Beruflich Dokumente

Kultur Dokumente

Unmanned Petrol Bunk Project

Hochgeladen von

Uday Kumar60%(5)60% fanden dieses Dokument nützlich (5 Abstimmungen)

2K Ansichten87 SeitenThis document describes a student project to create an unmanned petrol bunk system using smart card technology. The system would allow drivers to refuel their vehicles without human interaction by using a smart card containing credit that is read by a card reader at the petrol pump. When the driver inserts their card, the reader would display the card balance and allow the driver to enter the amount of fuel desired. It would then deduct the correct amount from the card and automatically dispense the fuel before shutting off. The project was undertaken to fulfill requirements for a Bachelor of Technology degree in Electronics and Communication Engineering.

Originalbeschreibung:

unmanned peterol punk projects using microcontroller and smart card

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document describes a student project to create an unmanned petrol bunk system using smart card technology. The system would allow drivers to refuel their vehicles without human interaction by using a smart card containing credit that is read by a card reader at the petrol pump. When the driver inserts their card, the reader would display the card balance and allow the driver to enter the amount of fuel desired. It would then deduct the correct amount from the card and automatically dispense the fuel before shutting off. The project was undertaken to fulfill requirements for a Bachelor of Technology degree in Electronics and Communication Engineering.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

60%(5)60% fanden dieses Dokument nützlich (5 Abstimmungen)

2K Ansichten87 SeitenUnmanned Petrol Bunk Project

Hochgeladen von

Uday KumarThis document describes a student project to create an unmanned petrol bunk system using smart card technology. The system would allow drivers to refuel their vehicles without human interaction by using a smart card containing credit that is read by a card reader at the petrol pump. When the driver inserts their card, the reader would display the card balance and allow the driver to enter the amount of fuel desired. It would then deduct the correct amount from the card and automatically dispense the fuel before shutting off. The project was undertaken to fulfill requirements for a Bachelor of Technology degree in Electronics and Communication Engineering.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 87

1

UNMANNED PETRO L BUNK SYSTEM USING SMART CARD

TECHNOLOGY

A mini project report submitted in partial fulfillment of the requirements for the

award of the degree of

BACHEULOR OF TECHNOLOGY

IN

ELECTRONICS AND COMMUNICATION ENGINEERING

Under the esteemed guidance of

J.Nehru

BE, M.Tech ,

Asst.Prof

Presented By

A.GANESH KUMAR REDDY - 11J21A0408

G.SATHWIK REDDY - 11J21A0437

DEPARTMENT OF ELECTRONICS & COMMUNICATION ENGINEERING

JOGINPALLY B.R. ENGINEERING COLLEGE

(Approved by AICTE & Affiliated to JNT University, Hyderabad)

2014-2015

2

COLLEGE CERTIFICATE

Date:

This is to certify that the mini project report entitled unmanned petrol bunk

system using smart card technology being submitted by A.GANESH KUMAR

REDDY(11J21A0408),G.SATHWIK REDDY(11J21A0437), during 2014-2015 in partial

fulfillment of the requirements for the award of the degree of BACHEULOR OF OF

TECHNOLOGY in ELECTRONICS & COMMUNICATION ENGINEERING is a

bonafide work carried out by her/him.

The results enclosed in this report have been verified and found correct. The results

embodied in this project report have not been submitted to any other University or Institute

for the award of any degree or diploma.

Internal Guide Head of the Department

J.Nehru M. SRINIVASA RAO

B.E.,M.Tech ,Asst.Prof B.E., M.Tech,

Department of ECE Head & Professor

Department of ECE

External Examiner

3

ORGANISATION CERTIFICATE

4

ACKNOWLEDGMENTS

I take this opportunity to remember and acknowledge the cooperation, good will and

support both moral and technical extended by several individuals out of which my project has

evolved. I shall always cherish my association with them.

I am greatly thankful to Dr. D. N. Rao, B.Tech., M.E., MBA., Ph.D, Principal of our college,

for extending his valuable help. I shall forever cherish my association with him for his

constant encouragement, perennial approachability, absolute freedom of thought and action.

I express my profound gratitude to Prof. M. Srinivasa Rao, B.E.,M.Tech.,(Ph.D), Head of

the Department of Electronics and Communication Engineering, for his constant support and

encouragement in completing my project.

I express our sincere thanks and gratitude to our project coordinators Prof.V.Sriram,

B.E.,M.Tech.,Prof A.Rajaiah B.E.,M.Tech.,(Ph.D),Sri R.Durga Gopal,B.Tech.,M.Tech.,(Ph.D) Associate

Professor Sri M.Govind B.Tech., M.Tech.,(Ph.D), Associate Professor, Department of ECE,

Joginapally B.R.Engineering college for their valuable help and encouragement throughout

the project work.

I would also like to thank Sri J.Nehru, B.Tech.,M.Tech. Assistant Professor, my internal

guide, without whose suggestions and encouragement, this project would not have been

possible.

I am also greatly thankful to all the faculty members of the department who provided

their feedback and valuable suggestions at different stages of the project and helped in the

success of the project.

With immense gratitude and pleasure I take this opportunity to thank my parents and

friends who have been a catalyst in the realization of my project.

A.GANESH KUMAR REDDY(11J21A0408)

G.SATHWIK REDDY(11J21A0437)

5

ABSTARCT

Today almost all petrol pumps have a microcontroller to control the electrical pump,

drive the display, measure the quantity and accordingly turn OFF the electrical pump. But

still a person is required to collect the money. Our project is designed to eliminate this human

interaction so that there is no need of workers to fill the petrol. In general, a smart card is an

integrated circuit card with memory capable of making decisions. A smart card, chip card or

integrated circuit card (ICC), is defined as any pocket-sized card with embedded integrated

circuits which can process information. This implies that it can receive input which is

processed by way of the ICC applications and delivered as an output. In this project, we are

using a contact smart card where the information inside the card is communicated with the

card reader by inserting card into the card reader. The card reader in this project used is an

SR-90 SDK of 1KB memory size.

The smart card reader contains a PIC 16F73 microcontroller, a voltage regulator,

serial cable connections and an LED which glows whenever a card is inserted into the reader

and also it glows whenever it issues any command or receives any command. The Smart Card

Reader is interfaced with the microcontroller through serial interface.

In this system, all drivers have a smart card called just like a petrocard. This card

can be recharged by some recharge points. The petrol pump is equipped with a smart card

reader. At the Petrol pump, the driver swaps the card and the smart card reader reads the

amount in the card and will display it on the LCD. The driver then enters the quantity of

petrol that has to be filled using a keypad. The corresponding amount is calculated and

deducted from his petrocard. The electrical pump is then turned ON according to the entered

amount, fills the tank and automatically turns OFF.

