Beruflich Dokumente

Kultur Dokumente

Bus Bar - 100x50x10 Channels

Hochgeladen von

Abraham JyothimonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bus Bar - 100x50x10 Channels

Hochgeladen von

Abraham JyothimonCopyright:

Verfügbare Formate

1

INDEX

Bustrunking System .. (1)

Standard & Specifcations .. (2)

Technical Parameters

Copper .. (3-4)

Aluminum .. (5-6)

Components

Straight Length (Feeder & Plug in type) .. (7)

Uniblock Joint, Edge Elbow & Ofset Edge Elbow .. (8)

Flat Elbow, Ofset Flat Elbow & Flat Tee .. (9)

Flanged End .. (10)

Flange End with Flat Elbow & .. (11)

Flange End with Edge Elbow .. (11)

Flange End Box & Flange Bellow .. (12)

Reducer & Sectional Isolator .. (13)

Center Feed Unit & Copper Flexible .. (14)

End Feed & End Cover .. (15)

Vertical Support & Vertical Rigid Hanger .. (16)

Vertical Spring Hanger .. (17)

Horizontal Support .. (18)

Plug in box .. (19)

Domestic References .. ( )

International References .. ( )

Installation References .. ( )

Certifcates .. ( )

2

GENERAL

GENERAL

SALIENT FEATURES

Busbar Trunking System for electrical

distribution is an alternative to cumbersome

conventional cable distribution system.

Busbar Trunking System has the advantage of

expansions, Changes, replacement and

reusing capability in the future.

Loads can be fed from Plug-in Box unlike

cables, where each foor/ machine is to be fed

separately from the main switchboard.

Repositioning of distribution points is simpler.

Installation time is much shorter then cable

system. This provides low installation and

manpower costs and help for better time

management.

Busbar Trunking systems have a modern and

aesthetic look.

System is maintenance free.

Close proximity of busbars reduces inductive

reactance, resistance, impedance and voltage

drop is much lower than cable & any other

busbar system.

Specially designed housing act as a heat sink

to yield improved thermal characteristic, high

mechanical and short circuit strength.

Busbar System has no chimney efect, hence

provide a better resistance to the spread of fre.

Automatic polarity is maintained during

installation.

System can be mounted edgewise OR fat wise

horizontally or vertically in any direction with all

kinds of bends and tees etc.

The compact structure and steel housing

allows much lower electromagnetic feld around

busbar system then cable.Busbars does not

generate electromagnetic.

3

SPECIFICATIONS

Compliance of Standard

Independent Certification Authority

Busbar Arrangement

Busbar Ratings

Busbar Configuration

Rated Operational Voltage (Ue)

Rated Insulation Voltage (Ui)

Rated Dielectric Voltage

Rated Impulse Withstand Voltage (Uimp)

Rated Frequency

Enclosure Material

Surface Coating on Enclosure

Busbar Material (Phase/Neutral)

Busbar Material (Internal Earth)

Busbar Material (External Earth)

Busbar Insulation

Degree of Protection

Joint

Plug -in-Box

IEC 60439 (1&2) & IS 8623 (1&2)

VMtec - Germany

Sandwich Type

Copper 630 ~ 6600A

Aluminium 400 ~ 5000A

3 Phase+50% Internal Earth

3 Phase+100% Neutral+50% Internal Earth

3 Phase+200% Neutral+50% Internal Earth

3 Phase+100%Neutral+100% Isolated Earth

+50%Internal Earth

1000 Volt, AC

1000 Volt, AC

3.5 KV r.m.s

12 kV (1.2/50 s)

50 Hz / 60 Hz

1.6mm G.I

Epoxy polyster powder coated (RAL-7032)

Copper (full round edge ),99.9% pure ETP

grade

Aluminium (full round edge), 99.5% pure.

G.I 1.5mm / Copper 1.5 mm.

Copper / Aluminium

Multi layer Class- 'F' Insulation (Polyster +Mica)

IP 54 for Plug in type.

IP55 / IP65 / IP67 for feeder bustrunking.

