Beruflich Dokumente

Kultur Dokumente

Blasting Coating Procedure For Fabricated Steel Structure

Hochgeladen von

Salman AlfarisiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Blasting Coating Procedure For Fabricated Steel Structure

Hochgeladen von

Salman AlfarisiCopyright:

Verfügbare Formate

Page

1 of

8

PROJECT / CONTRACT REF.: 2546 / GC07100300

ENGINEERING,PROCUREMENT,INSTALLATION AND

COMMISSIONING(EPIC) FOR BERTHS AND PORT

INFRASTRUCTURE FOR RAS LAFFAN PORT EXPANSION PROJECT

DOCUMENT TITLE :

BLASTING & COATING PROCEDURE FOR

FABRICATED STEEL STRUCTURE

CONSOLIDATED CONTRACTORS

GROUP

TEYSEER CONTRACTING

COMPANY

Reference NO. : RLP/965/2009/F-1308

Originators Doc. Ref. : RSC/F0658/QC-009 Rev.-01

29-APR-2009 0 ISSUED FOR REVIEW & APPROVAL

SUJITH Sunith Sunith

DATE

REV.

NO.

REASON FOR REVISION

Prepared Checked Approved Checked Approved

AL REYAMI CCC

DOC. NO:

BLASTING & COATING PROCEDURE

FOR FABRICAT STEEL STRUCTURE

Doc No.: RSC/F0658/QC-0009 Rev.01

RPGE-S0036-1-05-0009 REV. 1 Page # 2 of 8

TABLE OF CONTENTS

1. SCOPE.03

2. PURPOSE...03

3. REFERENCES...03

4. RESPONSIBILTY..03

5. SAFETY AND ENVIRONMENTAL

RISKS.03

6. INSPECTION & TEST EQUIPMENT..04

7. MATERIAL CONTROL.....04

8. PAINT SYSTEM QUALIFICATIONS......05

9. SURFACE PREPARATION..05

10. WEATHER CONDITIONS.05

11. COATING........06

12. REPAIR...07

13. IDENTIFICATION AND MARKING.07

14. HANDLING..07

15. DESPATCH.08

ATTACHMENT

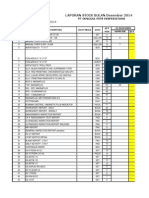

1.FORM NO C7 F4 REV.01 SHEET

BLASTING & COATING PROCEDURE

FOR FABRICAT STEEL STRUCTURE

Doc No.: RSC/F0658/QC-0009 Rev.01

RPGE-S0036-1-05-0009 REV. 1 Page # 3 of 8

1. SCOPE

This procedure is applicable for the manual / semi automatic blasting and coating of the

structural steel manufactured by Al Reyami for Berths and Port Infrastructure for Ras Laffan

Port Expansion Porject

2. PURPOSE

Purpose of this procedure is to identify the sequence to be followed during the manual /

semi automatic blasting and coating work. Inspection and testing requirements shall be as

per Project specific Inspection and Test Plan (ITP)

3. REFERENCES

RPGE-1-14-0004 Rev. A - Specification for structural steel works

QP-SPC-L002 - Specification for painting & wrapping of metal surfaces

SSPC-SP-5

8501 Sa 3

Inspection & Test Plan for the Fabrication of Structural Steel.

4. RESPONSIBILITIES

QA/QC Department is responsible for the review, control and implementation of this

procedure. Production Department is responsible for the implementation of this procedure

during the blasting and coating activities.

5. SAFETY AND ENVIRONMENTAL RISKS

All personnel involved in fabrication/erection works shall be informed of hazards and

will adopt preventive measures.

All electrical equipment shall be properly grounded.

All regular PPE shall be used i.e. hard hat, safety glasses, safety footwear & gloves. A

full body safety harness shall be worn by all workers working at high elevations and

properly clipped to anchor point at all times.

Painters should wear Mask while working.

BLASTING & COATING PROCEDURE

FOR FABRICAT STEEL STRUCTURE

Doc No.: RSC/F0658/QC-0009 Rev.01

RPGE-S0036-1-05-0009 REV. 1 Page # 4 of 8

The area should be isolated so as to avoid any overspray.