6

CONTENTS

Chapter 1 Introduction

1.1 Introduction

1.2 Literature Survey

Chapter 2 General Theory

2.1 Microcontroller

Chapter 3 Hardware

3.1 Main Block Diagram

3.2 Over view of Block Diagram

3.3 Individual Block Description

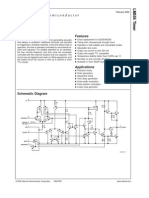

3.4 Schematic Diagram

Chapter 4 Software Description

4.1 About Software

4.2 Code/Program

Chapter 5 Result Analysis

5.1 Specifications

5.2 Screen Shots

7

LIST OF FIGURES

Fig 1.1.1 Layered Architecture of an Embedded System

Fig 1.1.2 Building Blocks of an Embedded System

Fig 2.1.1 Block Diagram of AT89C51

Fig 2.1.2 Lower part of Program Memory

Fig 2.1.3 Pin Configuration

Fig 2.1.4 Oscillator connection

Fig 2.1.5 TMOD Register

Fig 2.1.6 TCON Register

Fig 2.1.7 SBUF Register

Fig 2.1.8 SCON Register

Fig 3.1 Main Block Diagram

Fig 3.3.1 Components of Regulated Power Supply

Fig 3.3.2 Smart Card Content Chip

Fig 3.3.3 Smart Card Reader

Fig 3.3.4 Types of Chip Cards

Fig 3.3.5 8 Pin Smart Card Bus Point

Fig 3.3.6 Circuit For Motor Driver

Fig 3.3.7 Interfacing motor with 8051

Fig 3.3.8 Buzzer Circuit

Fig 3.3.9 Interfacing Buzzer to 8051

Fig 3.3.10 Types of Keypads

Fig 3.3.11 Matrix Keypad Connection to Ports

Fig 3.3.12 Lcd Display

8

Fig 3.3.13 Lcd screen

Fig 3.3.14 Procedure on 8-Bit Initialization

Fig 3.3.15 Variable resistor

Fig 3.3.16 Potentiometer symbol

Fig 3.3.17 Perset Symbol

Fig 3.3.18 Lcd Interfacing With 8051

Fig 3.4 Schematic Diagram

Fig 4.1 Keil Development Tools

9

LIST OF TABLES

Table 2.1.1 8051 Interrupt Priority Table

Table 2.1.2 Baud Rate in 8051

Table 2.1.3 SCON Register Functionality

Table 2.1.4 Serial Mode Type

Table 3.3.1 Smart Card Types

Table 3.3.2 Pin Functions

Table 3.3.3

Table 3.3.4 List of Commands

Table 4.1 Data Types

10

CHAPTER 1

INTRODUCTION

1.1 INTRODUCTION:

An embedded system can be defined as a computing device that does a specific

focused job. Appliances such as the air-conditioner, VCD player, DVD player, printer, fax

machine, mobile phone etc. are examples of embedded systems. Each of these appliances will

have a processor and special hardware to meet the specific requirement of the application

along with the embedded software that is executed by the processor for meeting that specific

requirement. The embedded software is also called firm ware. The desktop/laptop

computer is a general purpose computer. You can use it for a variety of applications such as

playing games,word processing, accounting, software development and so on. In contrast,

the software in the embedded systems is always fixed listed below:

Embedded systems do a very specific task that they cannot be programmed to do

different things. Embedded systems have very limited resources, particularly the memory.

Generally, they do not have secondary storage devices such as the CDROM or the floppy

disk. Embedded systems have to work against some deadlines. A specific job has to be

completed within a specific time. In some embedded systems, called real-time systems, the

deadlines are stringent. Missing a deadline may cause a catastrophe-loss of life or damage to

property. Embedded systems are constrained for power. As many embedded systems operate

through a battery, the power consumption has to be very low.

Some embedded systems have to operate in extreme environmental conditions such as

very high temperatures and humidity.

Application Areas

Nearly 99 per cent of the processors manufactured end up in embedded systems. The

embedded system market is one of the highest growth areas as these systems are used in very

market segment- consumer electronics, office automation, industrial automation, biomedical

engineering, wireless communication, data communication, telecommunications,

transportation, military and so on.

Consumer appliances: At home we use a number of embedded systems which include

digital camera, digital diary, DVD player, electronic toys, microwave oven, remote controls

11

for TV andair-conditioner, VCO player, video game consoles, video recorders etc. Todays

high-tech car has about 20 embedded systems for transmission control, engine spark control,

air-conditioning, navigation etc. Even wristwatches are nowbecoming embedded systems.

The palmtops are powerful embedded systems using which we can carry out many general-

purpose tasks such as playing games and word processing.

Office automation: The office automation products using embedded systems are copying

machine, fax machine, key telephone, modem, printer, scanner etc.

Industrial automation: Today a lot of industries use embedded systems for process control.

These include pharmaceutical, cement, sugar, oil exploration, nuclear energy, electricity

generation and transmission. The embedded systems for industrial use are designed to carry

out specific tasks such as monitoring the temperature, pressure, humidity, voltage, current

etc., and then take appropriate action based on the monitored levels to control other devices

or to send information to a centralized monitoring station. In hazardous industrial

environment, where human presence has to be avoided, robots are used, which are

programmed to do specific jobs. The robots are now becoming very powerful and carry out

many interesting and complicated tasks such as hardware assembly.

Medical electronics: Almost all medical equipments in the hospital are embedded systems.

These equipments include diagnostic aids such as ECG, EEG, blood pressure measuring

devices, X-ray scanners, equipment used in blood analysis, radiation, colonoscopy,

endoscopy etc. Developments in medical electronics have paved way for more accurate

diagnosis of diseases.

Computer networking: Computer networking products such as bridges, routers, Integrated

Services Digital Networks (ISDN), Asynchronous Transfer Mode (ATM), X.25 and frame

relay switches are embedded systems which implement the necessary data communication

protocols. For example, a router interconnects two networks. The two networks may be

running different protocol stacks. The routers function is to obtain the data packets from

incoming pores, analyze the packets and send them towards the destination after doing

necessary protocol conversion. Most networking equipments, other than the end systems

(desktop computers) we use to access the networks, are embedded systems.

Telecommunications: In the field of telecommunications, the embedded systems can be

categorized as subscriber terminals and network equipment. The subscriber terminals such as

12

key telephones, ISDN phones, terminal adapters, web cameras are embedded systems. The

network equipment includes multiplexers, multiple access systems, Packet Assemblers

Dissemblers (PADs), sate11ite modems etc. IP phone, IP gateway, IP gatekeeper etc. are the

latest embedded systems that provide very low-cost voice communication over the Internet.

Wireless technologies: Advances in mobile communications are paving way for many

interesting applications using embedded systems. The mobile phone is one of the marvels of

the last decade of the 20th century. It is a very powerful embedded system that provides voice

communication while we are on the move. The Personal Digital Assistants and the palmtops

can now be used to access multimedia services over the Internet. Mobile communication

infrastructure such as base station controllers, mobile switching centers are also powerful

embedded systems.

Insemination: Testing and measurement are the fundamental requirements in all scientific

and engineering activities. The measuring equipment we use in laboratories to measure

parameters such as weight, temperature, pressure, humidity, voltage, current etc. are all

embedded systems. Test equipment such as oscilloscope, spectrum analyzer, logic analyzer,

protocol analyzer, radio communication test set etc. are embedded systems built around

powerful processors. Thank to miniaturization, the test and measuring equipment are now

becoming portable facilitating easy testing and measurement in the field by field-personnel.

Security: Security of persons and information has always been a major issue. We need to

protect our homes and offices; and also the information we transmit and store. Developing

embedded systems for security applications is one of the most lucrative businesses nowadays.

Security devices at homes, offices, airports etc. for authentication and verification are

embedded systems. Encryption devices are nearly 99 per cent of the processors that are

manufactured end up in~ embedded systems. Embedded systems find applications in every

industrial segment- consumer electronics, transportation, avionics, biomedical engineering,

manufacturing, process control and industrial automation, data communication,

telecommunication, defense, security etc. They are used to encrypt the data/voice being

transmitted on communication links such as telephone lines.Biometric systems using

fingerprint and face recognition are now being extensively used for user authentication in

banking applications as well as for access control in high security buildings.

Finance: Financial dealing through cash and cheques are now slowly paving way for

transactions using smart cards and ATM (Automatic Teller Machine, also expanded as Any

13

Time Money) machines. Smart card, of the size of a credit card, has a small micro-controller

and memory; and it interacts with the smart card reader! ATM machine and acts as an

electronic wallet. Smart card technology has the capability of ushering in a cashless society.

Well, the list goes on. It is no exaggeration to say that eyes wherever you go, you can see, or

at least feel, the work of an embedded system!

Overview of Embedded System Architecture

Every embedded system consists of custom-built hardware built around a Central

Processing Unit (CPU). This hardware also contains memory chips onto which the software

is loaded. The software residing on the memory chip is also called the firmware. The

embedded system architecture can be represented as a layered architecture as shown in Fig.

