Beruflich Dokumente

Kultur Dokumente

Applications of Nanotechnology in Aerospace

Hochgeladen von

Smitha KollerahithluOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Applications of Nanotechnology in Aerospace

Hochgeladen von

Smitha KollerahithluCopyright:

Verfügbare Formate

APPLICATIONS OF NANOTECHNOLOGY IN AEROSPACE

ABSTRACT:

Aerospace, the very typical term heard by everyone in our daily lives, which

explores the universe which we cant see. The current exploration of space includes the huge

investment and effort to be expended. So, nanotechnology can be invested and developed in

aerospace to get much more advancement. This miniaturized technology would bring revolution

in the current trend. Application of nanotechnology is its infancy and no one can predict with

accuracy which will result from the full flowering of the field over the next several decades. The

aerospace applications for nanotechnology include high strength, low weight composites,

improved electronics and displays with low power consumption, variety of physical sensors etc.,

Nanotechnology has enormous potential to improve the reliability and performance of aerospace

hardware while lowering manufacturing cost. Carbon Nanotubes are being widely used for

aerospace programmes. It is used in the applications such as space elevators, launch vehicles,

rocket propulsion techniques etc. Not only NASA-the leading space organization in the world,

but every country is trying to integrate nanotechnology in aerospace applications.

EMERGENCE OF NANOTECHNOLOGY :

Nanotechnology, the creation of functional materials, devices and systems through

control of matter on the nanometer length scale and exploitation of novel phenomena and

properties (physical, chemical, biological, mechanical, electrical...) at that length scale.

The concept of nanotechnology originated with American physicist Richard P.

Feynman.He believed the creation of nanoscale devices was possible within the boundaries set

by the laws of physics. He specifically cited the possibility of atom-by-atom assemblythat is,

building a structure (a molecule or a device) from individual atoms precisely joined by chemical

forces. This possibility led to the concept of a universal assembler, a robotic device at

nanoscale dimensions that could automatically assemble atoms to create molecules of the

desired chemical compounds. Such a device, for example, could assemble carbon atoms to form

low-cost, large diamonds, a potentially important industrial material, now used only in limited

quantities due to the high cost of mining and synthesis. Such synthetic diamonds could have

many industrial and consumer applications because they are lightweight and yet extremely hard,

and are electrically insulating but excellent conductors of heat. The idea of a nanoscale robotic

assembler continues to be promoted by some researchers, although there is considerable debate

whether such a device is indeed possible within the known laws of chemistry, physics, and

thermodynamics.

EXPLORATI ON OF NANOTECHNOLOGY:

Nanotechnology, the creation and use of materials or devices at extremely

small scales. These materials or devices fall in the range of 1 to 100 nanometers (nm). One nm is

equal to one-billionth of a meter (.000000001 m), which is about 50,000 times smaller than the

diameter of a human hair.Scientists refer to the dimensional range of 1 to 100 nm as the

nanoscale, and materials at this scale are called nanocrystals or nanomaterials.

The nanoscale is unique because nothing solid can be made any smaller. It is also unique

because many of the mechanisms of the biological and physical world operate on length scales

from 0.1 to 100 nm. At these dimensions materials exhibit different physical properties; thus

scientists expect that many novel effects at the nanoscale will be discovered and used for

breakthrough technologies.

Nanotechnology is in its infancy, and no one can predict with accuracy what

will result from the full flowering of the field over the next several decades. Many scientists

believe it can be said with confidence, however, that nanotechnology will have a major impact

on aerospace; energy production and conservation; environmental cleanup and protection;

electronics, computers, and sensors; and world security and defense.

The scientific community began serious work in nanoscience when tools

became available in the late 1970s and early 1980sfirst to probe and later to manipulate and

control materials and systems at the nanoscale. These tools include the transmission electron

microscope (TEM), the atomic force microscope (AFM), and the scanning tunneling microscope

(STM).

