Beruflich Dokumente

Kultur Dokumente

Mipro-E (Hyb)

Hochgeladen von

pradeepdesaiuch0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

77 Ansichten1 SeiteThis document provides information on MIPRO-E HYB, a three-component chemically resistant epoxy mortar. It can be used to line floors, drains, tanks and vessels in areas exposed to acids and alkalis. The mortar exhibits excellent bond strength and resistance to 90% sulfuric acid, organic solvents, and caustic conditions. It has high compressive and flexural strengths, low shrinkage, and can be applied to surfaces like brick, tile, stone, rubber and plastic. The document describes the product's properties, mixing and application instructions, packaging, storage requirements, and health and safety precautions.

Originalbeschreibung:

Epoxy morter

Originaltitel

MIPRO-E (HYB)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides information on MIPRO-E HYB, a three-component chemically resistant epoxy mortar. It can be used to line floors, drains, tanks and vessels in areas exposed to acids and alkalis. The mortar exhibits excellent bond strength and resistance to 90% sulfuric acid, organic solvents, and caustic conditions. It has high compressive and flexural strengths, low shrinkage, and can be applied to surfaces like brick, tile, stone, rubber and plastic. The document describes the product's properties, mixing and application instructions, packaging, storage requirements, and health and safety precautions.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

77 Ansichten1 SeiteMipro-E (Hyb)

Hochgeladen von

pradeepdesaiuchThis document provides information on MIPRO-E HYB, a three-component chemically resistant epoxy mortar. It can be used to line floors, drains, tanks and vessels in areas exposed to acids and alkalis. The mortar exhibits excellent bond strength and resistance to 90% sulfuric acid, organic solvents, and caustic conditions. It has high compressive and flexural strengths, low shrinkage, and can be applied to surfaces like brick, tile, stone, rubber and plastic. The document describes the product's properties, mixing and application instructions, packaging, storage requirements, and health and safety precautions.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

MIPRO-E (HYB)

ACID/ALKALI/SOLVENT RESISTANT EPOXY MORTAR

CHEMIPROTECT ENGINEERS

WORKS: Plot No. 2114, Phase III, GIDC Estate, Vatva, AHMEDABAD-382445, INDIA

TEL: 25891689, FAX: 079-25830002 EMAIL: chemiprotect@vsnl.com chemiproad1@sancharnet.in

DESCRIPTION: MIPRO-E HYB mortar is a versatile

three (3)-component chemical resistant hybrid resin

base mortar. The product exhibits excellent bond

strength, high chemical resistance and reliable curing

characteristics.

AREAS OF USE: MIPRO-E HYB can be used in

construction of acid resistant screed & brick/tile linings

to floors, drains, sumps, tank farm areas, tanks &

process vessels, waste water treatment plants etc. and

jointing mortar for red Mandana stone flooring. It is the

most suitable for use in installation of acid resistant

brick/tile lined areas, which are very often subjected to

concentrated acids and alkaline conditions.

OUTSTANDING FEATURS

Resistant to 90% Sulfuric acid conditions at room

temperature

Resistant to organic solvents

Resistant to Caustic Conditions & Hypo chlorite

solutions.

Very low Shrinkage

Excellent bond strength to acid resistant

brick/tile/stone

PHYSICAL PROPERTIES

Color Brown

Mix Ratio by wt. Binder to Powder 1: 3.75 to 4.5

Compressive Strength kg/cm

2

500

Flexural Strength kg/cm

2

150

Bond Strength kg/cm

2

10

Water Absorption 1%

Max. Temp. * (Wet / Dry) 60 to 120

o

C

Setting Time 3 to 6 hrs.

MIXING Make sure that the contents of each container

are thoroughly mixed before use.

1. Pour measured quantity (100 parts by wt.) of part A

into clean, dry mixing container.

2. Add measured quantity of part B (50 part by wt.)

and mix thoroughly for one minute.

3. Add measured quantity of part C filler (600 parts by

wt.) a little at a time, mix slowly until the filler is

thoroughly wetted by the resin (Part A) & Hardener

(Part B) mix, to produce a homogenous trowel able

mortar.

