Beruflich Dokumente

Kultur Dokumente

Datasheet PDF

Hochgeladen von

perro sOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Datasheet PDF

Hochgeladen von

perro sCopyright:

Verfügbare Formate

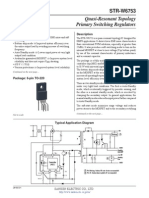

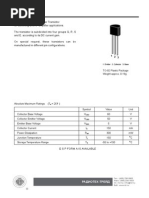

STR-W6251D

Description

The STR-W6200D series are current-mode PWM ICs that

incorporate controller chips. These devices are manufactured

using a proprietary high-voltage BCD process, and avalanche-

guaranteed MOSFETs. These elements allow power supply

systems designs that are highly reliable and simple, with fewer

peripheral components. These ICs also provide Auto-Burst

mode operation, which lowers input power requirements at

light loads, and improves efficiency over the entire load range

and universal-input range.

Applicatons include:

TV set top box

LCD PC monitor, LCD TV

Printer, scanner

General consumer, PC, and industrial applications

requiring SMPS power supply with standby mode

Features and Benefits

Overcurrent protection (OCP) with ac input voltage

compensation function; no additional peripheral circuits

requiredminimizes dependency of OCP on ac input

Overload protection (OLP) with integrated timer reduces

power stress (temperature rise) at overload condition,

requires no peripheral components

Avalanche-guaranteed MOSFET improves device

capability of withstanding excess surge voltage,

providing a simple surge absorber circuit without

breakdown voltage derating

Start-up circuit eliminates the need for a start-up resistor,

and helps to reduce input power consumption

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

Functional Block Diagram

Package: TO-220

Not to scale

Continued on the next page

28103.51

DRV

D/ST VCC

LEB S/OCP

TSD

PWM OSC

REG

FB

15.5 V/ 8.9 V

D

MAX

75%

28.5 V

7.8 V

GND

FM/ELP

160 A

R

SQ

S Q

R

7.1 V

Slope

Compensation

Drain Peak

Current

Compensation

VREG

STARTUP

I

startup

=1.6 mA

S2 Q

CK

S1

R

OLP

t

OLP

=

t

FM32

Frequency

Modulation

RQ

S

UVLO

ELP

RST

7.1 V

OVP

Feedback

Control

OCP

12 V

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Bias Assist function improves start-up performance by self-

biasing the VCC pin, and allows a use of a small value VCC

capacitor, resulting in improved response to overvoltage

conditions

Very low current consumption in nonoperating (UVLO) state:

I

CC(off)

= 5 A (typical) at V

CC

= 13.8 V

Slope compensation circuit stabilizes operation, preventing

interference from subharmonics

Leading Edge Blanking

Various protections:

Overcurrent Protection (OCP), pulse-by-pulse sensing

Overload Protection (OLP), auto restart after certain duration

External Latch Protection (ELP), latched

Overvoltage Protection (OVP), latched

Thermal Shut Down (TSD), latched

Externally-activated shut down protection (ELP) for

emergency system shut down

Auto-Burst Standby function (pin < 0.1 W at zero output load

condition)

Audible noise reducing function in Standby mode

TO-220 full-molded package with 6 pins

Features and Benefits (continued)

Selection Guide

Part Number Packing

STRW6251D 50 pieces per tube

Pin-out Diagram

All performance characteristics given are typical values for circuit or

system baseline design only and are at the nominal operating voltage and

an ambient temperature, T

A

, of 25C, unless oth er wise stated.

1 2 3 4 5 6 7

Terminal List Table

Number Name Description Functions

1 D/ST Drain/startup terminal MOSFET drain and input of start-up signal

2 NC Clipped No connection

3 S/OCP

Source/Overcurrent Protection

terminal

MOSFET source and input of overcurrent

detection signal

4 VCC Power supply terminal Input of power supply for control circuit

5 GND Ground terminal Ground

6 FB Feedback terminal Input of constant voltage control signal

7 FM/ELP

Frequency jittering and External

Latch Protection terminal

Control input for frequency jittering control and

External Latch Protection

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ABSOLUTE MAXIMUM RATINGS at T

A

= 25C

Characteristic Symbol Terminal Note Rating Unit

Drain Current

1

I

Dpeak

1-3 Single Pulse 2.6 A

Maximum Switching Current

2

I

DMAX

1-3 T

A

= 20 to 125C 2.6 A

Single Pulse Avalanche Energy

3

E

AS

1-3 Single Pulse 47 mJ

I

Dpeak

1-3 V

DD

= 99 V, L = 20 mH 2 A

S/OCP Terminal Voltage V

OCP

3-5 6 to 6 V

FM/ELP Terminal Voltage V

FM

7-5 0.3 to 14 V

FM/ELP Terminal Inflow Current I

FM

7-5 3 mA

FB Terminal Voltage V

FB

6-5 0.3 to 9 V

Controller (MIC) Input Voltage V

CC

4-5 0 to 32 V

MOSFET Power Dissipation

4

P

D1

8-1

With infinite heatsink 25 W

Without heatsink 1.3 W

Controller (MIC) Power Dissipation P

D2

5-3 For VccIcc 0.8 W

Operating Internal Frame Temperature T

F

Refer to T

OP

20 to 115 C

Operating Ambient Temperature T

op

20 to 115 C

Storage Temperature T

stg

40 to 125 C

Channel Junction Temperature T

J

150 C

1

Refer to figure 1

2

I

DMAX

is the drain current on the D/ST pin determined by the drive voltage of the IC and the threshold voltage, V

th

, of the MOSFET

3

Refer to figure 3

4

Refer to figure 4

Temperature, T

F

(C)

S

a

f

e

O

p

e

r

a

t

i

n

g

A

r

e

a

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

0

20

40

60

80

100

0 25 50 75 100 125 150

Drain-to-Source Voltage, V

DS

(V)

D

r

a

i

n

C

u

r

r

e

n

t

,

I

D

(

A

)

10.00

0.10

1.00

0.01

100.00

10 100 1000 1

1

m

s

0

.