Uniblock Joint (With Isolation and tamper

proof shear off nut)

32~800 A

4

TECHNICAL PARAMETRS

SBC (Copper Sandwich Insulated Bus Trunking)

151 151

172 172

3 Phase+50%

Internal Earth

3 Phase+100% Neutral

+50% Internal Earth

3 Phase+200% Neutral

+50% Internal Earth

3 Phase+100% Neutral+100%

Isolated Earth+50% Internal Earth

5

TECHNICAL PARAMETRS

Voltage Drop Calculation Formulae

V = k x 3 x ( Rt cos + X sin ) x IB x L

Where

V is the composite voltage drop of the system (V);

Rt & X are the mean resistance and reactance values of

the system ("/m);

IB is the actual load current of the circuit being

considered (A);

L is the length of the system being

considered (M);

Cos is the load power factor being

considered;

k is the load distribution factor.

k=1, if full load is concentred at the

end of the busbar trunking run;

k=(n+1)/2n, if the load is uniformly

spread between n branches.

6

TECHNICAL PARAMETRS

SBA (Aluminium Sandwich Insulated Bus Trunking)

151 151

172 172

3 Phase+50%

Internal Earth

3 Phase+100% Neutral

+50% Internal Earth

3 Phase+200% Neutral

+50% Internal Earth

3 Phase+100% Neutral+100%

Isolated Earth+50% Internal Earth

7

TECHNICAL PARAMETRS

Voltage Drop Calculation Formulae

V = k x 3 x ( Rt cos + X sin ) x IB x L

Where

V is the composite voltage drop of the system (V);

Rt & X are the mean resistance and reactance values of

the system ("/m);

IB is the actual load current of the circuit being

considered (A);

L is the length of the system being

considered (M);

Cos is the load power factor being

considered;

k is the load distribution factor.

k=1, if full load is concentred at the

end of the busbar trunking run;

k=(n+1)/2n, if the load is uniformly

spread between n branches.

8

COMPONENTS

Straigth Length (Feeder)

Transformer to Panel.

Panel to Panel.

Generator to Panel.

Panel to Rising mains.

Standard & Max. Length: 3000mm.

Mini. Length: 450mm.

Straigth Length (PIP)

Standard & Max. Length: 3000mm.

For tapping Power from Main Line through

Plug-in-Boxes.

Plug-in point shown are indicative only.

Rating and number of Plug-in -Point shall

be as per the site requirement (up to 5 Nos

max on either side).

Two type of Plug-in Points(PIP): (32~400A)

& (500 ~800A) can be provided as per

requirement.

L

e

n

g

t

h

o

f B

u

s

t

r

u

n

k

in

g

(L

)

L

e

n

g

t

h

o

f B

u

s

t

r

u

n

k

in

g

(L

)

L

e

n

g

t

h

o

f B

u

s

t

r

u

n

k

in

g

(L

)

L

e

n

g

t

h

o

f

B

u

s

t

r

u

n

k

in

g

(L

)

L

e

n

g

t

h

o

f

B

u

s

t

r

u

n

k

in

g

(L

)

9

COMPONENTS

Uniblock Joint

Edge Elbow

Ofset Edge Elbow

Shear of nut

Current Rating

Aluminum 400~5000A

Copper 630~6600A

300 x 300 x 300

Standard & Mini.

Dimn.AxBxC (mm)

Current Rating

Aluminum 400~5000A

Copper 630~6600A

300 x 300

Standard & Mini.

Dimn.AxB (mm)

Joint can be ftted / removed in installed condition

without removal of section.

Heavy duty disc spring used on both sides for

unifrom distribution of pressure.

Joint can be tightened easily with help of spanner

on nut side only.(spanner not required on bolt head

side)

Shear of nut ensure tightness of joint at desired

torque and eliminates the need of torque wrench

during installation.

Tamper proof cap over shear of nut prevents

opening of nut after achieving desired torque.

Nut can only be opened after breaking the cap.

10

COMPONENTS

Flat Elbow

Ofset Flat Elbow

Flat Tee

Aluminum 4000~5000A

Copper 6000~6600A

Aluminum 2000~3600A

Copper 3200~5000A

Aluminum 400~1800A

Copper 630~2500A

Standard & Mini.

Dimn. AxBxC (mm)

Current Rating

500 x 500 x 600

600 x 600 x 600

400 x 400 x 400

Aluminum 4000~5000A

Copper 6000~6600A

Aluminum 2000~3600A

Copper 3200~5000A

Aluminum 400~1800A

Copper 630~2500A

Standard & Mini.

Dimn. AxBxC (mm)

Current Rating

500 x 500 x 600

600 x 600 x 600

400 x 400 x 400

Aluminum 4000~5000A

Copper 6000~6600A

Aluminum 2000~3600A

Copper 3200~5000A

Aluminum 400~1800A

Copper 630~2500A

Standard & Mini.