4. Mortar, which has begun to set, cannot be

recovered by adding more resin. Such mortar must

be discarded.

5. Never add water and any other diluents.

USE INSTRUCTIONS: MIPRO-E HYB mortar is

applied by trowel to clean, dry, neutral surface with

following procedures:

1) All bonding surface shall be buttered completely

without voids.

2) Mortar joints should be kept full, and minimum

4mm wide.

3) Mortar may be applied directly over mastic

membrane surface and other membrane surfaces

including rubber and plastics.

4) Reducing the ratio of filler in the mix shall not

lengthen the working & setting time of mortar.

These factors are best controlled by temperature.

CLEAN UP: Mixing & application tools should be

cleaned radically using M.E.K., xylene or toluene.

Observe proper safety precautions while cleaning.

CURE TIME: If the substrate and ambient air

temperature in contact with the acid resistant brick/tile

construction are at 25

0

C allow a minimum of 24 hours

cure time before putting the acid resistant brick/tile

lining construction to its intended service.

PACKING: Resin: 25 kegs and 200 kegs Hardener 15

kegs Filler 50 kegs in LDPE+HDPE bags.

STORAGE: All the components Resin, Hardener &

Filler must be kept in cool, dry place and in covered

shed.

HEALTH & SAFETY: It is advisable to wear

protective wears at the time of use of MIPRO-E HYB

and all other MIPRO brand products. In case of contact

with eyes and skin, wash with plenty of water and

consult a doctor.

This information, given above in good faith, is based on

results gained from experience and tests. However, all

recommendations or suggestions are made without

guarantee since the conditions of use is beyond our

control.

Das könnte Ihnen auch gefallen

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsVon EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNoch keine Bewertungen

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Life Deck 1200 Series 100 Solids Epoxy Primer SpecDokument2 SeitenLife Deck 1200 Series 100 Solids Epoxy Primer SpecEugenio Remis DuranNoch keine Bewertungen

- BASF Concresive 2525Dokument3 SeitenBASF Concresive 2525budhikurniawanNoch keine Bewertungen

- Durakol G HMDokument3 SeitenDurakol G HMpbodooNoch keine Bewertungen

- Hydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneDokument2 SeitenHydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneVenkata Raju KalidindiNoch keine Bewertungen

- C 500Dokument2 SeitenC 500gaiagmrNoch keine Bewertungen

- Flo-Grout BP800Dokument26 SeitenFlo-Grout BP800qasim078100% (1)

- TDS - Concresive ERLDokument2 SeitenTDS - Concresive ERLVenkata RaoNoch keine Bewertungen

- TDS - Rheofinish 288 FDDokument2 SeitenTDS - Rheofinish 288 FDVenkata RaoNoch keine Bewertungen

- MS JDB 007 - Annexure 2 - ABE Epidermix 344Dokument2 SeitenMS JDB 007 - Annexure 2 - ABE Epidermix 344Ben WalkerNoch keine Bewertungen

- Tuffkote Protective CoatingsDokument2 SeitenTuffkote Protective CoatingsioginevraNoch keine Bewertungen

- Bituflex HSDokument2 SeitenBituflex HSAnoop ShankarNoch keine Bewertungen

- Damp FreeDokument2 SeitenDamp FreeShashi Bhushan SinghNoch keine Bewertungen

- Polypoxy MH PDFDokument2 SeitenPolypoxy MH PDFsudhialakkalNoch keine Bewertungen

- Epoxy Floor Coating: Description FeaturesDokument2 SeitenEpoxy Floor Coating: Description FeaturesRayon 9Noch keine Bewertungen

- Rapid Set Tds - NoRestrictionDokument4 SeitenRapid Set Tds - NoRestrictionFloorkitNoch keine Bewertungen

- CP MoyaShield BEDokument3 SeitenCP MoyaShield BEGanesh MurthyNoch keine Bewertungen

