Beruflich Dokumente

Kultur Dokumente

Component Locations: 777F and 777F OEM Off-Highway Truck Hydraulic System

Hochgeladen von

MScLxOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Component Locations: 777F and 777F OEM Off-Highway Truck Hydraulic System

Hochgeladen von

MScLxCopyright:

Verfügbare Formate

R

E

N

R

8

3

0

5

-

0

2

V

O

L

1

o

f

2

3

0

P

a

g

e

,

(

D

i

m

e

n

s

i

o

n

s

:

3

9

i

n

c

h

e

s

x

2

8

i

n

c

h

e

s

)

ONE POSITION TWO POSITION THREE POSITION

VENTED PRESSURIZED RETURNABOVE FLUIDLEVEL RETURN BELOWFLUIDLEVEL

LINES CROSSING LINES J OINING

TWO-WAY THREE-WAY FOUR-WAY

SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION

(FIXED)

2-SECTION PUMP

MAIN AUX.

SPRING

(ADJ USTABLE)

VARIABILITY LINE RESTRICTION

(VARIABLE)

LINE RESTRICTION

VARIABLE and PRESSURE COMPENSATED

PRESSURE

COMPENSATION

PUMP: VARIABLE and

PRESSURE COMPENSATED

ENERGY TRIANGLES

HYDRAULIC PNEUMATIC

MEASUREMENT

PRESSURE TEMPERATURE FLOW

ROTATING SHAFTS

UNIDIRECTIONAL BIDIRECTIONAL

PUSH-PULL LEVER PEDAL GENERAL MANUAL PUSH BUTTON SPRING

MANUAL CONTROL SYMBOLS

HYDRAULIC MOTORS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

HYDRAULIC PUMPS

FLUID STORAGE RESERVOIRS

CROSSING AND JOINING LINES

VALVE ENVELOPES VALVE PORTS

BASIC COMPONENT SYMBOLS

FLUIDCONDITIONER PUMP or MOTOR

FLUID POWER SYMBOLS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

VALVES

PILOT CONTROL SYMBOLS

RELEASEDPRESSURE

EXTERNAL RETURN INTERNAL RETURN

REMOTE SUPPLY PRESSURE

SIMPLIFIED COMPLETE INTERNAL

SUPPLY PRESSURE

ACCUMULATORS

SPRING LOADED GAS CHARGED

SOLENOID

or MANUAL

SOLENOID

and PILOT

SOLENOIDand

PILOT or MANUAL

COMBINATION CONTROLS

SOLENOID SERVO THERMAL DETENT

HYDRAULIC AND PNEUMATIC CYLINDERS

DOUBLE ACTING SINGLE ACTING

BASIC

SYMBOL

SPRING

LOADED

CHECK VALVES

TWO

POSITION

INFINITE

POSITIONING

FLOWIN ONE

DIRECTION

FLOWALLOWEDIN

EITHER DIRECTION

THREE

POSITION

CROSS

FLOW PARALLEL

FLOW

INTERNAL PASSAGEWAYS

NORMAL POSITION

A B

P T

A B

P T

SHIFTEDPOSITION INFINITE POSITION

CONTROL VALVES

ATTACHMENT

MANUAL SHUTOFF

SHUTTLE PILOT

CONTROLLED

Hydraulic Symbols (Electrical)

Electrical Symbols Table

325-AG135 PK-14

Circuit Identification

Number

Wire Color Wire Gauge

Harness identification code

This example indicates

wire 135 in harness "AG".

325-PK-14

Wire Gauge

Wire Color

Circuit Number

Identification

Wire Number Identification Codes

Current Standard

Previous Standard

Electrical Schematic Example Hydraulic Schematic Example

325-PK

Wire Color Circuit Number

Identification

B A

Wire

Wire

(EXAMPLE VALVE)

Current Standard

Transducer

(Fluid)

Transducer

(Gas / Air)

G

Generator

Electrical Wire

Pressure Switch

M

Electric Motor

Pressure Switch

(Adjustable)

Temperature Switch

T

Pressure

Symbol

Temperature

Symbol

Level

Symbol

Flow

Symbol

Electrical Symbols (Electrical)

777F:

JRP1-UP

777F OEM:

JXP1-UP

Volume 1 of 2: Brakes and Hoist

2010 Caterpillar

All Rights Reserved

Printed in U.S.A.

