Beruflich Dokumente

Kultur Dokumente

BA1011 Intellegent Pump Control Brochure FINAL LR

Hochgeladen von

Hamed GeramiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BA1011 Intellegent Pump Control Brochure FINAL LR

Hochgeladen von

Hamed GeramiCopyright:

Verfügbare Formate

Advanced control technology, intelligently applied.

TM

Advanced control technology, intelligently applied.

TM

PUMP

CONTROL

I

N

T

E

L

L

I

G

E

N

T

BRIGHT INTEGRATED

PRODUCTION FIELD SYSTEM

Bright Automation offers the only fully functional production eld automation system in the industry to

utilize advanced Bright VSD lift control technology. The Bright eld system provides full remote monitor

and control of up to 200 pumping units in a single eld, offering the following capabilities

Automatic speed optimization

Automatic auxiliary counterweight adjustment

Parameter optimization for reduced energy consumption

Remote start / stop

Condition analysis

Precise energy management

Display of status, speed, load, and faults for each pump in the eld

RAISING THE BAR

IN INTELLIGENT PUMP CONTROL

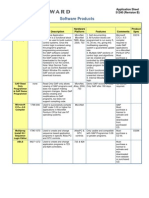

SYSTEM OPTIONS

FOR A RANGE OF OPERATOR NEEDS

Bright articial lift control systems provide smart technology that is unequaled in the industry.

Our systems are designed for reliable, high-performance control of pumping unit functions, from

simple timed off-on controls to the industrys only remote, automatic counterbalance adjustment

system. In addition, Bright lift control systems are proven reliable,

with thousands successfully operating in the most extreme hot,

cold, wet, and dusty environmental conditions.

Bright Automation offers a wide selection of articial lift control products, from simple to the

most sophisticated systems in the industry, in order to meet a wide range of industry needs.

The companys line of products includes:

Bright II, III, and IV Automation Systems these three advanced automation systems can each generate

a wide range of data in order to alert you to potential failures and production declines. These systems can also

produce surface cards, and allow download of all data to a computer via the Web or USB port.

Bright I Control Panel

this proven unit provides

reliable, basic control of timed runs, in addition to start

and stop functions.

Bright II Pump-Off Controller

will run a wide

range of custom programs and alert operators to poten-

tial problems and operator-selected conditions. Pumping

programs can be directly input into the control box or via

Web interface, using selection options that include a wide

range of industry parameters. This capability allows the

Bright II to maximize production through more efcient

run times and reduce power consumption.

The Bright II can transmit email or texts, alerting

operators to conditions which may indicate a potential

problem or need to modify a setting. In addition, should

problems arise that are outside of the running program,

the Bright II will preemptively shut down the pumping

unit before serious damage to equipment can occur.

Bright III VSD Controller

sets a new industry

standard for VSD sophistication and performance. Utilizing

advanced self-programming technology, the Bright III

requires minimal operator involvement, other than input

of the most basic parameters. This VSD combines data

from position sensors and a load cell with operator-input

parameters. From this combination of data, the Bright III

automatically adjusts the speed and optimizes the run

times of the pumping unit to achieve highest pump llage

and production levels.

The Bright III slows the pumping unit to a minimum

speed when production or peak run times are met. This

capability helps eliminate cold starts, power spikes, and

prime mover overloads, protecting the pumping unit,

prime mover, rods, and downhole pump. The Bright III

also identies stresses and loading issues, and slows

or shuts down the system before damage occurs.

Proven in hundreds of demanding applications, this

VSD also offers the latest in communications protocols

and provides for remote control of all functions.

BRIGHT III

VSD CONTROLLER

Bright IV Intelligent VSD Controller

in addition

to offering all of the monitoring and control capabilities

of the Bright II and III, the Bright IV is also able to

automatically adjust an auxiliary counterbalance located

on the pumping unit, in response to changing pumping

conditions. Utilizing sophisticated algorithms to process

data from the pumping unit, the Bright IVs VSD controller

automatically adjusts the beam-mounted, adjustable

auxiliary counterweight to provide the industrys closest

match to the mythical perfect balance status.