1

m

s

C

u

r

r

e

n

t

lim

it

d

u

e

t

o

R

D

S

(

o

n

)

Refer to figure 1 for MOSFET SOA

temperature derating coefficient

Figure 1 MOSFET Safe Operating Area

Derating Curve

Figure 2 MOSFET Safe Operating Area

Drain Current versus Voltage

at T

A

= 25C, Single Pulse

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

4

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Channel Junction Temperature, T

J

(C)

E

A

S

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

0

20

40

60

80

100

25 50 75 100 125 150

Time, t (s)

T

r

a

n

s

i

e

n

t

T

h

e

r

m

a

l

R

e

s

i

s

t

a

n

c

e

,

R

J

C

(

C

/

W

)

1.00

0.10

0.01

10.00

100 10 10m 1m 100m 1

Ambient Temperature, T

A

(C)

P

o

w

e

r

D

i

s

s

i

p

a

t

i

o

n

,

P

D

1

(

W

)

0

5

10

15

20

25

30

0 20 40 60 80 100 120 140 160

P

D1

= 1.3 W at T

A

25C

Without heatsink

With infinite heatsink

P

D1

= 25 W at T

A

25C

Figure 3 MOSFET Avalanche Energy Derating Curve Figure 4 Transient Thermal Resistance

Figure 5 MOSFET Power Dissipation versus Temperature

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

5

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ELECTRICAL CHARACTERISTICS valid at V

CC

= 18 V, T

A

= 25C, unless otherwise specified

Characteristic Symbol Terminal Test Conditions Min. Typ. Max Units

Power Supply Start-up Operation

Operation Start Voltage V

CC(ON)

4-5

(VCC voltage at which operation starts) Measurement

circuit 1, V

CC

= 0 through 13.9 through 17.1 V

13.9 15.5 17.1 V

Operation Stop Voltage V

CC(OFF)

4-5

(VCC voltage at which operation stops) Measurement

circuit 1, V

CC

= 17.1 through 9.8 to 8.0 V

8.0 8.9 9.8 V

Circuit Current in Operation I

CC(ON)

4-5

(Inflow current into VCC terminal in oscillation)

Measurement circuit 1

1.4 2.8 mA

Circuit Current in Non-Oscillation I

CC(STOP)

4-5

(Inflow current into VCC terminal at V

FB

= 0 V)

Measurement circuit 1

0.8 1.3 mA

Circuit Current in Non-Operation I

CC(OFF)

4-5

(Inflow current into VCC terminal prior to oscillation)

Measurement circuit 1, V

CC

= 13.8

5 20 A

Start-up Current I

startup

4-5

(Inflow current into D/ST terminal) Measurement

circuit 7, V

CC

= 0, D/ST = 450 V

0.9 1.6 2.3 mA

Bias Assist Voltage V

BIAS

4-5

(VCC voltage at which I

startup

starts, and I

startupBias

begins) Measurement circuit 7, V

CC

= 17.1 through

13.6 to 16.8 V

13.6 15.2 16.8 V

Normal Operating Characteristics

FM/ELP High Threshold Voltage V

FM(H)

7-5

(FM/ELP terminal voltage at which I

FM

changes from

13 A to 13 A) Measurement circuit 2

4.0 4.5 5.0 V

FM/ELP Low Threshold Voltage V

FM(L)

7-5

(FM/ELP terminal voltage at which I

FM

changes from

13 A to 13 A) Measurement circuit 2

2.4 2.8 3.2 V

FM/ELP Voltage Hysteresis V

FMhys

7-5 (V

FM(H)

V

FM(L)

) Measurement circuit 2 1.3 1.7 1.9 V

FM/ELP Outflow Current

1

I

FMsrc

7-5

(FM/ELP terminal outflow current at V

FM

= V

FM(L)

)

Measurement circuit 2

17.4 13 8.6 A

FM/ELP Inflow Current

1

I

FMsink

7-5

(FM/ELP terminal inflow current at V

FM

= V

FM(H)

)

Measurement circuit 2

8.6 13 17.4 A

Average Switching Frequency f

OSC(av)

1-5

(D/ST terminal average oscillation frequency)

Measurement circuit 2

60 67 74 kHz

Frequency Jitter Deviation f 1-5 f

OSC

(peak-to-peak) Measurement circuit 2 4.8 6.9 9 kHz

Maximum Duty Cycle D

MAX

1-5

(Maximum width of the low portion of the D/ST

terminal waveform) Measurement circuit 2

71 75 79 %

FB Maximum Feedback Current

1

I

FB(MAX)

6-5

(FB terminal outflow current at V

FB

= 0 V)

Measurement circuit 3

220 160 100 A

Burst Threshold Voltage V

burst(th)

6-5

Set V

FM

= 0 V and decrease V

FB

(V

burst(th)

is the FB

terminal voltage level at which D/ST changes from

low to high) Measurement circuit 3

0.99 1.10 1.21 V

Slope Compensation Start-up

Duty Cycle

D

SLP

6-5

D

SLP

= (t3 / t4) 100 (see figure for measurement

circuit 4 for values of t) Measurement circuit 4

27 %

Slope Compensation Rate SLP 6-5

SLP = 0.02 / (t2 t1) (see figure for measurement

circuit 4 for values of t) Measurement circuit 4

22 17 12 mV/s

Continued on next page

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

6

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Protection Operation

OCP Threshold Voltage at Zero

Duty Cycle (0% On-Duty)

V

OCP1

3-5

Set V

FM

= 0 V and increase V

OCP.