RENR8305-02

J une 2010

777F and 777F OEM Of f -Hi ghway Tr uc k

Hydr aul i c Syst em

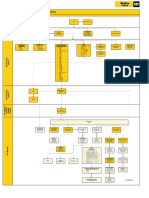

Item

Number

Description

Part

Number

Schematic

Location

1 TANK GP (HYD&TRANS) 258-9852 A-4

2A PUMP GP (BRAKE CHARGING) 255-5478 B-5

2B PUMP GP (BRAKE CHARGING) 256-0561 B-4

3 PUMP GP (BRAKE COOLING) 255-5478 B-4

4A PUMP GP (HOIST) 255-5478 B-4

4B PUMP GP (HOIST) 256-0561 B-4

5 VALVE GP- ACCUMULATOR CHARGING 257-0273 D-5

6 VALVE GP-MTG &(PARKING BRAKE) 289-0585 F-6

7 CONTROL GP-HYD(BRAKE RETRACT) 222-4744 D-7

8 ADJ USTER GP- SLACK 205-0557 D-8

9 ADJ USTER GP-SLACK 8X-7921 D-2

10 BRAKE GP-SERVICE &PARK 243-5545 B-8, F-8

11A BRAKE GP-SERVICE (FRONT BRAKES) 8X-3810 D-1, F-1

11B BRAKE GP-SERVICE (FRONT BRAKES) 243-5551 D-1, F-1

12 VALVE GP (CAB MANIFOLD) 261-1316 F-4

13 VALVE GP-CHECK 249-5521 E-4

14 SWITCH AS.- PRESSURE 3E-7806 E-4

15 PUMP GP-ELECTRIC (BRAKE RETRACT) 230-2637 D-5

16 VALVE GP-DIVERTER 3G-2887 E-6

17 VALVE GP-RELIEF 228-7839 E-5

18 FILTER (BREATHER) 8X-4575 A-6

19 SWITCH AS.-PRESSURE 160-2609 F-6

20 ACCUMULATOR GP (BRAKE) 220-5692 E-5

21 PEDAL GP-BRAKE VALVE 261-1317 F-3

22 VALVE GP-CONTROL (HOIST) 245-1668 B-3, C-3, D-3

23 CYLINDER GP-TELESCOPING (HOIST) 171-1232 A-3

24 PLATE-ORIFICE (HOIST) 8X-7224 A-3

26 SCREEN AS. 7J -3723 A-4

27 SCREEN AS. (BRAKE COOLING) 6E-6640 B-6, C-7

28 CORE AS.-OIL COOLER 141-4109 B-6, C-7

29 FILTER GP-OIL 155-6061 C-5

35 PUMP GP-ELECTRIC (STEERING) 230-2637 D-6

47 SCREEN AS. 7J -0725 A-5

54 PUMP GP-ELECTRIC (ENGINE OIL) 230-2637 D-5

58 VALVE GP-CHECK 185-4026 E-5

59 VALVE AS.-SHUTTLE 8J -6875 E-3

Component Locations (Volume 1)

Tap

Number

Description

Schematic

Location

A LEFT REAR SERVICE BRAKE F-8

B RIGHT REAR SERVICE BRAKE B-8

C REAR SLACK ADJ USTER INPUT D-8

D CAB MANIFOLDRESOLVER OUTPUT F-4

E ACCUMULATOR CHARGING OUTPUT D-4

F BRAKE CHARGING PUMP OUTPUT D-4

G LEFT PARK BRAKE D-7

H RIGHT PARK BRAKE C-7

I FRONT SLACK ADJ USTER INPUT E-1

J DRY FRONT BRAKE INPUT E-1

K CYLINDER HEADEND A-3

L CYLINDER RODEND A-3

M HOIST PUMP OUTPUT C-4

N HOIST VALVE RAISE PILOT D-3

O HOIST VALVE LOWER PILOT B-3

P BRAKE COOLING INPUT B-7

Tap Locations

Pressure, Sampling, and Sensor (Volume 1)

Purge Solenoid

COMPONENT LOCATIONS

BRAKING HOIST

10

7

23 24

16

1 26

17

18 2 3 4 20 5 14 11 29

9

21

12 14

35 15 54

27 28

11

8

6 19

22

10

23 24 59

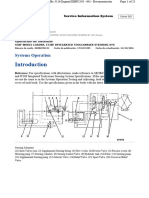

Showninthe visual is the newlocationof the hoist pump(4A, 4B). The hoist pumpis

a gear type pumpandis attachedto the brake coolingpump(3) andthe brake charg-

ing pump (2A, 2B). The hoist pump is now driven by the gears at the back of the

engine.