Fig 1.1.1 layered architecture of an Embedded system

The operating system runs above the hardware, and the application software runs

above the operating system. The same architecture is applicable to any computer including a

desktop computer. However, there are significant differences. It is not compulsory to have an

operating system in every embedded system. For small appliances such as remote control

units, airconditioners, toys etc., there is no need foran operating system and you can write

only the software specific to that application.

For applications involving complex processing, it is advisable to have an operating

system. In such a case, you need to integrate the application software with the operating

system and then transfer the entire software on to the memory chip. Once the software is

transferred to the memory chip, the software will continue to run for a long time you dont

need to reload new software.

14

Now, let us see the details of the various building blocks of the hardware of an embedded

system. As shown in Fig. the building blocks are;

Central Processing Unit (CPU)

Memory (Read-only Memory and Random Access Memory)

Input Devices

Output devices

Communication interfaces

Application-specific circuitry

Fig 1.1.2 Building Blocks of an Embedded systems

Central Processing Unit (CPU):

The Central Processing Unit (processor, in short) can be any of the following:

microcontroller, microprocessor or Digital Signal Processor (DSP). A micro-controller is a

low-cost processor. Its main attraction is that on the chip itself, there will be many other

components such as memory, serial communication interface, analog-to digital converter etc.

So, for small applications, a micro-controller is the best choice as the number of external

components required will be very less. On the other hand, microprocessors are more

powerful, but you need to use many external components with them. D5P is used mainly for

applications in which signal processing is involved such as audio and video processing.

Memory:

The memory is categorized as Random Access Memory (RAM) and Read Only

Memory (ROM). The contents of the RAM will be erased if power is switched off to the

chip, whereas ROM retains the contents even if the power is switched off. So, the firmware is

15

stored in the ROM. When power is switched on, the processor reads the ROM; the program is

program is executed.

Input devices:

Unlike the desktops, the input devices to an embedded system have very limited

capability. There will be no keyboard or a mouse, and hence interacting with the embedded

system is no easy task. Many embedded systems will have a small keypad-you press one key

to give a specific command. A keypad may be used to input only the digits. Many embedded

systems used in process control do not have any input device foruser interaction; they take

inputs from sensors or transducers and produce electrical signals that are in turn fed to other

systems.

Output devices:

The output devices of the embedded systems also have very limited capability. Some

embedded systems will have a fewLight Emitting Diodes (LEDs) to indicate the health status

of the system modules, or forvisual indication of alarms. A small Liquid Crystal Display

(LCD) may also be used to display someimportant parameters.

Communication interfaces:

The embedded systems may need to, interact with other embedded systems at they

may have to transmit data to a desktop. To facilitate this, the embedded systems are provided

with one or a few communication interfaces such as RS232, RS422, RS485, Universal Serial

Bus (USB), IEEE 1394, Ethernet etc.

Application-specific circuitry:

Sensors, transducers, special processing and control circuitry may be required fat an

embedded system, depending on its application. This circuitry interacts with the processor to

carry out the necessary work. The entire hardware has to be given power supply either

through the 230 volts main supply or through a battery. The hardware has to design in such a

way that the power consumption is minimized.

16

1.2 LITERATURE SURVEY:

Software Tools:

1. Keil compiler

2. Orcad

3. Proload

Hardware Tools:

1. Microcontroller AT89S52.

2. 24c04 as a smart card.

3. LCD

4. Buzzer and driver circuit

5. AC motor and driver circuit

6. Keypad

17

CHAPTER 2

GENERAL THEORY

2.1 MICROCONTROLLER:

INTRODUCTION:

A Micro controller consists of a powerful CPU tightly coupled with memory RAM,

ROM or EPROM), various I / O features such as Serial ports, Parallel Ports, Timer/Counters,

Interrupt Controller, Data Acquisition interfaces-Analog to Digital Converter (ADC), Digital

to Analog Converter (ADC), everything integrated onto a single Silicon Chip.

It does not mean that any micro controller should have all the above said features on

chip, Depending on the need and area of application for which it is designed, The ON-CHIP

features present in it may or may not include all the individual section said above.

Any microcomputer system requires memory to store a sequence of instructions

making up a program, parallel port or serial port for communicating with an external system,

timer / counter for control purposes like generating time delays, Baud rate for the serial port,

apart from the controlling unit called the Central Processing Unit.

INTRODUCTION TO 8051 MICROCONTROLLER

In 1981,Intel corporation introduced an 8 bit microcontroller called the 8051.This

microcontroller had 128 bytes of RAM,4K bytes of on-chip ROM, two timers, one serial port

and 4 ports(each 8-bits wide)all on single chip. At that time it was also referred to as a

system on a chip.

INTRODUCTION TO ATMEL MICROCONTROLLER

The major Features of 8-bit Micro controller ATMEL 89C51:

8 Bit CPU optimized for control applications

Extensive Boolean processing (Single - bit Logic) Capabilities.

On - Chip Flash Program Memory

On - Chip Data RAM

Bi-directional and Individually Addressable I/O Lines

18

Multiple 16-Bit Timer/Counters

Full Duplex UART

Multiple Source / Vector / Priority Interrupt Structure

On - Chip Oscillator and Clock circuitry.

On - Chip EEPROM

One Serial communication port

Block Diagram:

Fig 2.1.1 Block Diagram of AT89C51

COUNTER

INPUTS

INTERRUPT

CONTROL

ON-CHIP

FLASH

ON-CHIP

RAM

RAM

ON-CHIP

RAM

TIMER 1

TIMER 0

CPU

OSCILLATOR BUS

CONTROL

4 I/O

PORTS

SERIAL

PORT

PO P2 P1 P3

TXD RXD

ON-CHIP

FLASH

EXTERNAL

INTERRUPTS

19

The P89C51 provides the following standard features: 4K bytes of Flash, 128 bytes

of RAM, 32 I/O lines, two 16-bit timer/counters, five vector two-level interrupt architecture,

a full duplex serial port, and on-chip oscillator and clock circuitry. In addition, the P89C51 is

designed with static logic for operation down to zero frequency and supports two software

selectable power saving modes. The Idle Mode stops the CPU while allowing the RAM,

timer/counters, serial port and interrupt system to continue functioning. The Power-down

Mode saves the RAM contents but freezes the oscillator disabling all other chip functions

until the next hardware reset.

Memory Organization

Program Memory:

Below Fig shows a map of the lower part of the program memory. After reset, the

CPU begins execution from location 0000H. As shown in fig.4, each interrupt is assigned a

fixed location in program memory. The interrupt causes the CPU to jump to that location,

where it executes the service routine. External Interrupt 0, for example, is assigned to

location 0003H. If External Interrupt 0 is used, its service routine must begin at location

0003H. If the interrupt is not used, its service location is available as general purpose.

Fig 2.1.2 Lower Part of Program Memory

0033H

002BH

0023H

001BH

0013H

000BH

0003H

0000H

8 bytes

INTERRUPT

LOCATIONS

RESET

20

Program Memory:

Program memory addresses are always 16 bits wide, even though the actual amount o

program memory used may be less than 64Kbytes. External program execution sacrifices two

of the 8-bit ports, P0 and P2, to the function of addressing the program memory.

Data Memory:

The right half of Figure 3 shows the internal and external data memory spaces

available on Philips Flash microcontrollers. Fig.6 shows a hardware configuration for

accessing up to 2K bytes of external RAM. In this case, the CPU executes from internal flash.

Port0 serves as a multiplexed address/data bus to the RAM, and 3 lines of Port 2 are used to

page the RAM. The CPU generates RD and WR signals as needed during external RAM

accesses. You can assign up to 64K bytes of external data memory. External data memory

addresses can be either 1 or 2bytes wide.