Avoid contact with skin and inhalation of vapor.

Do not eat, drink or smoke in the workplace.

Wash Hands properly prior to eating or drinking.

Ensure experienced and trained personnel are engaged for Blasting and Painting jobs.

6. INSPECTION AND TEST EQUIPMENT

The following inspection /testing equipments shall be available at site to ensure that the

correct inspection and testing are carried out:-

Anchor pattern and measuring device.

Wet film thickness (WFT) gauge.

Dry film thickness (DFT) gauge.

Contact thermometer (for steel surfaced temperature).

Thermometer for air temperature.

Humidity gauge (or sling hygrometer).

Dew point calculator.

7. MATERIAL CONTROL

Pipe supports to be coated shall be fully identified and to be released for coating with

approval.

Coating shall be done as per the QP specification QP-SPC-L-002 coating schedule 1 un.

All painting material shall confirm to the approved MAR (Material Approval

Request).

Primer coat : Hempel , Hempadur Zinc-15350.

Mid coat 1 & 2 : Hempel , Hempadur MIO 47950

Final coat : Hempel , Hempathane Top coat 55210(RAL-10A03).

BLASTING & COATING PROCEDURE

FOR FABRICAT STEEL STRUCTURE

Doc No.: RSC/F0658/QC-0009 Rev.01

RPGE-S0036-1-05-0009 REV. 1 Page # 5 of 8

Paint material shall be verified against the batch certificates & stored in controlled

environment .The shelf life shall be monitored while receipt and issue.

The abrasive medium shall be used which is able to achieve the anchor profile, either

metallic or non metallic abrasive, specified on the coating manufacturers data sheet.

All materials received to complete the work shall be inspected to ensure that they

conform to the project specifications, purchase, order, codes and standards. These

inspection findings shall be recorded.

The coating materials that are to be used for this project shall be submitted to the

contractor / client for approval prior to commencement of the coating activities.

8. PAINT SYSTEM QUALIFICATIONS

Paint system qualifications shall be conducted under paint manufacturer supervision,

duly witnessed by Client/TPI.

9. SURFACE PREPARATION

Pipe supports shall be visually inspected to check whether the surface requires

additional cleaning, either solvent or detergent, prior to the start of the abrasive

blasting activities. All blast cleaning activities shall be done in accordance with the

requirement of QP-SPC-L-002.QP Technical specification for painting and wrapping

of metal surface or the coating manufacturers recommendations.

Compressed air supply shall be checked at specified intervals to ensure that air is

moisture and oil free.

Manual / semi automatic blast technique shall be used to gain the correct surface

preparation and anchor profile for the application of coating.

Used abrasive shall be removed from metal surfaces using a dry brush and blowing

down with clean dry compressed air.

When blasting is completed , the surface of the support shall be inspected to check

whether it meets the requirement of SA3, ISO 8501-1 or SSPC-SP-5 as per QP-

SPC-L-002 REV1. Profile range 50 to 70 microns.

BLASTING & COATING PROCEDURE

FOR FABRICAT STEEL STRUCTURE

Doc No.: RSC/F0658/QC-0009 Rev.01

RPGE-S0036-1-05-0009 REV. 1 Page # 6 of 8

After cleaning, the surface shall be kept away from oil, dirt etc. till the coating is

completed. Surface shall be coated within 4hours, depending upon the whether

conditions; surface not meeting the blasting profile shall be re-blasted prior to coating.

10. WEATHER CONDITIONS

Blasting operation should not be started if related humidity of the air exceeds 85% or the

Metal Surface temperature is not least 3 degree centigrade above the dew point temperature.

Priming and painting can be done when the weather condition are within the requirement of

project specification or paint manufacturers recommendations

11. COATING

Stripe coat shall be applied at weld & corners.

Spraying shall not be started until all the specified environment reading are taken and

are within specified limits.

Selection of materials, mixing, induction time, and pot life requirement, adequate

application and achieved WFT shall be to the relevant specification/manufacturers

recommendation and shall be overseen and monitored by the supervisor.

The spray operator shall monitor the WFT reading during the spraying to control and

achieve the specified DFT.