4A

3

2A

4B

2B

20

Showninthevisual arethethreebrakeaccumulators for the777F. Theaccumulators

(20) are charged by the brake charging pump and supply the required oil flow to

disengage the front and rear brakes. The outer accumulators are for the rear service

brakes. The middle accumulator is for the parking brake and front service brakes.

A check valve in the circuit between the parking accumulator and the rear service

accumulators allows only the parking brake accumulator to be filled when using the

secondary electric pump.

6

This visual shows the parking brake valve (6) for the 777F which is located on the

inside left frame rail behind the middle cross member. The parking brake release

valvenolonger works off pressurizedair. This valvereceives oil flowfromtheparking

brake accumulator. Contained within the valve is a parking brake solenoid valve (3)

and a purge solenoid valve (4).

Parking Brake Solenoid

B

F

Theaccumulator chargingvalve(5) is locatedontheleft sideof theframebythebrakeaccumulators This valve

directs oil to the brake accumulators, brake cooling, and the tank. Once the accumulators are charged, the

excess oil flowis sent to cool the brakes before returning to the tank.

The Brake ECMmonitors the pressure in the service brake accumulators with pressure switch. If the pressure

in the service brake accumulators are low, the pressure switch will open and the Brake ECM will signal the

monitoring systemto turn on the brake system-check indicator.

Pressure tap (B) is used to check the oil pressure in the service brake accumulators. Pressure tap (F) is used

to check the charge oil pressure fromthe pump.

The accumulator charging valve contains a CUT-IN/CUT-OUT spool. Once the maximum brake system

pressure is reached, the spool will shift and send the excess flow to brake cooling. As the systempressure

continues to drop to the CUT-IN pressure setting, the spool will shift again and the systemwill charge to the

CUT-OUT pressure setting. This process will continue to repeat as often as needed to keep the brake system

fully charged. The CUT-IN/CUT-OUT pressure is checked at pressure tap (B).

The relief valve setting is set slightly higher than the CUT-OUT pressure setting. In the event that the

CUT-IN/CUT-OUT valve spool fails, the relief valve will protect the systemfromextreme pressure. Relief valve

can only be tested on a hydraulic test bench.

If the charge oil pressure is lowat pressure tap (F), or the brake systemnever reaches the proper CUT-OUT

pressure, check relief valve. If relief valve is set properly and the brake systemis not reaching the specified

CUT-OUT pressure, replace the accumulator charging valve. The CUT-IN/CUT-OUT spool is not adjustable.

5

Relief Valve

Pressure Switch

29

The brake systemfilter (29) is located on the left outer frame rear next to the left rear strut mount.

The brake systemfilter has a bypass switch.

8

9

The 777F has two slack adjusters. The top visual is of the rear slack adjuster (8). The rear slack adjuster is

locatedabove the rear differential. The slackadjuster maintains a consistent feel andapplicationof the brakes

as the brake discs wear.

The lower visual is of the front slack adjuster (9). The front slack adjuster is located on the left strut frame

support. The slack adjuster maintains a consistent feel and application of the brakes as the brake discs wear.

Showninthis visual is thediverter (towing) valve(16) for the777F. Thediverter valvefunctions the

same however has changed locations. The diverter valve for the 777F is nowlocated on the left

frame rail in front of the left front strut. The diverter valve must be manually shifted before towing.

Oncethevalveis shifted, oil flowfromtheelectric secondarypumpis directedtotheparkingbrake

valve to release the parking brake. The relief valve (17) limits the maximumpressure when using

the towing pump.

16

17

4A 4B

Shown in the visual is the newlocation of the hoist pump (4A, 4B).