(V

OCP1

is the S/OCP

terminal voltage level at which D/ST changes from

low to high) Measurement circuit 5

0.71 0.78 0.86 V

Drain Peak Current Compensation

Coefficient

D

PC

D

PC

= 0.75 SLP / f

OSC(av)

1.5 1.9 2.3

mV/

DC%

OCP Threshold Voltage After

Compensation

V

OCP2

3-5 V

OCP2

= D

PC

D

MAX

+ V

OCP1

0.82 0.93 1.04 V

Leading Edge Blanking Time t

blank

1-5

(The low portion of the D/ST terminal waveform at

V

OCP

= 2 V) Measurement circuit 5

280 400 520 ns

OLP Delay Time t

OLP

1-5

(Time between setting FB terminal open and when

oscillation stops) Measurement circuit 6

200 ms

Circuit Current in OLP-Operation I

CC (OLP)

4-5

(Inflow current into VCC terminal after OLP operation)

Measurement circuit 6

410 700 A

OVP Protection Voltage V

CC(OVP)

4-5

(VCC terminal voltage at which the voltage of D/ST

terminal is switched from low to high by decreasing

V

FB

after setting V

FM

= 0 V) Measurement circuit 1,

V

CC

= 18.0 V through 27 to 30 V

27 28.5 30 V

Latch Circuit Sustaining Current

2

I

CC(La.H)

4-5

(Inflow current into VCC terminal after OVP operation)

Measurement circuit 1, V

CC

= 8 V

140 220 A

Latch Circuit Release Voltage

2

V

CC(La.OFF)

4-5

(VCC voltage at which I

CC

is dropped below 20 A by

decreasing V

CC

after OVP operation)

V

CC

= 31.0 V through 7.8 to 6.4 V

6.4 7.1 7.8 V

ELP Threshold Voltage V

ELP

7-5

(FM/ELP terminal voltage at which the oscillation of

the D/ST terminal waveform is stopped by increasing

V

FM

) Measurement circuit 2

6.4 7.1 7.8 V

Inflow Current at External Latch

Protection

I

ELP

7-5 (Inflow current at V

FM

= V

ELP

) Measurement circuit 2 55 100 A

Thermal Shut Down Operating

Temperature

T

JTSD

135 C

Power MOSFET Characteristics

Drain-to-Source Breakdown Voltage V

DSS

1-3 I

D

= 300 A, Measurement circuit 8 650 V

Drain Leakage Current I

DSS

1-3 V

D

= 650 V, Measurement circuit 7 300 A

ON-Resistance R

DS(ON)

1-3 I

D

= 0.6 A, V

FM

= 0 V Measurement circuit 10 3.95

Switching Time t

r

1-3 Measurement circuit 9 400 ns

Thermal Resistance R

J-F

Measured between junction and internal frame 2.23 C/W

Single Pulse Avalanche Energy E

AS

Measurement circuit 11

1

Input and output current polarity at the device pin; plus(+) represents sink and minus() represents source.

2

The latch circuit means a circuit operated ELP, OVP, and TSD.

ELECTRICAL CHARACTERISTICS, continued, valid at V

CC

= 18 V, T

A

= 25C, unless otherwise specified

Characteristic Symbol Terminal Test Conditions Min. Typ. Max Units

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

7

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

13.8V

VCC(ON)

VCC(OFF)

18V

ICC(OFF)

VCC

VD

ICC

VCCc(La.OFF)

8V

ICC(La.H) ICC(STOP)

32V

VD

VFM

VFML

VFMH

VLFM+(VFMH-VFML)/2

IFM

f osc(av)

t1

Isnk(FM)

f osc(Hi) f osc(Lo)

t2

f =f osc(Hi)-f osc(Lo)

Dmax= t2/ t1100

Isrc(FM)

0A

4.5Vtyp

2.8Vtyp

VELP

1F

VCC

100

A

+

ICC

VDD 10V

VD

100

VDD 10V

VD

A

IFM

VFM

18V

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

100

VDD 10V

VD

A

IFB

VFB

VFM

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

ICC(ON)

VFB

5V

VFB VFM

VFM

VCC(OVP)

2V

3.65V

0V

1F

VCC

+

18V

1F

VCC

+

0V

0V

VCC

18V

VFB

0V

VFB

5V

VFM

Vburst

VFB

VD

0V

IFB(MAX)

-IFB

VHYS

5V

0V

VCC

18V

VOFF(FM)

IELP

IFB(MIN)

5V

5V

0V

5V

5V

Measurement Circuit 1

Measurement Circuit 2

Measurement Circuit 3

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

8

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Measurement Circuit 4

Measurement Circuit 6

Measurement Circuit 5

VD

VOCP

VOCP1

VD(Lo)

t

blank

0V

2V

VFM

VD

ICC

100

VDD 10V

VD

t OLP(= t FM16)