Internal data memory addresses are always 1 byte wide, which implies an address

space of only 256bytes. However, the addressing modes for internal RAM can infact

accommodate 384 bytes. Direct addresses higher than 7FH access one memory space and

indirect addresses higher than 7FH access a different memory space. Thus, Figure.7 shows

the Upper 128 and SFR space occupying the same block of addresses, 80H through FFH,

although they are physically separate entities. The lowest 32 bytes are grouped into 4 banks

of 8 registers. Program instructions call out these registers as R0 through R7.

The next 16 bytes above the register banks form a block of bit-addressable memory

space. The microcontroller instruction set includes a wide selection of single-bit instructions,

and these instructions can directly address the 128 bits in this area. These bit addresses are

00H through 7FH. All of the bytes in the Lower 128 can be accessed by either direct or

indirect addressing.

REGISTERS:

In the CPU, registers are used to store information temporarily. That information

could be a byte of data to be processed, or an address pointing to the data to be fetched. The

vast majority of 8051 registers are 8bit registers. In the 8051 there is only one data type:

21

8bits. The 8bits of aregister are should in the diagram from the MSB (most significant bit)

D7 to the LSB (least significant bit) D0. With an 8-bit data type, any data larger than 8bits

must be broken into 8-bit chunks before it is processed.

The most widely used registers of the 8051 are A(Accumulator), B, R0, R1, R2, R3,

R4, R5, R6, R7, DPTR(Data Pointer), and PC(Program Counter). All of the above registers

are 8-bits, except DPTR and the program counter. The Accumulator, register A, is used for

all arithmetic and logic instructions.

SFRs (Special Function Registers):

Among the registers R0-R7 are part of the 128 bytes of RAM memory. Whatabout

registers A,B, PSW, and DPTR? Do they also have addresses? The answer is yes. In the

8051, registers A, B, PSW and DPTR are part of the group of registers commonly referred to

as SFR (special function registers). There are many special function registers and they are

widely used. The SFR can be accessed by the names (which is much easier) or by their

addresses. For example, register A has address E0h, and register B has been ignited the

address F0H.

PIN CONFIGURATION

fig 2.1.3 Pin configuration1

D7 D6 D5 D4 D3 D2 D1 D0

22

Pin Description:

VCC: Pin 40 provides supply voltage to the chip. The voltage source is +5v.

GND: Pin 20 is the ground.

Ports 0, 1, 2 and 3:

As shown in pin diagram, the four ports P0, P1, P2, and P3 each use of 8 pins, making

the 8-bit ports. All the ports upon Reset are configured as input, since P0-P3 have FFH on

them.

Port 0:

Port 0 occupies a total of 8 pins (pins 32-33). It can be used for input or output. Port0

is also designated as AD0-AD7, allowing it to be used for both address and data. When

connecting an 8051/31 to an external memory, port 0 provides both address and data. The

8051 multiplexes address and data through port 0 to save pins. ALE=0, it provides data D0-

D7, but when ALE=1, it has address A0-A7. Therefore, ALE is used for demultiplexing

address and data with the help of a 74LS373 latch. In the 8051-based systems where there is

no external memory connection, the pins of P0 must be connected externally to a 10k ohm

pull-up resistor.

This is due to the fact that P0 is an Open drain, Unlike P1, P2, P3. Open drain is a

term used for MOS chips in the same way that open collector is used for TTL chips. In many

systems using the 8751, 89C51, or DS89C4x0 chips, we normally connect P0 to pull-up

resistors. With external pull-up resistors connected to P0, it can be used as a simple I/O port,

just like P1 and P2. In contrast to Port 0, ports p1, p2, and p3 do not need any pull-up

resistors since they already have pull-up resistors internally. Upon reset, ports p1, p2, and p3

are configured as input ports.

Port 1:

Port 1 occupies a total of 8-pins (pins1-8). It can be used as input or output. In

contrast to port 0, this port does not need any pull-up resistors since it already has pull-up

resistors internally. Upon reset, port1 is configured as an input port.

Port 2:

23

Port 2 occupies a total 8 pins (pins 21-28). It can be used as input or output. However,

in 8031-based systems, port2 is also designated as A8-A15, indicating its dual function.

Since an 8051/31 is capable of accessing 64K bytes of external memory, it needs a path for

the 16 bits of the address. While P0 provides the lower 8 bits via A0-A7, it is the job of p2 is

used for the upper 8 bits of the 16-bit address, and it cannot be used for I/O. Just like P1, port

2 does not need any pull-up resistors since it already has pull-up resistors internally. Upon

reset, port2 is configured as an input port.

Port 3:

Port 3 occupies a total of 8 pins (pins 10-17). It can be used as input or output. P3

does not need any pull-up resistors, just as P1 and P2 did not. Although Port 3 is configured

as an input port upon reset, this is not the way it is most commonly used. Port 3 has the

additional function of providing some extremely important signals such as interrupts. The

below table provides these alternate functions of P3. This is information applies to both 8051

and 8031 chips.

Alternate Functions of PORT3:

Port 3 also receives some control signals for Flash programming and verification.

RST:

Reset input. A high on this pin for two machine cycles while the oscillator is running

resets the device.

ALE/PROG:

Prior to each reading from external memory, the microcontroller will set the lower

address byte (A0-A7) on P0 and immediately after that activates the output ALE. Upon

receiving signal from the ALE pin, the external register (74HCT373 or 74HCT375 circuit is

usually embedded) memorizes the state of P0 and uses it as an address for memory chip. In

the second part of the microcontrollers machine cycle, a signal on this pin stops being

emitted and P0 is used now for data transmission (Data Bus). In this way, by means of only

one additional (and cheap) integrated circuit, data multiplexing from the port is performed.

This port at the same time used for data and address transmission.

PSEN:

24

Program Store Enable is the read strobe to external program memory. When the

AT89C51 is executing code from external program memory, PSEN is activated twice each

machine cycle, except that two PSEN activations are skipped during each access to external

data memory.

EA/VPP:

External Access Enable. EA must be strapped to GND in order to enable the device to

fetch code from external program memory locations starting at 0000H up to FFFFH. Note,

however, that if lock bit 1 is programmed, EA will be internally latched on reset. EA should

be strapped to VCC for internal program executions. This pin also receives the 12-volt

programming enable voltage (VPP) during Flash programming, for parts that require 12-volt

VPP.

XTAL1 and XTAL2:

The 8051 has an on-chip oscillator but requires an external clock to run it. Most often

a quartz crystal oscillator is connected to inputs XTAL1 (pin19) and XTAL2 (pin18). The

quartz crystal oscillator connected to XTAL1 and XTAL2 also needs two capacitors of 30pf

value. One side of each capacitor is connected to the ground as shown below.

Fig 2.1.4Oscillator Connection

It must be noted that there are various speeds of the 8051 family. Speed refers to the

maximum oscillator frequency connected to XTAL. For example, a 12-MHz chip must be

connected to a crystal with 12 MHz frequency of no more than 20MHz. When the 8051 is

connected to a crystal oscillator and is powered up, we can observe the frequency on the

XTAL2 pin using the oscilloscope.

25

TIMERS:

On-chip timing/counting facility has proved the capabilities of the microcontroller for

implementing the real time application. These includes pulse counting, frequency

measurement, pulse width measurement, baud rate generation, etc,. Having sufficient number

of timer/counters may be a need in a certain design application. The 8051 has two

timers/counters. They can be used either as timers to generate a time delay or as counters to

count events happening outside the microcontroller. Let discuss how these timers are used to

generate time delays and we will also discuss how they are been used as event counters.

BASIC RIGISTERS OF THE TIMER:

Both Timer 0 and Timer 1 are 16 bits wide. Since the 8051 has an 8-bit architecture,

each 16-bit timer is accessed as two separate registers of low byte and high byte.