- ResiGard SL2Dokument4 SeitenResiGard SL2fhsn84Noch keine Bewertungen

- Mixbond SBRDokument5 SeitenMixbond SBRGelila TadesseNoch keine Bewertungen

- Mastertop 1705 TdsDokument3 SeitenMastertop 1705 TdsrenandiaNoch keine Bewertungen

- FloArm Coat EFG Ver 5Dokument3 SeitenFloArm Coat EFG Ver 5praveenpatel.pp7143Noch keine Bewertungen

- Chemical Content Based On Modifided Polycarboyxlate Density 1,03 - 1,07 KG/L PH 7,7 - 9,7 Color Brown Total Chlorine Maximum %0,1 Alkali 5Dokument5 SeitenChemical Content Based On Modifided Polycarboyxlate Density 1,03 - 1,07 KG/L PH 7,7 - 9,7 Color Brown Total Chlorine Maximum %0,1 Alkali 5DilshadNoch keine Bewertungen

- Bio ShieldDokument3 SeitenBio ShieldVimal GopalakrishnanNoch keine Bewertungen

- Joint EpoxiDokument1 SeiteJoint EpoximchanNoch keine Bewertungen

- Epocoat Primer 0Dokument3 SeitenEpocoat Primer 0Laurel Rivero Jr.Noch keine Bewertungen

- AD Type TC-55 SealerDokument2 SeitenAD Type TC-55 SealerTanmay GorNoch keine Bewertungen

- Maricoat 2000: Polyurethane Self-Leveling Floor CoatingDokument2 SeitenMaricoat 2000: Polyurethane Self-Leveling Floor CoatingSunny SinghNoch keine Bewertungen

- TDS ShaliPrime ScreedDokument2 SeitenTDS ShaliPrime ScreedRana MahatoNoch keine Bewertungen

- Masterbrace Adh 2200 TdsDokument2 SeitenMasterbrace Adh 2200 TdsarchahmedassafNoch keine Bewertungen

- MasterTile® 700 PDFDokument7 SeitenMasterTile® 700 PDFJong Dollente Jr.Noch keine Bewertungen

- Kan FlexDokument3 SeitenKan FlexSunny SinghNoch keine Bewertungen

- RHEOMIX 141 v7Dokument2 SeitenRHEOMIX 141 v7sudhreddyNoch keine Bewertungen

- Brushable Ceramic Red BlueDokument2 SeitenBrushable Ceramic Red BlueWildor Cordova SanchezNoch keine Bewertungen

- Linseed Oil TreatmentDokument2 SeitenLinseed Oil TreatmentsathiyanNoch keine Bewertungen

- Masterprotect 1814 TdsDokument3 SeitenMasterprotect 1814 TdsfirozembrayilNoch keine Bewertungen

- Coal Tar Epoxy 4: DescriptionDokument2 SeitenCoal Tar Epoxy 4: DescriptionAbhisheK MishrANoch keine Bewertungen

- Masterflex 700 PGDokument3 SeitenMasterflex 700 PGHaresh BhavnaniNoch keine Bewertungen

- Epoxy GroutDokument4 SeitenEpoxy GroutVineet ChauhanNoch keine Bewertungen

- Metz 19Dokument2 SeitenMetz 19dirafly3566Noch keine Bewertungen

- Nitomortar ElDokument4 SeitenNitomortar ElBalasubramanian AnanthNoch keine Bewertungen

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDokument3 SeitenMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNoch keine Bewertungen

- Nitomortar MHDokument4 SeitenNitomortar MHmilanbrasinaNoch keine Bewertungen

- Relipoxy P 301: Epoxy Based PrimerDokument3 SeitenRelipoxy P 301: Epoxy Based PrimerPRERAKNoch keine Bewertungen

- TDS - Concresive 1414Dokument2 SeitenTDS - Concresive 1414Venkata RaoNoch keine Bewertungen

- ChemFlex (2019 - 06 - 16 07 - 33 - 19 UTC)Dokument2 SeitenChemFlex (2019 - 06 - 16 07 - 33 - 19 UTC)smart construction solution solutionNoch keine Bewertungen

- Davco TTB ECO Brochure 1Dokument2 SeitenDavco TTB ECO Brochure 1hinal pNoch keine Bewertungen

- Conmix C800 2011Dokument2 SeitenConmix C800 2011Fredj Ben Salem50% (4)

- 80 34 Product Data Sheet Hi Flow Renovation June 2013Dokument2 Seiten80 34 Product Data Sheet Hi Flow Renovation June 2013faysal91Noch keine Bewertungen

- DR Fixit SafeguardDokument3 SeitenDR Fixit SafeguardrpdeepuNoch keine Bewertungen

- 14 - TDS - Concresive 2020Dokument2 Seiten14 - TDS - Concresive 2020aahtagoNoch keine Bewertungen

- TDS Bitulastic BituflexDokument3 SeitenTDS Bitulastic Bituflexd TjonasanNoch keine Bewertungen

- Masterflex 700 GGDokument3 SeitenMasterflex 700 GGHaresh BhavnaniNoch keine Bewertungen

- Thioflex 600Dokument4 SeitenThioflex 600Conifer YuNoch keine Bewertungen

- 8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5Dokument5 Seiten8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5yoxan25808Noch keine Bewertungen

- Epiplus 556Dokument2 SeitenEpiplus 556hareesh13h100% (1)

- Renderoc HSDokument2 SeitenRenderoc HSAdnan JadoonNoch keine Bewertungen

- 3 MS - Bostik CereBest FugaDokument3 Seiten3 MS - Bostik CereBest FugaAngelo Carlo MalabananNoch keine Bewertungen

- Creative Resin: Easy techniques for contemporary resin artVon EverandCreative Resin: Easy techniques for contemporary resin artNoch keine Bewertungen

- Detailers Dictionary Volume 2: The Industry StandardVon EverandDetailers Dictionary Volume 2: The Industry StandardNoch keine Bewertungen

- General Aspect of Energy Management and Energy AuditDokument259 SeitenGeneral Aspect of Energy Management and Energy Auditpradeepdesaiuch67% (3)

- 6533 1Dokument23 Seiten6533 1Er Ravinder Reddy DevireddyNoch keine Bewertungen

- Cyclone Pressure DropDokument8 SeitenCyclone Pressure DroppradeepdesaiuchNoch keine Bewertungen

- MTDC Hotel & Rooms With RentsDokument23 SeitenMTDC Hotel & Rooms With RentspradeepdesaiuchNoch keine Bewertungen

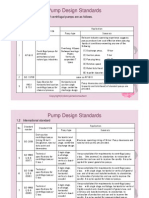

- Pump Standards ComparisonDokument4 SeitenPump Standards ComparisonAnish Dani50% (2)

- Doha 12 MahinaDokument1 SeiteDoha 12 Mahinapradeepdesaiuch100% (2)

- Design, Detailed Engineering For Chemical, Pharma and Oil & Gas IndustriesDokument25 SeitenDesign, Detailed Engineering For Chemical, Pharma and Oil & Gas IndustriespradeepdesaiuchNoch keine Bewertungen

- g01 PDFDokument1 Seiteg01 PDFpradeepdesaiuchNoch keine Bewertungen

- Starters Flash CardsDokument28 SeitenStarters Flash CardsNara GarridoNoch keine Bewertungen

- Ural Evelopment: 9 9 Rural DevelopmentDokument17 SeitenUral Evelopment: 9 9 Rural DevelopmentDivyanshu BaraiyaNoch keine Bewertungen

- Transformers: Z Z Z S S Z S SDokument17 SeitenTransformers: Z Z Z S S Z S SSreenivasaraoDharmavarapu100% (1)

- Study of Behavior of Bacterial ConcreteDokument20 SeitenStudy of Behavior of Bacterial ConcreteGodwin KopelliNoch keine Bewertungen

- ESR 2538 ChemofastDokument14 SeitenESR 2538 ChemofastEduardo Antonio Duran SepulvedaNoch keine Bewertungen