After the paint manufacturers recommended drying time, each coat shall be inspected

by Al Reyami Inspector to confirm the DFT and integrity by adhesion on testing of

the coating system.

Primer, intermediate coat and top coat shall be as per project specification QP-SPC-L-

002 coating schedule 1un.

Prior to application of primer all difficulties to coat areas such as corners, edges and

welds shall be brush coated with the specified primer.

The first coat ,one coat primer ,Hempel-Hempadur Zinc 15350 grey color shall be

applied manually by airless spray techniques with a minimum WFT of 100 to 125

microns to achieve the specified minimum DFT of 50 microns.

BLASTING & COATING PROCEDURE

FOR FABRICAT STEEL STRUCTURE

Doc No.: RSC/F0658/QC-0009 Rev.01

RPGE-S0036-1-05-0009 REV. 1 Page # 7 of 8

Primer application, pot life and recoat intervals shall be as per the paint

manufacturers data sheet or recommendations.

The intermediate coats shall be applied as specified by project specification.

Two intermediate coats shall be applied as per the project specifications the DFT of

100 microns on each coat.

The first intermediate coat Hempel-Hempadur Mastic MIO 47950 light grey shall be

applied manually by airless spray techniques with a minimum WFT of 125 to 150

microns to achieve minimum DFT of 100 microns after the recoat interval of the

previous coat.

The second intermediate coat, Hempel-Hempadur mastic MIO 47950 dark grey color

shall be applied manually by airless spray technique with a minimum WFT of 125 to

150 microns to achieve minimum DFT of 100 microns after the recoat interval of the

previous coat .

The final coat , Hempel Hempathane topcoat 55210 grey shall be applied manually

by airless spray technique with a minimum WFT of 100 microns to achieve a

minimum DFT of 50 microns after the recoat interval of previous coat.

12. REPAIR

When the coating is damaged back to the base metal that is areas of the metal

substrate are exposed, the exposed metal shall be blast cleaned to the original

specified standard prior to Re-painting it.

For small and isolated area or where the use of blast cleaning is not practical, hand

tool / power tools can be used to obtain the required and or profile. As with partially

damaged coating, the periphery of the repair areas shall be feathered back for at least

25mm from the edge of coating to the adjacent undamaged coating to produce a

smooth chamfered surface profile for the repair coating .This can be done by either

power tool or hand tool or both.

The prepared partially or completely damaged areas of the coating shall be repaired

by the local application of the repair number of coats of paint to obtain the original

coating system and thickness.

BLASTING & COATING PROCEDURE

FOR FABRICAT STEEL STRUCTURE

Doc No.: RSC/F0658/QC-0009 Rev.01

RPGE-S0036-1-05-0009 REV. 1 Page # 8 of 8

13. IDENTIFICATION & MARKING

All structural components shall be identified as per the project spec. RPGE- 1-14-0004 REV-

A. & AFC shop drawing requirements. Identification shall be done by proper metal

stamping before blasting and painting application. A job stencil or metal tag shall be

applied in accordance with project specification and after paint curing.

14. HANDLING

During and after coating the structural steel is moved by crane or forklift with contact

surfaces of a soft material.

The coated structural steel shall be stored on a suitable soft surface and allowed to full cure

as per the paint manufacturers requirements.

15. DESPATCH

Structural steel shall be dispatched from Al Reyami if all documents are in order, signed as

accepted .Shipping shall be carried out in accordance with client /contractors requirements.

16. ATTACHMENT.

PAINTING REPORT C7F4 REV.-0

Das könnte Ihnen auch gefallen

- QC - 06 Surface Preparation & Painting 2Dokument6 SeitenQC - 06 Surface Preparation & Painting 2mahendraNoch keine Bewertungen

- Blasting and Painting ProcedureDokument9 SeitenBlasting and Painting Procedureisukuru67% (12)

- Method Statement For APCS-113A (1) 22-6-2011Dokument7 SeitenMethod Statement For APCS-113A (1) 22-6-2011sharif339Noch keine Bewertungen

- Blasting and Coating ProcedureDokument8 SeitenBlasting and Coating Procedureaamirsaddiq100% (1)