I MPLI CATI ON OF NANOTECH ON AEROSPACE :

The aerospace applications for nanotechnology include high strength, low

weight composites, improved electronics and displays with low power consumption, variety of

physical sensors, multifunctional materials with embedded sensors, large surface area materials

and novel filters and membranes for air purification, nanomaterials in tires and brakes and

numerous others. The status of composite preparation polymer matrix, ceramic matrix and

metal matrix will be presented. Examples of current developments in the above application

areas, particularly physical sensors, actuators ,nanoelectromechanical systems etc. will be

presented to show what the aerospace industry can expect from the field of nanotechnology. Of

all the nanoscale materials, carbon nanotubes (CNTs) have received the most attention across

the world. These are configurationally equivalent to a two-dimensional graphene sheet rolled

up into a tubular structure. With only one wall in the cylinder, the structure is called a single-

walled carbon nanotube (SWCNT). The structure that looks like a concentric set of cylinders

with a constant interlayer separation of 0.34 Angstroms is called a multiwalled carbon nanotube

(MWCNT).

The development of nanotechnology is important for the exploration and future

settlement of space. Current manufacturing technologies limit the reliability, performance, and

affordability of aerospace materials, systems, and avionics. Nanotechnology has enormous

potential to improve the reliability and performance of aerospace hardware while lowering

manufacturing cost. For example, nanostructured materials that are perhaps 100 times lighter

than conventional materials of equivalent strength are possible. Embedding nanoscale

electromechanical system components into earth-orbiting satellites, planetary probes, and

piloted vehicles potentially could reduce the cost of future space programs. The miniaturized

sensing and robotic systems would enhance exploration capabilities at significantly reduced

cost. Thousands to millions of such miniaturized devices could help map a planet in a single

launch.

CNT I N AEROSPACE:

Carbon Nano Tubes(CNT) are being widely studied for various applications

ranging from medical to electronics and also optical devices. They are especially studied for the

suitability and applications in aerospace and aeronautical field. A useful application in

aerospace that we are studying is the improvement of electrical properties of composites made

from carbon nanotubes and epoxy resin. Carbon nanotubes were synthesized by thermal arc

plasma process after optimization of the synthesis parameters. These samples were then

analysed by electron microscopes like scanning electron and transmission electron microscopes

(SEM and TEM), in order to establish the morphology of the nanostructures. Atomic force

microscopy (AFM) and electron diffraction studies were also carried out before using the sample

for the composite material preparation.

Composites of epoxy resin with curing agent as well as a mixture of graphite

and carbon nanotubes were prepared with varying proportions of the mixture. The electrical

resistivity of the material was studied under varying humidity, temperature and voltage

conditions. The results of these studies present interesting features which are useful in choosing

the ideal composition and ratio of the composite material for use in shielding of electrical

circuits of space vehicles from radiations of the outer space.

ROCKET FUELS UTI LI SI NG NANOTECHNOLOGY:

Several aerospace firms have programmes under way for the use of nanosized

particles of aluminium or hafnium for rocket propulsion applications. The improved burn and

the speed of ignition of such particles are significant factors for this market. Aluminized liquid

hydrocarbon propellant fuels would increase propulsion energy; particularly in volume limited

systems through the utilization of nanosize aluminium.

Rocket-fuel additives containing iron-oxide particles 3nm wide can act as a

catalyst to convert solid propellants into gases that are burned when rockets or missiles are

launched, making it more reactive than traditional iron-oxide catalysts, allowing faster

conversion of the propellants and greater speed or range for the missiles.

An example of a future use of Nanotechnology in fuel is Nanogellant gelled

propellants. These gellants have a nanometre scale structure. The Nanogellent also has an

enormously high surface area per gram.Gelled fuel reduces leakage and increases safety.

Nanogellant for gelled cryogens has a surface area of nearly 1000m

2

/g, leading to cryogenic

fuels gelled with 25-50% less mass than traditional gellant material. Another use is the

Nanoparticulate of aluminium which can be used for jet fuels. These smaller particles allow for

more efficient combustion and lower specific fuel consumption. It is hoped the adoption of both

nano fuels will be seen used for the next generation of aerospace vehicles.