With the Bright IV providing for automatic adjustment

of the auxiliary counterbalance, the operator is able to

signicantly cut the frequency of eld crews being called

on to balance pump units. With less time dedicated to

balancing pumping units, the potential for safety events

is dramatically reduced, as is pumping downtime. In

addition, a pumping unit that is continuously balanced by

the Bright IV system has been demonstrated to consume

40 50% less energy to operate.

Advanced control technology, intelligently applied.

TM

Advanced control technology, intelligently applied.

TM

Bright Automation, Inc.

PMB 308

15814 Champion Forest Dr.

Spring, TX 77379-1184

Phone:

Main: 713-560-1395

Fax: 281-520-4618

www.BrightAutomation.com

Info@BrightAutomation.com

BA1011 0213 250

Bright Automation is an energy industry leader in the electronic

monitoring and control products and systems, offering a broad

range of advanced drilling products including VFDs, SCRs, top

drive control systems, and auto-drilling systems in addition to

its industry leading line of lift control systems.

Bright brings an intense focus to the application of its proprietary

engineering technology. With this commitment to improving

efciencies and simplifying operations, Bright can deliver a spectrum

of advanced systems for drilling and production operations, which

are redening the monitor and control functions.

Das könnte Ihnen auch gefallen

- Arduino Uno CNC ShieldDokument11 SeitenArduino Uno CNC ShieldMărian IoanNoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneVon EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNoch keine Bewertungen

- Control System For Mobile ApplicationsDokument8 SeitenControl System For Mobile ApplicationsAli Zamani100% (1)

- Mark VI DescriptionDokument22 SeitenMark VI Descriptionprasobh_mr100% (1)

- 385C Waw1-Up PDFDokument4 Seiten385C Waw1-Up PDFJUNA RUSANDI SNoch keine Bewertungen

- Gea S1004 PDFDokument8 SeitenGea S1004 PDFmeirangongNoch keine Bewertungen

- SINOPEC PartnersEngDokument42 SeitenSINOPEC PartnersEngHamed GeramiNoch keine Bewertungen

- Grid Pattern PortraitDokument8 SeitenGrid Pattern PortraitEmma FravigarNoch keine Bewertungen

- Mozal Finance EXCEL Group 15dec2013Dokument15 SeitenMozal Finance EXCEL Group 15dec2013Abhijit TailangNoch keine Bewertungen

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusVon EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNoch keine Bewertungen

- 2014.05.09 GN Jet Mud Mixer MaualDokument17 Seiten2014.05.09 GN Jet Mud Mixer MaualHamed GeramiNoch keine Bewertungen

- GE SpeedTronics MarkVI Turbine ControlDokument22 SeitenGE SpeedTronics MarkVI Turbine ControlBijayananda Nayak100% (3)

- Mark VieDokument4 SeitenMark VieWalid Bahi100% (1)

- Simocode ProDokument34 SeitenSimocode ProGregory KingNoch keine Bewertungen

- Injection Molding ControlDokument15 SeitenInjection Molding ControlNalin T BandaraNoch keine Bewertungen

- Progressive Cavity PumpsDokument20 SeitenProgressive Cavity PumpsHamed Gerami100% (1)

- Integrated Turbine-Compressor ControlDokument8 SeitenIntegrated Turbine-Compressor ControlAbdul RohmanNoch keine Bewertungen

- WoodwardDokument4 SeitenWoodwarddatastageNoch keine Bewertungen

- 2016TMC-SchneiderElectricTMCSolutions Services and ExperienceDokument4 Seiten2016TMC-SchneiderElectricTMCSolutions Services and ExperienceIkhtiander IkhtianderNoch keine Bewertungen

- Norris Recommended Makeup Procedures T003 V02 081908 PDFDokument2 SeitenNorris Recommended Makeup Procedures T003 V02 081908 PDFHamed GeramiNoch keine Bewertungen

- Home Automation: A Complete Guide to Buying, Owning and Enjoying a Home Automation SystemVon EverandHome Automation: A Complete Guide to Buying, Owning and Enjoying a Home Automation SystemBewertung: 2 von 5 Sternen2/5 (2)