- Blasting & Painting Procedure For Structural Steel Rev.00Dokument16 SeitenBlasting & Painting Procedure For Structural Steel Rev.00Hansel Francis64% (11)

- Blasting & Coating Procedure For Fabricated Steel StructureDokument8 SeitenBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- P143 PaintingDokument7 SeitenP143 PaintingkbldamNoch keine Bewertungen

- Method Statement For APCS-113A - MS-FBE-002 - 9 JULY 2011Dokument9 SeitenMethod Statement For APCS-113A - MS-FBE-002 - 9 JULY 2011sharif339Noch keine Bewertungen

- Coating SpecificationDokument17 SeitenCoating Specificationrahman196011Noch keine Bewertungen

- Fiberglass Coating SpecDokument3 SeitenFiberglass Coating Specponnivalavans_994423100% (1)

- Blasting Coating ProcedureDokument61 SeitenBlasting Coating ProcedureZohair Aftab100% (1)

- Painting ProcedureDokument10 SeitenPainting ProcedureLiyakathalikhan Shahjahan50% (2)

- Method Statement Installation Os Static Equipment and InternalsDokument24 SeitenMethod Statement Installation Os Static Equipment and InternalsAjin SNoch keine Bewertungen

- Joint Coating Application & Pipe Coating ProcedureDokument7 SeitenJoint Coating Application & Pipe Coating Proceduregst ajahNoch keine Bewertungen

- Blasting Painting ProcedureDokument4 SeitenBlasting Painting ProcedureRyanNoch keine Bewertungen

- Painting Specification For Storage TanksDokument27 SeitenPainting Specification For Storage TanksRohmat Benny IsmantoNoch keine Bewertungen

- Field Joint CoatingDokument7 SeitenField Joint CoatingTeodor EzaruNoch keine Bewertungen

- Painting Procedure GlobalDokument15 SeitenPainting Procedure GlobalUbed KudachiNoch keine Bewertungen

- Method Statement For Blasting and Painting of Process EquipmentDokument11 SeitenMethod Statement For Blasting and Painting of Process EquipmentNnamdi Amadi100% (3)

- Method Statement For Field Joint CoatingDokument8 SeitenMethod Statement For Field Joint CoatingAllouh Mohammed75% (4)

- Oil Pantriting ProcedureDokument5 SeitenOil Pantriting ProcedureSERT-QA/QC- BUZNoch keine Bewertungen

- Coating Procedure - General Rev.03Dokument35 SeitenCoating Procedure - General Rev.03moytabura96100% (2)

- Procedure For Fab, Erec & Testing of Undergroud PipingDokument12 SeitenProcedure For Fab, Erec & Testing of Undergroud Pipingvpsimbu86Noch keine Bewertungen

- Painting Procedures ADokument7 SeitenPainting Procedures AMaged Lotfy Abdel-aal100% (1)

- Procedure For Tin - inDokument13 SeitenProcedure For Tin - inAdil IjazNoch keine Bewertungen

- Joint Coating Application & Pipe Coating Procedure-009-RappDokument8 SeitenJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahNoch keine Bewertungen

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Dokument22 SeitenTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117Noch keine Bewertungen

- ID-PRC 21 - Anti-Corrosion Wrapping UG Steel PipingDokument10 SeitenID-PRC 21 - Anti-Corrosion Wrapping UG Steel Pipingcloud23Noch keine Bewertungen

- 19-Pipe Line Welding PDFDokument15 Seiten19-Pipe Line Welding PDFMustafa MubderNoch keine Bewertungen

- Procedure For Holiday Testing PDFDokument2 SeitenProcedure For Holiday Testing PDFSaptarshi MandalNoch keine Bewertungen

- Ms Painting Shaybah Rev 00Dokument14 SeitenMs Painting Shaybah Rev 00Haroonamjan MohammedNoch keine Bewertungen

- Surface Preparation and Painting Procedure Rev 01 PDFDokument23 SeitenSurface Preparation and Painting Procedure Rev 01 PDFNaceur Turki100% (3)

- WMS JOB Procedure FOR PIPING WORKDokument9 SeitenWMS JOB Procedure FOR PIPING WORKsatyamech1_395565923Noch keine Bewertungen