ICC(OLP)

t FM

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

VFM

5V

0V

3.65V

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

VFB

7.8 V typ

VFB

VFM

18V

1F

VCC

+

VOCP

100

VDD 20V

VD

1

VFM

47nF

1F

VCC

A

+

ICC

18V

VCC

18V

VCC

18 V

SW ONOFF

SW

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

VFB

4V

VFM

18V

1F

VCC

+

VOCP

100

VDD 10V

VD

VFB

VD

4V

VOCP

Internal f eedback signal

V1-0.04V

V1-0.02V

t1 t2

t4

0.68V

VCC

18V

VFM

3.65V

5V

t3

t5(t

blank

)

DSLP= t3 / t4 100

SLP = 0.02 / (t2-t1)

V1

V

OCP2

= (0.75 SLP D

MAX

/ f

OSC(av)

) + V

OCP1

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

9

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10V

90%

10%

tr

VDD

A

ID

ID

VD

V

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

VD

100

VDD 10V

VD

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

RDS(ON)=VD(Lo) / 0.6

1F

VCC

+

VFM

VFM

47nF

18V

1F

VCC

+

VFM

47nF

18V

1F

VCC

+

VD VD(Lo)

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

VFM

5V

0V

VFM

18V

1F

VCC

+

1

ID

VD

V

0.6A

VCC

18V

A

ICC

300

A

VDD

VCC

ID

650V

13V

IDSS

VFM

18V

5V

VBIAS

0V

0V

400V

ISTARTUP

ICC

Measurement Circuit 7

Measurement Circuit 8 Measurement Circuit 9

Measurement Circuit 10

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

10

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

TYPICAL APPLICATION CIRCUIT

1 4

3 7 5 6

VCC D/ST

FM/

ELP

STR-W 6200D

S/OCP

VIIN(ac)

GND

OUT

GND

FB

Option

Measurement Circuit 11

L

VDS

Vcc 18V

VGS 8V

VDS

IL

VDSpeak

VDD

t

VDD

VGS

1

D/ST S/OCP VCC GND FB

FM/

ELP

STR-W6200D

3 4 5 6 7 4 6

18V

1F

VCC

+

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

11

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

PACKAGE DIMENSIONS, TO-220

10.0 0.2

4.2 0.2

2.8 0.2

3

.

2

0

.

2

2.6 0.1

(

2

R

1

)

Terminal dimension at case surface

5.08 0.6

1.74

+0.2

0.1

1.34

+0.2

0.1

0.45

+0.2

0.1

1

6

.

9

0

.

3

1

0

.

4

0

.

5

5

.

0

0

.

5

7

.

9

0

.

2

4

0

.

2

2

.

8

M

A

X

(

5

.

4

)

Gate Burr

Branding

XXXXXXXX

XXXXXXXX

Gate burr: 0.3 mm (max.)

Terminal core material: Cu

Terminal treatment: Ni plating and solder dip

Heat sink material: Cu

Heat sink treatment: Ni plating

Leadform: 2003

Weight (approximate): 2.3 g

Dimensions in millimeters

Drawing for reference only

Branding codes (exact appearance at manufacturer discretion):

1st line, type: W6251

2nd line, lot: YMDD R

Where: Y is the last digit of the year of manufacture

M is the month (1 to 9, O, N, D)

DD is the 2-digit date

R is the manufacturer registration symbol

1 2 3 4 5 6 7

Terminal dimensions at case surface

6P1.27 0.15 = 7.62 0.15

Terminal dimension at lead tips

Leadframe plating Pb-free. Device composition

complies with the RoHS directive.

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

12

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

PACKING SPECIFICATIONS

Minimum packing option: Tube FM-205 E

Shipping Tube Dimensions:

Wall thickness: 0.60.3 mm

Wall warp: <2 mm

Material: Hardened polyvinyl

Coating: antistatic

Tolerance 0.4 mm,

unless otherwise specified

All dimensions: mm

Side marked

ANTISTATIC

(3.6)

(

1

5

.

4

)

9 R0.6

5.1

2.85

14.3

8

.

9

3

5

.

0

1.4

9

.

5

+

0

.

3

0

.

1

4.8

+0.4

0

1.3

+0.3

0.2

Shipping Carton Dimensions:

Capacity: 1800 pieces maximum per carton

36 tubes per carton

3 rows, 12 tubes per row

Spacer

Carton

(side

view)

Spacer

Tube

6

2

0

1

2

5

1

85

Tube

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

13

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Because reliability can be affected adversely by improper storage environments and handling methods, please observe the following cautions.

Cautions for Storage

Ensure that storage conditions comply with the standard temperature (5C to 35C) and the standard relative humidity (around 40 to 75%); avoid

storage locations that experience extreme changes in temperature or humidity.

Avoid locations where dust or harmful gases are present and avoid direct sunlight.

Reinspect for rust in leads and solderability of products that have been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and other standard test periods, protect the products from power surges from the testing device,

shorts between adjacent products, and shorts to the heatsink.

Remarks About Using Silicone Grease with a Heatsink

When silicone grease is used in mounting this product on a heatsink, it shall be applied evenly and thinly. If more silicone grease than required is

applied, it may produce stress.

Volatile-type silicone greases may produce cracks after long periods of time, resulting in reduced heat radiation effect. Silicone grease with low

consistency (hard grease) may cause cracks in the mold resin when screwing the product to a heatsink.