Dimn. AxB (mm)

Current Rating

500 x 500

600 x 600

400 x 400

11

COMPONENTS

Flanged End

BUSBAR WIDTH BUSBAR WIDTH BUSBAR WIDTH BUSBAR WIDTH

40 ~ 80mm 100 ~ 125mm 150 ~ 175mm 200 ~ 230mm

300 Std. & Mini

14) AS PER REQUIREMENT

TERMINATION HOLES

14) AS PER REQUIREMENT

TERMINATION HOLES

Flanged End cut out & Drilling

12

COMPONENTS

Flanged End with Flat Elbow

Flanged End with Edge Elbow

Aluminum 4000~5000A

Copper 6000~6600A

Aluminum 2000~3600A

Copper 3200~5000A

Aluminum 400~1800A

Copper 630~2500A

Current Rating

Standard & Mini.

Dimn. A x B (mm)

275 x 400

375 x 500

475 x 600

Copper 630~6600A

Aluminum 400~5000A

175 x 300

Current Rating

Standard & Mini.

Dimn. A x B (mm)

13

COMPONENTS

Flanged End Box

Aluminum 4000~5000A

Copper 6000~6600A

Aluminum 2000~3600A

Copper 3200~5000A

Aluminum 1350~1800A

Copper 1800~2500A

Aluminum 400~1250A

Copper 630~1600A

Current Rating

STANDARD DIMENSIONS

S.NO

800 700

700

Flange Bellow need to be fxed between Flanged End Box and Genset termination box to avoid impact of

vibrations of Genset being transferred to bustrunking.

Flange Bellow

Current Rating

Current Rating

Standard

Dimensions

Code

S.

No

Copper 630~1600A

Aluminum 400~1250A

Copper 1800~2500A

Aluminum 1350~1800A

SFBE-3

Code

S.

No

Copper 3200~5000A

Aluminum 2000~3600A

Current Rating

SFBE-4

Code

S.

No

Copper 6000~6600A

Aluminum 4000~5000A

14

COMPONENTS

Reducer

Sectional Isolator

These are required to isolate the bustrunking run in

between, for various reasons. Section Isolator Unit can be

ftted with load Break Switches / SFU's / MCCB's.

Reducer (Switchgear)

Reducer (Direct)

These are required to connect two dissimilar rating of

bustrunking. Reducer may be designed with switching or

isolating device.

15

COMPONENTS

Center Feed Unit

To charge bustrunking through cables from middle of bustrunking.

Center feed Unit is available with sufcient space for direct connection through lugs and bolts.

MCCB,SFU, lsolators, fuse holders etc. can be ftted in Center Feed Unit as per requirement.

Undrilled cable gland plate is provided at bottom for multiple cable entry.

Center Feed Unit (Direct)

Center Feed Unit (Switchgear)

Copper Flexible

Copper Flexible need to be used to connect fanged end

busbar with busbars (Terminals) of Panel / Transformer /

Generators.

Holes to be drilled at site

as per requirement

Switchgear side

(Panel/D.G/TFR.)

Bustrunking side

Thickness (t) & No of fexible

as per Rating

Tin Plated Braided Flexible

16

COMPONENTS

End Feed

It is used to terminate and to protect the end of plug-in bustrunking

(Rising mains run.)

It can be remove easily for extension of bustrunking .

End Cover

To charge bustrunking through cables from one end of bustrunking.

End feed is available with sufcient space for direct connection through lugs and bolts.

MCCB,SFU, lsolators, fuse holders etc. can be ftted in End Feed as per requirement.

300 mm length of bustrunking is integrally ftted (measured with bustrunking) along with End

Feed as standard practice so that joint between End Feed and bustrunking is exactly same as

joint of two normal bustrunking lengths.

Undrilled cable gland plate is provided at bottom for multiple

cable entry.

End Cover

It is used to terminate and to protect the end of plug-in bustrunking

(Rising mains run.)

It can be remove easily for extension of bustrunking .

End

End Feed (Direct)

End Feed (Switchgear)

17

COMPONENTS

Vertical Support

Vertical support is used to control Horizontal

movement of sandwich rising main .

Vertical Rigid Hanger

One set of Rigid hanger per rising main must be installed at the start of the rising mains (i.e. At the

lowest foor ) to prevent expansion of bustrunking in downward direction.These can be ftted on 100x50X5

(or equivalent) channels mounted on foor / wall as shown below (not in scope of VMtec supply)

Recommendation for using hangers per foor:-

Up to 3.5 M: 01 rigid hanger.