Showninthe visual is the newlocationof the hoist control valve (22). The valve (22) is locatedbehindthe engine on

the right side of the frame. The valve (22) will function the same as the hoist control valve on the 777D.

22

N

O

L

K

Shown in the visual to the left are the pressure taps for the hoist control

valve. The pressure tap (N) checks the pilot pressure for the hoist lower

solenoid. The pressure tap (O) checks the pilot pressure of the raise

solenoid.

Shown in the visual to the right are the pressure taps for the hoist

cylinders. These pressure taps are located on the cross-tube between

the lower hoist cylinder mounts. The pressure tap (L) checks the

pressure of the cylinder lower circuit. The pressure tap (K) checks the

pressure of the cylinder raise circuit.

47

58

CAB

R

E

N

R

8

3

0

5

-

0

2

V

O

L

1

o

f

2

3

0

P

a

g

e

,

(

D

i

m

e

n

s

i

o

n

s

:

3

9

i

n

c

h

e

s

x

2

8

i

n

c

h

e

s

)

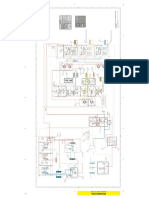

DRAIN / RETURN LINE

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

ELECTRICAL CIRCUITS

BRAKE CHARGING CIRCUIT PUMP

LOCK-UP CLUTCH VALVE PUMP CIRCUIT

BRAKE COOLING

HOIST PUMP CIRCUIT

PUMP SUPPLY LINE

HOIST CYLINDERS CIRCUIT

BRAKE CIRCUIT (FRONT ANDREAR)

THIS SCHEMATIC IS FOR THE 777F AND777F OEMOFF-HIGHWAY TRUCK

PART #: 255-6188 CHG 04

Components are shown installed on a fully operable machine with the key and engine off and transmission

shifter in neutral.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

LINE PATTERNS

Drain / Return Lines

Component Group

Pilot / Load Sensing Pressure

Pressure Line

Attachment

Air Line

CALLOUTS

Taps (Pressure, Sampling,Sensor) by letter

Components by number

YY

52

7

7 8 6 5 4 3 2 1

A

B

C

D

E

F

1 2 3 4 5 6 8

F

E

D

C

B

A

A

B

D

E

59

8

FromTorque Converter

Lock-up Clutch Pilot

(Volume 2, F-3)

ADJ USTER GP - SLACK

RIGHT REAR

LEFT REAR

M

P

T

A

1

4

5

P1

T1

A1

PARK BRAKE

SOLENOID

BLEEDDOWN

SOLENOID

3

ECM

P2

LEFT

FRONT

RAISE SOLENOID

LOWER, FLOAT,

SNUB SOLENOID

BRAKE COOLING RELIEF

LOWER

FLOAT

SNUB

HOLD

RAISE

RAISE RELIEF

LOWER RELIEF

DUAL STAGE

SIGNAL SPOOL

MAIN RELIEF

DUMP SPOOL

7

10

10

28 27

11A

11A

9

20 13

14

5

2B 4B

15 35 54

11B

11B

23 24

22

1

4A 3 2A

28 27

12

21

FRONT BRAKES

WET DRY

LEFT

FRONT

RIGHT

FRONT

RIGHT

FRONT

17

16

58

6

H

G

P

18

M

N

O

L K

D

E

F

29

C

B

A

J

FromTorque Converter

Lock-up Clutch.

(Volume 2, F-3)

FromTorque Converter

Lock-up Clutch. (Volume 2, E-2)

FromTorque Converter

(Volume 2, F-4)

See Note A

See Note A

See Note A

19

47 26

14

I

Note A: Dry brake configuration

R

E

N

R

8

3

0

5

-

0

2

V

O

L

2

o

f

2

3

0

P

a

g

e

,

(

D

i

m

e

n

s

i

o

n

s

:

3

9

i

n

c

h

e

s

x

2

8

i

n

c

h

e

s

)

ONE POSITION TWO POSITION THREE POSITION

VENTED PRESSURIZED RETURNABOVE FLUIDLEVEL RETURN BELOWFLUIDLEVEL

LINES CROSSING LINES J OINING

TWO-WAY THREE-WAY FOUR-WAY

SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION

(FIXED)

2-SECTION PUMP

MAIN AUX.

