Beruflich Dokumente

Kultur Dokumente

Aircraft Systems Lab Manual by GP

Hochgeladen von

shyamsundarsrOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aircraft Systems Lab Manual by GP

Hochgeladen von

shyamsundarsrCopyright:

Verfügbare Formate

PARISUTHAM INSTITUTE TECHNOLOGY & SCIENCE

THANJAVUR

AE-2405 AIRCRAFT SYSTEMS LABORATORY MANUAL

Prepare !"#

G$Pra%a&' M$E$#

A%%(%&a)& pr*+e%%*r

AE-2405 AIRCRAFT SYSTEMS LABORATORY

2

LIST OF E,PERIMENTS

S$N*$ Na-e *+ &'e E.per(-e)& Pa/e N*

1. Aircraft Jacking Up procedure 9

2. Aircraft Leveling procedure 15

3. Control S!te" #igging c$eck procedure 1%

&. Aircraft S""etr C$eck procedure 22

5. 'lo( te!t to a!!e!! of filter ele"ent clogging 25

). *re!!ure +e!t +o a!!e!! $draulic ,-ternal./nternal Leakage 20

0. 'unctional +e!t to ad1u!t operating pre!!ure 32

%. *re!!ure +e!t procedure on fuel !!te" co"ponent! 3&

9. 3rake +or4ue Load +e!t on ($eel 5rake unit! 30

12. 6aintenance and rectification of !nag! in $draulic and fuel !!te"! &2

3

INTRO0UCTION TO AIRCRAFT SYSTEM

An aeronautical engineer "u!t $ave a !olid foundation in 5a!ic! of A.C S!te"7 t$e principle

of cooling and !ound kno(ledge of t$e (a t$e principle i! applied to variou! !!te"! u!ed in t$e

A.C. +$e variou! !!te"! t$at e-i!t in aircraft! are a! follo(!

8draulic S!te"

Aircraft 9-gen S!te"

*neu"atic S!te"

Air:conditioning and *re!!uri;ation S!te"

,lectrical S!te"

,ngine oil < 'uel S!te"

Aircraft /n!tru"ent S!te"

/ce and rain protection !!te"

'ire protection and !"oke detection !!te"

Leak and =a!te !!te"

Aircraft (eapon >#ocket7 ?un7 6i!!ile!7 3o"5< ,1ection !!te"@

Co""unication and navigation !!te"

*ropul!ion !!te"

+$oug$ t$e !!te"! are u!ed to operate t$e variou! counter and co"ponent!7 t$e re4uire da to da

c$eck7 repair < e-a"ination for !"oot$ and proper function. +$e purpo!e to conduct A.C !!te" la5 i! to

fa"iliari;e da to da activitie! re4uired to "aintain air(ort$ condition of A.C.

AIR1ORTHINESS

+$e continuing capa5ilit of t$e A.C to perfor" in !ati!factor "anner7 t$e flig$t

operation for ($ic$ it i! de!igned.

INSPECTION

/t i! t$e "o!t i"portant for" of function of aviation "aintenance. A! t$e A.C give!

co"ple-it7 it 5eco"e! "ore i"portant to detect an po!!i5le trou5le 5efore it 5eco"e! !eriou!.

+o a!!i!t t$i!7 aero engineer! are provided (it$ detail !pecial c$eck li!t and t$e "aintenance

"anual for eac$ tpe of A.C. +$e engineer $a! to go t$roug$ "aintenance "anual t$oroug$l

5efore atte"pting an kind of activit in aircraft and it! co"ponent!. +$e operation! "a 5e

carried out on A.C on dail fling $our! and.or ccle 5a!i!.

MAINTAINENCE

+$e !et of action including in!pection7 !ervicing7 and deter"ination of condition re4uired to

ac$ieve a derived outco"e ($ic$ re!tore an A.C part and e4uip"ent in !ervicea5le condition.

&

OVERHAUL

9ver$aul "ean! !tripping a unit and re!toring it to it! de!ign perfor"ance level after

replacing7 re(orking of part! to a given !tandard.

SERVICING

/t "ean! preparing t$e A.C for flig$t7 include! providing t$e A.C (it$ fuel and ot$er fluid

and ga!e! 5ut do not include an (ork t$at i! "aintenance.

TROUBLE SHOOT

/t "ean! to anal!e! and identif t$e "alfunction.

REPAIR

/t "ean! to correct t$e defective condition.

MO0IFICATION

/t i! a continuou! proce!! to i"prove it! relia5ilit and perfor"ance.

SERVICING SCHE0ULES

Servicing on 8our!.Calendar.Ccle 5a!i!7 ($ic$ are to 5e carried out on aircraft at !et

8our!.Calendar.Ccle 5a!i! are "entioned in t$e "anual or A.C !ervicing !c$edule. +$e

!ervicing include! e-a"ination7 in!pection7 lu5rication and re"oval of "a1or co"ponent! !uc$ a!

landing gear 1ack!7 door lock!7 air:conditioning e4uip"ent!A aircraft 5rake unit! ($eel! etc.

landing gear functional te!t7 fling control range and "o"ent c$eck.7 A.C rigging procedure7

$draulic fluid conta"ination te!t7 fuel conta"ination te!t < !o"e activitie! re4uire! replace"ent

of co"ponent!.

Aircraft "aintenance c$eck! are periodical c$eck! t$at $ave to 5e done on all aircraft after a

certain a"ount of ti"e u!age. Aircraft! u!uall refer to a! one of t$e follo(ing c$eck!.

A CHEC2

+$i! i! perfor"ed appro-i"atel ever "ont$. +$i! i! u!uall done over nig$t. +$e actual

occurrence of t$i! c$eck varie! 5 t$e tpe7 ccle or nu"5er of $our! flo(n !ince t$e la!t c$eck. +$e

occurrence can 5e delaed 5 t$e aircraft if certain predeter"ine condition! are "et.

B CHEC2

+$i! i! perfor"ed in appro-i"atel 3 "ont$!.

5

C CHEC2

+$i! i! perfor"ed ever 12 to 1% "ont$!. +$i! c$eck put! aircraft out of !ervice and re4uire!

plent of !pace u!uall at t$e $anger and "aintenance 5a!e. Sc$edule and occurrence $a! "an factor!.

+$e co"ponent i! de!cri5ed and t$u! varie! (it$ t$e A.C categor and tpe.

0 CHEC2

+$i! i! t$e $eavie!t c$eck of an A.C. +$i! c$eck i! done appro-i"atel ever & to 5 ear.

+$i! i! t$e c$eck t$at take! t$e entire A.C apart for in!pection. A co"pre$en!ive c$eck7 anal!i!

Bon Ce!tructive +e!ting >BC+@ c$eck and co"plete $ealt$ "onitoring of t$e engine $a! to 5e

recorded. Co"plete over$auling of t$e A.C and it! co"ponent! even A.C painting i! al!o

re4uired in t$i! proce!!.

CONCLUSION

/n order to en!ure air (ort$ine!! condition of an A.C and it! a!!ociated !!te"!. Dariou!

c$eck!.in!pection! (it$in !tipulated ti"e7 follo(ing t$e !c$edule !$o( t$e A.C and it! !!te" are

kept in full !ervicea5le condition at all ti"e and in turn en$ance t$e A.C !afet. +$e ti"e fra"e

of !c$edule! varie! fro" A.C to A.C.

)

SAFETY PRECAUTIONS 1HILE HAN0LING AIRCRAFT

SYSTEMS AN0 ITS COMPONENTS

AIM

+o prevent accident and da"age to "an and "aterial.

OCCASIONS

=$enever re4uired to $andle t$e A.C and it! !!te" co"ponent! and ground e4uip"ent!.

AIRCRAFT

3efore caring out an (ork on t$e A.C7 t$e re!pective "aintenance "anual i! to 5e

referred for furt$er in!truction!. +$e nece!!ar !afet precaution! are to 5e !trictl

follo(ed.

3efore entering t$e cock pit of a fig$ter A.C7 en!ure t$at t$e e1ection !eat i! in !afe and all ar"a"ent

operating !(itc$e! are in !afe po!ition and all t$e !afel pin! are in po!ition.