3.5M >4.5 M: 01 rigid hanger + 01 Vertical support. (for ensuring vertical alignment of rising

mains.)

4.5 m > 6.0 M: 02 rigid hanger

Installation Sequence

Remove Nut A from Rigid Hanger on both sides.

Mount " Hanger Support" through 2Nos. 13 predrilled holes provided on desired rising main

section.

Insert "Rigid hanger bolts" into C-channel (already fxed at the foor level with desired holes)

Adjust Nut B on to the C-channel (on both sides parallely) ensuring center line ( ) of rigid

hanger support positioned as 175 mm from foor level (or as indicated in drawing )

Tighten & lock nut A.

Ensure nut C remains fully tightened during entire process.

Copper 630A~1250A

Aluminum 400A~1800A

Copper 1600A~ 2500A

Aluminum 2000A~ 5000A

Copper 3200A ~ 5000A

C-Channel With 14

holes not in scope of VMtec

Supply(100x50x5)

Rigid hanger

Bolt

Hanger support

18

COMPONENTS

Vertical Spring Hanger

sustain the bustrunking load and to allow vertical expansion of bustrunking in upward direction

below (not in scope of VMtec supply)

Up to 3.5 M: 01 Vertical spring hanger .

3.5M >4.5 M: 01 Vertical spring hanger + 01 Vertical support. ((for ensuring vertical alignment

of rising mains.)

4.5 M > 6.0 M: 02 Vertical spring hanger.

SVSH-1 SVSH-2 SVSH-3

Nut D

Nut C1

Nut C2

Nut B

Nut

107.5 107.5

3

2

5

3

0

0

1

7

5

1

0

0

3

2

5

3

0

0

1

7

5

1

0

0

3

2

5

3

0

0

1

7

5

1

0

0

215

Remove nut A from spring hanger on both sides.

Mount " Hanger support" through 2 Nos. 13 predrilled holes provided on desired Rising main

section

.

Adjust nut B on to the C-Channel ensuring center line ( ) of Hanger Support positioned at 300

open & bring down nut C1 & C2 slowly (on both sides parallely) until a gap of 1~2mm is created

between nut D and spring hanger support

Lock nut C1 & C2 at this position

Loosen Nut D for allowing thermal expansion of rising main.

Instalation Sequense

C-Channel With 14

holes not in scope of VMtec

Supply(100x50x5)

19

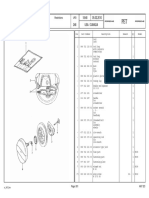

COMPONENTS

Edgewise Horizontal Support

250

400

650

850

300

450

700

900

SFHS-1

SFHS-2

SFHS-3

SFHS-4

Current Rating

Standard Dimensions

A B

Code Detail

12 Rod *

12 Rod 12 Rod *

A A A

12 Rod *

12 Rod *

12 Rod *

250

300

250

300

250

300

(SEHS-1)

(SEHS-1) (SEHS-1)

* Not in scope of VMtec Supply

* Not in scope of VMtec Supply

Flatwise Horizontal Support

These support need to be provided on horizontal feeder run at an interval

of 1.5 M (or as per site requirement)

These support need to be provided on horizontal feeder run at an interval

of 1.5 M (or as per site requirement)

20

COMPONENTS

Plug-in-Box

Plug in box enclosure is made from G.I with side hinged door.

Plug in contacts are made out of silver plated copper with spring steel backup pressure clips for

ensuring uniform pressure and low contact resistance .

For cables entry, provision of gland plates are provided on both sides and bottom of Plug in Box.

Earth contact of Plug-in boxes makes frst & breaks last.

Plug in box are suitable for MCCB/SFUs with rotary handle and door interlocking.

Plug in boxes are available with Interlocking with bustrunking to ensure "plug-in" and "Plug-Out"

possible only in "Of" Condition.

Silver Plated contacts are properly shrouded / isolated.

Plug in box up to 400 A are compatible to all ratings of Bustrunking with 400 A Plug-in-points

Plug in box from 500A to 800 A are compatible to all ratings of Bustrunking with 800 A plug in

points.

Plug in boxes can only be ftted on to the Bustrunking with corrected polarity i.e. ENRYBE.

Fig.-1 Fig.-2 Fig.-3

Fig.-4

* Available with Isolater.