SPRING

(ADJ USTABLE)

VARIABILITY LINE RESTRICTION

(VARIABLE)

LINE RESTRICTION

VARIABLE and PRESSURE COMPENSATED

PRESSURE

COMPENSATION

PUMP: VARIABLE and

PRESSURE COMPENSATED

ENERGY TRIANGLES

HYDRAULIC PNEUMATIC

MEASUREMENT

PRESSURE TEMPERATURE FLOW

ROTATING SHAFTS

UNIDIRECTIONAL BIDIRECTIONAL

PUSH-PULL LEVER PEDAL GENERAL MANUAL PUSH BUTTON SPRING

MANUAL CONTROL SYMBOLS

HYDRAULIC MOTORS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

HYDRAULIC PUMPS

FLUID STORAGE RESERVOIRS

CROSSING AND JOINING LINES

VALVE ENVELOPES VALVE PORTS

BASIC COMPONENT SYMBOLS

FLUIDCONDITIONER PUMP or MOTOR

FLUID POWER SYMBOLS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

VALVES

PILOT CONTROL SYMBOLS

RELEASEDPRESSURE

EXTERNAL RETURN INTERNAL RETURN

REMOTE SUPPLY PRESSURE

SIMPLIFIED COMPLETE INTERNAL

SUPPLY PRESSURE

ACCUMULATORS

SPRING LOADED GAS CHARGED

SOLENOID

or MANUAL

SOLENOID

and PILOT

SOLENOIDand

PILOT or MANUAL

COMBINATION CONTROLS

SOLENOID SERVO THERMAL DETENT

HYDRAULIC AND PNEUMATIC CYLINDERS

DOUBLE ACTING SINGLE ACTING

BASIC

SYMBOL

SPRING

LOADED

CHECK VALVES

TWO

POSITION

INFINITE

POSITIONING

FLOWIN ONE

DIRECTION

FLOWALLOWEDIN

EITHER DIRECTION

THREE

POSITION

CROSS

FLOW PARALLEL

FLOW

INTERNAL PASSAGEWAYS

NORMAL POSITION

A B

P T

A B

P T

SHIFTEDPOSITION INFINITE POSITION

CONTROL VALVES

ATTACHMENT

MANUAL SHUTOFF

SHUTTLE PILOT

CONTROLLED

Hydraulic Symbols (Electrical)

Electrical Symbols Table

325-AG135 PK-14

Circuit Identification

Number

Wire Color Wire Gauge

Harness identification code

This example indicates

wire 135 in harness "AG".

325-PK-14

Wire Gauge

Wire Color

Circuit Number

Identification

Wire Number Identification Codes

Current Standard

Previous Standard

Electrical Schematic Example Hydraulic Schematic Example

325-PK

Wire Color Circuit Number

Identification

B A

Wire

Wire

(EXAMPLE VALVE)

Current Standard

Transducer

(Fluid)

Transducer

(Gas / Air)

G

Generator

Electrical Wire

Pressure Switch

M

Electric Motor

Pressure Switch

(Adjustable)

Temperature Switch

T

Pressure

Symbol

Temperature

Symbol

Level

Symbol

Flow

Symbol

Electrical Symbols (Electrical)

Printed in U.S.A.

777F:

JRP1-UP

777F OEM:

JXP1-UP

Volume 2 of 2: Steering and Power Train

2010 Caterpillar

All Rights Reserved

RENR8305-02

J une 2010

777F and 777F OEM Of f -Hi ghway Tr uc k

Hydr aul i c Syst em

Item

Number

Description

Part

Number

Schematic

Location

1 TANK GP (HYD&TRANS) 258-9852 C-4

15 PUMP GP-ELECTRIC (BRAKE RETRACT) 230-2637 D-6

18 FILTER (BREATHER) 8X-4575 C-4

25 FILTER GP-OIL 249-2306 D-2

30 TANK GP-HYD(STEERING) 249-2925 A-7

31 PUMP GP-PISTON (STEERING) 261-5630 B-6

32 VALVE GP-CHECK (STEERING) 175-7050 E-7

33 PUMP GP-METERING (STEERING) 195-6617 E-7

34 CYLINDER GP-(STEERING) 105-2440 F-7

35 PUMP GP-ELECTRIC (STEERING) 230-2637 D-6

36

SWITCH AS.- PRESSURE

(STEERING PUMP OIL LOWPRESSURE) 313-5104 D-8

37 SWITCH AS.- PRESSURE (SECONDARY STEERING) 9X-4455 E-6

38 FILTER GP-OIL (STEERING) 173-0159 B-7

39 FILTER GP-HYD(STEERING) 249-2334 C-8

40 VALVE-BREAKER RELIEF 9T-0818 B-5

41 PUMP GP-GEAR (TORQUE CONV. SCAVENGE) 256-6123 D-3

42 FILTER GP 4T-4760 D-3

43 VALVE GP-MODULATING 244-3114 E-3

44 FILTER GP-OIL 244-0121 F-3

45 FILTER GP-OIL 270-5181 F-3

46 SWITCH AS.-LIQUIDLEVEL 172-8660 B-2

47 SCREEN AS. 7J -0725 C-2

48 CONVERTER GP-TORQUE 249-5539 D-4

49 VALVE GP-RELIEF 3P-0349 F-4

50 PUMP GP-GEAR (TORQUE CONV. CHARGE) 256-6123 D-3

51 PUMP GP-GEAR (LOCK-UP CLUTCH VALVE PILOT) 256-6123 D-3

52 PUMP GP-GEAR (TRANSMISSION SCAVENGE) 256-6123 D-2

53 PUMP GP-GEAR (TRANSMISSION CHARGING) 256-6123 D-2

54 PUMP GP-ELECTRIC (ENGINE OIL) 230-2637 D-5

55 VALVE GP-RELIEF 3P-0348 C-3

56 CORE GP- OIL COOLER 4W-5056 C-2

57 VALVE GP-CHECK 268-3451 C-2

60 VALVE GP-RELIEF 268-3998 E-2

61 VALVE GP-MTG & 277-8869 C-8

Component Locations (Volume 2)

Tap

Number

Description

Schematic

Location

Q HMU INPUT E-7

R STEERING LOADSENSE PILOT D-8

S LOCK-UP CLUTCH E-3

T LOCK-UP CLUTCH FILTER OUTPUT D-3

U TRANS CHARGE FILTER OUTPUT F-3

V TORQUE CONVERTER OUTLET RELIEF VALVE F-4

W SOS C-8

X SOS D-2

Y TRANSMISSION CHARGE PRESSURE E-2

Tap Locations

Pressure, Sampling, and Sensor (Volume 2)

Shown in the visual to the left is the electric

secondary steering pump (35) on the 777F. The

pump and motor are the same as the 777D

however thelocationhas changed. Thepumpand

motor are nowlocated on the front crossmember.

The secondary pressure switch (36) is also

mounted next to the secondary steering pump.

The pressure switch(36) detects if the wheels are

beingturnedvia the steeringwheel whensecond-

ary steering is applied. When the wheel is turned

in a secondary steering condition, the pressure

switch (36) will signal the Transmission/Chassis

ECMand the QuickEvac function will be disabled.

Relief Valve Relief Valve

Steering Disable

Solenoid

53 52

55

49

43

51 50 41

42

Shown in the left visual is the 777F transmission charge filters. The 777F has two filters mounted on the

cross member on the right side of the machine. Port (U) is an SOS port. Port (Y) is a pressure tap. The

pressure indicated at tap (Y) is charge pressure for the transmission control valves. The rear filter housing

also has a bypass switch. The bypass switch provides an input signal to the Caterpillar Monitoring System,

which informs the operator if the filter is restricted.

Shown in this visual is the 777F torque converter charging filter (42). The charging filter is located on the

right framerail, behindtheright front tire. TheSOS port is located on the torque converter filter. SOS Port

draws a sample fromthe outlet of the filter.

Shown in the top visual is the new five section gear pump. The gear pump is a different design then the

previous 777D. The gear pumps are for the following circuits:

Torque converter scavenge (41)

Torque converter charge (50)

Lockup clutch valve pilot circuit (51)

Transmission scavenge (52)

Transmission charge (53)

Shown in the lower visual are some of the torque converter systemcomponents for the 777F. The torque

converter systems are similar between the 777D and 777F. The torque converter inlet relief valve (55) and

the outlet relief valve (49) will function the same. The lockup clutch valve (43) on the 777F is nowan ECPC

valve.