- The Coca-Cola Company - Wikipedia, The Free EncyclopediaDokument11 SeitenThe Coca-Cola Company - Wikipedia, The Free EncyclopediaAbhishek ThakurNoch keine Bewertungen

- Tryout Consent Form - 2014 - Sign and ReturnDokument2 SeitenTryout Consent Form - 2014 - Sign and ReturnSanjeevan BaraNoch keine Bewertungen

- Meng Mammogram JulDokument4 SeitenMeng Mammogram JulLivia MillNoch keine Bewertungen

- Insulating Oil TestingDokument6 SeitenInsulating Oil TestingnasrunNoch keine Bewertungen

- Jurnal Gerd PDFDokument6 SeitenJurnal Gerd PDFdilaNoch keine Bewertungen

- Impact of Job Design On Employee Engagement: A Theoretical and Literature ReviewDokument6 SeitenImpact of Job Design On Employee Engagement: A Theoretical and Literature ReviewAnonymous CwJeBCAXpNoch keine Bewertungen

- Drake Family - Work SampleDokument1 SeiteDrake Family - Work Sampleapi-248366250Noch keine Bewertungen

- Alternative ObligationsDokument42 SeitenAlternative ObligationsJanella Gail FerrerNoch keine Bewertungen

- Uni of Glasgow Map PDFDokument1 SeiteUni of Glasgow Map PDFJiaying SimNoch keine Bewertungen

- Sociology/Marriage PresentationDokument31 SeitenSociology/Marriage PresentationDoofSadNoch keine Bewertungen

- 03 Secondary School Student's Academic Performance Self Esteem and School Environment An Empirical Assessment From NigeriaDokument10 Seiten03 Secondary School Student's Academic Performance Self Esteem and School Environment An Empirical Assessment From NigeriaKienstel GigantoNoch keine Bewertungen

- Om Deutz 1013 PDFDokument104 SeitenOm Deutz 1013 PDFEbrahim Sabouri100% (1)

- Ethics, Privacy, and Security: Lesson 14Dokument16 SeitenEthics, Privacy, and Security: Lesson 14Jennifer Ledesma-Pido100% (1)

- On How To Design A Low Voltage SwitchboardDokument11 SeitenOn How To Design A Low Voltage SwitchboardsabeerNoch keine Bewertungen

- Content of An Investigational New Drug Application (IND)Dokument13 SeitenContent of An Investigational New Drug Application (IND)Prathamesh MaliNoch keine Bewertungen

- Fortune Falls - Lou VaneDokument402 SeitenFortune Falls - Lou VanetesteNoch keine Bewertungen

- Martins Taylorb Os 10742 Final Opinion 2 11 2022 02898337xd2c78Dokument9 SeitenMartins Taylorb Os 10742 Final Opinion 2 11 2022 02898337xd2c78Live 5 NewsNoch keine Bewertungen

- Sampoong Department Store - A Literary Critique (Mimetic Theory)Dokument2 SeitenSampoong Department Store - A Literary Critique (Mimetic Theory)Ron Marc CaneteNoch keine Bewertungen

- AUDCISE Unit 1 WorksheetsDokument2 SeitenAUDCISE Unit 1 WorksheetsMarjet Cis QuintanaNoch keine Bewertungen

- Injection Analyzer Electronic Unit enDokument67 SeitenInjection Analyzer Electronic Unit enmayralizbethbustosNoch keine Bewertungen

- Silly VersesDokument29 SeitenSilly Verseskevin daleNoch keine Bewertungen

- Cisco - Level 45Dokument1 SeiteCisco - Level 45vithash shanNoch keine Bewertungen

- Why Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptDokument27 SeitenWhy Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptCrown Publishing Group62% (34)

- Plastic Omnium 2015 RegistrationDokument208 SeitenPlastic Omnium 2015 Registrationgsravan_23Noch keine Bewertungen

- InotroposDokument4 SeitenInotroposjuan camiloNoch keine Bewertungen