PIB with subcode 4B is applicable for-

3 Phase+50% Internal Earth

3 Phase+200% Neutral +50% Internal Earth

3 Phase+100% Neutral +50% Internal Earth

3 Phase+100% Neutral+100% Isolated Earth+50% Internal Earth

Das könnte Ihnen auch gefallen

- ASCO Miniature Valve Products (AV017R5)Dokument96 SeitenASCO Miniature Valve Products (AV017R5)vasudeva yasasNoch keine Bewertungen

- Hra Panel SpecDokument4 SeitenHra Panel SpecMuhammad Arslan Khurshid BhattiNoch keine Bewertungen

- Park FabricatorsDokument50 SeitenPark FabricatorsAnuj PanchalNoch keine Bewertungen

- 190 e Cr302 en Servomotors-For-steam-turbinesDokument10 Seiten190 e Cr302 en Servomotors-For-steam-turbinesscribdkhatnNoch keine Bewertungen

- Siemens Catalog 4f0d0f8422602Dokument44 SeitenSiemens Catalog 4f0d0f8422602Muhammad Shuaib100% (1)

- OE Brochure NPP 2 14 Lay ESDokument12 SeitenOE Brochure NPP 2 14 Lay ESguichen wangNoch keine Bewertungen

- 3.72.e.el Linear Electric ActuatorsDokument10 Seiten3.72.e.el Linear Electric ActuatorsSon Trinh PhuongNoch keine Bewertungen

- TB 01000001 eDokument61 SeitenTB 01000001 eRicardo LopezNoch keine Bewertungen

- 3kw Aeolos SpecificationDokument3 Seiten3kw Aeolos Specificationsweet_deny3000Noch keine Bewertungen

- 1STC007003D0201Dokument294 Seiten1STC007003D0201Niamat KhanNoch keine Bewertungen

- H-Compact 1LA4 CatalogueDokument12 SeitenH-Compact 1LA4 CatalogueThamizhselvan KNoch keine Bewertungen

- Street Light Using Renewable Energy: Jetpro Technology, IncDokument5 SeitenStreet Light Using Renewable Energy: Jetpro Technology, IncRoyal Kasepuhan IndonesiaNoch keine Bewertungen

- An Introduction To Pakistan's Sugar Industry: TH TH THDokument12 SeitenAn Introduction To Pakistan's Sugar Industry: TH TH THSennen DesouzaNoch keine Bewertungen

- Grundfos Fire Presentation - Consultants Webinar - 6-8th FebruaryDokument52 SeitenGrundfos Fire Presentation - Consultants Webinar - 6-8th FebruaryfebousNoch keine Bewertungen

- Introduction Cross Flow Turbine PDFDokument35 SeitenIntroduction Cross Flow Turbine PDFmeku44100% (2)

- SH5.0RT / SH6.0RT / SH8.0RT / SH10RT: User Manual 3-Phase Hybrid InverterDokument108 SeitenSH5.0RT / SH6.0RT / SH8.0RT / SH10RT: User Manual 3-Phase Hybrid InverterQuang TuanNoch keine Bewertungen

- Digital Input Modules TXM1 D A6V10068527 HQ enDokument8 SeitenDigital Input Modules TXM1 D A6V10068527 HQ enابوحاشرNoch keine Bewertungen

- English Full Catalouge Facing UpDokument96 SeitenEnglish Full Catalouge Facing Updaboo sanatNoch keine Bewertungen

- M+S Bót LáiDokument54 SeitenM+S Bót LáidoanmdatNoch keine Bewertungen

- Sinovoltaics Inverter Manufacturer Ranking Report Edition 1 2022Dokument16 SeitenSinovoltaics Inverter Manufacturer Ranking Report Edition 1 2022Wepa BizNoch keine Bewertungen

- Quot EPD-1178-BG (PT Renergon Inter JKT)Dokument7 SeitenQuot EPD-1178-BG (PT Renergon Inter JKT)Abdilla AlfathNoch keine Bewertungen

- Aepl Profile 2010Dokument61 SeitenAepl Profile 2010Waqas AhmadNoch keine Bewertungen

- EDITION 1/2022: Niclas Weimar & Dricus de RooijDokument17 SeitenEDITION 1/2022: Niclas Weimar & Dricus de RooijWepa BizNoch keine Bewertungen

- Fire Pump ControllerDokument2 SeitenFire Pump Controllerjoaofelipe.msNoch keine Bewertungen