- Method Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiDokument198 SeitenMethod Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiJohnNoch keine Bewertungen

- Paint Coating Stainless SteelsDokument2 SeitenPaint Coating Stainless SteelsSilva NumaNoch keine Bewertungen

- MOS-RO Pressure Vessel InstallationDokument16 SeitenMOS-RO Pressure Vessel InstallationShams TabrezNoch keine Bewertungen

- 250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchDokument22 Seiten250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchAbdullah AbdullahNoch keine Bewertungen

- Application Guide Penguard MidcoatDokument6 SeitenApplication Guide Penguard Midcoatadeoye_okunoyeNoch keine Bewertungen

- Chain Link FenceDokument3 SeitenChain Link Fencekarimakki100% (1)

- Method Statement For Surface Preparation PaintingDokument9 SeitenMethod Statement For Surface Preparation Paintingjamil100% (3)

- TPL-US-QMD-002 - Surface Preparation and Painting ProcedureDokument4 SeitenTPL-US-QMD-002 - Surface Preparation and Painting ProcedureSimbu ArasanNoch keine Bewertungen

- Painting Procedure Template PDFDokument14 SeitenPainting Procedure Template PDFjohn100% (1)

- METHOD STATEMENT FOR Pneumatic TestDokument11 SeitenMETHOD STATEMENT FOR Pneumatic TestzahidNoch keine Bewertungen

- Method Statement For Painting of ValvesDokument4 SeitenMethod Statement For Painting of ValvesRashid Kayum100% (1)

- PP WP28Dokument15 SeitenPP WP28mohd as shahiddin jafriNoch keine Bewertungen

- Internal Blasting and Painting Procedure For Storage TankDokument31 SeitenInternal Blasting and Painting Procedure For Storage TankMathias Onosemuode100% (3)

- Painting SpecificationDokument19 SeitenPainting SpecificationArunkumar Rackan0% (1)

- Hot Tap ProcedureDokument6 SeitenHot Tap ProcedureNatarajan MurugesanNoch keine Bewertungen

- Vessel Cleaning ProcedureDokument6 SeitenVessel Cleaning ProcedureZool HilmiNoch keine Bewertungen

- METHOD STATEMENT - PipingDokument12 SeitenMETHOD STATEMENT - PipingAnonymous M5rHHKNoch keine Bewertungen

- Ms-Mech-10, Ms Fabrication of PipingDokument13 SeitenMs-Mech-10, Ms Fabrication of PipingBabar Manzoor GhauriNoch keine Bewertungen

- Standard Specification FOR Pipeline Internal CoatingDokument2 SeitenStandard Specification FOR Pipeline Internal CoatingRanjan KumarNoch keine Bewertungen

- PFP ProcedureDokument6 SeitenPFP ProcedureRamesh100% (1)

- Hot Insulation Method Statement Rev.Dokument25 SeitenHot Insulation Method Statement Rev.Hassan Helmy100% (1)

- 12 Procedure For Coating Wrapping Rev 01Dokument6 Seiten12 Procedure For Coating Wrapping Rev 01dnbinh100% (2)

- 36 - Painting Procedure - Rev0Dokument21 Seiten36 - Painting Procedure - Rev0Duc ThinNoch keine Bewertungen

- Insulation ProceduresDokument8 SeitenInsulation ProceduresMark Darrel AranasNoch keine Bewertungen

- Working Procedure Ls1-Ls4Dokument9 SeitenWorking Procedure Ls1-Ls4Tuğrulhan ÖzdemirNoch keine Bewertungen

- Procedure Painting Mps Epoxcy - Final - PT KhiDokument12 SeitenProcedure Painting Mps Epoxcy - Final - PT KhisinambeladavidNoch keine Bewertungen

- Method Statement For APCS-113A For Alloy Steel - Otc - Fbe-002Dokument7 SeitenMethod Statement For APCS-113A For Alloy Steel - Otc - Fbe-002sharif339100% (2)

- Iso 30414 2018 FR en PDFDokument11 SeitenIso 30414 2018 FR en PDFSalman AlfarisiNoch keine Bewertungen