Our recommended silicone greases for heat radiation purposes, which will not cause any adverse effect on the product life, are indicated below:

Type Suppliers

G746 Shin-Etsu Chemical Co., Ltd.

YG6260 GE Toshiba Silicone Co., Ltd.

SC102 Dow Corning Toray Silicone Co., Ltd.

Soldering

When soldering the products, please be sure to minimize the working time, within the following limits:

2605C 10 s

3505C 3 s

Soldering iron should be at a distance of at least 1.5 mm from the body of the products

Electrostatic Discharge

When handling the products, operator must be grounded. Grounded wrist straps worn should have at least 1 M of resistance to ground to prevent

shock hazard.

Workbenches where the products are handled should be grounded and be provided with conductive table and floor mats.

When using measuring equipment such as a curve tracer, the equipment should be grounded.

When soldering the products, the head of soldering irons or the solder bath must be grounded in other to prevent leak voltages generated by them

from being applied to the products.

The products should always be stored and transported in our shipping containers or conductive containers, or be wrapped in aluminum foil.

Assembly

During soldering or other operations, the interior frame temperature of the device should never exceed 105C.

Recommended screw torque through the mounting tab is 0,588 to 0.785 N m (6 to 8 kgf cm)

WARNING These devices are designed to be operated at lethal voltages and energy levels. Circuit designs

that embody these components must conform with applicable safety requirements. Pre cau tions must be

taken to prevent accidental contact with power-line potentials. Do not connect ground ed test equipment.

The use of an isolation transformer is recommended during circuit development and breadboarding.

www.DataSheet4U.com

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

14

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

The products described herein are manufactured in Ja pan by Sanken Electric Co., Ltd. for sale by Allegro MicroSystems, Inc.

Sanken and Allegro reserve the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be re quired to per mit im-

prove ments in the per for mance, reliability, or manufacturability of its prod ucts. Therefore, the user is cau tioned to verify that the in for ma tion in this

publication is current before placing any order.

When using the products described herein, the ap pli ca bil i ty and suit abil i ty of such products for the intended purpose shall be reviewed at the users

responsibility.

Although Sanken undertakes to enhance the quality and reliability of its prod ucts, the occurrence of failure and defect of semi con duc tor products

at a certain rate is in ev i ta ble.

Users of Sanken products are requested to take, at their own risk, preventative measures including safety design of the equipment or systems

against any possible injury, death, fires or damages to society due to device failure or malfunction.

Sanken products listed in this publication are designed and intended for use as components in general-purpose electronic equip ment or apparatus

(home ap pli anc es, office equipment, tele com mu ni ca tion equipment, measuring equipment, etc.). Their use in any application requiring radiation

hardness assurance (e.g., aero space equipment) is not supported.

When considering the use of Sanken products in ap pli ca tions where higher reliability is re quired (transportation equipment and its control systems

or equip ment, fire- or burglar-alarm systems, various safety devices, etc.), contact a company sales representative to discuss and obtain written

confirmation of your spec i fi ca tions.

The use of Sanken products without the written consent of Sanken in applications where ex treme ly high reliability is required (aerospace equip-

ment, nuclear power-control stations, life-support systems, etc.) is strictly prohibited.

The information in clud ed herein is believed to be accurate and reliable. Ap pli ca tion and operation examples described in this pub li ca tion are

given for reference only and Sanken and Allegro assume no re spon si bil i ty for any in fringe ment of in dus tri al property rights, intellectual property

rights, or any other rights of Sanken or Allegro or any third party that may result from its use.

Copyright 2006-2007 Allegro MicroSystems, Inc.

This datasheet is based on Sanken datasheet SSE23661

w w w . D a t a S h e e t 4 U . c o m

30 W-Universal Input/45 W-230 Vac Input

PWM Switching Regulators

STR-W6251D

15

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Asia-Pacific

China

Sanken Electric Hong Kong Co., Ltd.

Suite 1026, Ocean Centre

Canton Road, Tsimshatsui

Kowloon, Hong Kong

Tel: 852-2735-5262, Fax: 852-2735-5494

Sanken Electric (Shanghai) Co., Ltd.

Room 3202, Maxdo Centre

Xingyi Road 8, Changning District

Shanghai, China

Tel: 86-21-5208-1177, Fax: 86-21-5208-1757

Taiwan Sanken Electric Co., Ltd.

Room 1801, 18th Floor

88 Jung Shiau East Road, Sec. 2

Taipei 100, Taiwan R.O.C.

Tel: 886-2-2356-8161, Fax: 886-2-2356-8261

Japan

Sanken Electric Co., Ltd.

Overseas Sales Headquarters

Metropolitan Plaza Building

1-11-1 Nishi-Ikebukuro, Toshima-ku

Tokyo 171-0021, Japan

Tel: 81-3-3986-6164, Fax: 81-3-3986-8637

Korea

Sanken Electric Korea Co., Ltd.

Samsung Life Yeouido Building 16F

23-10, Yeouido-Dong, Yeongdeungpo-gu

Seoul 150-734, Korea

Tel: 82-2-714-3700, Fax: 82-2-3272-2145

Singapore

Sanken Electric Singapore Pte. Ltd.

150 Beach Road, #14-03 The Gateway West

Singapore 189720

Tel: 65-6291-4755, Fax: 65-6297-1744

Europe

Sanken Power Systems (UK) Limited

Pencoed Technology Park

Pencoed, Bridgend CF35 5HY, United Kingdom

Tel: 44-1656-869-100, Fax: 44-1656-869-162

North America

United States

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01606, U.S.A.