- Prsentation Wind TurbineDokument10 SeitenPrsentation Wind TurbineMuhammad Ammad RasheedNoch keine Bewertungen

- Axial-Fan Transformers enDokument36 SeitenAxial-Fan Transformers enEko SusantoNoch keine Bewertungen

- 4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiDokument7 Seiten4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiZain KhanNoch keine Bewertungen

- Acuvim L Users ManualDokument90 SeitenAcuvim L Users ManualBảo Hân NguyễnNoch keine Bewertungen

- Power-Sonic Battery GuideDokument20 SeitenPower-Sonic Battery GuideGamal SalehNoch keine Bewertungen

- Technology Gas EngineDokument10 SeitenTechnology Gas Enginedtw26Noch keine Bewertungen

- Ismail Industries Annual Report 2014Dokument56 SeitenIsmail Industries Annual Report 2014ZeeJohn123Noch keine Bewertungen

- KWT Heat PumpsDokument36 SeitenKWT Heat PumpsanonimppNoch keine Bewertungen

- Cooling TowersDokument44 SeitenCooling TowersVeeturiVarunNoch keine Bewertungen

- Overview of Pakistan Power Sector and Role of Ipps: Shah Jahan MirzaDokument40 SeitenOverview of Pakistan Power Sector and Role of Ipps: Shah Jahan MirzaSaifullah BhuttoNoch keine Bewertungen

- E-Kabin - B Series - Busbar Support&Insulator - ENG PDFDokument56 SeitenE-Kabin - B Series - Busbar Support&Insulator - ENG PDFShrihari JNoch keine Bewertungen

- LG Chiller Reference SitesDokument21 SeitenLG Chiller Reference Sitesalexandra sunNoch keine Bewertungen

- Glatt PPT Master - EN PDFDokument30 SeitenGlatt PPT Master - EN PDFrahul aggarwalNoch keine Bewertungen

- Prof. Dr. Bernd Stephan University of Applied Science Bremerhaven, GermanyDokument47 SeitenProf. Dr. Bernd Stephan University of Applied Science Bremerhaven, GermanyCihad KurbanoğluNoch keine Bewertungen

- ATS - EnGDokument4 SeitenATS - EnGRamires AdeNoch keine Bewertungen

- 3 Quick Closing Valve SystemsDokument13 Seiten3 Quick Closing Valve SystemsrsalvasanNoch keine Bewertungen

- China - Wind Energy IndustryDokument36 SeitenChina - Wind Energy IndustrySamuel Arévalo GNoch keine Bewertungen

- InteliDrive Mobile Logger Datasheet 2011-09Dokument4 SeitenInteliDrive Mobile Logger Datasheet 2011-09MateVodokotlicNoch keine Bewertungen

- Trends in Electricity Generation 2006-07 To 2020-21: Pakistan Bureau of StatisticsDokument58 SeitenTrends in Electricity Generation 2006-07 To 2020-21: Pakistan Bureau of StatisticsSYED ALIYYAN IMRAN ALINoch keine Bewertungen

- Abb FlowmetersDokument84 SeitenAbb FlowmetersAna QuintanaNoch keine Bewertungen

- Control Solutions: ES - The Latest in Control TechnologyDokument6 SeitenControl Solutions: ES - The Latest in Control TechnologyFederico LiaudatNoch keine Bewertungen

- PS Cat EdisonNewton EN 0614 9041319 1454275409Dokument8 SeitenPS Cat EdisonNewton EN 0614 9041319 1454275409sebastianNoch keine Bewertungen

- Corporate Profile: GasgenDokument44 SeitenCorporate Profile: GasgenAhmad SolichinNoch keine Bewertungen

- Sindh Industry AssociationsDokument23 SeitenSindh Industry AssociationsLumentexNoch keine Bewertungen

- Brief Introduction: Kohler Power Systems (USA) - Generators and Switchgears (Ranging From 20kW To 3250kW)Dokument13 SeitenBrief Introduction: Kohler Power Systems (USA) - Generators and Switchgears (Ranging From 20kW To 3250kW)kyahuaNoch keine Bewertungen

- Co Generation PDFDokument6 SeitenCo Generation PDFDo The Best Just For YouNoch keine Bewertungen

- The History of Private Power in PakistanDokument29 SeitenThe History of Private Power in Pakistanmastoi786Noch keine Bewertungen

- CL NabllabDokument71 SeitenCL NabllabBhart AutomationNoch keine Bewertungen

- CBEND - Ankur WBG 400 Operation and Maintenance ManualDokument78 SeitenCBEND - Ankur WBG 400 Operation and Maintenance ManualSanjivi Jagadish KumarNoch keine Bewertungen