- 3 - ISO22316 - 2017 - Kan Brukes Kostnadsfritt I Forbindelse Med Korona-KrisenDokument18 Seiten3 - ISO22316 - 2017 - Kan Brukes Kostnadsfritt I Forbindelse Med Korona-KrisenSalman AlfarisiNoch keine Bewertungen

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDokument6 SeitenSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartSalman Alfarisi100% (1)

- SCAT OriginalDokument2 SeitenSCAT OriginalFuadNoch keine Bewertungen

- Sample Inventory List GudangDokument10 SeitenSample Inventory List GudangSalman AlfarisiNoch keine Bewertungen

- SACPCMP Annexure Report Guidelines (VNP SHEQ) PDFDokument2 SeitenSACPCMP Annexure Report Guidelines (VNP SHEQ) PDFSalman AlfarisiNoch keine Bewertungen

- Annex SL PresentationDokument22 SeitenAnnex SL PresentationsonicefuNoch keine Bewertungen

- Job Desk Service AdvisorDokument11 SeitenJob Desk Service AdvisorSalman AlfarisiNoch keine Bewertungen

- SACPCMP Annexure Report Guidelines (VNP SHEQ)Dokument2 SeitenSACPCMP Annexure Report Guidelines (VNP SHEQ)Salman AlfarisiNoch keine Bewertungen

- Selection of Incident Investigation MethodsDokument12 SeitenSelection of Incident Investigation Methodsdarya2669Noch keine Bewertungen

- Lifework Portfolio Teaching ResourceDokument78 SeitenLifework Portfolio Teaching ResourceSalman AlfarisiNoch keine Bewertungen

- Complaints Management ProcedureDokument17 SeitenComplaints Management ProcedureSalman Alfarisi0% (1)

- 2006 PPAP Manual 4th Edition ManualDokument51 Seiten2006 PPAP Manual 4th Edition ManualK FinkNoch keine Bewertungen

- IFSQN ISO 22000 Food Safety Management System Product InformationDokument23 SeitenIFSQN ISO 22000 Food Safety Management System Product Informationgareth1190% (1)

- Corporate Social ResponsibilityDokument4 SeitenCorporate Social ResponsibilityHendri MickyNoch keine Bewertungen

- Lean Six SigmaDokument31 SeitenLean Six SigmaSalman AlfarisiNoch keine Bewertungen

- Six Sigma in Measurement Systems Evaluating The Hidden FactoryDokument30 SeitenSix Sigma in Measurement Systems Evaluating The Hidden FactorymaniiscribdNoch keine Bewertungen

- Hazard Identification and Risk Assessment Form: AreaDokument12 SeitenHazard Identification and Risk Assessment Form: AreaSalman Alfarisi100% (3)

- Hazard Identification and Risk Assessment Form: AreaDokument12 SeitenHazard Identification and Risk Assessment Form: AreaSalman Alfarisi100% (3)

- Road Map QHSSE IndonesiaDokument9 SeitenRoad Map QHSSE IndonesiaSalman AlfarisiNoch keine Bewertungen

- Basic of Performance Evaluation Developmentprocess-130411232621-Phpapp02Dokument12 SeitenBasic of Performance Evaluation Developmentprocess-130411232621-Phpapp02Salman AlfarisiNoch keine Bewertungen

- Logistic Report 014Dokument13 SeitenLogistic Report 014Salman AlfarisiNoch keine Bewertungen

- Checklist Audit OHSAS 18001Dokument15 SeitenChecklist Audit OHSAS 18001Marcelo Marmello Pinheiro50% (2)

- Corporate Social ResponsibilityDokument4 SeitenCorporate Social ResponsibilityHendri MickyNoch keine Bewertungen

- Complaints Management ProcedureDokument17 SeitenComplaints Management ProcedureSalman Alfarisi0% (1)

- NDT Method and Acceptance CriteriaDokument1 SeiteNDT Method and Acceptance CriteriaSalman Alfarisi100% (2)

- Nptel ManuDokument516 SeitenNptel ManuMohammad ArshadNoch keine Bewertungen

- Methods of Concrete Column Repair For Cracks and DamagesDokument3 SeitenMethods of Concrete Column Repair For Cracks and DamagesOladunni AfolabiNoch keine Bewertungen