TIMER 0 REGISTERS:

The 16-bit register of Timer 0 is accessed as low byte and high byte. the low byte

register is called TL0(Timer 0 low byte)and the high byte register is referred to as TH0(Timer

0 high byte).These register can be accessed like any other register, such as

A,B,R0,R1,R2,etc.for example, the instruction MOV TL0, #4Fmoves the value 4FH into

TL0,the low byte of Timer 0.These registers can also be read like any other register.

TIMER 1 REGISTERS:

Timer 1 is also 16-bit register is split into two bytes, referred to as TL1 (Timer 1 low

byte) and TH1(Timer 1 high byte).these registers are accessible n the same way as the

register of Timer 0.

TMOD (Timer Mode) REGISTER:

Both timers 0 and 1 use the same register, called TMOD, to set the various timer

operation modes. TMOD is an 8-bit register in which the lower 4 bits are set aside for Timer

0 and the upper 4 bits for Timer 1.in each case; the lower 2 bits are used to set the timer mode

and the upper 2 bits to specify the operation.

26

Fig 2.1.5TMOD Register

TCON Register:

TCON controls the timer/counter operations. The lower four bits of TCON cater to

interrupt functions, but the upper four bits are for timer operations. The details of the TCON

register are as shown.

Fig 2.1.6 TCON Register

INTERRUPTS:

A single microcontroller can serve several devices. There are two ways to do that:

INTERRUPTS or POLLING.

POLLING:

In polling the microcontroller continuously monitors the status of a given device;

when the status condition is met, it performs the service .After that, it moves on to monitor

the next device until each one is serviced. Although polling can monitor the status of several

devices and serve each of them as certain condition are met.

INTERRUPTS:

In the interrupts method, whenever any device needs its service, the device notifies

the microcontroller by sending it an interrupts signal. Upon receiving an interrupt signal, the

microcontroller interrupts whatever it is doing and serves the device. The program associated

with the interrupts is called the interrupt service routine (ISR).or interrupt handler.

27

Various Interrupts in the 8051:

In reality, only five interrupts are available to the user in the 8051, but many

manufacturers data sheets state that there are six interrupts since they include reset .the six

interrupts in the 8051 are allocated as above.

1. Reset. When the reset pin is activated, the 8051 jumps to address location 0000.this is

the power-up reset.

2. Two interrupts are set aside for the timers: one for Timer 0 and one for Timer

1.Memory location 000BH and 001BH in the interrupt vector table belong to Timer 0

and Timer 1, respectively.

3. Two interrupts are set aside for hardware external harder interrupts. Pin number

12(P3.2) and 13(P3.3) in port 3 are for the external hardware interrupts INT0 and

INT1,respectively.These external interrupts are also referred to as EX1 and

EX2.Memory location 0003H and 0013H in the interrupt vector table are assigned to

INT0 and INT1, respectively.

4. Serial communication has a single interrupt that belongs to both receive and transmit.

The interrupt vector table location 0023H belongs to this interrupt.

8051/52 Interrupt Priority upon Reset

External Interrupt 0 INT0

Timer Interrupt 0 TF0

External Interrupt 1 INT1

Timer Interrupt 1 TF1

Serial Communication RI+TI

Timer 2(8052 only) TF2

NOTE:Highest to Lowest Priority

Table 2.1.1 8051 Interrupt Priority table

28

SERIAL COMMUNICATION:

Computers can transfer data in two ways: parallel and serial. In parallel data

transfers, often 8 or more lines (wire conductors) are used to transfer data to a device that is

only a few feet away. An example of parallel transfers a printers and hard disks; each uses

cables with many wire strips. Although in such cases a lot of data can be transferred in a

short amount of time by using many wires in parallel, the distance cannot be great.

To transfer to a device located many meters away, the serial method is used. In serial

communication, the data is sent one bit at a time, in contrast to parallel communication, in

which the data is sent a byte or more at a time. Serial communication of the 8051 is the topic

of this chapter. The 8051 has serial communication capability built into it, thereby making

possible fast data transfer using only a few wires.

If data is to be transferred on the telephone line, it must be converted from 0s and 1s to

audio tones, which are sinusoidal-shaped signals. This conversion is performed by a

peripheral device called a modem, which stands for modulator/demodulator.Serial data

communication uses two methods, asynchronous and synchronous. The synchronous method

transfers a block of data at a time, while the asynchronous method transfers a single byte at a

time.

In data transmission if the data can be transmitted and received, it is a duplex

transmission. This is in contrast to simplex transmissions such as with printers, in which the

computer only sends data. Duplex transmissions can be half or full duplex, depending on

whether or not the data transfer can be simultaneous.

Asynchronous serial communication and data framing:

The data coming in at the receiving end of the data line in a serial data transfer is all 0s

and 1s; it is difficult to make sense of the data unless the sender and receiver agree on a set of

rules, a protocol, on how the data is packed, how many bits constitute a character, and when

the data begins and ends.

Start and stop bits:

Asynchronous serial data communication is widely used for character-oriented

transmissions, while block-oriented data transfers use the synchronous method. In the

asynchronous method, each character is placed between start and stop bits. This is called

29

framing. In the data framing for asynchronous communications, the data, such as ASCII

characters, are packed between a start bit and a stop bit. The start bit is always one bit, but the

stop bit can be one or two bits. The start bit is always a 0 (low) and the stop bit (s) is 1

(high).

Data transfer rate:

The rate of data transfer in serial data communication is stated in bps (bits per second).

Another widely used terminology for bps is baud rate. The data transfer rate of given

computer system depends on communication ports incorporated into that system. For

example, the early IBMPC/XT could transfer data at the rate of 100 to 9600 bps. In recent

years, however, Pentium based PCS transfer data at rates as high as 56K bps. It must be

noted that in asynchronous serial data communication, the baud rate is generally limited to

100,000bps.

Baud rate in the 8051:

The 8051 transfers and receives data serially at many different baud rates. The baud

rate in the 8051 is programmable. It is done with the help of Timer1. The 8051 divides the

crystal frequency by 12 to get the machine cycle frequency. In the case of

XTAL=11.0592MHZ, the machine cycle frequency is 921.6 KHz

(11.0592MHz/12=921.6KHz). The 8051s serial communication UART circuitry divides the

machine cycle frequency of 921.6KHZ divided by 32 once more before it is used by Timer 1

to set the Baud rate. Therefore, 921.6 KHz divided by 32 gives 28,800 Hz. This is the

number well use to find the Timer 1 value to set baud rate.

Baud Rate TH1(Decimal) TH1(Hex)

9600 -3 FD

4800 -6 FA

2400 -12 F4

1200 -24 E8

NOTE: XTAL=11.0592MHz

Table 2.1.2 Baud Rate in 8051

30

SBUF register:

SBUF is an 8-bit register used solely for serial communication in the 8051. for a byte

of data to be transferred via the TXD line, it must be placed in the SBUF register. Similarly,

SBUF holds the byte of data when it is received by the 8051s RXD line. SBUF can be

accessed like any other register in the 8051. Look at the following the examples of how this

register is accessed.

MOV SBUF, #D ; load SBUF=44h, ASCII for D

MOV SBUF, A ; copy accumulator into SBUF

MOV A, SBUF ; copy SBUF into accumulator

The moment a byte is written into SBUF, it is framed with the start and stop bits and

transferred serially via the TXD pin. Similarly, when the bits are received serially via RXD,

the 8051 defames it by eliminating the stop and start bits, making a byte out of the data

received, and then placing it in the SBUF.

Fig 2.1.7 SBUF Register

SCON (serial control) register:

The SCON register is an 8-bit register used to program the start bit, stop bit, and data

bits of data framing, among other things.The following describes various bits of the SCON

register.

Fig 2.1.8 SCON Register

BIT NAME BIT NUMBER FUNCTION

SM0 SCON.7 Serial port mode specifier

31

SM1 SCON.6 Serial port mode specifier

SM2 SCON.5 Used for multiprocessor

communication. (Make it 0.)

REN SCON.4 Set/cleared by software to

enable/disable reception

TB8 SCON.3 Not widely used

RB8 SCON.2 Not widely used

TI SCON.1 Transmit interrupt flag. Set

by hardware at the beginning

of the stop bit in mode 1.

Must be cleared by software.

RI SCON.0 Receive interrupt flag. Set by

hardware halfway through the

stop bit time mode 1. Must

be cleared by software.

Note: Make SM2, TB8, and RB8=0.

Table 2.1.3 SCON Register Functionality

SM0, SM1:

SM0 and SM1 are D7 and D6 of the SCON register, respectively. These two bits

determine the framing of data by specifying the number of bits per character and the start and

stop bits. They take the following combinations.

SMO SM1 FUNCTION

0 0 Serial Mode-0

0 1 Serial Mode-1

1 0 Serial Mode-2

1 1 Serial Mode-3

Table 2.1.4 Serial Mode Type

Of the 4 serial modes, only mode 1(8-bit data, 1-start bit, 1-stop bit) is of interest to us.

In the SCON register, when serial mode 1 is chosen, the data framing is 8 bits, 1 stop bit, and

1 start bit, which makes it compatible with the COM port of IBM/compatible PCs. More

importantly, serial mode 1 allows the baud rate to be variable and is set by Timer 1 of the

32

8051. In serial mode 1, for each character a total of 10 bits are transferred, where the first bit

is the start bit, followed by 8 bits of data, and finally 1 stop bit.

33

CHAPTER 3

HARDWARE DESCRIPTION

3.1 MAIN BLOCK DIAGRAM:

Fig 3.1 Main Block Diagram

34

3.2 OVERVIEW OF BLOCK DIAGRAM:

35

3.3 INDIVIDUAL BLOCK DESCRIPTION:

POWER SUPPLY

The input to the circuit is applied from the regulated power supply. The a.c. input

i.e., 230V from the mains supply is step down by the transformer to 12V and is fed to a

rectifier. The output obtained from the rectifier is a pulsating d.c voltage. So in order to

get a pure d.c voltage, the output voltage from the rectifier is fed to a filter to remove

any a.c components present even after rectification. Now, this voltage is given to a

voltage regulator to obtain a pure constant dc voltage.

Fig 3.3.1 Components Of Regulated Power Supply

Transformer:

Usually, DC voltages are required to operate various electronic equipment and these

voltages are 5V, 9V or 12V. But these voltages cannot be obtained directly. Thus the a.c

input available at the mains supply i.e., 230V is to be brought down to the required voltage

level. This is done by a transformer. Thus, a step down transformer is employed to decrease

the voltage to a required level.

Rectifier:

36

The output from the transformer is fed to the rectifier. It converts A.C. into pulsating

D.C. The rectifier may be a half wave or a full wave rectifier. In this project, a bridge rectifier

is used because of its merits like good stability and full wave rectification.

Filter:

Capacitive filter is used in this project. It removes the ripples from the output of

rectifier and smoothens the D.C. Output received from this filter is constant until the mains

voltage and load is maintained constant. However, if either of the two is varied, D.C. voltage

received at this point changes. Therefore a regulator is applied at the output stage.

Voltage regulator:

As the name itself implies, it regulates the input applied to it. A voltage regulator is an

electrical regulator designed to automatically maintain a constant voltage level. In this

project, power supply of 5V and 12V are required. In order to obtain these voltage levels,

7805 and 7812 voltage regulators are to be used. The first number 78 represents positive

supply and the numbers 05, 12 represent the required output voltage levels.

SMART CARD TECHNOLOGY:

A Smart Card is a plastic card the size of a credit card with an integrated circuit built

into it. This integrated circuit may consist only of EEPROM in the case of a memory card, or

it may also contain ROM, RAM and even a CPU.

A smart card, a type of chip card is a plastic card embedded with a computer chip that

stores and transacts data between users. This data is associated with either value or

information or both and is stored and processed within the card's chip, either a memory or

microprocessor. The card data is transacted via a reader that is part of a computing system.

Smart card-enhanced systems are in use today throughout several key applications, including

healthcare, banking, entertainment and transportation. To various degrees, all applications

can benefit from the added features and security that smart cards provide.

Smart cards are portable data cards that must communicate with another device to gain

access to a display device or a network. Cards can be plugged into a reader, commonly

referred to as a card terminal, or they can operate using radio frequencies (RF).

37

When the smart card and the card reader come into contact, each identifies itself to the

other by sending and receiving information. If the messages exchanged do not match, no

further processing takes place. So, unlike ordinary bank cards, smart cards can defend

themselves against unauthorized users and uses in innovative security measures.

Fig 3.3.2 Smart Card Contact Chip

The history of Smart cards

The proliferation of plastic cards started in the USA in the early 1950s. The low price

of the synthetic material PVC made it possible to produce robust, durable plastic cards that

were much more suitable for everyday use than the paper and cardboard cards previously

used, which could not adequately withstand mechanical stresses and climatic effects. The first

all-plastic payment card for general use was issued by the Diners Club in 1950. It was

intended for an exclusive class of individual, and thus also served as a status symbol,

allowing the holder to pay with his or her good name instead of cash. Initially, only the

more select restaurants and hotels accepted these cards, so this type of card came to be known

as a travel and entertainment card.

The entry of Visa and MasterCard into the field led to a very rapid proliferation of

plastic money in the form of credit cards. A cardholder is never at a loss for means of

payment, yet he or she avoids exposure to the risk of loss due to theft or other unpredictable

hazards, particularly while traveling. Using a credit card also eliminates the tedious task of

exchanging currency when traveling abroad. These unique advantages helped credit cards

become rapidly established throughout the world.

38

At first, the functions of these cards were quite simple. They served as data storage

media that were secure against forgery and tampering. General information, such as the card

issuers name, was printed on the surface, while personal data elements, such as the

cardholders name and the card number, were embossed.

Increasing handling costs for merchants and banks made a machine-readable card

necessary, while at the same time, losses suffered by card issuers as the result of customer

insolvency and fraud grew from year to year.

The first improvement consisted of a magnetic stripe on the back of the card, which

allowed digital data to be stored on the card in machine-readable form as a supplement to the

visual information. This made it possible to minimize the use of paper receipts, which were

previously essential, although the customers signature on a paper receipt was still required in

traditional credit card applications as a form of personal identification. However, magnetic-

stripe technology has a crucial weakness, which is that the data stored on the stripe can be

read, deleted and rewritten at will by anyone with access to the necessary equipment. It is

thus unsuitable for storing confidential data. Additional techniques must be used to ensure

confidentiality of the data and prevent manipulation of the data.

The development of the smart card, combined with the expansion of electronic data

processing systems, has created completely new possibilities for devising such solutions.

Enormous progress in microelectronics in the 1970s made it possible to integrate data storage

and processing logic on a single silicon chip measuring a few square millimeters.

The great breakthrough was achieved in 1984, when the French PTT (postal and

telecommunications services agency) successfully carried out a field trial with telephone

cards. In this field trial, smart cards immediately proved to meet all expectations with regard

to high reliability and protection against manipulation.

39

The smart card proved to be an ideal medium. It made a high level of security (based on

cryptography) available to everyone, since it could safely store secret keys and execute

cryptographic algorithms. In addition, smart cards are so small and easy to handle that they

can be carried and used everywhere by everybody in everyday life. It was a natural idea to

attempt to use these new security features for bank cards, in order to come to grips with the

security risks arising from the increasing use of magnetic-stripe cards.

The smart cards high degree of functional flexibility, which even allows programs for

new applications to be added to a card already in use, has opened up completely new

application areas extending beyond the boundaries of traditional card uses. Smart cards are

also being used as electronic tickets for local public transport in many cities throughout the

world.

Specifications of a smart card

Smarts cards may have up to 8 kilobytes of RAM, 346 kilobytes of ROM, 256

kilobytes of programmable ROM and a 16-bit microprocessor. The smart card uses a serial

interface and receives its power from external sources like a card reader. The processor uses a

limited instruction set for applications such as cryptography.

Characteristics of smart card:

A "SMART CARD" is also characterized as follows:

Dimensions are normally credit card size. The ID-1 of ISO/IEC 7810 standard defines

them as 85.60 53.98 mm. Another popular size is ID-000 which is 25 x 15 mm.

Both are .76 mm thick.

Contains a security system with tamper-resistant properties (e.g. a secure crypto

processor, secure file system, human-readable features) and is capable of providing

security services (e.g. confidentiality of information in the memory).

Asset managed by way of a central administration system which interchanges

information and configuration settings with the card through the security system. The

latter includes card hot listing, updates for application data.

40

Card data is transferred to the central administration system through card reading

devices, such as ticket readers, ATMs etc.

Smart card readers:

Fig 3.3.3 Smart Card Reader

Smart Card Readers are also known as card programmers (because they can write to a

card), card terminals, card acceptance device (CAD) or an interface device (IFD). There is a

slight difference between the card reader and the terminal. The term 'reader' is generally used

to describe a unit that interfaces with a PC for the majority of its processing requirements. In

contrast, a 'terminal' is a self-contained processing device.

Smart cards are portable data cards that must communicate with another device to gain

access to a display device or a network. Cards can be plugged into a reader, commonly

referred to as a card terminal, or they can operate using radio frequencies (RF).

When the smart card and the card reader come into contact, each identifies itself to the

other by sending and receiving information. If the messages exchanged do not match, no

further processing takes place. So, unlike ordinary bank cards, smart cards can defend

themselves against unauthorized users and uses in innovative security measures.

Communicating with a Smart Card Reader

The reader provides a path for the application to send and receive commands from the

card. There are many types of readers available, such as serial, PC Card, and standard

keyboard models.

41

Each manufacturer provides a different protocol for communication with the reader.

First you have to communicate with the reader.

Second, the reader communicates with the card, acting as the intermediary before

sending the data to the card.

Third, communication with a smart card is based on the APDU format. The card will

process the data and return it to the reader, which will then return the data to its

originating source.

The following classes are used for communicating with the reader:

ISO command classes for communicating with 7816 protocol

Classes for communicating with the reader

Classes for converting data to a manufacturer-specific format

An application for testing and using the cards for an intended and specific purpose.

Readers come in many forms, factors and capabilities. The easiest way to describe a reader is

by the method of its interface to a PC. Smart card readers are available that interface to

RS232 serial ports, USB ports, PCMCIA slots, floppy disk slots, parallel ports, infrared

IRDA ports and keyboards and keyboard wedge readers. Card readers are used to read data

from - and write data to - the smart card.

42

Another difference in reader types is on-board intelligence and capabilities. An

extensive price and performance difference exists between an industrial strength reader that

supports a wide variety of card protocols and the less expensive win-card reader that only

works with microprocessor cards and performs all processing of the data in the PC.

To process a smart card, the computer has to be equipped with a smart card reader

possessing the following mandatory features:

1. Smart Card Interface Standard - ISO 7816 is an international standard that describes

the interface requirements for contact-type smart cards. These standards have multiple

parts. For instance, part 1, 2 and 3 are applicable to card readers. Part 1 defines the

physical characteristics of the card. Part 2 defines dimension and location of smart

card chip contacts. Part 3 defines the electronic signals and transmission protocols of

the card. Card readers may be referred to as conforming to ISO 7816 1/2/3, or in its

simplified term, ISO 7816.

2. Driver - This refers to the software used by the operating system (OS) of a PC for

managing a smart card and applicable card reader. To read a smart ID card, the driver

of the card reader must be PC/SC compliant which is supported by most card reader

products currently available. It should be noted that different OS would require

different drivers. In acquiring card readers, the compatibility between the driver and

the OS has to be determined and ensured.

Desirable Features in a Smart Card Reader

Card Contact Types refers to how the contact between a card reader and a smart card is

physically made. There are two primary types of contact: landing contact and friction contact

(also known as sliding or wiping).

1. For card readers featuring friction contact, the contact part is fixed. The contact wipes

on the card surface and the chip when a card is inserted.

2. For card readers featuring the landing type, the contact part is movable. The contact

"lands" on the chip after a card is wholly inserted. In general, card readers of the

landing type provide better protection to the card than that of the friction type.

Smart card readers are also used as smart card programmers to configure and

personalize integrated circuit cards. These programmers not only read data, but also put data

into the card memory. This means that not only CPU based smart cards, but also simple

43

memory cards can be programmed using a smart card reader. Of course the card reader must

support the appropriate protocol such as the asynchronous T=0, T=1 or synchronous I2C

protocols.

Types of Chip Cards

Smart cards are defined according to

1) How the card data is read and written

2) The type of chip implanted within the card and its capabilities.

There is a wide range of options to choose from when designing your system.

Fig 3.3.4 Types Of Chip Cards

Contact Cards

This is the most common type of smart card. The electrical contacts, located on the

outside of the card, connect to a card reader when the card is inserted. In this project, we are

using a contact smart card where the information inside the card is communicated with the

card reader by inserting the card into the reader.

44

The below figure defines the pinout of the smart card. This comprises of gold plated contact

pads which makes contact with the reader.

Fig 3.3.5 8 Pin Smart Card Bus Point

Electrical characteristics of smart card pinout:

C1-VCC: Power supply input.

C2-RST: Either used itself (reset signal supplied from the interface device) or in combination

with an internal reset control circuit. If internal reset is implemented, the voltage supply on

Vcc is mandatory.

C3-CLK: Clocking or timing signal.

C4-GND: Ground (reference voltage).

C6-VPP: Programming voltage input.

C7-I/O: Input or Output for serial data to the integrated circuit inside the card.

Memory Cards

Memory cards have no sophisticated processing power and cannot manage files

dynamically. All memory cards communicate to readers through synchronous protocols. In

all memory cards, the reading and writing is done to a fixed address on the card. There are

three primary types of memory cards: 1) Straight, 2) Protected and 3) Stored Value.

1. Straight Memory Cards

These cards just store data and have no data processing capabilities. These cards are the

lowest cost per bit for user memory. They should be regarded as floppy disks of varying sizes

without the lock mechanism. These cards cannot identify themselves to the reader, so the host

system has to know what type of card is being inserted into a reader. These cards are easily

duplicated and cannot be tracked by on-card identifiers.

45

2. Protected / Segmented Memory Cards

These cards have built-in logic to control the access to the memory of the card. These

devices can be set to write protect some or the entire memory array and thus sometimes

referred to as Intelligent Memory cards. Some of these cards can be configured to restrict

access to both reading and writing. This is usually done through a password or system key.

Segmented memory cards can be divided into logical sections for planned multi-functionality.

These cards are not easily duplicated but can possibly be impersonated by hackers. They

typically can be tracked by an on-card identifier.

3. Stored Value Memory Cards

These cards are designed for the specific purpose of storing value or tokens. The cards

are either disposable or rechargeable. Most cards of this type incorporate permanent security

measures at the point of manufacture. These measures can include password keys and logic

that are hard-coded into the chip by the manufacturer. The memory arrays on these devices

are set up as decrements or counters. There is little or no memory left for any other function.

For simple applications such as a telephone card, the chip has 60 or 12 memory cells, one for

each telephone unit. A memory cell is cleared each time a telephone unit is used. Once all the

memory units are used, the card becomes useless and is thrown away. This process can be

reversed in the case of rechargeable cards.

CPU/MPU Microprocessor Multifunction Cards

These cards have on-card dynamic data processing capabilities. Multifunction smart

cards allocate card memory into independent sections or files assigned to a specific function

or application. Within the card, a microprocessor or microcontroller chip is present that

manages this memory allocation and file access. This type of chip is similar to those found

inside all personal computers and when implanted in a smart card, manages data in organized

file structures, via a card operating system (COS). Unlike other operating systems, this

software controls access to the on-card user memory.

This capability permits different and multiple functions and/or different applications to

reside on the card, allowing businesses to issue and maintain a diversity of products through

the card. One example of this is a debit card that also enables building access on a college

campus.

46

Multifunction cards benefit issuers by enabling them to market their products and

services via state-of-the-art transaction and encryption technology. Specifically, the

technology enables secure identification of users and permits information updates without

replacement of the installed base of cards, simplifying program changes and reducing costs.

For the card user, multifunction means greater convenience and security, and ultimately,

consolidation of multiple cards down to a select few that serve many purposes.

There are many configurations of chips in this category including chips that support

cryptographic PKI functions with on board math co-processors or Java virtual machine

hardware blocks. As a rule of thumb, the more functions the higher the cost.

Contactless Cards

These are smart cards that employ a radio frequency (RFID) between card and reader

without physical insertion of the card. Instead the card is passed along the exterior of the

reader and read. Types include proximity cards which are implemented as a read-only

technology for building access. These cards function with a limited memory and

communicate at 125 MHz. True read & write contactless cards were first used in

transportation for quick decrementing and re-loading of fare values where their lower security

was not an issue. They communicate at 13.56 MHz, and conform to the ISO14443 standard.

These cards are often straight memory types. They are also gaining popularity in retail stored

value, since they can speed-up transactions and not lower transaction processing revenues

(i.e. VISA and MasterCard), like traditional smart cards.

Contactless card drawbacks include the limits of cryptographic functions and user

memory versus microprocessor cards and the limited distance between card and reader

required for operation.

Combination Cards

These are hybrids that employ both contact and contactless technology in one card.

Combination cards can also contain two different types of chips in contrast to a Dual

Interface card where a single chip manages both the functions.

Common smart cards include:

47

Table 3.3.1 Smart Card Types

Applications

First introduced in Europe over a decade ago, smart cards debuted as a stored value

tool for pay phones to reduce theft. As smart cards and other chip-based cards advanced,

people found new ways to use those including charge cards for credit purchases and for

record keeping in place of paper.

In U.S, consumers have been using chip cards for everything from visiting libraries to

buying groceries to attending movies, firmly integrating them into our everyday lives. Several

states have chip card programs in progress for government applications ranging from the

Department of Motor Vehicles to Electronic Benefit Transfer (EBT). Many industries have

implemented the power of smart cards into their products such as the new GSM digital

cellular phones to TV satellite decoders.

The most common smart card applications are:

Credit cards

Electronic cash

Computer security systems

Wireless communication

Loyalty systems (like frequent flyer points)

Banking

Satellite TV

48

Government identification

Uses of Smart Cards

Smart cards greatly improve the convenience and security of any transaction. They

provide tamper-proof storage of user and account identity. Smart cards also provide vital

components of system security for the exchange of data throughout virtually any type of

network. They protect against a full range of security threats, from careless storage of user

passwords to sophisticated system hacks. Multifunction cards can also serve as network

system access and store value and other data. People worldwide are now using smart cards

for a wide variety of daily tasks, these include:

Loyalty and Stored Value

A primary use of smart cards is stored value, particularly loyalty programs that track

and incentive repeat customers. Stored value is more convenient and safer than cash. For

issuers, float is realized on unspent balances and residuals on balances that are never used.

Securing Information and Physical Assets

In addition to information security, smart cards achieve greater physical security of

services and equipment, because the card restricts access to all but the authorized user(s). E-

mail and PCs are being locked-down with smart cards. Information and entertainment is

being delivered via to the home or PC. Home delivery of service is encrypted and decrypted

per subscriber access. Digital video broadcasts accept smart cards as electronic keys for

protection. Smart cards can also act as keys to machine settings for sensitive laboratory

equipment and dispensers for drugs, tools, library cards, health club equipment etc.

E-Commerce

Smart cards make it easy for consumers to securely store information and cash for

purchasing. The advantages they offer consumers are:

The card can carry personal account, credit and buying preference information that

can be accessed with a mouse click instead of filling out forms.

Cards can manage and control expenditures with automatic limits and reporting.

Internet loyalty programs can be deployed across multiple vendors with disparate

POS systems and the card acts as a secure central depository for points or rewards.

49

Micro Payments - paying nominal costs without transaction fees associated with

credit cards or for amounts too small for cash, like reprint charges.

Personal Finance

As banks enter competition in newly opened markets such as investment brokerages,

they are securing transactions via smart cards at an increased rate. This means:

Smart cards increase trust through improved security. Two-Factor Authentication

insures protection of data and value across the internet. Threats such as the "Man in

the middle" and "Trojan Horses" that replay a user name and password are eliminated

This will improve customer service. Customers can use secure smart cards for fast,

24-hour electronic funds transfers over the internet

Costs are reduced: transactions that normally would require a bank employee's time

and paperwork can be managed electronically by the customer with a smart card

Health Care

The explosion of health care data brings up new challenges to the efficiency of patient

care and privacy safeguards. Smart cards solve both challenges with secure storage and

distribution of everything from emergency data to benefits status.

Rapid identification of patients; improved treatment

A convenient way to carry data between systems or to sites without systems

Reduction of records maintenance costs

Network Security

Business to business Intranets and Virtual Private Networks VPNs are enhanced by

the use of smart cards. Users can be authenticated and authorized to have access to specific

information based on preset privileges. Additional applications range from secure email to

electronic commerce.

MOTOR DRIVER:

Digital systems and microcontroller pins lack sufficient current to drive the circuits like

relays, buzzer circuits, motors etc. While these circuits require around 10milli amps to be

operated, the microcontrollers pin can provide a maximum of 1-2milli amps current. For this

reason, a driver such as a power transistor is placed in between the microcontroller and the

motor.

50

Fig 3.3.6 Circuit for Motor Driver

OPERATION:

The input to the base of the transistor is applied from the microcontroller port pin

P1.0. The transistor will be switched on when the base to emitter voltage is greater than 0.7V

(cut-in voltage). Thus when the voltage applied to the pin P1.0 is high i.e., P1.0=1 (>0.7V),

the transistor will be switched on and thus the motor will be switched ON.

When the voltage at the pin P1.0 is low i.e., P1.0=0 (<0.7V) the transistor will be in

off state and the motor will be switched OFF. Thus the transistor acts like a current driver to

operate the motor accordingly.

Motor Interfacing with the Microcontroller:

Fig 3.3.7 Interfacing Motor with 8051

51

Buzzer:

Audio Indication:

Digital systems and microcontroller pins lack sufficient current to drive the circuits

like relays, buzzer circuits etc. While these circuits require around 10milliamps to be

operated, the microcontrollers pin can provide a maximum of 1-2milli amps current. For this

reason, a driver such as a power transistor is placed in between the microcontroller and the

buzzer circuit.

Fig 3.3.8 Buzzer circuit

Operation:

The input to the base of the transistor is applied from the microcontroller port pin P1.0.

The transistor will be switched on when the base to emitter voltage is greater than 0.7V (cut-

in voltage). Thus when the voltage applied to the pin P1.0 is high i.e., P1.0=1 (>0.7V), the

transistor will be switched on and thus the buzzer will be ON.

52

When the voltage at the pin P1.0 is low i.e., P1.0=0 (<0.7V) the transistor will be in

off state and the buzzer will be OFF. Thus the transistor acts like a current driver to operate

the buzzer accordingly.

Buzzerinterfacing with the Microcontroller:

Fig 3.3.9 Interfacing Buzzer with 8051

KEYPAD:

Keypads and LCDs are the most widely used input/output devices of the 8051 and a

basic understanding of them is essential. The keypads are mainly three types:

1. 4*3 keypad

2. 4*4 keypad

3. 4*8 keypad.

53