- List of World Capitals by CountriesDokument11 SeitenList of World Capitals by CountriesVipin SajwanNoch keine Bewertungen

- UntitledDokument80 SeitenUntitledwarick mNoch keine Bewertungen

- Sawan Gas Field Internship ReportDokument47 SeitenSawan Gas Field Internship ReportAbdullah chang100% (1)

- Cable Glands EMEA WC Sec 18Dokument44 SeitenCable Glands EMEA WC Sec 18Anonymous ziG2oaNoch keine Bewertungen

- Aman Technical - Handbook PDFDokument70 SeitenAman Technical - Handbook PDFeliahud100% (1)

- Technical - Handbook - OMAN CABLES PDFDokument70 SeitenTechnical - Handbook - OMAN CABLES PDFSahul HameedNoch keine Bewertungen

- Eaton Nonsegregated BusductDokument28 SeitenEaton Nonsegregated BusducthanythekingNoch keine Bewertungen

- GDL Louvre CalculatorDokument1 SeiteGDL Louvre CalculatorAbraham JyothimonNoch keine Bewertungen

- (Dewa-98%) Anova-Safety and Secuirty ScoreDokument6 Seiten(Dewa-98%) Anova-Safety and Secuirty ScoreAbraham JyothimonNoch keine Bewertungen

- Notes On Work System Concepts1Dokument12 SeitenNotes On Work System Concepts1Abraham JyothimonNoch keine Bewertungen

- Selton's Horse (Posterior Lottery Model)Dokument3 SeitenSelton's Horse (Posterior Lottery Model)Abraham JyothimonNoch keine Bewertungen

- Survey Works Rev 1Dokument12 SeitenSurvey Works Rev 1Abraham JyothimonNoch keine Bewertungen

- Upper & Lower Contour SetsDokument12 SeitenUpper & Lower Contour SetsAbraham JyothimonNoch keine Bewertungen

- Examples Done On Orthogonal ProjectionDokument79 SeitenExamples Done On Orthogonal ProjectionAbraham JyothimonNoch keine Bewertungen

- Sizing of Generators: Abraham Jyothimon, MSC, B.E Senior Electrical Engineer B.K GulfDokument6 SeitenSizing of Generators: Abraham Jyothimon, MSC, B.E Senior Electrical Engineer B.K GulfAbraham JyothimonNoch keine Bewertungen

- Adaptaflex - Price ListDokument42 SeitenAdaptaflex - Price ListAbraham Jyothimon100% (1)

- Elec - HV LV SwitchroomsDokument1 SeiteElec - HV LV SwitchroomsAbraham JyothimonNoch keine Bewertungen

- WrenchesDokument1 SeiteWrenchesFelix VioletaNoch keine Bewertungen

- Dealer PricingDokument1.978 SeitenDealer PricingKyle D VorhisNoch keine Bewertungen

- Plumbing ToolsDokument24 SeitenPlumbing ToolsHarold Abubo Haber100% (4)

- Steering Unit: Service ManualDokument28 SeitenSteering Unit: Service ManualmusafirNoch keine Bewertungen

- Catálogo TFT PDFDokument189 SeitenCatálogo TFT PDFjanusfire100% (1)

- PPPPUDokument24 SeitenPPPPUSaurav ShresthaNoch keine Bewertungen

- SK 350 - Manual de PartesDokument737 SeitenSK 350 - Manual de PartesDaniel Pacheco Llantoy100% (2)

- SpannersDokument48 SeitenSpannersvineeshNoch keine Bewertungen

- TOOL MAKING.-Bench WorkDokument175 SeitenTOOL MAKING.-Bench Workpbkamatar17944100% (2)

- Assessment 1 - Questioning: AURTTK102 Use and Maintain Tools and Equipment in An Automotive WorkplaceDokument27 SeitenAssessment 1 - Questioning: AURTTK102 Use and Maintain Tools and Equipment in An Automotive WorkplaceARSHAD TURINoch keine Bewertungen

- Manual de Partes Martillo Hidraulco Atlas Copco Mb1200Dokument36 SeitenManual de Partes Martillo Hidraulco Atlas Copco Mb1200Robinson Guaneme100% (1)

- MAXIMUM 7-Piece Crow Foot Wrench Set Canadian TireDokument3 SeitenMAXIMUM 7-Piece Crow Foot Wrench Set Canadian Tireming_zhu10Noch keine Bewertungen

- SKF 2017 Lock NutsDokument31 SeitenSKF 2017 Lock Nutswilliams vasquezNoch keine Bewertungen

- 996 Usa Katalog PDFDokument599 Seiten996 Usa Katalog PDFFlatouteautougeNoch keine Bewertungen

- Reality of Copper Titanium Tools - BreakageDokument9 SeitenReality of Copper Titanium Tools - BreakageTaherNoch keine Bewertungen

- Rothenberger Pipe and Installation ToolsDokument46 SeitenRothenberger Pipe and Installation ToolsjenelbNoch keine Bewertungen

- SSC - Construction QP Code - CON/Q0602 Job Role - Assistant Electrician NSQF Level - 3Dokument4 SeitenSSC - Construction QP Code - CON/Q0602 Job Role - Assistant Electrician NSQF Level - 3patkai ndlmNoch keine Bewertungen

- Electrical Tools, Equipment, and Their Uses: Circuit TestersDokument6 SeitenElectrical Tools, Equipment, and Their Uses: Circuit TestersJonalyn SalesNoch keine Bewertungen

- 03.0-310 Checking and Tightening Connecting Rod BoltsDokument2 Seiten03.0-310 Checking and Tightening Connecting Rod BoltsSchmiernippel OskarNoch keine Bewertungen

- Containers Data 2022 - CPP QRT ProjectDokument86 SeitenContainers Data 2022 - CPP QRT ProjectNizaModdinNoch keine Bewertungen

- Assembly Instructions Cable Gland 501 453 RACDokument3 SeitenAssembly Instructions Cable Gland 501 453 RACempibkNoch keine Bewertungen

- Chapter 3 Basic Hand ToolsDokument13 SeitenChapter 3 Basic Hand Toolspapipapii50% (4)

- F-14934 Parts BookDokument138 SeitenF-14934 Parts BookFredyNoch keine Bewertungen

- B41a RRH8x20 Installation GuideDokument32 SeitenB41a RRH8x20 Installation GuideNicolás RuedaNoch keine Bewertungen

- LM6000-InD-240 - Improved Forward Fan Shaft Coupling NutDokument18 SeitenLM6000-InD-240 - Improved Forward Fan Shaft Coupling NutIqbal Usmani100% (1)

- Manual de Instrucciones Manual de Instruções Instruction ManualDokument15 SeitenManual de Instrucciones Manual de Instruções Instruction ManualKaren Morales de LeonNoch keine Bewertungen

- MANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsDokument24 SeitenMANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsLUIS SAENZ100% (4)

- FXJ 125 2014Dokument34 SeitenFXJ 125 2014SerkanAlNoch keine Bewertungen

- Lopx 709 SFD-34Dokument56 SeitenLopx 709 SFD-34Surajkumar KumaranNoch keine Bewertungen

- If TCCDokument38 SeitenIf TCCKasturi MJNoch keine Bewertungen

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonVon EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonBewertung: 5 von 5 Sternen5/5 (2)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Von EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Noch keine Bewertungen

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionVon EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionBewertung: 4.5 von 5 Sternen4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tVon EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tBewertung: 4.5 von 5 Sternen4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosVon EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosBewertung: 5 von 5 Sternen5/5 (1)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsVon EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNoch keine Bewertungen

- Power System Control and ProtectionVon EverandPower System Control and ProtectionB. Don RussellBewertung: 4 von 5 Sternen4/5 (11)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersVon Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersBewertung: 5 von 5 Sternen5/5 (1)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceVon EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNoch keine Bewertungen

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeVon EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeBewertung: 4.5 von 5 Sternen4.5/5 (10)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionVon EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionBewertung: 4 von 5 Sternen4/5 (331)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesVon EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesBewertung: 5 von 5 Sternen5/5 (1)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Von EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Bewertung: 4 von 5 Sternen4/5 (2)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsVon EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Teach Yourself Electricity and Electronics, 6th EditionVon EverandTeach Yourself Electricity and Electronics, 6th EditionBewertung: 3.5 von 5 Sternen3.5/5 (15)

- Build Your Own Electronics WorkshopVon EverandBuild Your Own Electronics WorkshopBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldVon EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldBewertung: 4 von 5 Sternen4/5 (87)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingVon EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingBewertung: 4 von 5 Sternen4/5 (1)