- Forging and Heat TreatmentDokument2 SeitenForging and Heat TreatmentAlexNoch keine Bewertungen

- Kaizen Lean Management Service Sector2Dokument22 SeitenKaizen Lean Management Service Sector2Mahathir FansuriNoch keine Bewertungen

- Ferrous MetalDokument39 SeitenFerrous MetalAshwani DograNoch keine Bewertungen

- CV Tauarai CVDokument5 SeitenCV Tauarai CVgeorgiaNoch keine Bewertungen

- Air Products Hydrogen Plant CapacitiesDokument16 SeitenAir Products Hydrogen Plant CapacitiesAlexReitu100% (1)

- Jewellery Manufacturing ProcesDokument29 SeitenJewellery Manufacturing ProcesDr. Neeru jain83% (6)

- Is 5484 1997Dokument9 SeitenIs 5484 1997Cristian Walker100% (2)

- Bronze Castings For Bridges and TurntablesDokument5 SeitenBronze Castings For Bridges and Turntablesnicu1212Noch keine Bewertungen

- A 227Dokument1 SeiteA 227AnuranjanNoch keine Bewertungen

- Galeb Packaging SerbiaDokument20 SeitenGaleb Packaging SerbiaYogesh GuptaNoch keine Bewertungen

- ICO Brochure 2.0 - BCGDokument20 SeitenICO Brochure 2.0 - BCGСергей СтепынинNoch keine Bewertungen

- Jigs and Fixtures: Presented By:-Abhilekh AgrawalDokument30 SeitenJigs and Fixtures: Presented By:-Abhilekh AgrawalIoan PascaNoch keine Bewertungen

- JUNGHEINRICH ERC 216 Ersatzteilkatalog Seri 90265863Dokument123 SeitenJUNGHEINRICH ERC 216 Ersatzteilkatalog Seri 90265863Fatich Pradana Putra Phobia100% (2)

- A Review of FSW Research On Dissimilar MetalDokument19 SeitenA Review of FSW Research On Dissimilar MetalTayyab HussainNoch keine Bewertungen

- (BS en 124) - Gully Tops and Manhole Tops For Vehicular and Pedestrian AreasDokument78 Seiten(BS en 124) - Gully Tops and Manhole Tops For Vehicular and Pedestrian Areasion ingenieria ion ingenieria100% (2)

- Accepted Engineering Practice StandardsDokument5 SeitenAccepted Engineering Practice StandardsMuhammad Shakil JanNoch keine Bewertungen

- ShigeoshingoDokument30 SeitenShigeoshingoezzaneeNoch keine Bewertungen

- 1 FirstFileDokument3 Seiten1 FirstFileMarysun TlengrNoch keine Bewertungen

- ENGEL Press Release Inject2blowDokument4 SeitenENGEL Press Release Inject2blowTirthankar ChandraNoch keine Bewertungen

- Installation - Instructions For Taper BushDokument2 SeitenInstallation - Instructions For Taper BushhibhavuNoch keine Bewertungen

- Master Production ScheduleDokument9 SeitenMaster Production ScheduleglamboyzNoch keine Bewertungen

- Welders Certification Designation Acc. To EN ISO 9606-1Dokument1 SeiteWelders Certification Designation Acc. To EN ISO 9606-1vonipko100% (9)

- Raymond PTQM Roll No.02Dokument13 SeitenRaymond PTQM Roll No.02Sana Moon100% (1)

- Notice Singer InitialeDokument82 SeitenNotice Singer InitialeMULLIERNoch keine Bewertungen

- Tensa Neoferma: Expansion JointsDokument4 SeitenTensa Neoferma: Expansion JointsAlexandra SanduNoch keine Bewertungen

- By: Loy Lobo Aapa Angchekar Priyanka BendaleDokument45 SeitenBy: Loy Lobo Aapa Angchekar Priyanka BendaleLoy LoboNoch keine Bewertungen

- GleniumDokument2 SeitenGleniumlebu84Noch keine Bewertungen

- Universal Slice Applicators Data SheetDokument2 SeitenUniversal Slice Applicators Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen