Beruflich Dokumente

Kultur Dokumente

Hydro PDF

Hochgeladen von

Van QuynhOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydro PDF

Hochgeladen von

Van QuynhCopyright:

Verfügbare Formate

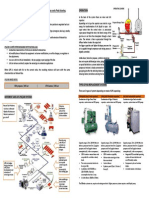

OPERATION AND MAINTENANCE MANUAL

FOR THE

TELEDYNE TITAN

TM

HM GENERATOR SERIES

HYDROGEN/OXYGEN GAS SYSTEM

HM Generator Operations and Maintenance Manual March 2007

iii

"THESE COMMODITIES, TECHNOLOGY OR SOFTWARE WERE EXPORTED

FROM THE UNITED STATES IN ACCORDANCE WITH THE EXPORT

ADMINISTRATION REGULATIONS. DIVERSION CONTRARY TO U.S. LAW IS

PROHIBITED.

UNITED STATES LAW PROHIBITS DISPOSITION OF THESE COMMODITIES,

TECHNOLOGY OR SOFTWARE TO ANY END-USER FOR ANY END-USE

RELATED TO THE DESIGN, DEVELOPMENT, PRODUCTION, STOCKPILING,

OR USE OF CHEMICAL, BIOLOGICAL OR NUCLEAR WEAPONS OR

MISSILES, WITHOUT THE PRIOR APPROVAL OF THE UNITED STATES

GOVERNMENT."

HM Generator Operations and Maintenance Manual March 2007

v

FOREWORD

Electrolysis of water is in principle a simple process. The equipment necessary

to assemble a system that supports the process effectively and efficiently results

in a configuration that is relatively complex. The technology that has evolved at

Teledyne Energy Systems represents a continuous development effort to

improve systems that support the basic alkaline water electrolysis process. The

HM incorporates the latest developments to provide an efficient, reliable and safe

system for the production of hydrogen gas.

The purpose of this manual is to provide the operator with a basic description of

the system and sufficient information to install, operate, and maintain the

equipment. This information is intended for use by qualified personnel. Use of

the information by other than qualified personnel may negate the warranty

extended by Teledyne Energy Systems to the equipment Purchaser.

.

HM Generator Operations and Maintenance Manual March 2007

vii

NOTICE

The manual contains Teledyne Energy Systems, Inc. proprietary information which

may not be used for the benefit of others except by express permission.

Distribution and availability of this manual should be restricted to activities

concerned with operation and maintenance of the equipment described herein.

LIMITED WARRANTY

This equipment is covered by a limited warranty that establishes limitation of

obligations. See form ES-588 Warranty, Gas Generator System.

ALL FOREIGN CUSTOMERS AND REPRESENTATIVES

To avoid unnecessary charges and delays in U. S. Customs, any and all returned

components of the Teledyne Energy Systems equipment should be handled as

follows:

1. Notify Teledyne Energy Systems (Attention Marketing Department) of the

need and reason for returning the part. Identify the part as to catalog

and/or part number, name, and the purchase order and equipment serial

number under which the part was originally purchased.

2. Supply Teledyne Energy Systems with Proforma Invoices and copies of

Bills of Lading indicating the part as "Returned U. S. Goods."

3. All shipments should be made to Teledyne Energy Systems, 10707 Gilroy

Road, Hunt Valley, Maryland 21031, U.S.A., by way of the Port of

Baltimore, Maryland (for ocean) and Baltimore-Washington International

Airport (by air).

4. Failure to clear these returned components through U. S. Customs as

"Returned U. S. Goods" will result in payment of duty which will be to the

customer's account.