Tel: 1-508-853-5000, Fax: 1-508-853-7895

Allegro MicroSystems, Inc.

14 Hughes Street, Suite B105

Irvine, California 92618, U.S.A.

Tel: 1-949-460-2003, Fax: 1-949-460-7837

Worldwide Contacts

www.DataSheet4U.com

Das könnte Ihnen auch gefallen

- STRW6252Dokument15 SeitenSTRW6252miltoncgNoch keine Bewertungen

- 60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsDokument14 Seiten60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsIBSDIALLO0% (1)

- AZ3842 PWM Controller Data Sheet SummaryDokument13 SeitenAZ3842 PWM Controller Data Sheet SummaryEngr Khalid IqbalNoch keine Bewertungen

- SSC2001S Application NoteDokument18 SeitenSSC2001S Application NoteGerardo Mendez CamarilloNoch keine Bewertungen

- Ic 3843Dokument4 SeitenIc 3843nishatiwari82Noch keine Bewertungen

- Transition-Mode PFC Controller: 1 FeaturesDokument17 SeitenTransition-Mode PFC Controller: 1 Featuresadriancho66Noch keine Bewertungen

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6756Dokument8 SeitenQuasi-Resonant Topology Primary Switching Regulators: STR-W6756perro sNoch keine Bewertungen

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6735Dokument13 SeitenQuasi-Resonant Topology Primary Switching Regulators: STR-W6735perro sNoch keine Bewertungen

- Uc284xa Uc384xaDokument16 SeitenUc284xa Uc384xayusufwpNoch keine Bewertungen

- Uc2854b EpDokument13 SeitenUc2854b EpBruno NascimentoNoch keine Bewertungen

- SG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorDokument10 SeitenSG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorJayesh SuryavanshiNoch keine Bewertungen

- UC2842A/3A/4A/5A UC3842A/3A/4A/5A: High Performance Current Mode PWM ControllerDokument16 SeitenUC2842A/3A/4A/5A UC3842A/3A/4A/5A: High Performance Current Mode PWM ControllerCortés BernaNoch keine Bewertungen

- UC3845ANDokument15 SeitenUC3845ANMiloud ChouguiNoch keine Bewertungen

- Uc3842b 3843BDokument10 SeitenUc3842b 3843Bbob75Noch keine Bewertungen

- Tps 40057 PWPDokument33 SeitenTps 40057 PWPcatsoithahuong84Noch keine Bewertungen

- DatasheetDokument12 SeitenDatasheetDjalma MoreiraNoch keine Bewertungen

- 8205Dokument16 Seiten8205sonytinNoch keine Bewertungen

- LTC 1625Dokument24 SeitenLTC 1625Sakura KunNoch keine Bewertungen

- Tle6220gp DatasheetDokument18 SeitenTle6220gp Datasheetmaelo99999Noch keine Bewertungen

- DatasheetDokument13 SeitenDatasheetebertecnicoNoch keine Bewertungen

- XR-215 PLLDokument32 SeitenXR-215 PLLJ Jesús Villanueva GarcíaNoch keine Bewertungen

- 1-Tle6240gp V3 1 1Dokument24 Seiten1-Tle6240gp V3 1 1Alexandre Da Silva PintoNoch keine Bewertungen

- Datasheet STR 6757Dokument11 SeitenDatasheet STR 6757Walter CarreroNoch keine Bewertungen

- STR W6753 DatasheetDokument8 SeitenSTR W6753 DatasheetjgerabmNoch keine Bewertungen

- Order DC servo motor controller/driver semiconductor technical data sheetDokument16 SeitenOrder DC servo motor controller/driver semiconductor technical data sheetLuiz EduardoNoch keine Bewertungen

- A4954 DatasheetDokument9 SeitenA4954 DatasheetAngly1959Noch keine Bewertungen

- High Voltage Resonant Controller: DescriptionDokument17 SeitenHigh Voltage Resonant Controller: DescriptionJesus SilvaNoch keine Bewertungen

- L 6565Dokument17 SeitenL 6565tatatabuchoNoch keine Bewertungen

- Ane Str3a100Dokument17 SeitenAne Str3a100vietanh_askNoch keine Bewertungen

- 74HC4852 (Driver Injector)Dokument16 Seiten74HC4852 (Driver Injector)el_george0079491Noch keine Bewertungen

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesDokument13 SeitenPWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygNoch keine Bewertungen

- Data SheetDokument7 SeitenData Sheetitamar_123Noch keine Bewertungen

- Switching IC for compact power supply STR-A6252Dokument9 SeitenSwitching IC for compact power supply STR-A6252Fernando ChingaNoch keine Bewertungen

- Data SheetDokument14 SeitenData SheetGavril GiurgiNoch keine Bewertungen

- Isolated Flyback Switching Regulator W - 9V OutputDokument16 SeitenIsolated Flyback Switching Regulator W - 9V OutputCasey DialNoch keine Bewertungen

- Fan 7530Dokument20 SeitenFan 7530aldo_suviNoch keine Bewertungen

- 3845CMDokument13 Seiten3845CMJosé Miguel Barbosa HernándezNoch keine Bewertungen

- CA3140Dokument20 SeitenCA3140Brzata PticaNoch keine Bewertungen

- 1.5-A Peak Boost/Buck/Inverting Switching Regulators: FeaturesDokument23 Seiten1.5-A Peak Boost/Buck/Inverting Switching Regulators: FeaturesReinaldo VergaraNoch keine Bewertungen

- 04 Spec Sheet PWM Controller ChipDokument16 Seiten04 Spec Sheet PWM Controller Chipxuanhiendk2Noch keine Bewertungen

- MC33030PDokument17 SeitenMC33030PGisela ValdezNoch keine Bewertungen

- UC2842B/3B/4B/5B UC3842B/3B/4B/5B: High Performance Current Mode PWM ControllerDokument15 SeitenUC2842B/3B/4B/5B UC3842B/3B/4B/5B: High Performance Current Mode PWM ControllertoajuiceNoch keine Bewertungen

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Dokument9 SeitenOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezNoch keine Bewertungen

- 161 20551 0 FS7M0880Dokument16 Seiten161 20551 0 FS7M0880Edwin Vitovis TorresNoch keine Bewertungen

- Off-Line Quasi-Resonant Switching Regulators Features and Benefits (39Dokument9 SeitenOff-Line Quasi-Resonant Switching Regulators Features and Benefits (39ch3o10836266Noch keine Bewertungen

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDokument28 SeitenLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84Noch keine Bewertungen

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesDokument19 SeitenCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesRicardo Teixeira de AbreuNoch keine Bewertungen

- Datasheet Controlaor CiDokument17 SeitenDatasheet Controlaor Cineta123abcNoch keine Bewertungen

- 3000W Single Output Power Supply Spec SheetDokument6 Seiten3000W Single Output Power Supply Spec SheetGrigoriu CodrutaNoch keine Bewertungen

- 78 S 40Dokument9 Seiten78 S 40Luis AlbertoNoch keine Bewertungen

- TL494-D PWM Duty Cycle GenerationDokument14 SeitenTL494-D PWM Duty Cycle GenerationMashood NasirNoch keine Bewertungen

- Lin 1.3 TC 80310Dokument32 SeitenLin 1.3 TC 80310MohanakrishnanNoch keine Bewertungen

- Dap006 Dap6a DataDokument15 SeitenDap006 Dap6a DataluisfeipezzNoch keine Bewertungen

- AZ7500BC D1.3 070427nDokument13 SeitenAZ7500BC D1.3 070427nroozbehxoxNoch keine Bewertungen

- Precision Phase-Locked Loop: ... The Analog Plus CompanyDokument21 SeitenPrecision Phase-Locked Loop: ... The Analog Plus Companykao08Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Power Amplifier Applications Driver Stage Amplifier ApplicationsDokument3 SeitenPower Amplifier Applications Driver Stage Amplifier Applicationsperro sNoch keine Bewertungen

- C3280 PDFDokument2 SeitenC3280 PDFperro sNoch keine Bewertungen

- Power Amplifier Applications Driver Stage Amplifier ApplicationsDokument3 SeitenPower Amplifier Applications Driver Stage Amplifier Applicationsperro sNoch keine Bewertungen

- Old Company Name in Catalogs and Other DocumentsDokument13 SeitenOld Company Name in Catalogs and Other Documentsperro sNoch keine Bewertungen

- DST 2sa1943-Tde en 7673Dokument5 SeitenDST 2sa1943-Tde en 7673perro sNoch keine Bewertungen

- 2sa1015 TosDokument3 Seiten2sa1015 Tosmei jonieNoch keine Bewertungen

- C3280 PDFDokument2 SeitenC3280 PDFperro sNoch keine Bewertungen

- str-w6754 Ds enDokument8 Seitenstr-w6754 Ds enAdah BumbonNoch keine Bewertungen

- Ffpf10up60s PDFDokument5 SeitenFfpf10up60s PDFperro sNoch keine Bewertungen

- str-w6754 Ds enDokument8 Seitenstr-w6754 Ds enAdah BumbonNoch keine Bewertungen

- Upc 4558 PDFDokument13 SeitenUpc 4558 PDFperro sNoch keine Bewertungen

- Datasheet Dh321Dokument20 SeitenDatasheet Dh32193082Noch keine Bewertungen

- 1-ICE2xxx Ver4.5Dokument34 Seiten1-ICE2xxx Ver4.5Lachlan NolanNoch keine Bewertungen

- str-w6754 Ds enDokument8 Seitenstr-w6754 Ds enAdah BumbonNoch keine Bewertungen

- CQ 0765RTDokument24 SeitenCQ 0765RTsonivitel100% (2)

- STRG6653Dokument8 SeitenSTRG6653perro sNoch keine Bewertungen

- CQ 0765RTDokument24 SeitenCQ 0765RTsonivitel100% (2)

- FSFR-Series - : Fairchild Power Switch (FPS™) For Half-Bridge Resonant ConvertersDokument18 SeitenFSFR-Series - : Fairchild Power Switch (FPS™) For Half-Bridge Resonant ConvertersGioVoTamNoch keine Bewertungen

- ST 2SC1740: G S P Form A Is AvailableDokument2 SeitenST 2SC1740: G S P Form A Is Availableperro sNoch keine Bewertungen

- Fa5501 PDFDokument4 SeitenFa5501 PDFperro sNoch keine Bewertungen

- STK4162IIDokument9 SeitenSTK4162IIFredy Reinaldo Rivera MartínezNoch keine Bewertungen

- DST 2sa1943-Tde en 7673Dokument5 SeitenDST 2sa1943-Tde en 7673perro sNoch keine Bewertungen

- STK4162IIDokument9 SeitenSTK4162IIFredy Reinaldo Rivera MartínezNoch keine Bewertungen

- STR G 6653Dokument8 SeitenSTR G 6653Saif RehmanNoch keine Bewertungen

- STK4162IIDokument9 SeitenSTK4162IIFredy Reinaldo Rivera MartínezNoch keine Bewertungen

- STK4162IIDokument9 SeitenSTK4162IIFredy Reinaldo Rivera MartínezNoch keine Bewertungen

- STR G 6653Dokument8 SeitenSTR G 6653Saif RehmanNoch keine Bewertungen

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Dokument9 SeitenOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sNoch keine Bewertungen

- HOT D1877 Datasheet PDFDokument1 SeiteHOT D1877 Datasheet PDFlaurentina52Noch keine Bewertungen

- The Graphics Class: Maging, System - Drawing2D and System - Design NamespacesDokument12 SeitenThe Graphics Class: Maging, System - Drawing2D and System - Design NamespacesnehaNoch keine Bewertungen

- Master StationDokument138 SeitenMaster StationWilmer Quishpe AndradeNoch keine Bewertungen

- Solu of Assignment 9Dokument5 SeitenSolu of Assignment 9dontstopmeNoch keine Bewertungen

- Oracle WDP GuideDokument5 SeitenOracle WDP GuidePrashant PrakashNoch keine Bewertungen

- Infix To PostfixDokument2 SeitenInfix To PostfixZorana Z JovanovichNoch keine Bewertungen

- Technic Error CodesDokument1 SeiteTechnic Error CodesprajwalNoch keine Bewertungen

- Vidyashree B K: Career ObjectiveDokument2 SeitenVidyashree B K: Career ObjectiveVidya K GowdaNoch keine Bewertungen

- Post Test Principles of TeachingDokument8 SeitenPost Test Principles of TeachingGibriel SllerNoch keine Bewertungen

- State of Michigan: (Insert System or Project Name Here) (Inset Phase or Product Increment)Dokument5 SeitenState of Michigan: (Insert System or Project Name Here) (Inset Phase or Product Increment)SamNoch keine Bewertungen

- Disini Vs Secretry DigestDokument2 SeitenDisini Vs Secretry DigestChristian John Dela CruzNoch keine Bewertungen

- Cad StandardsDokument21 SeitenCad Standardsarch_ankitNoch keine Bewertungen

- 26152980Dokument41 Seiten26152980gsdimitNoch keine Bewertungen

- Theory of Interactive FictionDokument438 SeitenTheory of Interactive Fictionscpedicini1199100% (1)

- Nestle Wellness Campus Facebook Group OrientationDokument55 SeitenNestle Wellness Campus Facebook Group OrientationJenelyn ValoisNoch keine Bewertungen

- Ancient God Deadlift RoutineDokument2 SeitenAncient God Deadlift Routinebasuthker raviNoch keine Bewertungen

- Experiment No.5Dokument11 SeitenExperiment No.5Kshitij DudheNoch keine Bewertungen

- Soal Pretest Bhs Inggris 2017Dokument9 SeitenSoal Pretest Bhs Inggris 2017RIZKY ELECTRIKA SAPTIAN SAPUTRANoch keine Bewertungen

- 5 BM-03 Composite Function BM-03 Worksheet-02Dokument4 Seiten5 BM-03 Composite Function BM-03 Worksheet-02Marcus Maccoy AcordaNoch keine Bewertungen

- Airport Management SystemDokument4 SeitenAirport Management SystemFrish MirNoch keine Bewertungen

- Lifebook P702 Notebook: Data SheetDokument3 SeitenLifebook P702 Notebook: Data SheetIman SulaimanNoch keine Bewertungen

- ERPSCM MM SRVServiceEntrySheet 180915 0417 1152Dokument7 SeitenERPSCM MM SRVServiceEntrySheet 180915 0417 1152ronnzaaNoch keine Bewertungen

- ASP.NET Core MVC Web App with CRUD for Departments and SellersDokument11 SeitenASP.NET Core MVC Web App with CRUD for Departments and SellersElder MoraisNoch keine Bewertungen

- LTE Serving Cell Performance Report for Semarang 3 NetworkDokument11 SeitenLTE Serving Cell Performance Report for Semarang 3 NetworkNarto MujiatmikoNoch keine Bewertungen

- Manufacturing KPI Dashboard Someka Excel Template V3 Free VersionDokument11 SeitenManufacturing KPI Dashboard Someka Excel Template V3 Free VersionYoro Diallo50% (2)

- Introduction To Computer SystemDokument66 SeitenIntroduction To Computer SystemIrfan Fazail100% (1)

- A.V AidsDokument19 SeitenA.V AidsRohini RaiNoch keine Bewertungen

- Help - Mens Work Jacket Mock UpDokument8 SeitenHelp - Mens Work Jacket Mock UpMuhammad Zen WawazerNoch keine Bewertungen

- MIPlus 20Dokument28 SeitenMIPlus 20TrbvmNoch keine Bewertungen

- Zebradesigner XML Release Notes v2509427Dokument13 SeitenZebradesigner XML Release Notes v2509427atacaraNoch keine Bewertungen

- Buyside Risk Management SystemsDokument16 SeitenBuyside Risk Management SystemsjosephmeawadNoch keine Bewertungen