3efore !(itc$ing on t$e "a!ter 5atter !(itc$ en!ure t$at t$e under carriage !elector

lever i! in do(n po!ition and latc$ed and all t$e ar"a"ent !tore door !(itc$e! are in

!afe condition.

,n!ure t$at t$e ($eel c$ock! are engaged.

3efore operating t$e control !urface7 en!ure t$at t$e control lock! are re"oved.

3efore !tarting t$e engine.

C$ock! are to 5e kept in front of t$e ($eel.

A.C 5rake !!te" in !ervicea5le.

A !ervicea5le fire e-tingui!$er i! availa5le.

Bever to( an aircraft (it$out a per!on in!ide t$e cockpit 5efore to(ing t$e A.C7 c$eck

t$e 5rake pre!!ure.

=$ile to(ing t$e A.C never e-ceed t$e (alking !peed.

Bever drop an tool ($ile (orking.

=$ile (orking in!ide t$e A.C7 collect all t$e tool! and !pace on co"pletion of t$e 1o5

and en!ure no ite"! are left 5e$ind.

HY0RAULIC SYSTEM

Al(a! relea!e t$e !!te" pre!!ure 5efore re"oving a co"ponent fro" t$e A.C

Bever doe! an "aintenance (ork on airplane (it$ an ot$er !pecified oil ot$er t$an t$e

reco""ended one.

Carr out t$e patc$ te!t on t$e !!te" to prevent t$e conta"ination of oil. +$i! can

5e carried out u!ing 6illipore patc$ te!t kit.

Bever "i- different grade of $draulic oil to !ervice t$e A.C.

0

3lank all t$e port! of t$e re"oved co"ponent! and t$e A.C pipe end! to avoid t$e entr

of du!t7 dirt and foreign particle!.

'ollo( t$e nece!!ar precaution! to di!"antle t$e $draulic co"ponent!.

Avoid !pilling of $draulic fluid on t$e A.C and in and around fro" t$e A.C. /f !pilled it

!$ould 5e cleaned i""ediatel to avoid !lipping.

3efore fitting a ne( $draulic co"ponent7 it !$ould 5e un5lanked7 degrea!ed7 (a!$ed

and flu!$ed.

=$ile fitting t$e non return valve and re!trictor!7 en!ure t$at t$e "arked arro(! are in

t$e de!ired direction.

PNEUMATIC SYSTEM

#elea!e t$e !!te" pre!!ure 5efore atte"pting a 1o5.

Clean all t$e vent! of t$e aircraft

9n re"oval of co"ponent!7 5lank all t$e part! of t$e co"ponent and t$e re!pective pipe!.

=$ile carring out t$e pre!!ure te!t never e-ceed t$e given li"itation

=$ile c$arging t$e pneu"atic pre!!ure al(a! u!e t$e pre!!ure regulator and !afet valve.

Crain t$e oil and (ater !eparator.

Bever $andle an 5ottle or clinder fro" it! c$arging no;;le. Al(a! u!e protective

cover

O,YGEN SYSTEM

S"oking7 open fla"e! or !"oke! !$ould not 5e per"itted ($ile (orking on t$e o-gen

!!te".

Co not carr "atc$e! ($ile $andling t$e 92 !!te"

A.C "u!t 5e grounded and all electrical po(er "u!t 5e !(itc$ed off.

Eeep (orking area and e4uip"ent free of oil7 grea!e or an ot$er fla""a5le "aterial.

Eeep t$e tool! and clot$ing free of oil and grea!e.

951ect !$ould not co"e in contact (it$ grea!e or !olvent! a! t$i! (ill cau!e !pontaneou!

e-plo!ion!.

Bever lu5ricate t$e 92 !!te" co"ponent! e-cept on approved co"pati5le lu5ricant.

8and !$ould 5e clean and free fro" oil. Co not u!e grea!ing glove!.

A !park i! not nece!!ar to cau!e a fire or e-plo!ion 5ut t$e c$e"ical reaction of fuel7 ga!

and oil co"5ined (it$ 92 i! !ufficient to develop in!tant co"5u!tion and cau!e fire and

e-plo!ion.

Bever per"it 92 clinder to co"e in contact (it$ electrical (elding circuit!

and apparatu!.

Bever u!e o-gen fro" clinder (it$out reducing t$e pre!!ure t$roug$ a

reducing regulator and !afet valve!.

Bever "i- ot$er ga! or co"pre!!ed air i! an 92 clinder.

%

Bever te!t for pipe line leak! or flo( pipe line (it$ o-gen unle!! t$e line! are

!pecificall "ade for t$at.

SAFETY PRECAUTIONS TO BE FOLLO1E0 0URING FUELLING AN0

0EFUELLING

Co not operate radio7 radar or an ot$er electrical and electronic e4uip"ent e-cept

t$o!e !pecified.

?round t$e fuel !uppl unit and aircraft.

6ake !ure t$e fuelling !ource contain t$e proper fuel grade a! !pecified 5

t$e "anufacture.

Bo !"oking7 open fla"e i! per"itted in and around t$e A.C.

/t i! not per"itted to drop an tool ($ile t$e operation i! on.

+$e operation !$ould 5e carried out in an open or full ventilated !pace.

Co not carr out o-gen related (ork.

CONCLUSION

+$u! t$e variou! !afet precaution! ($ile $andling aircraft !!te" are !tudied.

9

E, NO3 4 JAC2ING UP OF AIRCRAFT

AIM

+o 1ack t$e aircraft fro" it! !tead po!ition

JAC2ING

All aircraft $draulic 1ack! are eit$er a-le or airfra"e >tripod@ 1ack!. +$e!e 1ack! u!e

!tandard aut$ori;ed aircraft $draulic fluid. +$e $ave a !afet 5pa!! valve t$at prevent!

da"age ($en a load in e-ce!! of 12 percent over t$e rated capacit i! applied. 'or e-a"ple7 t$e

!afet valve on a 12:ton 1ack (ill 5pa!! fluid at 11 ton! of pre!!ure.

+$ere are "an different tpe! of aircraft 1ack! currentl in u!eA $o(ever7 t$e all fall into t(o

group!7 "ec$anical and $draulic.

Me5'a)(5a6 L(+&()/ Ja57%

+$e "ec$anical 1ack! operate on a !i"ple screw jack principle7 ($ere a ratc$et

"ec$ani!" i! u!ed to rai!e t$e tele!copic ra" 5 u!e of a !4uare t$read. +$e!e 1ack! are u!uall

onl u!ed for rai!ing !"all lig$t aeroplane!7 and !o"e $elicopter!.

H"ra86(5 L(+&()/ Ja57%

+$e "a1orit of aircraft lifting 1ack! operate on a $draulic principle7 ($ic$ u!e t$e fact

t$at oil (ill flo( freel et act a! a !olid7 5ecau!e it i! in t$i! conte-t inco"pre!!i5le. Anot$er

advantage of u!ing t$e $draulic principle7 i! t$at a relativel !"all pi!ton pu"p can generate a

lot of pre!!ure to "ove t$e 1ack ra" and aircraft up(ard!7 (it$ onl a "oderate effort on t$e part

of t$e operator.

OCCASION

=$en aircraft i! need to 5e in!pected for da"age to c$ange tpe and during rigging c$eck

fro" 9?CA 1acking of an aircraft $a! to 5e carried out

RE9UIREMENTS

6an po(erF3G1

6an $our!F3 $r!

Cocu"ent! of aircraft "aintenance "anual

TOOLS E9UIPMENT RE9UIRE0

Jacking pad

Bece!!ar 1ack!7 5ottle 1ack17 ($eel c$ock!HH

12

Tr(p* :a57

11

98rar8p* :a57

12

PRECAUTIONS

#efer aircraft "aintenance "anual 7 en!ure t$e capacit and !e"i circularit of 1ack

+$e 1acking area !$ould 5e oil free

+$e 1acking point !$ould of ($ic$ 2 at (ing! and one at "a-i"u" c.g location

+$ere !$ould 5e no per!on in!ide t$e aircraft ($ile 1acking

Central !urface! !$ould 5e locked

+$e 5alla!ted (eig$t !$ould 5e re"oved 5efore 1acking

Jack $andle !$ould not da"age !tructure of (eig$t

Clearance of propeller !$ould 5e en!ured 5efore 1acking

PROCE0URE

Jacking *rocedure:#ai!ing

+$e general procedure for rai!ing t$e co"plete aircraft on 1ack! i! a! follo(!I

/t differ! fro" variou! aircraft and refer re!pective aircraft "aintenance "anual

#e"ove t$e "ooring

/dentif t$e 1acking point! of t$e aircraft 5 placing it in level

After finding t$e 1acking point! place t$e 1ack! at t$e point!.

