eering work i s typically divided into -0 basic

par#s: " ~ I O C ~ S S ~ngiazeerhf and ' Trojed Engineering."

u Mttrough the swpt~n&b%Ges for the 'Trocess Engineer"

and "Project 1E-eef7 might vary for Licensors,

Contractors and Refiners, the Easks required to execute a

project tend to be the same,

s Discuss best practices in setting up the Project

s Proceed through the various sgeps of Process and

Project Engirreering to see how these topics come

Project Definition

m Process and Project Engineerkg is isrequired for any project

requiring desig~ and c o ~ c c i o n

- Grass roots refinery k&a&fioa with

mdtiple processes and utilities

- Addition of a complex of new psocess

techologies in an existkg facitity

- Additia of a singie pntcess d t

- Addition b or revamp of an existing

- TmuMesJroding an existing unit or

piece of equipment, wi& subsequent

8 Scope Definition

n DesignBasis

i

I Basic Engineering h i p Dab

i Project Schedule

Project Defifinition

Scope Definiiion

8 The Scope fm each inv01ved party must be defined:

- Who i s invdved - liicesor, de#aWi engineering axxi

coprs~Lction company, mmagexnent consaltants,

sulbcoahcfQ;rs, vend~rs

- Resp&W1ties?

- Where do v d o w pm4ies respnsibitities end and anogher

party ?s begin?

- Basic Engineering Design Data & - Bash

- Pmjw% Wedale

Setting the Design Basis

A well-defined Design Basis i s a critical part of the

Project Defmitiun

m Design Bask is set in:

- Design basis meetin&s)

- Legal agreements

- Yield estiwkes

S&ng the Design Basis

m Set Ultit CapaciQ

- Based on feed or product rates

- Based on on-stream efE~iencp (example: 330 dayslyear)

- Turndown reqwirezneents or fvture capacities

m Feed Defmition

- Limited number of feed cases

- Def hecom~t i ons

- Defme contaminant limitations

m Product Specifications

- Other sp&cations

Identify S ~ % C pFOWS f bw c~&$?,tioion

B Identify specific design decisiogs for major equipmeat

r Produce st-ream properties that are needed to

specify the process unit equipment

Process Engineering

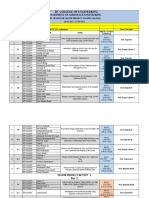

Process Engineering Design Steps

My Be?Needed For

1

Design Basis - Yield Estimate

m Feed Definition

= PrMiucts

- Yields - pea cb/ f w J + ~ ~ h ~ e

i - Properties

m Reactor Conditions

- Temperature

- Pressure

- Space velocity or cat / oil

- We u p and recycfe gas rates

- Heatrelease

- Deactivation rates or catalyst cycle length

I ~ . W m l S

Mass and Energy Balance in Process Design

Yield &ha$e te the basis fur producing detailed

r At UOP, generated by in-house sirnulation package

m Various property pa- a-ble

r Determines h ydmdic profile

m Provides information for equipment specifications

Select Property Package

The accuracy of physical properties is critical to

design processes and equipment

Sonne understanding is needed in this area to

insure that appropsiate choice of property

package is made

8 Crude Heatem

m Vacuum Heaters

m Hydrotreating Heaks

m Plaffbdng (per Hates)

m The& Crackers

Typical Heater Pressure Drops

3-20 0.20-2.0

Typical Heater Pressure Drops

(continued)

r Coker Heaters

= Visbreakers

= Hot Oil Heaters

= Fired Reboilers

R Fractionator Cbarge

Prelinrinaly Pressare Drops - Must Be Confirmed or

Comted Based on Final Heater Design

Frationator Pressure Drops

m Allour Qd5 $0 0-2 psi per tray

- (0.0035 ts @.OX4 k;gl~m.~)

r 0-12 psi per tray is typical (0.008 kg/cm2)

m Most sirnulators use theoretical stages, so make

the appropriate adjustment for the actmi

numkr of trays

Typical Heat Exchanger Pressure Drops

r Consider other heat exchmge schemes

Consider other separation sequences

r Systematic approaches to optimization - for eymple,

piach andgsis, steam-power, LP

Op~mize Flow Scheme

Exchanger Optimizatt*on

Process Flow D~g r a m

m The PFD provirEes an easy to understand view

of the anit

- major equipmen$

- sixearn dispositions and stream inforanatZon

- eonirol system

Hydraafics

r Line Sizing

i r Equipment Design Pressures

r Equipment Design Temperatures

m Material Selection

r Range Ratings

a Equipment Speciftcat-iom

r Standard ~iecifteaions & Drawings

m P&I Diagram

m Plot PI=

r Ins&-ument SpetSkations

r Relief Vatve SpecBcatiom

r Use of Project fnfomtion

r Transition into fEetaifed Design

8 A fJOP definition of "ProjecVTngirneering

- Engineeri~g work related to the specification of the equipment

- Starts after the ''procd' engineering

- Leads into the detaiIed design work

- An organized mrkfhw Do deliver the specifications for the

project in an efficient schedde

- Many orga&m%ns consider l$e production of a Schedufe A as

"processfY work, while 'project" work is the de&&&ed design

(equipmt Iaywt and purchase, piping isometrics, civil

engineering, e t ~ )

Project Specifications

I The UOP Schedu1e A includes She typical

detivembles that define the z-quirmenfs of a

design &#a book for the process

- 200 Generat Specifications

- 200 Fired Heat-err;

- 300 Ve s e f s a ndXnt e ~

- 400 Heat Excha~efs

- 500 Pumpsand Compressors

- 600 Imtrurnenfs

Project Specifcutions

B The UOP Schedule A (continued)

i

- 700 EIectrical

- 800 Piping

- 900 1;2/liscellfaneclus

- fW P&XDiagram

- Drawings

- Standard Specifications and Drawings

- Typical or Proposed Plot Pfan

Standard Drawings and Specifiations

Refated to eq&pmer].t types

m Provide genera1 specifications tfxat are not influenced

by the p m type

m Referenced by Project Sp&cations

I Reflect operating experience and industry practice

m Provide cmistency across the Merent refinery units

m Overridden by s p M~ c Project Specifications

Tmhhg Services

4

Piping and Instrument ~i agkams

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Anatomy Anal CanalDokument14 SeitenAnatomy Anal CanalBela Ronaldoe100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elements of ArtDokument1 SeiteElements of Artsamson8cindy8louNoch keine Bewertungen

- Dokumen - Pub - Bobs Refunding Ebook v3 PDFDokument65 SeitenDokumen - Pub - Bobs Refunding Ebook v3 PDFJohn the First100% (3)

- Week 7 Sex Limited InfluencedDokument19 SeitenWeek 7 Sex Limited InfluencedLorelyn VillamorNoch keine Bewertungen

- Chapter 8 Data Collection InstrumentsDokument19 SeitenChapter 8 Data Collection InstrumentssharmabastolaNoch keine Bewertungen

- Role of Losses in Design of DC Cable For Solar PV ApplicationsDokument5 SeitenRole of Losses in Design of DC Cable For Solar PV ApplicationsMaulidia HidayahNoch keine Bewertungen

- Checklist & Guideline ISO 22000Dokument14 SeitenChecklist & Guideline ISO 22000Documentos Tecnicos75% (4)

- WebLMT HelpDokument12 SeitenWebLMT HelpJoão LopesNoch keine Bewertungen

- Organization and Management Module 3: Quarter 1 - Week 3Dokument15 SeitenOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoNoch keine Bewertungen

- Appendix - Pcmc2Dokument8 SeitenAppendix - Pcmc2Siva PNoch keine Bewertungen

- My Personal Code of Ethics1Dokument1 SeiteMy Personal Code of Ethics1Princess Angel LucanasNoch keine Bewertungen

- B. Geoinformatics PDFDokument77 SeitenB. Geoinformatics PDFmchakra720% (1)

- Problem Set-02Dokument2 SeitenProblem Set-02linn.pa.pa.khaing.2020.2021.fbNoch keine Bewertungen

- Washing Machine: Service ManualDokument66 SeitenWashing Machine: Service ManualFernando AlmeidaNoch keine Bewertungen

- Outdoor Air Pollution: Sources, Health Effects and SolutionsDokument20 SeitenOutdoor Air Pollution: Sources, Health Effects and SolutionsCamelia RadulescuNoch keine Bewertungen

- WEB DESIGN WITH AUSTINE-converted-1Dokument9 SeitenWEB DESIGN WITH AUSTINE-converted-1JayjayNoch keine Bewertungen

- CAT 320D2: Hydraulic ExcavatorDokument5 SeitenCAT 320D2: Hydraulic Excavatorhydeer 13Noch keine Bewertungen

- Unit 16 - Monitoring, Review and Audit by Allan WatsonDokument29 SeitenUnit 16 - Monitoring, Review and Audit by Allan WatsonLuqman OsmanNoch keine Bewertungen

- 15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsDokument42 Seiten15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsShashank SinglaNoch keine Bewertungen

- DP 2 Human IngenuityDokument8 SeitenDP 2 Human Ingenuityamacodoudiouf02Noch keine Bewertungen

- DN Cross Cutting IssuesDokument22 SeitenDN Cross Cutting Issuesfatmama7031Noch keine Bewertungen

- LEIA Home Lifts Guide FNLDokument5 SeitenLEIA Home Lifts Guide FNLTejinder SinghNoch keine Bewertungen

- Ito Na Talaga Yung FinalDokument22 SeitenIto Na Talaga Yung FinalJonas Gian Miguel MadarangNoch keine Bewertungen

- Career Essay 1Dokument2 SeitenCareer Essay 1api-572592063Noch keine Bewertungen

- The Indonesia National Clean Development Mechanism Strategy StudyDokument223 SeitenThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNoch keine Bewertungen

- Bana LingaDokument9 SeitenBana LingaNimai Pandita Raja DasaNoch keine Bewertungen

- Nutrition and CKDDokument20 SeitenNutrition and CKDElisa SalakayNoch keine Bewertungen

- Review1 ScheduleDokument3 SeitenReview1 Schedulejayasuryam.ae18Noch keine Bewertungen

- A Case Study Puga Geothermal System,: OF IndiaDokument7 SeitenA Case Study Puga Geothermal System,: OF IndiaPERIKALA TARUNNoch keine Bewertungen

- Test ScienceDokument2 SeitenTest Sciencejam syNoch keine Bewertungen