HM Generator Operations and Maintenance Manual March 2007

ix

Table of Contents

1 System Description............................................................................. 1-1

1.1 Introduction........................................................................................ 1-1

1.2 Electrolyte.......................................................................................... 1-2

1.3 Electrolysis Module............................................................................ 1-2

1.4 Electrolyte Subsystem....................................................................... 1-3

1.4.1 KOH Pump.......................................................................... 1-3

1.4.2 KOH Reservoir.................................................................... 1-4

1.4.3 Heat Exchanger .................................................................. 1-4

1.4.4 KOH Filter ........................................................................... 1-4

1.4.5 Flow Switch......................................................................... 1-5

1.4.6 KOH Temperature Sensors ................................................ 1-5

1.4.7 KOH Level .......................................................................... 1-5

1.5 Feedwater Subsystem....................................................................... 1-5

1.5.1 Feedwater........................................................................... 1-6

1.5.2 Feedwater Quality Monitor.................................................. 1-6

1.5.3 Feedwater Pump ................................................................ 1-6

1.5.4 Feedwater Control .............................................................. 1-6

1.6 Gas Control and Conditioning Subsystem......................................... 1-7

1.6.1 Pressure Transducers ........................................................ 1-7

1.6.2 Production Rate.................................................................. 1-7

1.6.3 Prepressurization................................................................ 1-8

1.6.4 Standby............................................................................... 1-8

1.6.5 Pressure Release ............................................................... 1-9

1.6.6 Back Pressure Regulator.................................................... 1-9

1.6.7 Differential Pressure Regulators......................................... 1-9

1.6.8 Relief Valves..................................................................... 1-10

1.6.9 Vent Valve ........................................................................ 1-10

1.6.10 Condensers and Traps ..................................................... 1-10

1.6.11 Matrix Barrier .................................................................... 1-11

1.6.12 Nitrogen Purge.................................................................. 1-11

1.7 Hydrogen Drying.............................................................................. 1-11

1.7.1 Dryers............................................................................... 1-12

1.7.2 Dryer Valves ..................................................................... 1-12

1.8 Cooling and Condenser Cooling Water Subsystems....................... 1-12

1.8.1 Temperature Regulating Valve......................................... 1-13

1.8.2 Condenser Cooling and Water Control ............................. 1-13

1.9 System Safety ................................................................................. 1-13

1.9.1 Hydrogen In Oxygen Monitor............................................ 1-14

1.9.2 Hydrogen Detector............................................................ 1-14

1.9.3 Shutdown Alarms.............................................................. 1-15

1.10 Electrical Power and Process Control Subsystems......................... 1-15

1.10.1 DC Power Supply ............................................................. 1-15

1.10.2 Programmable Controller.................................................. 1-16

1.10.3 Process Control and Sequencing ..................................... 1-19

1.10.4 Dryer Sequencing............................................................. 1-21

March 2007 HM Generator Operations and Maintenance Manual

x

1.11 Data Display and Process Monitoring.............................................. 1-21

1.11.1 Touch Screen Display....................................................... 1-22

1.11.2 LED Monitoring................................................................. 1-23

2 Generator Installation.......................................................................... 2-1

2.1 System Classification ........................................................................ 2-1

2.2 Generator Mounting........................................................................... 2-2

2.3 Facility Connections .......................................................................... 2-2

2.3.1 Feedwater........................................................................... 2-3

2.3.2 Cooling Water ..................................................................... 2-4

2.3.3 Condenser Cooling Water................................................... 2-4

2.3.4 Hydrogen and Oxygen Vents.............................................. 2-4

2.3.5 Product Gas Delivery.......................................................... 2-5

2.3.6 Electrical Power .................................................................. 2-5

2.3.7 Nitrogen Purge.................................................................... 2-5

2.4 Power Supply Electrical Connections................................................ 2-6

2.5 External Alarm Connections.............................................................. 2-6

3 Generator Operation........................................................................... 3-1

3.1 General.............................................................................................. 3-1

3.2 Initial Startup ..................................................................................... 3-1

3.3 Start Mode......................................................................................... 3-2

3.4 Run Mode.......................................................................................... 3-2

3.5 Standby Mode ................................................................................... 3-3

3.6 Normal Operation.............................................................................. 3-3

3.7 Pressure Release.............................................................................. 3-4

3.8 Shutdowns......................................................................................... 3-5

3.9 Emergency Stop Switch .................................................................... 3-5

4 Maintenance and Calibration Procedures........................................... 4-1

4.1 General.............................................................................................. 4-1

4.2 Electrolyte.......................................................................................... 4-2

4.2.1 Electrolyte Mixing................................................................ 4-3

4.2.2 Electrolyte Fill ..................................................................... 4-5

4.2.3 Electrolyte Check................................................................ 4-5

4.2.4 Electrolyte Drain ................................................................. 4-8

4.3 Module Inspection ........................................................................... 4-10

4.3.1 External Inspection ........................................................... 4-10

4.3.2 Internal Inspection ............................................................ 4-11

4.3.3 Retorque Procedure ......................................................... 4-11

4.4 Matrix Barrier Replacement ............................................................. 4-12

4.5 Cross Leak Check ........................................................................... 4-14

4.6 KOH Filter Replacement.................................................................. 4-15

4.7 Feedwater Filter Replacement ........................................................ 4-18

4.8 KOH Pump Inspection..................................................................... 4-20

4.9 Valve and Regulator Maintenance And Calibration......................... 4-22

4.9.1 Solenoid Valves................................................................ 4-24

HM Generator Operations and Maintenance Manual March 2007

xi

4.9.2 Differential Pressure Regulators....................................... 4-27

4.9.3 Back Pressure Regulators................................................ 4-30

4.9.4 Check Valve and Relief Valve........................................... 4-32

4.10 Hydrogen in Oxygen Monitor Maintenance and Calibration ............ 4-33

4.10.1 Flow Controller.................................................................. 4-34

4.10.2 Filter Tank......................................................................... 4-36

4.10.3 Temperature Sensor......................................................... 4-36

4.11 System Pressure Test ..................................................................... 4-37

4.12 Pressure Transducer Calibration Check.......................................... 4-38

4.13 KOH Flow Switch Check ................................................................. 4-38

4.14 Feedwater Pump Priming and Purging............................................ 4-41

4.15 Feedwater Monitor Check ............................................................... 4-41

4.16 Dryer Maintenance.......................................................................... 4-41

4.16.1 Orifice Maintenance.......................................................... 4-43

4.16.2 Check Valve Maintenance................................................ 4-45

4.16.3 Molecular Sieve Change................................................... 4-45

4.16.4 Gas Filter Replacement .................................................... 4-46

4.17 Temperature Regulating Valve Check............................................. 4-47

4.18 Dryer Switching Valve Check .......................................................... 4-47

5 Troubleshooting Guide........................................................................ 5-1

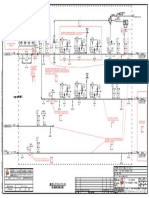

6 System Schematics ............................................................................ 6-1

7 Parts List............................................................................................. 7-1

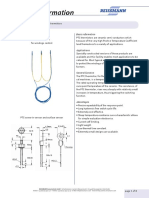

8 Optional Instrumentation..................................................................... 8-1

8.1 INSTRUMENT DESCRIPTION.......................................................... 8-1

8.1.1 INTRODUCTION................................................................ 8-1

8.1.2 COMBUSTIBLE GAS DETECTOR..................................... 8-1

8.1.3 HYGROMETER.................................................................. 8-1

8.1.4 TRACE OXYGEN ANALYZER ........................................... 8-2

8.2 INSTALLATION................................................................................. 8-2

8.2.1 COMBUSTIBLE DETECTOR ............................................. 8-2

8.2.2 HYGROMETER.................................................................. 8-2

8.2.3 TRACE OXYGEN ANALYZER ........................................... 8-3

8.2.4 WIRING.............................................................................. 8-3

8.3 OPERATION..................................................................................... 8-6

8.3.1 GENERAL........................................................................... 8-6

8.3.2 INSTRUMENT DATA SCREENS ....................................... 8-7

8.3.3 INSTRUMENT OPERATION............................................ 8-15

9 Attachments........................................................................................ 9-1

9.1 Frame Assembly A-1................................................................. 9-1

9.2 Electrolyte Assembly A-2............................................................ 9-1

9.3 Feedwater And Cooling Water Assembly A-3 ................................ 9-1

9.4 Gas Control Assembly A-4 ......................................................... 9-1

March 2007 HM Generator Operations and Maintenance Manual

xii

9.5 Control Panel Assembly A-5........................................................ 9-1

9.6 Dryer Assembly A-6................................................................... 9-1

9.7 HM Generator P&I Diagram M14156............................................ 9-1

9.8 HM Generator Piping Diagram M14001 ........................................ 9-1

9.9 Combustible Gas Detector Installation TS1075.............................. 9-1

9.10 Hygrometer Sensor Installation TS1078........................................ 9-1

9.11 Trace Oxygen Analyzer Installation TS1077 .................................. 9-1

HM Generator Operations and Maintenance Manual March 2007

xiii

List of Figures

Figure 4-1 Matrix Barrier ............................................................................................ 4-13

Figure 4-2 KOH Filter ................................................................................................. 4-17

Figure 4-3 Feedwater Filter ........................................................................................ 4-19

Figure 4-4 KOH Pump................................................................................................ 4-21

Figure 4-5 Hydrogen Valve Assembly........................................................................ 4-23

Figure 4-6 Normally Closed Solenoid Valve............................................................... 4-25

Figure 4-7 Condenser Water Solenoid Valve............................................................. 4-26

Figure 4-8 Hydrogen Regulator.................................................................................. 4-28

Figure 4-9 Oxygen Regulator ..................................................................................... 4-29

Figure 4-10 Back Pressure Regulator ........................................................................ 4-31

Figure 4-11 Relief Valve Assembly ............................................................................ 4-33

Figure 4-12 Flow Controller........................................................................................ 4-35

Figure 4-13 Flow Switch............................................................................................ 4-40

Figure 4-14 Dryer Purge Control Assembly................................................................ 4-43

Figure 4-15 Dryer Check Valve.................................................................................. 4-44

Figure 8-1: Instrument Wiring Diagram........................................................................ 8-4

Figure 8-2: Wiring Schematic for Control Panel Instrument Wires ............................... 8-5

Figure 8-3: Instrument Menu Screen............................................................................ 8-7

Figure 8-4: Combustible Gas Detector Data Screen.................................................... 8-8

Figure 8-5: Combustible Gas Warning Screen............................................................. 8-9

Figure 8-6: Combustible Gas Shutdown Screen .......................................................... 8-9

Figure 8-7: Hygrometer Data Screen ......................................................................... 8-10

Figure 8-8: High Moisture Warning Screen ................................................................ 8-11

Figure 8-9: High Moisture Shutdown Screen.............................................................. 8-11

Figure 8-10: Trace Oxygen Data Screen.................................................................... 8-13

Figure 8-11: High Oxygen Content Warning Screen.................................................. 8-14

Figure 8-12: High Oxygen Content Shutdown Screen................................................ 8-14

List of Tables

Table 2-1 HM Generator Input Requirements .............................................................. 2-3

Table 2-2 Interconnecting Wire Runs........................................................................... 2-6

Table 3-1 Module Voltage at 250 Amps ....................................................................... 3-3

Table 3-2 System Shutdowns ...................................................................................... 3-5

Table 4-1 Regular Maintenance Schedule................................................................... 4-1

Table 4-2 Specific Gravity of KOH Solution at Various Temperatures ......................... 4-4

Table 4-3 Electrolyte Quantities ................................................................................... 4-5

Table 4-4 Mixing Ratios and Quantities for Producing 25% Solution ........................... 4-7

Table 4-5 Maximum Allowable Module Cross Leakage.............................................. 4-15

HM Generator Operations and Maintenance Manual March 2007

1-1

1 System Description

1.1 Introduction

The basic HM system configuration includes two pieces of equipment, the

hydrogen generator, and the power supply. The hydrogen generator contains all

the mechanical components and plumbing necessary for sustaining the

electrolysis process. The system control and instrumentation functions are

located within the generator. A control panel displays process conditions and

data necessary for efficient operation of the system. The requirements for the

process are fed to the generator, and the products of the process leave from it.