*lace a per!on at t$e 1acking point to look after t$e rai!ed 1ack!

All t$e 1ack! !$ould 5e !i"ultaneou!l rai!ed.

After 1acking7 1ack lock! !$ould 5e c$ecked for !ta5ilit and tig$tened.

+$e nece!!ar in!pection $a! to 5e carried out.

/f t$e aircraft i! likel to 5e c$ecked for "ore t$an 2& $r!7 place t$e ad1u!ta5le tru!! at

!pecified !tation

*lace t$e di!place 5oard aircraft 1ack! near t$e aircraft

Jacking *rocedure:Lo(erin g

+$e general procedure for lo(ering t$e co"plete aircraft on 1ack! i! a! follo(!I

,n!ure t$at t$e landing gear control lever in t$e cockpit i! !elected to

t$eDown po!ition.

,n!ure t$at ?round Safet Lock! are fitted on all Landing ?ear!.

,n!ure t$at t$e 3rake! are relea!ed.

,n!ure t$at all t$e pa!!enger.cre( door!7 t$e e"ergenc e-it! and t$e cargo door!

are clo!ed and locked or full open and locked.

Clear t$e area around t$e aircraft of all ground !upport and "aintenance e4uip"ent

and en!ure t$at no ot$er (ork i! 5eing carried out.

Loo!en t$e 1ack Safet Locking Collar!.

13

Slo(l operate t$e 1ack! to lo(er t$e aircraft at t$e !a"e ti"e to keeping t$e aircraft level

until all t$e landing gear ($eel! !upport t$e full (eig$t of t$e aircraft.

,n!ure t$at t$roug$out t$e 1acking operation! t$e 1ack Safet Locking Collar! are

kept appro-i"atel 2.5 c"! clear of t$e 1ack 5od.

=$en t$e 1ack ra"! $ave fully (it$dra(n into t$eir 1ack 5odie! t$e 1ack! "a t$en 5e

re"oved fro" under t$e aircraft. +$e re"oval of 1ack! prior to t$i! point can 5e dangerou! if

t$e aircraft !uddenl !ettle! o(ing to an stiction in t$e landing gear!.

Appl t$e 3rake!.

'it =$eel C$ock!.

#ein!tate t$e relevant circuit 5reaker! deactivated prior to rai!ing t$e aircraft. #e!toring

t$e aircraft to t$e Ground Configuration.

#e"ove (arning notice! fro" t$e aircraft cockpit.

#e"ove Safet 3arrier! fro" around t$e aircraft.

RESULT

+$u! t$e 1acking of an aircraft $a! 5een carried out for furt$er in!pection

VIVA-VOCE 9UESTIONS I

1. =$at i! t$e procedure for 1acking upJ

2. =$at i! t$e procedure for 1acking do(nJ

3. =$at i! t$e purpo!e of 1ack!J

4. =$at are t$e tpe! of a-ial 1ack!J

5. =$at i! t$e difference 5et(een !cre( and $draulic 1ackJ

6. Cefine lifting 5ag!.

7. =$at i! "eant 5 tripod 1ackJ

8. =$at i! "eant 5 3ipod 1ackJ

9. =$at i! "eant 5 4uradrupod 1ackJ

1&

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. ,-plain 5riefl a5out t$e 1acking up and 1acking do(n procedure for Ce!ena "odel

aircraftJ

2. ,-plain a5out variou! tpe! of 1ack! are currentl u!ed to rai!ing and lo(ering t$e

aircraftJ

3. Ce!cri5e a5out t$e variou! tpe! of e4uip"entK! are u!ed to 1acking up and do(n t$e

aircraftJ

15

E, NO3 2 LEVELLING OF PUSHPA2 AIRCRAFT

AIM

+o level t$e aircraft for in!pection purpo!e

LEVELING

Leveling i! t$e proce!! of placing an aircraft in it! rigging po!ition 5 "ean!

of $draulic or !cre( 1ack!

+$e rigging po!ition i! t$e po!ition of t$e aircraft at ($ic$ longitudinal and lateral

a-i! are parallel to ground.

Leveling "ean! leveling t$e aircraft in t$e $ori;ontal po!ition for rigging. +$ere

are t$ree tpe! of leveling. +$e are a! follo(!

Straig$t edge "et$od

?rid plate "et$od

,ngineer! tran!"it "et$od

OCCASION

Curing replace"ent or rene(al of "a1or co"ponent!7 rigging c$eck!7 !""etr

c$eck! and a! ($en C?CA re4uire leveling proce!! i! carried out.

RE9UIREMENTS

6an $our! F 3 $r!

6an po(erF 3G1

Cocu"ent!F Aircraft "aintenance "anual

1)

TOOLS RE9UIREMENT

+ripod !cre(.$draulic 1ack

Spirit level Lad1u!ta5le.fi-edM

Leveling 5oard!

+ail tre!tle!Lfi-ed.ad1u!ta5leM

PRECAUTION

95!erve on !afet precaution! for 1ack up

C$eck t$e accurac of !pirit level

Al(a! fini!$ leveling procedure once 5 c$ecking t$e Llongitudinal level

(it$out an ad1u!t"entM

PROCE0URE

*lace t$e "ain 1ack 5elo( t$e undercarriage near t$e fu!elage

*lace t$e tre!tle of t$e !pecified !tation 5 lifting t$e tail unit

*lace t$e longitudinal leveling 5oard at 5ot$ !ide of cockpit

*lace t$e lateral leveling 5oard at rear of t$e !lat!

*lace t$e !pirit level over it and ad1u!t "ain 1ack till t$e 5u55le of !pirit level

i! 5roug$t in centre

#ec$eck t$e longitudinal level

/f t$e 5u55le i! in t$e centre in 5ot$ t$e !pirit level7 t$e aircraft i! con!idered to 5e

5roug$t into level condition

/f not7 t$en repeat t$e operation fro" !tep 3 to 0

CONCLUSION

+$u! t$e aircraft i! leveled and i! "ade read for furt$er c$eck!

VIVA-VOCE 9UESTIONS I

1. =$at i! t$e procedure for levelingJ

2. =$at i! t$e function of plu"5 5o5J

3. =$at i! t$e purpo!e of levelingJ

10

4. =$at are t$e tpe! of e4uip"entK! are u!ed for levelingJ

5. =$at i! t$e function of !prit levelJ

6. =$at i! "eant 5 datu" plate levelingJ

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. ,-plain 5riefl a5out tpe of t$e leveling "et$od! (it$ !uita5le diagra"!J

2. ,-plain a5out align"ent and (ing t(i!t c$eck of Ce!ena 152 "odel aircraft

1%

E, NO3 ; RIGGING CHEC2ING UP OF AILERON 0EFLECTION AN0

ELEVATOR 0EFLECTION

AIM

+o en!ure t$e deflection angle of aileron and elevator

THEORY

N#iggingN i! t$e ter" u!ed to de!cri5e t$e geo"etric !et:up of t$e fling !urface! of

an aircraft. +$i! include!I

1) Setting t$e angle of incidence of eac$ (ing and fi-ed !ta5ili;ing !urface in relation

to !o"e defined reference line in t$e fu!elage

2) Ad1u!ting t$e !urface! for an di$edral

3) Ad1u!ting t$e (ing! for an geo"etrical t(i!t or N(a!$outN >relative incidence of eac$

!eg"ent of t$e (ing@

4) Ad1u!t"ent of control !urface! for t$e correct angular travel

5) C$ecking t$e !""etr of t$e aircraft7 t$at i!7 for e4ualit left.rig$t and

overall !4uarene!! or regularit

AileronI t$e "ove"ent of aircraft a5out lateral a-i! i! called rolling or 5ank. +$i!

"o"ent aileron! are linked toget$er 5 control ca5le. So t$i! one aileron i! do(n ($en ot$er i!

up t$at i! t$e function in different direction!.