- T5 B11 Victor Manuel Lopez-Flores FDR - FBI 302s Re VA ID Cards For Hanjour and Almihdhar 195Dokument11 SeitenT5 B11 Victor Manuel Lopez-Flores FDR - FBI 302s Re VA ID Cards For Hanjour and Almihdhar 1959/11 Document Archive100% (2)

- HMIDokument447 SeitenHMIsokol_polece100% (2)

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFDokument19 SeitenGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- Steam Turbine Control and Safety - 51229 - D PDFDokument8 SeitenSteam Turbine Control and Safety - 51229 - D PDFharis tambunan100% (1)

- Burner Management SystemDokument11 SeitenBurner Management SystemMaurthi UppalapatiNoch keine Bewertungen

- 505 Enhanced: Digital Control For Steam Turbines (With Redundancy)Dokument5 Seiten505 Enhanced: Digital Control For Steam Turbines (With Redundancy)kazmi81Noch keine Bewertungen

- 2014.05.08 GNJBQ Agitator ManualDokument31 Seiten2014.05.08 GNJBQ Agitator ManualHamed Gerami100% (1)

- 2014.05.07 GNZS Linear Motion Shale ShakerDokument47 Seiten2014.05.07 GNZS Linear Motion Shale ShakerHamed Gerami100% (1)

- Sigma Control 2Dokument8 SeitenSigma Control 2aljavier1004Noch keine Bewertungen

- Seabank Statement 20220726Dokument4 SeitenSeabank Statement 20220726Alesa WahabappNoch keine Bewertungen

- Introduction To AutomationDokument20 SeitenIntroduction To AutomationGourav Solanki100% (1)

- Micronet SoftwaresDokument4 SeitenMicronet SoftwaresHasan FarooqNoch keine Bewertungen

- Participants ListDokument13 SeitenParticipants Listmailway002Noch keine Bewertungen

- Student Management SystemDokument232 SeitenStudent Management Systemslu_mangal73% (37)

- DCS & MisDokument61 SeitenDCS & MisParmeshwar Nath Tripathi100% (1)

- Vs 20Dokument10 SeitenVs 20Mari PrunaNoch keine Bewertungen

- Famous Little Red Book SummaryDokument6 SeitenFamous Little Red Book SummaryMatt MurdockNoch keine Bewertungen

- CE Jan 2013Dokument68 SeitenCE Jan 2013Jose PeñaNoch keine Bewertungen

- Features: Electronic Preset Delivery SystemDokument6 SeitenFeatures: Electronic Preset Delivery Systemcemcem mecemNoch keine Bewertungen

- D Woodward Integrated Compressor Control Afjfkjfj FJFJFJFDokument5 SeitenD Woodward Integrated Compressor Control Afjfkjfj FJFJFJFDiego PareschiNoch keine Bewertungen

- Sicam 230 Brochure enDokument8 SeitenSicam 230 Brochure enLuis Enrique PariapazaNoch keine Bewertungen

- Acuvim L Power Meter User ManualDokument154 SeitenAcuvim L Power Meter User ManualThi Ha Yu SheinNoch keine Bewertungen

- Gas System and Solution Overview Smart Gas Metering/Advanced Metering InfrastructureDokument17 SeitenGas System and Solution Overview Smart Gas Metering/Advanced Metering InfrastructureLuis Ballesteros ChoqueNoch keine Bewertungen

- FC360 Selection GuideDokument16 SeitenFC360 Selection GuideMukund FarjandNoch keine Bewertungen

- SkidWeigh Plus, ED2 Series For Lift Truck FleetsDokument2 SeitenSkidWeigh Plus, ED2 Series For Lift Truck FleetsTed JurcaNoch keine Bewertungen

- 505XT Digital Control: ApplicationsDokument6 Seiten505XT Digital Control: ApplicationsdavonesNoch keine Bewertungen

- 5B. - Steam Turbine Control - Petrotech PDFDokument4 Seiten5B. - Steam Turbine Control - Petrotech PDFJaviStg1100% (1)

- 5939 VM600 Integrated-BrochureDokument8 Seiten5939 VM600 Integrated-BrochurescribdkhatnNoch keine Bewertungen

- PEEDTRONICTM Mark VI For Gas Turbine Control RetrofitsDokument20 SeitenPEEDTRONICTM Mark VI For Gas Turbine Control Retrofitsewok2030100% (1)

- Altronic de 3000Dokument93 SeitenAltronic de 3000Mohammad AliNoch keine Bewertungen

- 100 - 505XT Digital ControlDokument5 Seiten100 - 505XT Digital ControlWilliam Will Controle WoodwardNoch keine Bewertungen

- 8e294532 24Dokument96 Seiten8e294532 24Ignacio MarínNoch keine Bewertungen

- ReportDokument8 SeitenReportWaqas AhmedNoch keine Bewertungen

- Trakker IIProd Info 2Dokument2 SeitenTrakker IIProd Info 2Ahmed MagdyNoch keine Bewertungen

- Ds TMF Mfs MFC EngDokument12 SeitenDs TMF Mfs MFC EngBharathi RajaNoch keine Bewertungen

- Banas DairyDokument5 SeitenBanas DairyManjari MundanadNoch keine Bewertungen

- 09 # Flexible Motor ControlDokument4 Seiten09 # Flexible Motor ControlRaj ChavanNoch keine Bewertungen

- Manual-Motor de Gasolina Cm11 MkiiDokument4 SeitenManual-Motor de Gasolina Cm11 MkiiNallely MassoNoch keine Bewertungen

- What Is AutomationDokument2 SeitenWhat Is AutomationFaiz Syed MohammedNoch keine Bewertungen

- System 800xa Control and I o OverviewDokument16 SeitenSystem 800xa Control and I o OverviewGabriel Maxo PapagalloNoch keine Bewertungen

- Industrial Automation Systems Part 1Dokument62 SeitenIndustrial Automation Systems Part 1Mohamedi ShafiiNoch keine Bewertungen

- GDGDFDokument8 SeitenGDGDFHoàng Minh ÁiNoch keine Bewertungen

- Fanuc IC697VRD008 User ManualDokument59 SeitenFanuc IC697VRD008 User ManualsunhuynhNoch keine Bewertungen

- Industrial Automation ReadingDokument33 SeitenIndustrial Automation Readingsaurabhrai85Noch keine Bewertungen

- Control Engineering 05 2013Dokument84 SeitenControl Engineering 05 2013Edgar Rojas ZAcarias100% (1)

- I-Monitor Flyer - 01-14-10Dokument2 SeitenI-Monitor Flyer - 01-14-10Novan WPNoch keine Bewertungen

- Shedule GAs BoyDokument4 SeitenShedule GAs BoyChristian Alberto Soto MullerNoch keine Bewertungen

- Csi 4500Dokument16 SeitenCsi 4500Harold AlconzNoch keine Bewertungen

- 08-45.2 E SW MCal200Dokument2 Seiten08-45.2 E SW MCal200ctmtectrolNoch keine Bewertungen

- 0201 MACH7 Hot Redundant PDFDokument8 Seiten0201 MACH7 Hot Redundant PDFSyed Mohammed HussainNoch keine Bewertungen

- 85-ODP2B-In V3.03 Optidrive P2 BrochureDokument12 Seiten85-ODP2B-In V3.03 Optidrive P2 BrochureHamed GeramiNoch keine Bewertungen

- Al14 0056 en Rev00 Grenco Pcpwelldata Metric 081114 WebDokument1 SeiteAl14 0056 en Rev00 Grenco Pcpwelldata Metric 081114 WebHamed GeramiNoch keine Bewertungen

- Rare Photos of CelebritiesDokument60 SeitenRare Photos of CelebritiesHamed GeramiNoch keine Bewertungen

- Photos by Laurent SchwebelDokument51 SeitenPhotos by Laurent SchwebelHamed GeramiNoch keine Bewertungen

- A-ESP-V Water Injection Pumping SystemDokument1 SeiteA-ESP-V Water Injection Pumping SystemHamed GeramiNoch keine Bewertungen

- Omar Vetrano English ADokument3 SeitenOmar Vetrano English AHamed GeramiNoch keine Bewertungen

- ESP Training 1 AL SLB Introduction 19 Pgs PDFDokument19 SeitenESP Training 1 AL SLB Introduction 19 Pgs PDFHamed Gerami100% (1)