NANOSATELLI TES:

Nanosatellites are miniature, intelligent LEO satellites weighing from 5to10

kilograms. Nanosatellites can be designed using silicon micromachining and micropropulsion

techniques.These nanosatellites can be effectively used for disaster management , small span

communications and environmental monitoring.

Low cost nanosatellite with GPS System which could effectively be used for tsunami

warning system. With the aid of silicon micromachining technique, miniature semiconductor

components can be fabricated for this tiny satellite. Nanotechnology forms the backbone of

micromachining technique.

In India, nanosatellites will effectively serve in disaster management especially this

satellite can be used with Tsunami warning system. Using GPS and four such nanosatellites, the

reciever position (latitude , longitude , and altitude) can be determined accurately.

The production of micronanosatellites will lead to two main advantages: a reduction of

costs in launching the satellite due to their lower mass, and with the same weight launched, there

will be an increased number of functionalities in orbit.

SPACE ELEVATOR:

Experts proposed a space elevator, a cable extending from the Earth's surface into

space with a center of mass at geosynchronous altitude. If such a system could be built, it should

be mechanically stable and vehicles could ascend and descend along the cable at almost any

reasonable speed using electric power. The first incredibly difficult problem with building a

space elevator is strength of materials. Maximum stress is at geosynchronous altitude so the

cable must be thickest there and taper exponentially as it approaches Earth.

Any potential material may be characterized by the taper factor -- the ratio

between the cable's radius at geosynchronous altitude and at the Earth's surface. For steel the

taper factor is tens of thousands - clearly impossible. Diamond is, however, brittle. Carbon

nanotubes have a strength in tension similar to diamond, but bundles of these nanometer-scale

radius tubes shouldn't propagate cracks nearly as well as the diamond tetrahedral lattice.

Thus, if the considerable problems of developing a molecular nanotechnology capable of

making nearly perfect carbon nanotube systems approximately 70,000 kilometers long can be

overcome, the first serious problem of a transportation system capable of truly large scale

transfers of mass to orbit can be solved. The next immense problem with space elevators is safety

-- how to avoid dropping thousands of kilometers of cable on Earth if the cable breaks.

How NASA is Planning to Use Nanotechnology in its Space Projects:

NASA is the world's leading organization for aeronautical research.

It's world-class capability is built on a tradition of expertise in aeronautical engineering and its

core research areas, including aerodynamics, aeroacoustics, materials and structures,

propulsion, dynamics and control, sensor and actuator technologies, advanced computational

and mathematical techniques, and experimental measurement techniques. Beginning with

theoretical insight, augmented by research and testing in the laboratory and in flight, NASA

scientists and engineers develop and use rich databases of information, unique analytical tools,

and their singular expertise to close the gap between empirical and abstract knowledge. This

leads to design better tools and technologies for improving vehicle and air system safety and

performance.

Many of the nanotechnology objectives of NASA aim at a long-term

time horizon, and are more or less visionary at present. One main goal is a significant increase

in spacecraft capabilities with simultaneous mass reduction and miniaturization, which can not

be achieved with conventional technologies. A new era of robotic exploration of the solar system

is to be proposed by application of nanotechnology, among other technologies, through the

development of small economical spacecrafts with high autonomy and improved capabilities.

Furthermore, nanotechnological diagnostics and therapy procedures will improve life support

systems, and an autonomous medical supply for astronauts which will pave the way for long-

term and more complex manned space missions.

Status of I ndia:

India,a late starter in nanotechnology, sputtered along in fits and starts before

readying for take-off. While there is support for the sector at the highest scientific levels, funding

remains low. And with negligible interest from industry and only a small pool of skilled

scientists, India is a long way from using nanoscience to solve its problems.

It seems that India has not learnt any lessons from the past. It missed the

microelectronics revolution of the 1970s and 1980s through a lack of timely investment, and was

no wiser in the 1990s when nanoscience emerged, now we have to create the technical

manpower to work in this emerging field. We have to train students, teachers and research

scholars. Unless we do this, there will not be enough work happening in this area in the near

future.

There has been some very good work from some of the laboratories, particularly

from Bangalore, in synthesising and characterising a large variety of new materials.This centre

will include pilot-scale facilities for producing and manipulating carbon nanotubes, ceramic and

polymer composites.

FAQ:

Most space enthusiasts are disappointed with the current state of space

exploration. To what extent will nanotechnology facilitate the exploration of

space?

=>Nanotech would be a great help in reaching space and living in space. Aerospace

hardware would be many times lighter, which saves fuel. Avionics would be literally billions of

times lighter. That's just with first-stage molecular nanotech that can only build diamondoid.

Advanced mechanochemistry would allow 100% recycling--life support--in a very small box. No

more worries about how to grow wheat in zero-G. Nanotechnology makes a lot cheaper to reach

orbit because most of the energy input is not from chemical fuel. Nanotech will also reduce the

need for space access. When we can build anything we want with carbon, we won't have to go

after metal-rich asteroids. When our technology is 10 to 100 times more efficient, we'll be easier

on the environment down here.

Assuming diamondoid materials we can predicted the performance of

several existing single-stage-to-orbit (SSTO) vehicle designs. The predicted payload to dry mass

ratio for these vehicles using titanium as a structural material varied from < 0 to 36%, i.e., the

vehicle weighs substantially more than the payload. With hypothetical diamondoid materials the

ratios varied from 243% to 653%, i.e., the payload weighs far more than the vehicle.

CONCLUSI ON:

Many of the applications discussed here are speculative to say the least. However, they

do not appear to violate the laws of physics. Something similar to these applications at these

performance levels should be feasible if we can gain complete control of the three-dimensional

structure of materials, processes and devices at the atomic scale.

How to gain such control is a major, unresolved issue. However, it is clear that

computation will play a major role regardless of which approach -- positional control with

replication, self-assembly, or some other means -- is ultimately successful.

As nanotechnology progresses we may expect applications to become feasible at a

slowly increasing rate. However, if and when a general purpose programmable

assembler/replicator can be built and operated, we may expect an explosion of applications.

Nanotechnology advocates and detractors are often preoccupied with the question

"When?" There are three interrelated answers to this question:

=>Nobody knows. There are far too many variables and unknowns. Beware of those who

have excessive confidence in any date.

=>The time-to-nanotechnology will be measured in decades, not years. While a few

applications will become feasible in the next few years.

=>The time-to-nanotechnology is very sensitive to the level of effort expended. Resources

allocated to developing nanotechnology are likely to be richly rewarded, particularly in the long

term.

In recent years every country is showing a lot of interest regarding the space

exploration programs.And, hence let's expect a faster growth of nanotechnology in aerospace-

applications.

Das könnte Ihnen auch gefallen

- Molecular Nanotechnology in Aerospace: 1999: Richard P. Feynman's Visionary Talk at CaltechDokument43 SeitenMolecular Nanotechnology in Aerospace: 1999: Richard P. Feynman's Visionary Talk at CaltechVisinoae AndreiNoch keine Bewertungen

- Essentials of Lasers: The Commonwealth and International Library: Selected Readings in PhysicsVon EverandEssentials of Lasers: The Commonwealth and International Library: Selected Readings in PhysicsNoch keine Bewertungen

- High Tc Superconductors: Electronic StructureVon EverandHigh Tc Superconductors: Electronic StructureA. BianconiNoch keine Bewertungen

- 1900 45 From atom models to atomic bomb-Year 1945- English Edition: Year 1945 VolumeVon Everand1900 45 From atom models to atomic bomb-Year 1945- English Edition: Year 1945 VolumeNoch keine Bewertungen

- Surfaces and Interfaces: Physics and ElectronicsVon EverandSurfaces and Interfaces: Physics and ElectronicsR.S. BauerNoch keine Bewertungen

- Introduction to Gas Lasers: Population Inversion Mechanisms: With Emphasis on Selective Excitation ProcessesVon EverandIntroduction to Gas Lasers: Population Inversion Mechanisms: With Emphasis on Selective Excitation ProcessesNoch keine Bewertungen

- Advances in Materials: Proceedings of a Symposium Organised by the North Western Branch of the Institution of Chemical Engineers Held at Manchester, 6–9 April, 1964Von EverandAdvances in Materials: Proceedings of a Symposium Organised by the North Western Branch of the Institution of Chemical Engineers Held at Manchester, 6–9 April, 1964Noch keine Bewertungen

- Microwave Electronics: Measurement and Materials CharacterizationVon EverandMicrowave Electronics: Measurement and Materials CharacterizationNoch keine Bewertungen

- Nanotechnology in Aerospace Industry 12.42.21 PMDokument28 SeitenNanotechnology in Aerospace Industry 12.42.21 PMAkshay HegdeNoch keine Bewertungen

- On War (Von Clausewitz, Carl Maude, F.N. Willmot Etc.)Dokument557 SeitenOn War (Von Clausewitz, Carl Maude, F.N. Willmot Etc.)Valantis TheocharidisNoch keine Bewertungen

- NANOTECHNOLOGYDokument28 SeitenNANOTECHNOLOGYAndrea Jashan FerryNoch keine Bewertungen

- Space Nanotechnology VDIDokument135 SeitenSpace Nanotechnology VDIkrithika rajendran100% (1)

- Aerospace Technologies Advancements PDFDokument514 SeitenAerospace Technologies Advancements PDFskilmag100% (1)

- Basic Process DiffusionDokument104 SeitenBasic Process DiffusionBalamurugan Velayutham100% (1)

- Optical Satellite Communication Space Terminal Tec PDFDokument11 SeitenOptical Satellite Communication Space Terminal Tec PDFMustafaNoch keine Bewertungen

- Space Micropropulsion SystemDokument37 SeitenSpace Micropropulsion Systemjidong jidongNoch keine Bewertungen

- Disadvantages of LCPDokument2 SeitenDisadvantages of LCPEdwin Okoampa BoaduNoch keine Bewertungen

- MSthesis Raja July2002Dokument152 SeitenMSthesis Raja July2002Rajasekarakumar VadapooNoch keine Bewertungen

- Risat I:: OrbitDokument35 SeitenRisat I:: OrbitNirmalrahul_1990Noch keine Bewertungen

- A Review On The Dielectric Materials For High EnerDokument15 SeitenA Review On The Dielectric Materials For High EnerTuhina Adit MaarkNoch keine Bewertungen

- Electromagnetic Bomb For Seminar in Electrical EngineeringDokument20 SeitenElectromagnetic Bomb For Seminar in Electrical Engineeringgourishankar2Noch keine Bewertungen

- Intro MechanicsDokument3 SeitenIntro MechanicsAlrizalNoch keine Bewertungen

- Electric Propulsion: Akash Kumar Chanchal 16AE60R08Dokument44 SeitenElectric Propulsion: Akash Kumar Chanchal 16AE60R08AkashNoch keine Bewertungen

- Shelby Bates Kevin Chun Eric GambillDokument64 SeitenShelby Bates Kevin Chun Eric GambillEricNoch keine Bewertungen

- Polymer Composites in Aviation Sector IJERTV6IS060291Dokument8 SeitenPolymer Composites in Aviation Sector IJERTV6IS060291rahul reddyNoch keine Bewertungen

- Project On: Submitted ByDokument16 SeitenProject On: Submitted Bypratibha bawankuleNoch keine Bewertungen

- Current Research: What Is NanotechnologyDokument4 SeitenCurrent Research: What Is NanotechnologyHamid HafeezNoch keine Bewertungen

- Module-4 Additive Manufacturing 18 SchemeDokument36 SeitenModule-4 Additive Manufacturing 18 SchemeSANTOSHNoch keine Bewertungen

- Applications of Nanotechnology - KSVDokument6 SeitenApplications of Nanotechnology - KSVvicksksNoch keine Bewertungen

- Nanomaterial PDFDokument5 SeitenNanomaterial PDFSetya AdjieNoch keine Bewertungen

- The Scope of NanotechnologyDokument24 SeitenThe Scope of NanotechnologyHarkirat BediNoch keine Bewertungen

- Reviewer STS ExamDokument18 SeitenReviewer STS ExamHera OneNoch keine Bewertungen

- Nanotechnology: The Limitless Possibilities of Tiny ScienceVon EverandNanotechnology: The Limitless Possibilities of Tiny ScienceNoch keine Bewertungen

- Ilm 8 - Chapter 8 PDFDokument11 SeitenIlm 8 - Chapter 8 PDFMarielle Eser JoseNoch keine Bewertungen

- Heart Erica B. Abag 10:00-11:00 44188Dokument7 SeitenHeart Erica B. Abag 10:00-11:00 44188Heart Erica AbagNoch keine Bewertungen

- Applications of Nano MaterialsDokument7 SeitenApplications of Nano Materials78956Noch keine Bewertungen

- Ashis Rana Singh Regd No-2101287485Dokument22 SeitenAshis Rana Singh Regd No-2101287485q8vie2eropNoch keine Bewertungen

- Seminar ReportDokument36 SeitenSeminar ReportAbhinav RajNoch keine Bewertungen

- NanotechnologyDokument52 SeitenNanotechnologySomayya AnsaryNoch keine Bewertungen

- Chapter 3. Nano Technology in Industrial Wastewaters TreatmentDokument121 SeitenChapter 3. Nano Technology in Industrial Wastewaters TreatmentSophie LvNoch keine Bewertungen

- Study About Scope of Nano Technology in Real World Past, Present and FutureDokument3 SeitenStudy About Scope of Nano Technology in Real World Past, Present and FutureSAMI UR REHMANNoch keine Bewertungen

- Nano 6Dokument1 SeiteNano 6api-3761679Noch keine Bewertungen

- NanoDokument6 SeitenNanoshivani saiNoch keine Bewertungen

- Am. J. Applied Sci., 9 (6) : 784-793, 2012: Materials and MethodsDokument9 SeitenAm. J. Applied Sci., 9 (6) : 784-793, 2012: Materials and MethodsKareem_adel_000Noch keine Bewertungen

- Shivanand SeminarDokument17 SeitenShivanand SeminarVenkat SaiNoch keine Bewertungen

- Lecture40 NptelDokument37 SeitenLecture40 NptelSitaramaraju VengalarajuNoch keine Bewertungen

- An Overview On Application of Nanotechnology in Construction IndustryDokument5 SeitenAn Overview On Application of Nanotechnology in Construction IndustryNel HenaoNoch keine Bewertungen

- Composed of Nanotubes Membrane Filtration Technique UltrafiltrationDokument4 SeitenComposed of Nanotubes Membrane Filtration Technique UltrafiltrationAbubacker SiddiqNoch keine Bewertungen

- Topic 7 NanotechnologyDokument8 SeitenTopic 7 NanotechnologyAngel Lou DagalaNoch keine Bewertungen

- Nanotechnology: S. Tom PicrauxDokument18 SeitenNanotechnology: S. Tom PicrauxrinilkvNoch keine Bewertungen

- Institute of Technology and Science Proddatur Kadapa: Vignan BharathiDokument12 SeitenInstitute of Technology and Science Proddatur Kadapa: Vignan BharathiYsr Reddy JaganNoch keine Bewertungen

- Nanotechnology:: The God of Small ThingsDokument41 SeitenNanotechnology:: The God of Small ThingsBiswajit PaulNoch keine Bewertungen

- Nano - MechDokument13 SeitenNano - MechPulsarpriyaNoch keine Bewertungen

- Systems Engineering For NanosystemsDokument41 SeitenSystems Engineering For NanosystemsincosewmaNoch keine Bewertungen

- Nanotechnology The New Era of Science FDokument134 SeitenNanotechnology The New Era of Science FammukartiNoch keine Bewertungen

- By 090913131431 Phpapp02Dokument22 SeitenBy 090913131431 Phpapp02Vaibhav DahiyaNoch keine Bewertungen

- Carbon Nanotube: A Future MaterialsDokument12 SeitenCarbon Nanotube: A Future MaterialsJayanth MurthyNoch keine Bewertungen

- A Nanotechnology Aircraft With Stealth TechnologyDokument6 SeitenA Nanotechnology Aircraft With Stealth TechnologyABUBAKAR ALINoch keine Bewertungen

- Nr-40 Multiferroics MaterialsZSurowiakDBochenekDokument49 SeitenNr-40 Multiferroics MaterialsZSurowiakDBochenekSmitha KollerahithluNoch keine Bewertungen

- Nano Tech BookDokument112 SeitenNano Tech BookKenneth LeeNoch keine Bewertungen

- Wilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EEDokument288 SeitenWilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EESmitha Kollerahithlu70% (10)

- Metallic ImplantsDokument38 SeitenMetallic ImplantsSmitha Kollerahithlu100% (1)

- Nano in Agriculture - Scope & Current Relevance PDFDokument26 SeitenNano in Agriculture - Scope & Current Relevance PDFSmitha KollerahithluNoch keine Bewertungen

- Nanotechnologies in AgricultureDokument10 SeitenNanotechnologies in AgricultureSmitha KollerahithluNoch keine Bewertungen

- Ijftr 33 (3) 304-317Dokument14 SeitenIjftr 33 (3) 304-317Dulce BaezaNoch keine Bewertungen

- Pre Regulatory MedicineDokument14 SeitenPre Regulatory MedicineSmitha KollerahithluNoch keine Bewertungen

- Wilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EEDokument288 SeitenWilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EESmitha Kollerahithlu70% (10)

- ThermodynamicsDokument15 SeitenThermodynamicsSmitha KollerahithluNoch keine Bewertungen

- CMOS Process: Material Mainly Taken From UMBC, Kang and CampbellDokument38 SeitenCMOS Process: Material Mainly Taken From UMBC, Kang and CampbellSmitha KollerahithluNoch keine Bewertungen

- Materials Science & Engineering Introductory E-BookDokument13 SeitenMaterials Science & Engineering Introductory E-BookSmitha KollerahithluNoch keine Bewertungen

- Photo Induced Effects in Biological SystemsDokument25 SeitenPhoto Induced Effects in Biological SystemsSmitha KollerahithluNoch keine Bewertungen

- Centrosome CentriolesDokument9 SeitenCentrosome CentriolesSmitha KollerahithluNoch keine Bewertungen

- Cell Division: Mitosis and MeiosisDokument31 SeitenCell Division: Mitosis and MeiosisSmitha KollerahithluNoch keine Bewertungen

- Titanium Dioxide (Tio) : Epidemiol 1998 148: 241-248Dokument10 SeitenTitanium Dioxide (Tio) : Epidemiol 1998 148: 241-248Smitha KollerahithluNoch keine Bewertungen

- FactSheet PseudomonasDokument3 SeitenFactSheet PseudomonasSmitha KollerahithluNoch keine Bewertungen

- Water Quality MonitoringDokument3 SeitenWater Quality MonitoringJoa YupNoch keine Bewertungen

- Useful C Library FunctionDokument31 SeitenUseful C Library FunctionraviNoch keine Bewertungen

- C779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesDokument7 SeitenC779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesFahad RedaNoch keine Bewertungen

- Pre-Qin Philosophers and ThinkersDokument22 SeitenPre-Qin Philosophers and ThinkersHelder JorgeNoch keine Bewertungen

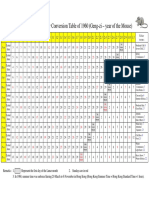

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Dokument1 SeiteGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamNoch keine Bewertungen

- Mooka Panchsati Arya SatakamDokument18 SeitenMooka Panchsati Arya SatakamPrasad Raviprolu100% (1)

- CSMP77: en Es FRDokument38 SeitenCSMP77: en Es FRGerson FelipeNoch keine Bewertungen

- Linguistic LandscapeDokument11 SeitenLinguistic LandscapeZara NurNoch keine Bewertungen

- Centiloquium of PtolemyDokument37 SeitenCentiloquium of PtolemyNatasa Karalic Koprivica100% (9)

- FinancialAccountingTally PDFDokument1 SeiteFinancialAccountingTally PDFGurjot Singh RihalNoch keine Bewertungen

- Salik Sa Mga Estudyante NG Hindi Wastong Pagsuot NG Uniporme NG Senior High School Sa Paaralang Ama Computer College Fairview CampusDokument1 SeiteSalik Sa Mga Estudyante NG Hindi Wastong Pagsuot NG Uniporme NG Senior High School Sa Paaralang Ama Computer College Fairview CampusIsrael ManansalaNoch keine Bewertungen

- Ap Reg W# 5-Scaffold For Transfer TemplateDokument2 SeitenAp Reg W# 5-Scaffold For Transfer TemplateJunafel Boiser Garcia100% (2)

- Worship Aid - May Crowning 2020Dokument5 SeitenWorship Aid - May Crowning 2020Kevin RyanNoch keine Bewertungen

- Introduction To Hydraulic System in The Construction Machinery - Copy ALIDokument2 SeitenIntroduction To Hydraulic System in The Construction Machinery - Copy ALImahadNoch keine Bewertungen

- Solution Manual For C How To Program 8th Edition Paul J Deitel Harvey DeitelDokument34 SeitenSolution Manual For C How To Program 8th Edition Paul J Deitel Harvey Deiteldryas.czech0gkl100% (47)

- Dispersion Relation of Electromagnetic WavesDokument2 SeitenDispersion Relation of Electromagnetic WavesFidel SouzaNoch keine Bewertungen

- AMST 398 SyllabusDokument7 SeitenAMST 398 SyllabusNatNoch keine Bewertungen

- I. Errors, Mistakes, Accuracy and Precision of Data Surveyed. A. ErrorsDokument53 SeitenI. Errors, Mistakes, Accuracy and Precision of Data Surveyed. A. ErrorsJETT WAPNoch keine Bewertungen

- Solution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan MchughDokument36 SeitenSolution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan Mchughquoterfurnace.1ots6r100% (51)

- Allowable Nozzle LoadsDokument6 SeitenAllowable Nozzle Loads김동하Noch keine Bewertungen

- Asia Pacific SAR Plan V2.0Dokument38 SeitenAsia Pacific SAR Plan V2.0Joci SimõesNoch keine Bewertungen

- Ga-Ta10 (LHH)Dokument181 SeitenGa-Ta10 (LHH)Linh T.Thảo NguyễnNoch keine Bewertungen

- T.Y.B.B.A. (CA) Sem VI Practical Slips 2019 PatternDokument30 SeitenT.Y.B.B.A. (CA) Sem VI Practical Slips 2019 PatternJai Ramteke100% (2)

- Year 10 English Unit Plan AdvertisingDokument5 SeitenYear 10 English Unit Plan Advertisingapi-333849174Noch keine Bewertungen

- Joy BoosterDokument2 SeitenJoy BoosterAlexsandro TorezinNoch keine Bewertungen

- Some Sunsickday - Kitchenro11Dokument356 SeitenSome Sunsickday - Kitchenro11Spencer HNoch keine Bewertungen

- Kyoto Seika UniversityDokument27 SeitenKyoto Seika UniversityMalvinNoch keine Bewertungen

- Group Screening Test, English 6Dokument4 SeitenGroup Screening Test, English 6Jayson Alvarez MagnayeNoch keine Bewertungen

- TCC Number 153-4-4Dokument1 SeiteTCC Number 153-4-4jeremie gamonNoch keine Bewertungen

- VukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedDokument19 SeitenVukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedputhenkulamNoch keine Bewertungen