The HM-C1D2 generator has been designed for operation in a NEC class I,

division 2, location. The power supply contains the equipment for converting an

ac power input to the dc power necessary for electrolysis. The power supply is

intended for installation in a separate unclassified area.

The inputs required to operate the system include high purity water and electrical

power for electrolysis, nitrogen for initial purging and cooling water for waste heat

removal. Using these inputs the system will supply hydrogen at 100 PSIG (7.0

kg/cm

2

). Oxygen, which is vented to the atmosphere, is produced at one-half of

the rate of hydrogen. The complete generator installation must include

provisions for supplying the feedwater, nitrogen, cooling water and electrical

power inputs, and plumbing for delivering the hydrogen product gas and separate

hydrogen and oxygen vents.

The system is designed for completely automatic operation. When operation is

initiated with a depressurized system, an automatic start-up sequence brings the

system into operation and up to pressure ready to deliver gas. The gas

production rate of the system responds directly to the user's demand rate up to

the maximum capacity of the generator. If gas delivery is not required, the

system will remain at pressure in a standby mode where gas is instantly available

for delivery. All important operating parameters are continually monitored.

Should conditions within the system deviate beyond the allowable range, system

shutdown will automatically occur. If turned off, the system will remain at

pressure ready for immediate delivery when power is restored.

The system has been designed for safe and reliable operation. However, it is

important that preventive maintenance be scheduled and performed to maintain

system reliability. Routine maintenance includes component inspection and

adjustment, electrolyte checks and changes, and controller and instrumentation

calibration. In the event of component failure, the system instrumentation and

display provides information useful in determining the cause of system shutdown

and in locating the problem area.

March 2007 HM Generator Operations and Maintenance Manual

1-2

The system description that follows uses letter coded references to system

components. These references can be found as component labels on the piping

diagram and wiring diagram in appendix b of this manual. It is recommended

that the reader refer to these diagrams as an aid in understanding the HM

system. The physical location of each of the components is illustrated in the

exploded views in Section 6.

1.2 Electrolyte

Electrolysis of pure water is inefficient because water has a low ionization

constant and a relatively high electrical resistance. Alkaline water electrolysis

uses a strong aqueous alkaline solution to provide an abundance of hydroxyl

ions (oh

-)

and minimize the electrical resistance between electrodes. When a

voltage is applied and a DC current flows through to the electrodes, an individual

half-cell electrochemical reaction occurs at each electrode. At the anode

4OH- O

2

+ 2H

2

O + 4E-

and at the cathode

4H

2

O + 4E- 2H

2

+ 4OH-

the overall reaction is

2H

2

O 2H

2

+ O

2

The rate of the reaction is directly proportional to the amount of current that flows

between electrodes.

The HM system uses an electrolyte, commonly referred to as KOH, which is a 25

weight percent aqueous solution of potassium hydroxide. The Equivalent

Specific Gravity Is 1.236 At 20C (68F). The electrolyte is a strong caustic

requiring specific materials for plumbing and components throughout the system.

Adequate safety precautions should be observed when handling KOH. The

solution is harmful and a severe irritant to skin and eyes.

1.3 Electrolysis Module

The heart of the HM system is the electrolysis module. This is where the basic

process of separating H

2

O into its elemental components occurs. The HM

HM Generator Operations and Maintenance Manual March 2007

1-3

electrolysis module seems deceivingly simple from the outside but the process

occurring inside is complex. The configuration requires close tolerances and

special equipment and tooling for disassembly and assembly.

The module consists of a series of individual electrolysis cells where hydrogen

and oxygen are produced on separate electrode surfaces. Each cell contains a

hydrogen electrode and flow screen, a membrane, and an oxygen electrode and

flow screen. The electrodes in each cell are separated by a porous matrix

material saturated with electrolyte. When wet the matrix material provides a gas

impervious membrane, preventing the generated gases from recombining. The

thin cells within the module are electrically connected in series using bipolar

plates. All the cells are compressed between two large endplates using 16 tie

rods evenly spaced around the circumference of the endplates. The

configuration, usually referred to as bipolar or filter-press construction, results in

a compact and efficient electrolysis module.

The module arrangement requires electrolyte circulation through each cell. The

HM module is unique in that it only requires electrolyte circulation through the

anode (oxygen) half-cell side of each cell. This single irriguous design greatly

simplifies the electrolyte subsystem that supplies the module. The single

irriguous process is achieved by maintaining the production of hydrogen at a

slightly higher pressure than the oxygen production. The pressure difference

allows the matrix material to stay saturated with electrolyte while preventing the

cathode (hydrogen) half-cell side of each cell from flooding with electrolyte.

1.4 Electrolyte Subsystem

The electrolyte is continually circulated within a closed plumbing loop. The loop

includes a reservoir, filter, circulating pump, heat exchanger, flow switch,

temperature sensors, and the module itself. Circulation of the electrolyte through

the loop allows for a continuous supply of water for each cell of the module while

removing the waste heat of the process.

The oxygen produced in each cell is carried away with the electrolyte and

separated in the reservoir. The electrolyte is cooled in the heat exchanger and

solids are removed in the filter. The flow switch and temperature sensors provide

for electrolyte flow and temperature monitoring. The system will shut down as a

result of either low electrolyte flow or high electrolyte temperature.

1.4.1 KOH Pump

The electrolyte is circulated by means of a magnetically coupled centrifugal

March 2007 HM Generator Operations and Maintenance Manual

1-4

pump. The centrifugal design allows for continuous and long-life operation. The

use of a magnetic coupling between the pump motor and pump impeller provides

for leak-free operation by eliminating rotating seals at the pump shaft. Except for

bearing surfaces, all wetted parts of the pump are stainless steel. The impeller

bearing is a carbon and thermoplastic compound that rotates on a ceramic shaft.

Periodic inspection of these bearing surfaces is recommended as part of the

preventive maintenance schedule. Nominal KOH flow rate is between 8 and 11

GPM (30 and 42 LPM) depending on electrolysis module size and electrolyte

filter condition.

1.4.2 KOH Reservoir

The reservoir is a stainless steel pressure vessel providing a storage volume for

KOH within the electrolyte plumbing loop. Tri-Clamp fittings at both the top and

bottom of the reservoir provide access to the level sensors and electrolyte filter in

the reservoir. The system is also filled with electrolyte through the top Tri-Clamp

fitting on the reservoir. The reservoir is located upstream of the KOH pump

supplying the necessary suction conditions for proper pump start-up and

operation. Oxygen and electrolyte returning from the electrolysis module are

separated within this volume. The make-up feedwater necessary to replenish the

water consumed by electrolysis is added to the reservoir.

1.4.3 Heat Exchanger

The heat exchanger is a standard shell and tube configuration of stainless steel

construction. The electrolyte passes on the shell side and is cooled by water on

the tube side. The heat rejection rate is controlled to maintain a stable electrolyte

temperature into the electrolysis module by varying the cooling water flow rate.

The water flow rate is varied by the temperature-regulating valve (BV1).

1.4.4 KOH Filter

The electrolyte filter is located in the bottom of the KOH reservoir. The filter

element is a stainless steel cartridge. The cartridge is capable of removing all

particles down to 100 microns in size. Keeping the electrolyte subsystem free of

particulate matter is especially important for the electrolysis module where solids

can deposit on charged surfaces and clog intricate flow passages. Cleaning or

replacing the cartridge at regular intervals is part of the routine maintenance

schedule.

HM Generator Operations and Maintenance Manual March 2007

1-5

1.4.5 Flow Switch

Adequate electrolyte flow to the electrolysis module must be maintained in order

to prevent drying out of the matrix material within each cell and prevent

overheating of the module. The flow switch (FS1) is a vane-operated device that

is actuated by the flow of fluid through the device. When the flow drops below

the minimum that actuates the vane, a magnetic switch is activated and the

system is shut down due to low flow.

1.4.6 KOH Temperature Sensors

Two iron-Constantine thermocouples (TC1 and TC2) are used to sense the

electrolyte temperature within the flow loop. Thermocouple TC1 monitors the

KOH temperature leaving the electrolyte heat exchanger before entering the

module. This temperature is used in controlling the heat rejection rate by varying

the cooling water flow to the heat exchanger. The TC2 thermocouple monitors

the KOH temperature leaving the electrolysis module to prevent overheating. If

this temperature exceeds a preset maximum, the system is shut down.

1.4.7 KOH Level

The quantity of electrolyte in the system is controlled by monitoring the liquid

level in the KOH reservoir. The top-mounted level switch assembly consists of

two magnetically actuated reed switches (LS1 and LS2) each with a designated

float. Feedwater addition to the reservoir is controlled by the lower switch, LS1.

As the system consumes water, the electrolyte level drops. When LS1 drops, the

magnetic switch is set signaling additional feedwater is required. Feedwater is

added by running the feedwater pump in 30 second time intervals, until LS1 is

reset. If, for any reason, the KOH level cannot be reestablished within 120

seconds (4 time intervals) and LS1 is not reset, then the system will shutdown

on low level. In the event of a high level KOH condition, the upper switch, LS2 is

actuated and the system is shut down to prevent overflowing the reservoir.

1.5 Feedwater Subsystem

The feedwater subsystem delivers the high purity water required for electrolysis

to the electrolyte in the KOH reservoir. The system includes a feedwater quality

monitor, a high-pressure pump, and switches and valves for control.

March 2007 HM Generator Operations and Maintenance Manual

1-6

1.5.1 Feedwater

The HM system consumes approximately three GPH (11 LPH) of water at a

hydrogen production rate of 200 SLM. At other gas production rates, the

feedwater consumption rate is directly proportional.

Feedwater should conform to the American Society for Testing and Materials

(ASTM) specification D1193-72 for Type IV water. This water may be prepared

by distillation, ion exchange, reverse osmosis, or electrodialysis. The minimum

allowable electrical resistivity is 200k ohm-cm at 25C (77F). Using feedwater of

inferior quality may lead to the formation of deposits in the electrolysis module

which, if extreme, can cause module failure.

1.5.2 Feedwater Quality Monitor

A water resistivity monitor is used to monitor feedwater quality. The flow probe is

located in a plastic tee just inside of the feedwater inlet port. The probe has a

fixed set point of 200K ohms-cm. When the resistivity is above the set point the

water purity is acceptable. If the resistivity drops below the set point, the HM will

shutdown.

1.5.3 Feedwater Pump

The feedwater pump (K2) is a positive displacement rotary-vane type pump. It

pumps from the feedwater supply pressure head to a nominal 100 PSIG (7.0

kg/cm

2

) pressure in the reservoir. Pump capacity from near atmospheric

conditions to the 100 PSIG (7.0 kg/cm

2

) discharge is approximately 15 GPH (1.0

LPM). The pump does not require any routine maintenance. The internal

bearings, vanes, and liner are made from a carbon graphite material. The

remainder of the wetted parts are stainless steel. However, the pump internals

can be damaged if run dry for more than 30 seconds.

1.5.4 Feedwater Control

Level switch LS1 initiates automatic control of the feedwater subsystem

components. When the liquid level drops to activate switch LS1, solenoid valves

SV1 and SV8 are opened and feedwater pump operation begins. Feedwater will

be added for only a very short time interval. A button located inside the system

control panel door can be used to manually run the feedwater pump. The pump

will run as long as the button is depressed. Feedwater valves SV1 and SV8 do not

open during manual feedwater pump activation. Manual operation of the pump is

provided for pump priming or purging of the feedwater quality monitor probe.

HM Generator Operations and Maintenance Manual March 2007

1-7

1.6 Gas Control and Conditioning Subsystem

The majority of the equipment located in the upper-half of the hydrogen

generator is associated with controlling and conditioning the two products of the

process, hydrogen and oxygen. The gas controls are set to produce hydrogen at

a nominal system pressure of 100 PSIG (7.0 kg/cm

2

). Oxygen is produced at a

nominal 90 PSIG (6.3 kg/cm

2

). The pressure difference between hydrogen and

oxygen is necessary to maintain the single irriguous process. Pressure controls

and monitors are included to maintain system pressure within normal operating

range and shut the system down if pressures diverge out of the normal range. In

the event that the demand for the supply of hydrogen is too great, a back

pressure regulator will allow only the maximum production capacity.

Hydrogen from the electrolysis module and oxygen from the KOH reservoir leave

as gases saturated with water vapor. Both gases flow through separate water

cooled condensers and moisture traps to remove much of the moisture. The

condensate from the oxygen condenser collects in a trap and returns directly to

the KOH reservoir. Condensate from the hydrogen condenser collects in the

hydrogen trap, but must flow through a matrix barrier in the bottom of the trap to

reach the KOH reservoir. The matrix barrier prevents hydrogen from entering the

electrolyte plumbing.

1.6.1 Pressure Transducers

Pressure control is the key to the automatic operation of the HM system.

Pressure transducers (PT1, PT2) continuously monitor both the hydrogen and

oxygen pressure. The 0 to 10 VDC signals from the transducers are input

directly to the programmable controller to provide complete system pressure

control. Two separate pressure transducers (PT3, PT4) are used with the dryer

process. These pressure transducers monitor the hydrogen pressure at the exit

of each dryer assembly.

1.6.2 Production Rate

The HM generator uses a separate DC power supply to provide electrical power

for electrolysis. The power supply is matched to provide specific requirements

for the electrolysis module (five sizes available) used in the generator. The

programmable controller in the generator controls the DC current output to the

electrolysis module through a signal to the power supply control board. The

programmable controller determines the DC current, depending on pressure and

temperature conditions in the HM generator.

March 2007 HM Generator Operations and Maintenance Manual

1-8

The programmable controller in the HM has been programmed to vary the

electrolysis production rate to constantly maintain the nominal system hydrogen

pressure. At hydrogen production demands of 17 to 100 percent (50 to 280

amps) of the maximum capacity of the generator, the current to the electrolysis

module is varied proportionally so that the production rate matches the demand

while maintaining the nominal system pressure. At production demands greater

than 100 percent, the generator produces at the maximum rate and the system

pressure is allowed to drop to the set point of a back pressure regulator (BPR2).

At production demands of less than 17 percent, the generator will vent the

excess hydrogen through a back pressure regulator (BPR3) at the 17 percent

capacity while maintaining system pressure. BPR3 functions as a relief valve for

the system. It is set to maintain a system pressure below 110 psig (7.7 kg/cm

2

).

In addition to pressure control, the production rate may be limited by the

electrolyte temperature. When the electrolyte temperature is below the

acceptable operating temperature (55C), the maximum production rate is

limited. The limit is proportional to the difference between the measured

electrolyte temperature and the acceptable operating temperature.

1.6.3 Prepressurization

When the HM system initially starts without any residual hydrogen pressure, a

15-minute prepressurization period is required. The system is pressurized with

nitrogen to 20 PSIG (1.4 kg/cm

2

) and then stops for 15 minutes. During this

period, the higher pressure on the hydrogen side of the system pushes any

electrolyte that may have drained into the hydrogen half-cells of the module

through the cell matrix into the oxygen half-cells. This establishes the single

irriguous condition by which the module operates.

1.6.4 Standby

The HM has been designed to always remain at pressure during normal

operation, whether there is demand for hydrogen or not. The nominal hydrogen

system pressure has been factory set for 100 PSIG (7.0 kg/cm

2

). If there is no

gas demand (the delivery line from the system is closed off), the internal

pressure of the system will begin to increase above the nominal pressure. When

the pressure reaches reaches110 PSIG (7.7 kg/cm

2

) the excess hydrogen is

vented. If the pressure reaches 115 PSIG (8.1 kg/cm

2

) gas generation will stop.

The system remains at pressure, in a standby condition, ready to deliver

hydrogen on demand. When the internal pressure of the system drops to the

nominal system pressure, generation will begin again.

HM Generator Operations and Maintenance Manual March 2007

1-9

1.6.5 Pressure Release

A pressure release button (S2) is provided to allow the operator to depressurize

the system. Depressing this button shuts the system down and opens the vent

valves to initiate a controlled pressure release. Pressure is also released during

several of the automatic shutdowns.

1.6.6 Back Pressure Regulator

There are (3) back pressure regulators, which serve as the upper and lower limit

controls for the system pressure.

Back pressure regulator BPR1 is set to maintain a system pressure of

approximately 20 psig (1.4 kg/cm

2

) below the nominal system hydrogen pressure.

It prevents damage to the electrolysis module in the event of a hydrogen dryer fill

problem. If the system switches into an empty dryer, BPR1 will prevent a reverse

differential pressure on the module.

Back pressure regulator BPR2 is set to maintain a system pressure of

approximately 10 psig (0.7 kg/cm

2

) below the nominal system hydrogen pressure.

It prevents loss of system pressure when the hydrogen demand is greater than the

maximum capacity of the HM system. The BPR2 will allow delivery of only as

much gas as the hydrogen generator can produce.

Back pressure regulator BPR3 functions as a relief valve for the system. It is set to

maintain a system pressure below 110 psig (7.7 kg/cm

2

). When the hydrogen

demand drops to zero or when the hydrogen demand is less than flow produced by

the idle current, the system pressure will rise to the set point of BPR3 and the

excess hydrogen produced will be vented through this regulator.

.

1.6.7 Differential Pressure Regulators

The hydrogen and oxygen differential pressure regulators are designed to keep

the hydrogen pressure at 5 to 15 PSIG (0.4 to 1.1 kg/cm

2

) above the oxygen

pressure. The pressure difference is necessary to maintain the single irriguous

process in the electrolysis module. Both regulators are dome-loaded controllers

that are designed to maintain a specific back pressure in the system depending

on the reference gas pressure in the dome.

The oxygen regulator (DPR2) maintains the correct oxygen pressure using the

March 2007 HM Generator Operations and Maintenance Manual

1-10

hydrogen pressure as a reference. During normal operation, the electrolysis

production rate is controlled to constantly maintain the nominal system hydrogen

pressure. The oxygen regulator references the hydrogen pressure and vents

excess oxygen to maintain the proper oxygen pressure.

Similarly, the hydrogen regulator (DPR1) maintains a safe hydrogen pressure

using the oxygen pressure as a reference. If the system suddenly loses oxygen

pressure, the hydrogen regulator releases hydrogen through the hydrogen vent

to maintain the correct pressure difference within the system. This situation does

not occur during normal steady state operation, but may occur during transient

periods when the system pressurizes or depressurizes.

The two differential pressure regulators are not adjustable and as such can not

be recalibrated. However, as part of the periodic maintenance schedule, it is

recommended that the regulators be disassembled, cleaned, and checked for

proper functioning.

1.6.8 Relief Valves

A relief valve (RV1) in the hydrogen delivery plumbing is used to provide a

redundant safeguard against system over-pressure. A second relief valve (RV2)

in the dryer delivery plumbing is used to provide a safeguard against dryer over-

pressure. Both relief valves are set to open at 130 PSIG (9.1 kg/cm

2

).

1.6.9 Vent Valve

Solenoid valve SV2 is the system vent valve for depressurizing the generator.

The vent valve releases hydrogen to the hydrogen vent. SV2 activates

automatically during several of the system shutdowns or it can be manually

actuated by depressing the pressure release button on the system control panel.

During venting, the valve pulses to provide a slow, controlled pressure release to

prevent violent pressure fluctuations and possible liquid loss.

1.6.10 Condensers and Traps

Conditioning of the product gases begins in the condensers. The hydrogen and

oxygen condensers are shell and tube configurations. The gas and vapor

mixture enters the shell side of the condenser and the chilled or cooling water

flows in the tube side. The cooling water requirement is approximately 1 GPM (4

LPM). The cooled gas leaves the shell at a temperature approaching the water

temperature and with the condensate exits from the shell into a trap. The volume

HM Generator Operations and Maintenance Manual March 2007

1-11

in the trap allows the gas and condensate to separate. The condensate from the

oxygen trap returns directly to the KOH reservoir. Condensate from the

hydrogen trap must first pass through the matrix barrier before draining to the

reservoir.

The effectiveness of the condensers is directly dependent on the temperature of

the cooling water. The system is provided with a separate cooling water circuit

for the condensers. Using a small chilled water source to cool the condensers

assures a high rate of condensation and delivery of high purity product gases.

1.6.11 Matrix Barrier

The bottom of the hydrogen condensate trap includes the matrix barrier. The

matrix barrier allows condensate from the hydrogen trap to return to the

electrolyte reservoir while preventing the flow of hydrogen to the reservoir. A

gas-impervious membrane made of the same matrix membrane used in the

electrolysis module provides the barrier. When saturated with condensate, the

porous matrix material will allow the condensate to be transferred through from

the higher pressure hydrogen side. Acting as a filter, the matrix material tends to

collect particulates that may interfere with the transfer of liquid. Replacement of

the matrix is recommended as part of the periodic maintenance schedule.

1.6.12 Nitrogen Purge

The HM-C1D2 generator includes valves for purging the gas plumbing with

nitrogen before starting from zero pressure. A forward pressure regulator (FPR1)

reduces the facility nitrogen pressure input to about 30 PSIG (2.1 kg/cm

2

) as

indicated by pressure gauge PG5. Two solenoid valves (SV6 and SV7) distribute

nitrogen to the hydrogen and oxygen side plumbing of the generator. Check

valves (CV4 and CV5) prevent the flow of the product gases back into the

nitrogen distribution plumbing when the generator is producing gas.

1.7 Hydrogen Drying

Dryers are included for further conditioning of the hydrogen delivery gas. The

drying process uses a molecular sieve bead material that removes water vapor

from the gas by adsorption. The dryers are capable of drying the gas to an

atmospheric dew point of less than -73C (-100F), corresponding to a volumetric

concentration of less than one part per million. After the adsorption process, the

molecular sieve beads are automatically regenerated for reuse using a thermal

cycling procedure.

March 2007 HM Generator Operations and Maintenance Manual

1-12

1.7.1 Dryers

The HM dryer system contains a pair of internally mounted dryers for

conditioning the hydrogen. The two dryers automatically alternate through a

12-hour adsorption and desorption cycle. After 6 hours of adsorption, the on-line

dryer is switched off-line to begin a 6-hour regeneration process. The dryer is

depressurized and an electric resistance heater within the dryer heats the

molecular sieve beads to release the adsorbed water vapor. A small purge of

product gas is used to drive the water vapor out through the vent gas tubing.

The purge flow is controlled by an orifice located between the dryers. After

desorption, the heating element is turned off and the dryer is allowed to cool

before going back on line.

The hydrogen dryers also contain a small amount of catalyst that will recombine

any minute amount of oxygen produced in the hydrogen. The recombined

product is water that is adsorbed in the dryer beads.

1.7.2 Dryer Valves

The dryer valve assembly (BV2) is a four-way motor-operated ball valve. The

valve directs the hydrogen product gas through the active dryer while also

directing the hydrogen purge gas from the regenerating dryer to the gas vent.

Every six hours the valve position is alternated, selecting the opposite dryers for

product gas conditioning and dryer purge venting.

A regenerated dryer must be pressurized to system operating pressure before it

goes back on line. This is done to prevent a sudden pressure transient through

the system. Solenoid valve SV4 controls the hydrogen purge vent. This valve

automatically closes before the dryer switch to bring the regenerated dryer up to

system pressure.

The dryer system includes a solenoid valve (SV5) for venting the dryers during a

system pressure release. Check valves (CV2 and CV3) are provided to separate

product gas from the purge gas following the drying process. A back pressure

regulator (BPR2) is used to prevent the loss of dryer pressure when the

hydrogen demand is greater than the maximum capacity of the HM system.

1.8 Cooling and Condenser Cooling Water Subsystems

The cooling water, required to cool the electrolyte, and the chilled water, required

for condenser cooling, flow in separate plumbing circuits. This arrangement allows

the operator to use any economical means of cooling for the majority of the heat

HM Generator Operations and Maintenance Manual March 2007

1-13

load and only a small chilled water source for condenser cooling. Chilled water is

necessary for condenser cooling in order to provide maximum condenser

effectiveness and deliver specified product gas purity. Using the cooling water

source for condenser cooling is permissible if minimum moisture content in the

product gas is not necessary.

The cooling water system includes the heat exchanger and a temperature

regulating valve (BV1). An externally mounted strainer is recommended to protect

the control valve. The condenser cooling water system includes a solenoid valve

(SV3), the oxygen and hydrogen condensers, and a flow adjustment valve (MV3).

1.8.1 Temperature Regulating Valve

Temperature control of the electrolyte is important for maintaining an efficient

process and preventing premature failure of the electrolysis module. Operating at

too low a temperature can be as detrimental as overheating the module. The

programmable controller maintains the temperature of the electrolyte into the

module at a nominal set point of 64C.

The temperature regulating valve (BV1) controls the electrolyte temperature by

varying the cooling water flow through the heat exchanger. The regulating valve is

a stepper motor driven ball valve. Thermocouple TC1 sends the KOH control

temperature signal directly to the programmable controller. Ball valve actuation is

controlled by the programmable controller and is positioned by varying an analog

signal. The programmable controller monitors the temperature change versus time

response of the TC at the heat exchanger outlet and varies the valve position

proportionally. As long as adequate cooling water is available, the PLC determines

the correct valve position to maintain the KOH temperature set point.

1.8.2 Condenser Cooling and Water Control

Control of the chilled water to the condensers is accomplished using two valves. A

solenoid valve (SV3) provides the on and off control and a manual valve (MV3) is

used to adjust the flow. Solenoid valve SV3 opens and allows flow only when the

system is running. The chilled water flow is adjusted to approximately 1 GPM using

MV3.

1.9 System Safety

Operator and system safety has been a primary consideration in the design of the

HM system. The system maintains only a small inventory of hydrogen during

March 2007 HM Generator Operations and Maintenance Manual

1-14

operation. This limits any potential danger related to combustible gas storage. The

system is designed to be operated in a well-ventilated environment monitored by a

suitable hydrogen detection device. The system can easily be interlocked to the

hydrogen detection device or any other external alarm device.

The operational features of the system provide for automatic shutdown of the

system should operation deviate significantly from normal design conditions.

Temperatures, pressures, and liquid levels are continuously monitored throughout

the system to assure system operation within the established design conditions.

Latch-out alarms are used to interrupt gas generation should any of the parameters

which are monitored drift outside the allowable range. The cause for shutdown

must be corrected before system operation can continue.

1.9.1 Hydrogen In Oxygen Monitor

The oxygen produced in the system is continuously monitored to determine the

hydrogen content. The amount of hydrogen in the oxygen is a direct indication of

module integrity. Hydrogen, which is produced at a slightly higher pressure than

the oxygen to maintain the single irriguous process, will be present in the oxygen if

internal module integrity fails. Another cause of hydrogen in oxygen is failure of the

matrix barrier membrane. When the concentration of hydrogen approaches the

lower combustion limit of 4 percent, the system is shut down.

Detection of hydrogen in oxygen is accomplished using a catalyzed electrode that

chemically combines the two gases. The heat of reaction is proportional to the

concentration of hydrogen in the oxygen. The heat of reaction is indicated as the

temperature rise of the catalyzed electrode (TC3) minus the ambient temperature

(TC4). If the temperature difference exceeds a preset maximum of 200C, the

system is shut down. Only a small constant flow of the oxygen produced is used

for hydrogen detection. This amount is precisely controlled by a flow controller

(FC1) and indicated by a flowmeter (FM1). A filter tank prevents water vapor from

entering the flow stream and a flame arrester prevents a reaction from traveling

back into the system.

1.9.2 Hydrogen Detector

A hydrogen detector is recommended to be used to monitor the atmosphere

surrounding the HM system. The HM system can be interlocked to a compatible

hydrogen detector by using the available external alarm inputs. The hydrogen

detector will shut the system down if a sufficient amount of hydrogen is present.

HM Generator Operations and Maintenance Manual March 2007

1-15

1.9.3 Shutdown Alarms

There are 19 possible alarms indicated on the system control panel. The

conditions which cause the system to shut down include: high KOH temperature,

high or low reservoir KOH level, low KOH flow, high or low hydrogen pressure, high

or low oxygen pressure, low differential pressure, low prepressurization pressure,

high hydrogen in the oxygen, power supply failure, low feedwater resistivity, loss of

power, high or low ambient temperature, dryer cycle or purge failure, and any

external alarm which may be connected to the system. When one of these

conditions occurs, the appropriate alarm screen will be indicated on the control

panel and the system will shut down.

System pressure will automatically be released when the generator shuts down on

low KOH flow, high KOH temperature, high hydrogen in oxygen, high hydrogen or

high oxygen pressure, low differential pressure, and high or low KOH level. All the

other shutdowns will not automatically activate the pressure release. The

automatic pressure release is a partial release to a preset set point. The default

factory set point is 0 PSIG. The full pressure release may also be initiated by a

manual pressure release from the generator control panel.

The shutdown condition is indicated by a flashing screen on the touch screen

display. The shutdown will continue to flash until the alarm reset button is pressed.

Operation can continue after the condition is corrected and the system start/reset

button is depressed. If system power is lost or turned off during a shutdown, the

shutdown will resume flashing when the power is restored again and the alarm

indication will not be lost.

1.10 Electrical Power and Process Control Subsystems

The electrical conversion and control subsystems link all the components required

to carry out the electrolysis process and operate the generator as a working

system. The AC power input is converted into DC power for the electrolysis module

and also stepped down to 115 VAC for system process and control power. After

facility power has been applied to the HM system and the start/reset touch switch is

pressed, the electrical control system automatically directs all system functions.

The wiring diagrams in Appendix B show the numbered wire runs for the generator.

1.10.1 DC Power Supply

The power supply is contained in a cabinet separate from the hydrogen generator.

It is a current control DC power supply with an output of up to 300 amps DC. AC to

DC conversion is accomplished with a full wave, full control bridge rectifier. A

March 2007 HM Generator Operations and Maintenance Manual

1-16

constant current regulator is used to maintain a steady-state DC output current

within plus or minus 1 percent of rated current. A voltmeter and ammeter are

located on the front panel to display the DC voltage and current applied to the

electrolysis module. The power supply also contains several auxiliary transformers

for supplying 115 AC for generator control power and pump power. Overload

protection devices on the power supply include fuses for the SCRs, temperature

switches for the transformer and SCRs, and several circuit breakers.

Operation of the power supply is controlled from the generator. Terminals for

stop/start, current control inhibit, and variable current control are available on the

power supply and wired to the generator. A separate main power switch, installed

in close proximity to the generator, actuates the power supply electrical power.

Current control inhibit of the DC power and proportional control of the current is

managed by the generator's programmable controller. Other connections from the

power supply to the generator include the 115 AC output for control power and

pump power, power supply alarm signal and the DC power output for electrolysis.

1.10.2 Programmable Controller

The HM system uses a programmable controller for managing the operation of the

system. The controller allows the system to operate with no need for an operator to

do manual switching, make adjustments, or continuously monitor the process. The

controller has been programmed to do the switching, make the adjustments, and

monitor the system to maintain efficient and safe operation. System process

conditions (temperature, pressure, and level) are input directly to the programmable

controller and output signals are directed to the process control devices (power

supply, valves, and pumps). All the process functions, such as feedwater addition,

cooling water flow, and electrolysis rate, are handled by the controller. Should

process conditions stray beyond the allowable bounds, the controller will stop gas

production and indicate the appropriate shutdown alarm.

The programmable controller consists of a rack mounted CPU with 10 slots

available for input or output modules. Memory units are separate devices that plug

into the CPU. The HM-C1D2 uses a 8K word EEPROM unit for program and data

memory. A total of seven input and output modules are used in the generator.

The input and output wiring to the programmable controller is shown in the wiring

diagrams (Appendix B). The inputs are either 115 VAC on/off signals, 0-10 VDC or

4-20 mA analog signals or direct thermocouple voltages. The on/off inputs include

two KOH level switches (feedwater add, high level), the KOH flow switch, two

external alarms (normally open, normally closed), and the power supply alarm.

Four analog inputs are from the hydrogen, oxygen, dryer 1 and dryer 2 pressure

transducers, with a fifth analog input from the feedwater quality monitor. Four

thermocouple inputs include the temperatures for KOH control, module outlet,

HM Generator Operations and Maintenance Manual March 2007

1-17

hydrogen in oxygen catalyst, and internal ambient air.

Outputs from the programmable controller are either on/off, triac 115 VAC power,

24 VDC power, or 0-10 VDC analog signals. On /off outputs control the KOH

pump, condenser water valve, feedwater pump, vent valves, feedwater valve, dryer

selection and purge valves, nitrogen purge valves, dryer heaters and power supply

inhibit. An analog output controls the power supply current and BV1 valve position.

The front of each on/off input and output module on the programmable controller

has small LED lights to indicate when an input signal is being powered and when

an output is on. The HM operator can use these indicators to monitor system

operation, and to check on the input and output functions. Much of the operating

sequence can be reviewed by observing these lights. A listing of the inputs and

outputs, and where they initiate or terminate, is shown below.

AC Input Module Slot No. 1

Bit No. Function LED No. Input From Switch Position

00003 Feedwater Add 3 LS1 closed when dry

00004 High KOH Level 4 LS2 closed when dry

00006 Low KOH Flow 6 FS1 open with no flow

00008 External Alarm 8 TB1-7 normally closed

00009 External Alarm 9 TB1-8 normally open

00012 Power Supply Alarm 12 TB2-10 normally open

Triac Output Module Slot No. 2

Bit No Function LED No Output To Operation

00100 KOH Pump 0 K1 ON

00100 Condenser Valve 0 SV3 OPEN

00101 Feedwater Pump 1 K2 ON

00102 Vent Valve 2 SV2 OPEN

00103 Feedwater Valve 3 SV1 OPEN

00104 Dryer Vent Valve 4 SV5 OPEN

00105 Shutdown Indication 5 K6 ON to indicate

00106 Power Supply Inhibit 6 TB2-5/6 OFF to inhibit

00107 Run Indication 7 K7 ON to indicate

March 2007 HM Generator Operations and Maintenance Manual

1-18

Analog Input Module Slot No. 3

Channel

No

Function Input

From

Signal

101 Hydrogen Pressure PT1 0-10 VDC

102 Oxygen Pressure PT2 0-10 VDC

103 Dryer 1 Pressure PT3 0-10 VDC

104 Dryer 2 Pressure PT4 0-10 VDC

105 Feedwater Quality FQM 4-20 mA

Analog Output Module Slot No. 4

Channel

No

Function Output

To

Signal

110 Current Control TB2-7/8 0-10 VDC

111 Temp Valve Position BV1 0-10 VDC

Temperature Input Module Slot No. 5

Channel

No

Function Input

From

Signal

121 KOH Control TS1 type J TC

122 Module Outlet TS2 type J TC

123 Hydrogen in Oxygen

Sensor

TS3 type J TC

124 Internal Ambient Air FQM type J TC

Triac Output Module Slot No. 6

Bit No Function LED No Output To Operation

00502 Dryer Heater #1 2 K3 ON

00503 Dryer Heater #2 3 K4 ON

00504 Dryer Purge Valve 4 SV4 OPEN

00505 Nitrogen Purge Valve 5 SV6 purge hydrogen tubing

00506 Nitrogen Purge Valve 6 SV7 purge oxygen tubing

24 VDC Output Module Slot No. 7

Bit No Function LED No Output To Operation

00600 Dryer Valve Motion 0 BV2 dryer #2 online

00601 Dryer Valve Motion 1 BV2 dryer #1 online

The entire operation of the programmable controller can be monitored by either a

hand-held programmer or an IBM PC compatible computer using proprietary

software. Both the programmer and the PC software are available for purchase.

Contact Teledyne Energy Systems, Inc. for more information.

HM Generator Operations and Maintenance Manual March 2007

1-19

1.10.3 Process Control and Sequencing

The main circuit breaker to the power supply must be closed for the system to

receive electrical power. Turning on the emergency stop switch, which is located

on the front panel of the HM generator will activate a contactor that energizes the

circuits in both the hydrogen generator and the power supply.

When the system is at zero pressure the start sequence will include a purge and

prepressurization period. Pressing the "Start/Reset" touch switch on the

"Generator Ready" screen will begin operation and the following will occur:

1. The "Generator Purging" screen displays on the touch screen panel

showing hydrogen and oxygen pressures.

2. Solenoid valve SV7 opens to provide a nitrogen purge of the oxygen side

plumbing of the generator. An increase in the oxygen pressure should be

seen.

3. After a 30 second delay, solenoid valve SV6 opens to begin pressurizing

the hydrogen side plumbing.

4. The hydrogen pressure in the system rises and the oxygen pressure

follows maintaining about a 3 to 10 PSIG (0.7 kg/cm

2

) pressure difference.

The hydrogen pressure continues to rise until it reaches 20 PSIG (1.4 kg/cm

2

). At

this pressure, SV6 will close and the system will begin a 15-minute

prepressurization period. During prepressurization, the 900 second time period (15

minutes) is seen counting down on the "Pre-pressurizing" screen. A 3 to 10 PSI

(0.7 kg/cm

2

) pressure difference should be maintained during this period.

Hydrogen pressure may drop as electrolyte is forced over to the oxygen side on the

system and the hydrogen volume expands. Solenoid valve SV6 will cycle on and

off to maintain the prepressure condition.

After prepressurization the following will occur:

1. The KOH pump is energized and the pump begins to circulate KOH. The

flow switch (FS1) is actuated to indicate proper flow conditions.

2. The condenser cooling shut-off valve (SV3) is energized and opens to

allow flow through the condensers.

3. The Restart Delay screen will appear. The restart delay will last a

minimum of 15 seconds and will continue until the KOH control

temperature is less than or equal to 66C.

March 2007 HM Generator Operations and Maintenance Manual

1-20

4. The inhibit signal to the power supply actuates and power is applied to the

electrolysis module and gas generation begins.

5. The "Generator Operating" screen displays on the touch screen display

showing the hydrogen production rate as a percentage of full capacity.

As operation continues, the system pressure builds at the maximum production rate

allowed by the temperature of the electrolyte. Full 100 percent maximum current is

not available until the electrolyte temperature reaches the acceptable operating

temperature of 55C.

System pressure increases until it reaches the first back pressure regulator (BPR1)

set point. Next, the dryers begin pressurizing. The dryer assembly is filled until the

system pressure reaches the second back pressure regulator (BPR2) set point.

Hydrogen is now available to be delivered. When the internal pressure reaches the

nominal system pressure of 100 PSIG (7.0 kg/cm

2

) the production rate is regulated

to meet the demand rate imposed by the user. If the demand for gas exceeds the

production capacity of the generator, the second back pressure regulator, BPR2,

will maintain the internal system pressure and the flow of gas is limited to the

maximum capacity of the generator. If there is no demand for gas, the pressure will

rise until the set point of BPR3 is reached and the gas will vent through this

regulator. If the BPR3 set point has drifted or is set above 115 PSIG (8.1 kg/cm

2

)

standby pressure is reached and gas generation stops. The "Generator Standby"

screen displays on the touch screen display showing the hydrogen and oxygen

pressures. When demand for hydrogen resumes and the generator pressure drops

to the nominal system pressure, gas generation starts again, the "Generator

Operating" screen redisplays on the touch screen and the production rate is

regulated to meet the demand. If the generator is turned off when at pressure, the

pressure will be retained and the system can restart without requiring

prepressurization.

When the electrolyte reaches operating temperature the temperature regulating

valve (BV1) will begin actuating. The valve will rotate back and forth until the

correct position is found to maintain the electrolyte temperature within the

acceptable operating range. A control routine in the programmable controller varies

the valve position to maintain the electrolyte temperature over a wide range of

production rates and cooling water conditions. A "Temperature Control Valve

Position" screen, which is accessed from the "System Information" screen on the

touch screen display, can be used to monitor the temperature regulating valve

position, from zero to 100 percent open, along with the electrolyte temperature.

During normal operation, feedwater is periodically added to the electrolyte. The

feedwater valves (SV1, SV8) will open and the feedwater pump will supply

feedwater when the feedwater add level switch (LS1) is set. A graphic will display

on the touch screen display during the water add interval. If there is no feedwater

supply available and LS1 does not reset, then the system will shut down on a low

HM Generator Operations and Maintenance Manual March 2007

1-21

level alarm. Feedwater is not added during the start and prepressurization interval

or during a shutdown.

1.10.4 Dryer Sequencing

The dryer assembly begins its timing sequence after the online dryer has been

pressurized. The dryers are not pressurized until the generator is running at

pressure and hydrogen can be delivered to the dryers through the generator back

pressure regulator (BPR1). When the pressure transducer (PT3 or PT4) in the

online dryer senses adequate dryer pressure, the dryer sequence begins.

The dryer timing sequence begins with the online dryer delivering hydrogen at

pressure for 6 hours while the regenerating dryer is being heated for 90 minutes at

atmospheric pressure. After 90 minutes of heating, the regenerating dryer is

allowed to cool for four and a half hours before it goes on line. During heating and

cooling a small portion of the dry product gas purges through the regenerating dryer

to the hydrogen vent. Thirty minutes before the regenerating dryer is to go on line,

the vent valve for the purge (SV4) is closed and the regenerating dryer begins to

build pressure. When the dryer ball valve (BV2) switches to bring the regenerated

dryer on line, both dryers are at equal system operating pressure allowing for a

smooth transition between dryers. The dryers now switch on line and regenerating

duties for the remaining 6 hours for a complete 12 hour cycle.

Except for the 30 minute pressurizing period before dryer switch over, the actual

dryer sequence will restart wherever the 12 hour cycle was interrupted when the

system was last shutdown. This prevents one dryer from becoming saturated from

repeated, short time on-line duty. When a restart occurs within the 30 minute

pressurizing period before dryer switch over, the sequence starts at the beginning

of the period to allow time for both dryers to reach system operating pressure.

The dryer sequence status can be seen by pressing the "Dryer Sequence" touch

switch on the "Generator Operating" screen. The screen indicates:

dryer sequence (on/off)

which dryer is online (on/off)

number of minutes to switch (dryer)

which heater is on (on/off)

number of minutes to turn off (heater)

purge valve (on/off)

1.11 Data Display and Process Monitoring

A touch screen display panel and LED lights on the programmable controller allow

March 2007 HM Generator Operations and Maintenance Manual

1-22

the operator to monitor the gas generating process. The status of various process

conditions can be displayed and operational sequences can be observed. Close

monitoring of the generator operation provides the operator with useful information

for determining overall system condition and detecting possible problems.

1.11.1 Touch Screen Display

A touch screen panel has been provided. Ten meters of power and signal cables

have been provided and the touch screen should be mounted in a Class 1, Division

2 enclosure or in a non-hazardous location. This display is programmed to

communicate directly with the programmable controller to provide operational data

monitoring and operator control input. The display is used to indicate production

rate, feedwater pump timing, purge status, prepressurization timing, gas pressures,

process temperatures, elapsed time, system data set points, shutdown alarms and

troubleshooting summaries.

During normal operation, the "Generator Operating" screen displays the hydrogen

production rate from 17 to 100 percent of capacity as regulated by the controller.

The pressure release is manually activated from this screen by pressing the

"Pressure Release" touch switch and pressing Yes or No to confirm. When the

system is in the standby mode the touch screen will display the "Generator

Standby" screen. The water add graphic is shown whenever the pump is running

during the feedwater addition process. When the system is started with no residual

hydrogen pressure, the screen displays the "Pre-pressurizing" screen while

counting down the 900 second timing during the prepressurization period. The

Restart Delay screen will flash for at least 15 seconds after prepressurization has

been completed or immediately when the system is started with residual pressure.

If a shutdown occurs, the display will flash and indicate the specific shutdown

condition.

The touch screen display can be prompted to indicate various process conditions.

Generator temperatures and pressures can be accessed from most touch screen

by pressing the "Temperature Display" or "Pressure Display" touch switch. The

pressure release is activated from most screens by pressing the "Pressure

Release" touch switch and pressing Yes or No to confirm. The dryer sequence

status and system information screens can be accessed from the "Generator