,levatorI +$e "ove"ent of aircraft a5out longitudinal a-i! i! called pitc$ing. ,levator

are u!ed to control t$i! pitc$ing "ove"ent. ,levator! are linked toget$er 5 actual ca5le !o

t$at 5ot$ elevator are do(n t$at i! "ove in !a"e direction

OCCASION

6a1or !ervicing of aircraft

Aircraft flie! ($en one (ing lo(

A! and ($en re4uired 5 C?CA

19

RE9UIREMENTS

6an $our!F3

6an po(erF3G1

Cocu"ent!F Aircraft "aintenance "anual

TOOLS AN0 E9UIPMENTS

+ripod

Aircraft ladder

Longitudinal and lateral leveling 5oard

Spirit level

*lu"5 5o5

6ea!uring tape

PRECAUTIONS

FOR AILERONS

95!erve all t$e !afet precaution! for levelingM

Accurac of !pirit level $a! to 5e c$ecked

PROCE0URE

*lace t$e aircraft over t$e level 5oard

22

Locate t$e C.? point and place t$e leveling 5oard and !pirit level on it

Locate t$e C.? point and place t$e leveling 5oard and !pirit level over it

Level t$e aircraft a! per t$e concerned "aintenance "anual

6ea!ure t$e c$ord lengt$ of aileron

6ea!ure t$e di!tance travelled 5 aileron in up(ard direction fro"

neutral po!ition to port !ide

+ake t$e di!tance fro" upper (ing

6ea!ure t$e do(n(ard di!tance travelled 5 aileron for" neutral po!ition

'ind deflection angle fro" "ea!ured di!tance

C$eck angle of deflection (it$in !pecified li"it

FOR ELEVATORS

6ea!ure t$e di!tance travelled in up(ard direction fro" neutral po!ition to

deflected po!ition

+ake di!tance fro" upper $inge

6ea!ure di!tance travelled 5 elevator fro" neutral po!ition

'ind t$e deflection angle fro" neutral po!ition

C$eck t$e angle of deflection i! (it$in t$e !pecified li"it

RESULT

+$u! t$e aileron and elevator deflection i! verified and c$ecked.

VIVA-VOCE 9UESTIONS I

1. =$at i! "eant 5 riggingJ

2. =$at i! t$e purpo!e of #ig pinJ

3. =$at i! t$e purpo!e of riggingJ

4. =$at are t$e tpe! of a-ial 1ack!J

5. =$at i! t$e purpo!e of ten!io"eterJ

6. =$at i! t$e purpo!e of t$ro(5oardJ

7. =$at i! "eant 5 ter"inal !(agingJ

8. =$at i! t$e procedure for ca5le "aintenance

21

9. =$at i! t$e procedure for 4uick di!connectingJ

10. =$at i! "eant 5 4uick di!connectJ

9UESTIONS E,PECTE0 FROM UNIVERSITY3

11. ,-plain 5riefl a5out t$e rigging procedure for control !urface! of t$e aircraftJ

12. ,-plain a5out variou! tpe! of co"ponent! are currentl u!ed for rigging of flig$t

control !!te"!J

22

E, NO3 4 AIRCRAFT SYMMETRY CHEC2S

AIM

+o c$eck t$e !""etr of aircraft

SYMMETRY CHEC2

A !""etr c$eck i! an in!pection to !ee $o( t$e aircraftK! individual co"ponent! are

po!itioned in relation!$ip to eac$ ot$er.

METHO034

3 "ean! of direct "ea!uring (it$ tape

MEHTO032

3 dropping plu"5 5o5 and "arking and "ea!uring "et$od

OCCASION

9n a!!e"5le.erection of ne( aircraft

#eplace"ent.re"oval of "a1or co"ponent

8eav landing report!

'ollo(ed 5 flig$t t$roug$ tur5ulence

#epeated !"og on flig$t c.!

An "odification! on aircraft ($ic$ affect it! perfor"ance

A! and ($en re4uired 5 C?CA

PRECAUTIONS

#efer aircraft "aintenance "anual en!ure t$e caution !urrounding! of aircraft

+$e 1acking area !$ould 5e free

95!erve all !afet precaution for leveling

C$eck t$e accurac of !pirit level

Al(a! fini!$ leveling procedure onl 5 c$ecking t$e longitudinal level

RE9UIREMENT

=orking $r!F3

6an po(erF3

Cocu"entF aircraft "aintenance "anual and rigging c$eck up

23

TOOLS USE0

6ea!uring tape

Spirit level

*lu"5 5o5

Leveling 5oard

+ripod 1ack

Support 1ack

PROCE0URE

*lace t$e aircraft in rigging po!ition

C$eck t$e incident angle of (ing

2&

C$eck t$e di$edral angle of "ain plane

C$eck t$e !(eep 5ack angle

C$eck t$e di$edral angle of tail plane

Crop t$e plu"5 5o5 fro" !pin centre and tail ($eel centre and "ea!ure t$e

lengt$ of aircraft

Crop t$e plu"5 5o5 fro" eit$er (ing tip! and "ark it on t$e ground

'ro" fin top $inge or tail ($ere centre drop! t$e plu"5 5o5 and "ark it

6ea!ure t$e diagonal di!tance

C$eck t$e fin verticalit

6ea!ure t$e !pin centre to eac$ (ing tip

+a5ulate in t$e for"at given

RESULT

A5ove !tated difference are "ea!ured and co"pared (it$ t$e rigging c$art and found

(it$ per"i!!i5le li"it!

VIVA-VOCE 9UESTIONS I

1. =$at i! "eant 5 !""etr c$eckJ

2. =$at are t$e e4uip"entK! are involved in !""etr c$eckJ

3. =$at i! t$e purpo!e of !""etr c$eckJ

9UESTIONS E,PECTE0 FROM UNIVERSITY3

4$ ,-plain 5riefl a5out t$e !""etr c$eck procedure for naval aircraftJ

25

E, NO3 5 FLO1 TEST TO ASSESS OF FILTER ELEMENT CLOGGING

AIM

+o en!ure t$e cleanline!! of t$e follo(ing ele"ent and for t$e oil a flo( te!t i! carried out

in order to deter"ine t$e filtering capacit of t$e filtering ele"ent.

OCCASION

1. Specified period interval!

2. 'ollo(ed 5 a filter! failure or !nag

3. After in!tall of ne( filter

PRECAUTION

1. ,n!ure t$at t$e filter ele"ent! are !u51ected to a ultra!onic cleaning 5efore carring out

t$i! te!t

2. Carrout t$i! te!t onl in a du!t proof roo" condition.

3. U!e $and glove! during t$i! te!t for $andling filter ele"ent and te!t e4uip"ent

PROCE0URE

1. *our !pecified $draulic oil >!kdroll @ up to "ove in t$e container

2. ,ngage t$e 5otto" plug to t$e filter ele"ent! 5otto" 5 pu!$ing top

3. ,ngage t$e upper adapter on t$e top of t$e fitter ele"ent 5 pu!$ing do(n.

4. ,ngage t$e plunger a!!e"5l to t$e top of adapter 5 !creening do(n

2)

5. 3lank t$e upper part of t$e plunger . !te" 5 t$u"5 clip t$e plunger (it$ t$e fitter

fuel t$e upper adapter flange i""er!e in t$e oil of t$e container.

6. Un 5lank t$e upper part of t$e plunger

7. 3 re"oving t$e t$u"5:clip and !i"ultaneou!l !tart t$e !top (atc$ to note do(n

t$e ti"ing.

8. Bote do(n t$e ti"e taken for t$e !te" to co"e up unlike (it$ plunger and t$e ti"ing u!e

(it$in 5 to ) !econd!

9. /ncrea!e of e-ce!! ti"ing !u51ected t$e filtering ele"ent again to ultra!onic cleaning.

10. #e1ect t$e filtering ele"ent! for aircraft and it doe! not filter (it$in 5:) !econd!

follo(ed 5 t(o !ucce!!ive ultra!onic cleaning operation!.

RESULT

+$e !u51ected te!t i! carried out and found !ati!factor.

VIVA-VOCE 9UESTIONS I

1. =$at i! "ean 5 $draulic fluidJ

2. +pe! of $draulic fluid.

3. =$at i! t$e !i;e of filter ele"ent!J

4. =$at i! "ean 5 !trainerJ

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. Co a flo( te!t to a!!e!! of filter ele"ent clogging

2. +e!t a filter ele"ent for clogging.

20

E, NO3 < =PRESSURE TEST> TO ASSESS HY0RAULIC E,TERNAL?INTERNAL

LEA2AGE

AIM

+o perfor" t$e pre!!ure te!t on $draulic !!te" co"ponent! to locate t$e internal and

e-ternal leakage

HY0RAULIC LEA2AGE

An $draulic !!te" (ill $ave a certain a"ount of leakage. An leakage (ill reduce efficienc

and cau!e po(er lo!!. So"e leakage i! 5uilt in >planned@7 !o"e i! not. Leakage "a 5e internal7

e-ternal7 or 5ot$.

I)&er)a6 6ea7a/e

+oo "uc$ internal leakage (ill !lo( do(n actuator!. +$e po(er lo!! i! acco"panied 5

t$e $eat generated at a leakage pat$. /n !o"e in!tance!7 e-ce!! leakage in a valve could cau!e a

clinder to drift or even creep ($en a valve i! !uppo!edl in neutral. /n t$e ca!e of flo( or

pre!!ure:control valve!7 leakage can often reduce effective control or even cau!e control to 5e

lo!t.

Bor"al (ear increa!e! internal leakage7 ($ic$ provide! larger flo( pat$! for t$e leaking oil.

An oil t$at i! lo( in vi!co!it leak! "ore readil t$an a $eav oil. +$erefore oilK! vi!co!it and

vi!co!it inde- are i"portant con!ideration! in providing or preventing internal leakage. /nternal

leakage al!o increa!e! (it$ pre!!ure7 1u!t a! $ig$er pre!!ure cau!e! a greater flo( t$roug$ an orifice.

9perating a5ove t$e reco""ended pre!!ure! add! t$e danger of e-ce!!ive internal leakage and $eat

generation to ot$er po!!i5le $ar"ful effect!.

A 5lo(n or ruptured internal !eal can open a large enoug$ leakage pat$ to divert all of a

pu"pO! deliver. =$en t$i! $appen!7 evert$ing e-cept t$e oil flo( and $eat generation at a

leakage point can !top.

E.&er)a6 6ea7a/e

,-ternal leakage can 5e $a;ardou!7 e-pen!ive7 and un!ig$tl. 'ault in!tallation and poor

"aintenance are t$e pri"e cau!e! of e-ternal leakage. Joint! "a leak 5ecau!e t$e (ere not put

toget$er properl or 5ecau!e !$ock and vi5ration in t$e line! !$ook t$e" loo!e. Adding !upport! to t$e

line! prevent! t$i!. /f a!!e"5led and in!talled correctl7 co"ponent! !eldo" leak. 8o(ever7 failure to

connect drain line!7 e-ce!!ive pre!!ure!7 or conta"ination can cau!e !eal! to 5lo( or 5e da"aged7

re!ulting in e-ternal leakage fro" t$e co"ponent!.

2%

PREVENTION

*roper in!tallation7 control of operating condition!7 and proper "aintenance $elp prevent

leakage.

OCCASION

1. Specified period interval!

2. 'ollo(ed 5 a $draulic !!te" failure or !nag

PROCE0URE

I)&er)a6 6ea7a/e

1. #e"ove t$e !(ivel nut fro" t$e !trainer 5o(l and drain t$e fluid co"pletel.

2. +urn off t$e $draulic pu"p.

3. +urn off t$e fluid !elector valve.

4. /f t$e valve i! looking interval!7 fluid (it$ flo( into t$e !trainer 5o(l.

E.&er)a6 6ea7a/e

1. Locating leak! or dete!t in t$e $draulic !!te" e-ternal portion! involved ver little

ti"e in co"pari!on!

2. C$eck for !train! on ne(l developed (et !pot! in t$e fluid line! and $o!e!.

3. /f t$ere i! onl fuel o dour t$at (ill indicating fluid leak!.

4. Carefull e-a"ine t$e plu"5ing7 cla"p!7 ga!ket! !upport! etc for fluid leak! or

aircraft !tructure for evidence of fluid leak!.

5. C$eck t$e repaired tank! "anufacturing an defect! on leak! in t$e internal or

e-ternal fluid !!te" i! potential $a;ard.

29

RESULT

+$u! pre!!ure te!t on $draulic fluid !!te" co"ponent! carried out to detect (it$ t$e

internal and e-ternal leakage.

VIVA-VOCE 9UESTIONS I

1. =$at i! !nagJ

2. =$at i! 5oo!ter pu"pJ

3. ,nu"erate t$e different tpe! of pu"p!.

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. 'ind t$e leakage! in $draulic !!te" and do pre!!ure! te!t.

32

E, NO3 @ FUNCTIONAL TEST TO AGJUST OPERATING PRESSURE

AIM

+o deflecting a !$ock !trut !ervicing and reinflate

THEORY

+$e 5a!ic (eig$t !upport function of t$e oleo:pneu"atic !$ock !trut!7 ($ic$ $ave a $ig$

efficienc under dna"ic condition! 5ot$ in ter"! of energ a5!orption and di!!ipation7 i! provided

5 a co"pre!!ed clinder of air and oil. A !ingle:acting !$ock a5!or5er7 ($ic$ i! t$e "o!t co""onl

u!ed de!ign for co""ercial tran!port!. +$i! tpe of !$ock !trut a5!or5! energ 5 fir!t forcing a

c$a"5er of oil again!t a c$a"5er of dr air or nitrogen and t$en co"pre!!ing t$e ga! and oil. Curing

t$e co"pre!!ion proce!!7 t$e oil and ga! eit$er re"ain !eparated or are "i-ed depending on t$e tpe

of de!ign. After t$e initial i"pact7 energ i! di!!ipated a! t$e air pre!!ure force! t$e oil 5ack into it!

c$a"5er t$roug$ recoil orifice!.

Alt$oug$ t$e co"pre!!ion orifice could 5e "erel a $ole in t$e orifice plate7 "o!t de!ign!

$ave a "etering pin e-tending t$roug$ it7 and 5 varing t$e pin dia"eter t$e orifice area i!

varied. +$i! variation i! ad1u!ted !o t$at t$e !trut load i! fairl con!tant under dna"ic loading. /f

t$i! can 5e "ade con!tant7 t$e gear efficienc (ould 5e 122 percent. /n practice7 t$i! i! never

o5tained and efficiencie! of %2 to 92 percent are "ore u!ual. Since onl t$e efficienc factor i! of

intere!t in t$e conceptual de!ign p$a!e7 no additional di!cu!!ion on t$e de!ign of t$e "etering pin

(ill 5e provided.

31

OCCASION

1. Specified period interval!

2. Lack! in pre!!ure

3. 'ailure of !$ock !trut

32

PROCE0URE

1. *lace t$e aircraft on 1ack po!ition !o t$e !$ock !trut! are in t$e nor"al ground operating

!!te" po!ition.

2. 6ake !ure t$at no per!on and ot$er o5!tacle are cleared under t$e aircraft.

3. #e"ove t$e du!t cap fro" t$e aircraft.

4. C$eck t$e !(ivel $e- nut for tig$tne!! (it$ (renc$.

5. /f t$e air valve e4uipped (it$ core relea!e t$e air pre!!ure t$at "a 5e trapped 5et(een

t$e valve core and valve !eat

6. #e"ove t$e valve core

7. #elea!e t$e air pre!!ure in t$e !trut 5 !lo(l turning t$e !(ivel nut counter clock(i!e

8. ,n!ure t$at t$e !$ock !trut co"pre!!e! a! t$e air pre!!ure i! relea!ed

9. =$en t$e !trut i! full co"pre!!ed t$e air valve a!!e"5l i! re"oved

10. #ein!tall t$e air valve core a!!e"5l

11. /nflate t$e !trut u!ing a lig$t pre!!ure !ource of an air on a !$ock !trut7 t$e correct

a"ount of inflation i! deter"ine 5 "ea!uring t$e a"ount of e-ten!ion.

12. S$ock !trut !$ould al(a! 5e inflated !lo(l to avoid e-ce!!ive $eating and over

inflation.

13. +ig$t t$e !(ivel $e- nut u!ing t$e tor4ue valve !pecified in t$e applica5le "anufacture

"anual

14. #e"ove t$e lig$t pre!!ure airline

15. C$eck and in!tall t$e valve cap tig$t valve cap finger tig$t.

RESULT

+$u! t$e !ervicing and functional te!t of !$ock !trut carried a! per t$e "anufacture

in!truction

33

VIVA-VOCE 9UESTIONS I

1. Cifferent tpe! of !$ock a5!or5er

2. =$at i! orifice valve

3.=$at i! t$e function of "etering pin

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. *refor" t$e functional te!t on oleo pneu"atic !$ock a5!or5er.

2. =rite t$e for !ervicing t$e oleo pneu"atic !$ock a5!or5er.

3&

E, NO3 A PRESSURE TEST ON FUEL SYSTEM COMPONENTS

AIM

+o perfor" t$e pre!!ure te!t on fuel !!te" co"ponent! to locate t$e internal and e-ternal

leakage

THEORY3

Fuel System Components: 3efore doing an fuel pre!!ure te!ting7 it i! a good idea to under!tand $o( fuel

!!te" co"ponent! (ork and $o( t$e relate to one anot$er. +$e fuel pu"p pu"p! fuel fro" t$e fuel

tank to t$e fuel pre!!ure regulator and fuel in1ector!. +$e fuel pre!!ure regulator divide! fuel 5et(een t$e

pre!!ure line and t$e return line. +$e fuel in t$e pre!!ure line goe! to t$e fuel in1ector!A ($ile t$e fuel in

t$eir turn line i! returned to t$e fuel tank

Fuel Tank: A large container t$at $old! our ve$icle! !uppl of fuel.

Fuel Pump Filter: A filter t$at i! u!uall located in t$e fuel tank. /t! function i! to prevent

foreign particle! fro" reac$ing t$e fuel pu"p. A clogged or re!tricted fuel pu"p filter can cau!e

lo( fuel pre!!ure reading!. =$en replacing a fuel pu"p it i! a good idea to clean or replace t$e

fuel pu"p filter.

Fuel Pump: An electric "otor t$at pu"p! fuel into t$e fuel !!te" at a con!tant pre!!ure. /t i!

"ounted in t$e fuel tank or on t$e fra"e. So"e ve$icle! $ave "ore t$an one fuel pu"p.

Return Line: *at$ (a for e-ce!! fuel to return to t$e fuel tank.

Pressure Line: A pre!!uri;ed fuel line t$at carrie! fuel fro" t$e fuel tank to t$e fuel in1ector!.

Fuel Filter: A filter t$at i! located in:line (it$ t$e pre!!ure line. /t! function i! to prevent foreign

particle! fro" reac$ing t$e fuel in1ector!. A clogged or re!tricted fuel filter can al!o cau!e lo( fuel

pre!!ure reading!. +$i! i! t$e onl fuel !!te" co"ponent t$at re4uire! periodic replace"ent.

#efer to ve$icle o(nerK! "anual for replace"ent interval.

Fuel Pressure Regulator: +$e fuel pre!!ure regulator i! connected acro!! t$e pre!!ure line and return line. /t

contain! a !pring loaded valve a!!e"5l t$at open! to allo( fuel to "ove into t$e return line7 ($en t$e pre!!ure

line fuel pre!!ure i! e-ceeded. /t i! u!ed to keep a con!tant fuel pre!!ure drop acro!! t$e fuel in1ector!. So"e

fuel pre!!ure regulator! $ave a vacuu" port !o fuel pre!!ure can 5e ad1u!ted 5a!ed on engine load. +$e!e are

co""onl called vacuu" actuated

35

>co"pen!ated@ fuel pre!!ure regulator!. A leaking fuel pre!!ure regulator can cau!e lo( fuel

pre!!ure reading! and $ard !tarting pro5le"!.

Fuel Injectors: A preci!ion valve t$at i! controlled 5 a !olenoid. 'uel in1ection i! controlled 5 t$e a"ount of

fuel pre!!ure and t$e !i;e and duration of t$e valve opening. 'uel in1ector! contain a filter u!ed to prevent ver

!"all particle! fro" 56*//()/ t$e valve. Leaking fuel in1ector! (ill cau!e fuel pre!!ure to !lo(l decrea!e

($en t$e ignition ke i! on and engine i! off.

PREVENTION

*roper in!tallation7 control of operating condition!7 and proper "aintenance $elp prevent

leakage.

OCCASION

1. Specified period interval!

2. 'ollo(ed 5 a fuel !!te" failure or !nag

PROCE0URE

I)&er)a6 6ea7a/e

#e"ove t$e !(ivel nut fro" t$e !trainer 5o(l and drain t$e fuel co"pletel.

3)

+urn off t$e fuel engine 5oo!ter pu"p.

+urn off t$e fuel !elector valve.

/f t$e valve i! looking interval!7 fuel (it$ flo( into t$e !trainer 5o(l.

E.&er)a6 6ea7a/e

Locating leak! or dete!t in t$e fuel !!te" e-ternal portion! involved ver little ti"e

in co"pari!on!

C$eck for !train! on ne(l developed (et !pot! in t$e fuel line! and $o!e!.

/f t$ere i! onl fuel odour t$at (ill indicating fuel leak!.

Carefull e-a"ine t$e plu"5ing7 cla"p!7 ga!ket! !upport! etc for fuel leak! or aircraft

!tructure for evidence of fuel leak!.

C$eck t$e repaired tank! "anufacturing an defect! on leak! in t$e internal or

e-ternal fuel !!te" i! potential $a;ard.

RESULT

+$u! pre!!ure te!t on fuel !!te" co"ponent! carried out to detect (it$ t$e internal and

e-ternal leakage.

VIVA-VOCE 9UESTIONS I

1. Cifferent fuel !!te".

2. =$at i! cloggingJ

3. =$at i! function of pre!!ure regulatorJ

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. ,-plain 5riefl a5out t$e fuel !!te" pre!!ure te!t.

2. =rite a procedure for pre!!ure te!t on fuel !!te".

30

E, NO3 B BRA2E TOR9UE LOA0 TEST

AIM

+o prevent t$e 5rake failure during 5rake application and to keep t$e 5rake !!te" al(a!

in !ervicea5le condition

THEORY

+$e aircraft ($eel 5rake! are de!igned to provide !lo(ing do(n of aircraft on

touc$do(n and totall to !top t$e aircraft

/t $old! t$e aircraft ($ile parking and during ground running of engine

+$e 5rake unit "a 5e !$oe tpe7 di!c tpe or "ulti di!c tpe

3 proper "aintenance of 5rake unit t$e "a-i"u" flig$t accident! "a 5e

prevented

/f t$e air i! found in t$e $draulic 5rake !!te" 5rake (ill not 5e effective

So t$e pre!ence of air i! found in t$e $draulic 5rake !!te" i! to 5e e-pelled

fro" !!te" i! called 3L,,C/B? 9' SPS+,6

/f air i! not re"oved t$e 5rake! !!te" (ill 5e !pong

+o avoid t$at 5rake 5leeding $a! to 5e carried out of regular interval!

OCCASION

9n an periodic !ervicing a! per la do(n in !ervicing !c$edule

/f an $draulic 5rake detected fro" pi!ton a!!e"5l of 5rake unit

=$enever pilot report! t$at t$e 5rake unit i! !lugging.!pong action of 5rake

pedal!

At t$e ti"e of 5rake pipe rene(al and topping up of 5rake re!ervoir

RE9UIREMENTS

6an $ourF3 $r!

6an po(erF3G1

Cocu"ent! F aircraft !ervicing for"7 aircraft "aintenance "anual

E9UIPMENTS?TOOLS

+ripod !cre(.$draulic or 5ottle 1ack

3leeding $o!e

Clean container (it$ !pecified $draulic oil

8and glove!

3%

SAFETY PRECAUTION

+ake proper precaution of 1acking up of aircraft

Clean t$e !ervicea5ilit of 1ack!

Jacking !ufficient $draulic oil in a cleaned container

3leeding !$ould 5e contained until no "ore oil 5u55le! are e-pelled fro" t$e

!!te" and fin 5rake pedal i! o5tained

PROCE0URE

+$ere are t(o "et$od! of 5leeding t$e 5rake !!te"7 gravit and pre!!ure

"et$od!. gravit "et$od i! de!cri5ed 5elo(

Jack up t$e aircraft (it$ all nece!!ar condition!

#e"ove t$e 5leeder !cre( fro" t$e 5leeding point on t$e 5rake unit7 5 cutting

t$e locking (ire

Connect one end of 5rake $o!e to 5leeding point and ot$er end of $o!e i""er!e in

to t$e !pecified oil in !"all container

+$e fluid i! t$en forced fro" t$e !!te" of operating t$e 5rake pedal!

=atc$ for t$e 5u55le! fro" oil ($ic$ co"e! out fro" 5rake !!te" t$roug$ $o!e

3leeding !$ould 5e contained till $draulic oil co"e! out (it$out air 5u55le!

'ill t$e 5rake "a!ter clinder (it$ fre!$ $draulic oil ($ic$ $a! lo!t during t$i!

proce!!

Appl t$e 5rake !everal ti"e! and c$eck for an pro5le" in 5rake !!te"

=ire lock t$e 5leeder !cre(

39

Lo(er t$e aircraft 5 taking proper precaution

6ake nece!!ar entr in t$e aircraft !ervicing for".log 5ook

RESULT

+$e aircraft 5rake !!te" 5leeding i! carried out and found !ati!factor.

VIVA-VOCE 9UESTIONS I

1. ,nu"erate different tpe! of 5rake !!te" u!ed in aircraft.

2. =$at i! 5leedingJ

3. =$at i! "ean 5 di!k 5rakeJ

4. Cifferentiate 5et(een di!k 5rake and dru" 5rake.

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. =rite a procedure for find a 5leeding in 5rake !!te".

2. Ce!cri5e t$e 5rake load tor4ue te!t.

&2

E, NO3 40 MAINTENANCE AN0 RECTIFICATION OF SNAG IN HY0RAULIC AN0

FUEL SYSTEMS

AIM

+o !tud t$e trou5le !$ooting procedure on aircraft $draulic !!te"

HY0RAULIC SYSTEM MAINTENANCE PRACTICES

+$e "aintenance of $draulic and pneu"atic !!te"! !$ould 5e perfor"ed in accordance

(it$ t$e aircraft "anufacturerK! in!truction!. +$e follo(ing i! a !u""ar of general practice!

follo(ed ($en dealing (it$ $draulic and pneu"atic !!te"!.

SerC(5e

+$e !ervicing of $draulic and pneu"atic !!te"! !$ould 5e perfor"ed at t$e interval i!

!pecified 5 t$e "anufacturer. So"e co"ponent!7 !uc$ a! $draulic re!ervoir!7 $ave !ervicing

infor"ation ad1acent to t$e co"ponent. =$en !ervicing a $draulic re!ervoir7 "ake certain to u!e

t$e correct tpe of fluid. 8draulic fluid tpe can 5e identified 5 color and !"ellA $o(ever7 it i!

good practice to take fluid fro" t$e original "arked container and t$en to c$eck t$e fluid 5

color and !"ell for verification. 'luid container! !$ould al(a! 5e clo!ed7 e-cept ($en fluid i!

5eing re"oved.

I)%pe5&(*)%

8draulic and pneu"atic !!te"! are in!pected for leakage7 (orn or da"aged tu5ing7 (orn or

da"aged $o!e!7 (ear of "oving part!7 and !ecurit of "ounting for all unit!7 !afe ting7 and an ot$er

condition !pecified 5 t$e "aintenance "anual. A co"plete in!pection include! con!idering t$e age7 cure date7

!tiffne!! of t$e $o!e7 and an operational c$eck of all !u5!!te"!.

1. Leakage fro" an !tationar connection in a !!te" i! not per"itted7 and if found7 it !$ould

5e repaired. A !"all a"ount of fluid !eepage "a 5e per"itted on actuator pi!ton rod! and

rotating !$aft!. /n a $draulic !!te"7 a t$in fil" of fluid in t$e!e area! indicate! t$at t$e !eal!

are 5eing properl lu5ricated. =$en a li"ited a"ount of leakage i! allo(ed at an point7 it i!

u!uall !pecified in t$e appropriate "anual.

2. +u5ing !$ould not 5e nicked7 cut7 dented7 collap!ed7 or t(i!ted 5eond approved li"it!.

+$e identification "arking! or line! on a fle-i5le $o!e (ill !$o( ($et$er t$e $o!e $a!

5een t(i!ted.

3. All connection! and fitting! a!!ociated (it$ "oving unit! "u!t 5e e-a"ined for pla

evidencing (ear. Suc$ unit! !$ould 5e in an unpre!!uri;ed condition ($en t$e are

c$ecked for (ear.

&1

4. Accu"ulator! "u!t 5e c$ecked for leakage7 air or ga! preload7 and po!ition. /f t$e

accu"ulator i! e4uipped (it$ a pre!!ure gauge7 t$e preload can 5e read directl.

5. An operational c$eck of t$e !!te" can 5e perfor"ed u!ing t$e engine:driven pu"p7 an

electricall:operated au-iliar pu"p >if !uc$ a pu"p i! included in t$e !!te"@7 or a ground

te!t unit. +$e entire !!te" and eac$ !u5!!te" !$ould 5e c$ecked for !"oot$ operation7

unu!ual noi!e!7 and !peed of operation for eac$ unit. +$e pre!!ure !ection of t$e !!te"

!$ould 5e c$ecked (it$ no !u5!!te"! to !ee t$at pre!!ure $old! for t$e re4uired ti"e (it$out

t$e pu"p !uppling t$e !!te". S!te" pre!!ure !$ould 5e o5!erved during operation of eac$

!u5!!te" to en!ure t$at t$e engine:driven pu"p "aintain! t$e re4uired pre!!ure.

S$)* PROBLEM CAUSE REME0Y

1. Lack of $draulic pre!!ure Cefective pu"p #eplace t$e pu"p

in a !!te"

Ceflective relief valve

*re!!ure regulator defective

Lack of $draulic fluid 'ill (it$ fluid

2. S!te" failed to $old Cefective pre!!ure regulator #eplace t$e valve

pre!!ure >or@ Unloading valve

Leaking relief valve >or@ c$eck

valve

3. 8ig$ pre!!ure in a !!te" Cefective >or@ i"properl Set t$e re4uired pre!!ure

ad1u!ted o5!truction in a line in regulator and re"ove

or control unit t$e o5!truction.

&. U!uall noi!e in a Air >or@ conta"ination in t$e #e"ove conta"ination

$draulic !!te"! !uc$ a! !!te"

#eplace (it$ ne( one

c$attering and 5earing

'ault pre!!ure regulator

C$eck fluid level in

Lack of proper accu"ulator accu"ulator

5. ?ra55ing 5rake 9il or !o"e ot$er foreign Clean t$e di!k

"atter on di!k and lining

#eplace t$e di!k or dru"

#eplace t$e lining

&2

). 'ailing 5rake 3rake $ave 5een over $eated #e"ove t$e air

and t$ing! 5urned #eplace t$e !pring

C$ange t$e ne( valve

0. Cragging 5rake Air in $draulic #e"ove t$e air

3roken do(n or (eak return #eplace t$e !pring

!pring

C$ange t$e ne( valve

Cefective valve!

RESULT

+$u! a different !nag on aircraft $draulic !!te" and t$eir cau!e and re"ed i!

fa"iliari;ed.

VIVA-VOCE 9UESTIONS I

1. =$at i! ,ngine Align"entJ

2. =$at i! in!pectionJ

3. 8o( often t$e $draulic !!te" !ervice!J

4. =$at i! A66J

9UESTIONS E,PECTE0 FROM UNIVERSITY3

1. Ce!cri5e t$e different !nag! and pro5le" occur! in $draulic !!te" and it! rectification!.

&3

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Practitioner Guide 0512 Inspection, Maintenance & Testing of Equipment Installed at PetroleumDokument88 SeitenPractitioner Guide 0512 Inspection, Maintenance & Testing of Equipment Installed at PetroleumsusanwebNoch keine Bewertungen

- Method of Statement For Pressure Testing ProceduresDokument3 SeitenMethod of Statement For Pressure Testing ProceduresBen Lim82% (11)

- jt3020 SuplementoDokument115 Seitenjt3020 SuplementoArmando Chavez VazquezNoch keine Bewertungen

- Well Test ProgramDokument24 SeitenWell Test ProgramLaw100% (1)

- Well Integrity MaintenanceDokument164 SeitenWell Integrity MaintenanceZool Hilmi100% (1)

- Hydraulic Fault FindingDokument9 SeitenHydraulic Fault Findingkukuriku13Noch keine Bewertungen

- Intex Owners Manual Inflatable Boat ISO 6185 Boat Design Category DDokument14 SeitenIntex Owners Manual Inflatable Boat ISO 6185 Boat Design Category DALBMARINE SHIPPING CONoch keine Bewertungen

- Installation of Closed-Circuit Ammonia Refrigeration SystemsDokument28 SeitenInstallation of Closed-Circuit Ammonia Refrigeration SystemsWalisson HenriqueNoch keine Bewertungen

- Starting and IgnitionDokument9 SeitenStarting and IgnitionshyamsundarsrNoch keine Bewertungen

- Aircrafft Lubrication SystemDokument8 SeitenAircrafft Lubrication SystemshyamsundarsrNoch keine Bewertungen

- 0901b80380959cc7 PDFDokument2 Seiten0901b80380959cc7 PDFRonaldo ArlandNoch keine Bewertungen

- 50 Questions on Marine Auxiliary EquipmentDokument10 Seiten50 Questions on Marine Auxiliary Equipmentavm4343100% (6)

- Failure Analysis of Weld Neck Flange in A RefineryDokument10 SeitenFailure Analysis of Weld Neck Flange in A RefineryVenkat RanganNoch keine Bewertungen

- How To Prepare Literature ReviewsDokument18 SeitenHow To Prepare Literature ReviewsshyamsundarsrNoch keine Bewertungen

- Cement SqueezeDokument41 SeitenCement SqueezeHadi HendizadehNoch keine Bewertungen

- Daniel OrificeDokument60 SeitenDaniel Orificedocrafi75% (4)

- IBAMDokument10 SeitenIBAMSameer SalamNoch keine Bewertungen

- ModelDokument19 SeitenModelshyamsundarsrNoch keine Bewertungen

- LedDokument5 SeitenLedshyamsundarsrNoch keine Bewertungen

- UiicnDokument19 SeitenUiicnJeshiNoch keine Bewertungen

- Airport Authority of India Junior Executive (Cargo) - SyllabusDokument2 SeitenAirport Authority of India Junior Executive (Cargo) - SyllabusshyamsundarsrNoch keine Bewertungen

- Chief Educational Officer, Thanjavur Screening Test For Lab Assistant - May - 2015 Hall TicketDokument1 SeiteChief Educational Officer, Thanjavur Screening Test For Lab Assistant - May - 2015 Hall TicketshyamsundarsrNoch keine Bewertungen

- National Aerospace Laboratories: (NAL Website: WWW - Nal.res - In)Dokument2 SeitenNational Aerospace Laboratories: (NAL Website: WWW - Nal.res - In)Nishant UpadhyayaNoch keine Bewertungen

- AbbreviationsDokument10 SeitenAbbreviationsVivek MishraNoch keine Bewertungen

- Engine System Helicopter Theory NotesDokument20 SeitenEngine System Helicopter Theory NotesgurunathanpitsNoch keine Bewertungen

- How LCD Displays WorkDokument5 SeitenHow LCD Displays WorkshyamsundarsrNoch keine Bewertungen

- Financial Market OverviewDokument20 SeitenFinancial Market OverviewmuntaquirNoch keine Bewertungen

- Icing and AntiicingDokument11 SeitenIcing and AntiicingshyamsundarsrNoch keine Bewertungen

- Airport Authority of India Junior Executive (Cargo) - SyllabusDokument2 SeitenAirport Authority of India Junior Executive (Cargo) - SyllabusshyamsundarsrNoch keine Bewertungen

- Resume Cover Letter SamplesDokument7 SeitenResume Cover Letter Samplesklumer_xNoch keine Bewertungen

- Re Advt 2015Dokument7 SeitenRe Advt 2015Study IitNoch keine Bewertungen

- HCL Placement Paper 5Dokument9 SeitenHCL Placement Paper 5Nandini ReddyNoch keine Bewertungen

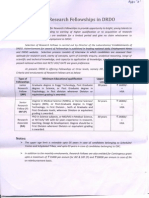

- The Scheme of Research Fellowships in DRDO: To To To To To To ToDokument1 SeiteThe Scheme of Research Fellowships in DRDO: To To To To To To ToVeera ChaitanyaNoch keine Bewertungen

- Composite 2014 IMP PDFDokument2 SeitenComposite 2014 IMP PDFshyamsundarsrNoch keine Bewertungen

- Ae2451 CM Nov 2013 QPDokument2 SeitenAe2451 CM Nov 2013 QPshyamsundarsrNoch keine Bewertungen

- Onwing Test PDFDokument27 SeitenOnwing Test PDFshyamsundarsrNoch keine Bewertungen

- Jet EngineDokument0 SeitenJet EngineV DhinakaranNoch keine Bewertungen

- Ae2451 CM Nov 2013 QPDokument2 SeitenAe2451 CM Nov 2013 QPshyamsundarsrNoch keine Bewertungen

- 4 2 2 1Dokument13 Seiten4 2 2 1raul19rsNoch keine Bewertungen

- Cms April 2010Dokument3 SeitenCms April 2010shyamsundarsrNoch keine Bewertungen

- Ae2037 Esc 2014Dokument2 SeitenAe2037 Esc 2014shyamsundarsrNoch keine Bewertungen

- Catia DrawingsDokument5 SeitenCatia DrawingsshyamsundarsrNoch keine Bewertungen

- MSH-2 FinalDokument26 SeitenMSH-2 FinalHarry Wart WartNoch keine Bewertungen

- D1503me3 PDFDokument47 SeitenD1503me3 PDFhristea marian100% (1)

- 10578200Dokument90 Seiten10578200Bradda Derru Nesta MarleyNoch keine Bewertungen

- Section 27 - Ranarex GravitometerDokument48 SeitenSection 27 - Ranarex GravitometeriqmpslabNoch keine Bewertungen

- Ozone LeaksDokument4 SeitenOzone Leaksdj22500Noch keine Bewertungen

- Din en 1074-1-2000Dokument19 SeitenDin en 1074-1-2000Bbiettg AndiarNoch keine Bewertungen

- Ok RH31LT HP200LP HP200LPWF Operating Instruction With BrochureDokument32 SeitenOk RH31LT HP200LP HP200LPWF Operating Instruction With Brochurehandoyo_eko20017573Noch keine Bewertungen

- Plug and Abandonment CatalogDokument12 SeitenPlug and Abandonment CatalogInes delcianeNoch keine Bewertungen

- FSA-G-605-11 Determinación Del TorqueDokument16 SeitenFSA-G-605-11 Determinación Del TorqueLuis Vallejo ZarzaNoch keine Bewertungen

- Formosa Air Permit 19168Dokument195 SeitenFormosa Air Permit 19168Victoria AdvocateNoch keine Bewertungen

- Htms Full Catalogue EnglishDokument51 SeitenHtms Full Catalogue EnglishReza PramataNoch keine Bewertungen

- Mitsubishi Electric MXZ-F Service Manual EngDokument206 SeitenMitsubishi Electric MXZ-F Service Manual EngMarina CoskovicNoch keine Bewertungen

- Terex Digger Derrick Operators Manual 7Dokument16 SeitenTerex Digger Derrick Operators Manual 7Israel SotoNoch keine Bewertungen

- Basic Pre Commissioning and Commissioning Safety 220826 082857Dokument32 SeitenBasic Pre Commissioning and Commissioning Safety 220826 082857İlyas FeyziyevNoch keine Bewertungen

- Fist3 30Dokument87 SeitenFist3 30flegias100% (1)

- Druckminderstation 300 200 eDokument35 SeitenDruckminderstation 300 200 ebehnam fallahNoch keine Bewertungen

- SF6 MSDSDokument7 SeitenSF6 MSDSjaycarpioNoch keine Bewertungen