- FreetDokument32 SeitenFreetHamed GeramiNoch keine Bewertungen

- Norris Recommended Makeup Procedures T003 V02 081908Dokument2 SeitenNorris Recommended Makeup Procedures T003 V02 081908Hamed Gerami100% (1)

- Schlumberger Technology v. Borets Weatherford Et. Al.Dokument6 SeitenSchlumberger Technology v. Borets Weatherford Et. Al.PriorSmartNoch keine Bewertungen

- Installation Tools and Spare PartsDokument1 SeiteInstallation Tools and Spare PartsHamed GeramiNoch keine Bewertungen

- Features: - Automatic Speed Adjustment - Embedded DBR - Easy Installation, Operation, and MaintenanceDokument2 SeitenFeatures: - Automatic Speed Adjustment - Embedded DBR - Easy Installation, Operation, and MaintenanceHamed GeramiNoch keine Bewertungen

- File 1487Dokument8 SeitenFile 1487Hamed GeramiNoch keine Bewertungen

- File 1488Dokument8 SeitenFile 1488Hamed GeramiNoch keine Bewertungen

- Signature Object Detection Based On YOLOv3Dokument4 SeitenSignature Object Detection Based On YOLOv3Lý Khánh NhưNoch keine Bewertungen

- ThorpeDokument267 SeitenThorpezaeem73Noch keine Bewertungen

- Facebook: Daisy BuchananDokument5 SeitenFacebook: Daisy BuchananbelenrichardiNoch keine Bewertungen

- ALE Manual For LaserScope Arc Lamp Power SupplyDokument34 SeitenALE Manual For LaserScope Arc Lamp Power SupplyKen DizzeruNoch keine Bewertungen

- Bba VDokument2 SeitenBba VkunalbrabbitNoch keine Bewertungen

- LspciDokument4 SeitenLspciregistroosNoch keine Bewertungen

- Alkosign Product CatalogeDokument20 SeitenAlkosign Product CatalogeShree AgrawalNoch keine Bewertungen

- Syllabus PDFDokument3 SeitenSyllabus PDFBibin Raj B SNoch keine Bewertungen

- Mosharaf HossainDokument2 SeitenMosharaf HossainRuhul RajNoch keine Bewertungen

- Binary OptionsDokument24 SeitenBinary Optionssamsa7Noch keine Bewertungen

- GE 7 ReportDokument31 SeitenGE 7 ReportMark Anthony FergusonNoch keine Bewertungen

- Basic Econometrics Questions and AnswersDokument3 SeitenBasic Econometrics Questions and AnswersRutendo TarabukuNoch keine Bewertungen

- 3 Diversion&CareDokument2 Seiten3 Diversion&CareRyan EncomiendaNoch keine Bewertungen

- Case Study - Kelompok 2Dokument5 SeitenCase Study - Kelompok 2elida wenNoch keine Bewertungen

- Alternative Network Letter Vol 7 No.1-Apr 1991-EQUATIONSDokument16 SeitenAlternative Network Letter Vol 7 No.1-Apr 1991-EQUATIONSEquitable Tourism Options (EQUATIONS)Noch keine Bewertungen

- Research 093502Dokument8 SeitenResearch 093502Chrlszjhon Sales SuguitanNoch keine Bewertungen

- Brigade Product Catalogue Edition 20 EnglishDokument88 SeitenBrigade Product Catalogue Edition 20 EnglishPelotudoPeloteroNoch keine Bewertungen

- Lab Report SBK Sem 3 (Priscilla Tuyang)Dokument6 SeitenLab Report SBK Sem 3 (Priscilla Tuyang)Priscilla Tuyang100% (1)

- S4 HANALicensing Model External V19Dokument28 SeitenS4 HANALicensing Model External V19Edir JuniorNoch keine Bewertungen

- 1 Bacterial DeseaseDokument108 Seiten1 Bacterial DeseasechachaNoch keine Bewertungen

- Smart Protein Plant Based Food Sector Report 2Dokument199 SeitenSmart Protein Plant Based Food Sector Report 2campeon00magnatesNoch keine Bewertungen