This view shows the torque converter lockup clutch filter. Port (X) is an SOS port. Port (T) is a pressure tap.

The pressure indicated at tap (T) is pump pressure for the lockup clutch pilot circuit.

X T

a b c d e f g h j

U

Y

Shown in this visual is the 777F ECPC transmission. This newtransmission has pressure taps located

on the outside of the transmission. This feature will aid in preventing contamination fromentering the

transmission as well as saving time when checking the pressures on the 777F transmission.

Lube oil pressure can be checked at tap (3).

Systempressure can be checked at tap (4).

Clutch 6 pressure can be checked at tap (5).

Clutch 5 pressure can be checked at tap (6).

Clutch 7 pressure can be checked at tap (7).

Clutch 4 pressure can be checked at tap (8).

Clutch 3 pressure can be checked at tap (9).

Clutch 2 pressure can be checked at tap (10).

Clutch 1 pressure can be checked at tap (11).

45 44

V 44

45

31

32

35 36

30

Q

61

Shown in this visual is the steering pump (31) for the 777F. The steering pump is nowmounted on the back of the newC32

ACERT engine. The steering pump is still a load sensing, pressure compensated, piston-type pump

Shown in this visual is the steeringvalve (32) for the 777F. The 777F uses the same steeringvalve as the 777D. The steering

valveis locatedinthesameplacehowever thesteeringvalveis mounteddifferently. Thepressuretap(Q) checks thepressure

in the supply line to the HMU. If the supply oil pressure to the HMU is belowspecification, the relief valve

many need to be adjusted.

The steeringdisable valve (61) is locatedbehindthe shock onthe right frame rail. Whenthe steeringdisable solenoidvalve is

energized, the flowfromthe steering to the steering valve is blocked by the steering disable valve (61). This allows servicing

behind the

S

Showninthe this visual is pressure tap(S) for the lockupclutchvalve andpressure tap(V) for the outlet

relief valve. Thepressureindicatedat tap(S) is thepressureinthelockupclutch. Thepressureindicated

at tap (V) is the pressure inside the torque converter.

CAB

1 26 46 47 59 52 25 60 18

33

34 15 35 37 54

34

56

32 36 61 31 42 30 38 39 40 44 45

53 57 51 50 41

49 55 43 48

Shown in the visual to the right is the 777F

steering systemtank. The tank is located on the

right platform. The 777F steering tank functions

the same as the the 777Dsteering tank.

SOS

NOTE: The taps shown in this visual

do not appear on the schematic.

COMPONENT LOCATIONS

POWER TRAIN

STEERING SYSTEM

R

E

N

R

8

3

0

5

-

0

2

V

O

L

2

o

f

2

3

0

P

a

g

e

,

(

D

i

m

e

n

s

i

o

n

s

:

3

9

i

n

c

h

e

s

x

2

8

i

n

c

h

e

s

)

DRAIN / RETURN LINE

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

ELECTRICAL CIRCUITS

STEERING PUMP CIRCUIT

TRANSMISSIONANDTORQUE CONVERTER SCAVENGE PUMP CIRCUIT

LOCK-UP CLUTCH VALVE PUMP CIRCUIT

BRAKE COOLING

PUMP SUPPLY LINE

TRANSMISSION CHARGE PUMP CIRCUIT

TORQUE CONVERTER CHARGE PUMP CIRCUIT

SECONDARY STEERING PUMP CIRCUIT

THIS SCHEMATIC IS FOR THE 777F AND777F OEMOFF-HIGHWAY TRUCK

PART #: 255-6188 CHG 04

Components are shown installed on a fully operable machine with the key and engine off and

transmission shifter in neutral.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

LINE PATTERNS

Drain / Return Lines

Component Group

Pilot / Load Sensing Pressure

Pressure Line

Attachment

Air Line

CALLOUTS

Taps (Pressure, Sampling,Sensor) by letter

Components by number

YY

52

8 6 5 4 3 2 1

A

B

C

D

E

F

1 2 3 4 5 6 8

F

E

D

C

B

A

7

7

ECM

M

B

A C

D

E

A

B

LOAD SENSE STEERING SYSTEM

POWERTRAIN:

TRANSMISSION AND TORQUE CONVERTER

15

35

54

53 52 51

50 41

55

47 26

46

48

42

1

43

25

18

49

60

44 45

S

39

30

38

31

61

40

Q

33

32

37

34

V

T

U

R

W

HYDRAULIC

CONTROLS

TORQUE

CONVERTER

TRANSMISSION

LOCK UP

VALVE

LOCK-UP CLUTCH

PRESSURE

TO BRAKE

COOLING

TO BRAKE

COOLING

To Traction Control Valve

To Hoist Pilot

Signal Resolver

To Rockford Fan

Clutch Control

(Attachment)

36

56

57

X

Y

Das könnte Ihnen auch gefallen

- Construction and Manufacture of AutomobilesVon EverandConstruction and Manufacture of AutomobilesBewertung: 5 von 5 Sternen5/5 (1)

- Diagrama Hidraulico 777FDokument4 SeitenDiagrama Hidraulico 777Ffabioalbor100% (1)

- Uenr1281uenr1281-00 SisDokument2 SeitenUenr1281uenr1281-00 SisFabrizio JesúsNoch keine Bewertungen

- GEB d11T PDFDokument23 SeitenGEB d11T PDFVictor AugustoNoch keine Bewertungen

- 777F MG SistemasDokument118 Seiten777F MG SistemasDavid Mercado100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument13 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Carlos Andres Campos TorresNoch keine Bewertungen

- 994K Wheel Loader Brake SystemDokument2 Seiten994K Wheel Loader Brake SystemHéctorHernándezDíaz100% (1)

- 797F Off-Highway Truck Steering System: Global Manpower DevelopmentDokument24 Seiten797F Off-Highway Truck Steering System: Global Manpower DevelopmentEdin Raul Yalle RafaelNoch keine Bewertungen

- Plano Hidraulico D10T PDFDokument2 SeitenPlano Hidraulico D10T PDFJHOSMAR_22Noch keine Bewertungen

- Cat Dcs Sis ControllerDokument2 SeitenCat Dcs Sis ControllerIGNACIO GARCIA100% (1)

- Prodsup 16MDokument69 SeitenProdsup 16MBrayan Villanueva VillenaNoch keine Bewertungen

- 797F Enfriamiento PDFDokument2 Seiten797F Enfriamiento PDFJuan MuñozNoch keine Bewertungen

- Plano Power Train D8TDokument2 SeitenPlano Power Train D8Talexander_1985100% (3)

- Plano Hidraulico 24M UENR2143UENR2143-03 - SISDokument4 SeitenPlano Hidraulico 24M UENR2143UENR2143-03 - SISFredy Manrique AstoNoch keine Bewertungen

- 785C Plano Hidraulico PDFDokument2 Seiten785C Plano Hidraulico PDFChristian Vásquez BasilioNoch keine Bewertungen

- Tractor d8 TDokument2 SeitenTractor d8 TAkira TamashiroNoch keine Bewertungen

- (KENR9561-00) Schematic - 793F OHT Air SystemDokument2 Seiten(KENR9561-00) Schematic - 793F OHT Air SystemFredy Manrique Asto100% (1)

- Plano Hyd d8tDokument2 SeitenPlano Hyd d8tMilton Frank Bobadilla100% (1)

- Manual Hidraulico Excavadora 395Dokument19 SeitenManual Hidraulico Excavadora 395Ramon MontesNoch keine Bewertungen

- 6060HydMiningShvl M08 SwingSys enDokument20 Seiten6060HydMiningShvl M08 SwingSys enJonathan José Alvis GonzalesNoch keine Bewertungen

- 008 - Cat-6060 - Attachment Functions FSDokument38 Seiten008 - Cat-6060 - Attachment Functions FSJorby CuadrosNoch keine Bewertungen

- 777D 3PR Senr6910Dokument2 Seiten777D 3PR Senr6910Putra Jawa100% (1)

- HYD0035 DX Axle - WheelDokument16 SeitenHYD0035 DX Axle - WheelvarthotNoch keine Bewertungen

- Service Courses - Final VersionDokument1 SeiteService Courses - Final VersionDanuth Yashantha IllukkumburaNoch keine Bewertungen

- Cat 390d Excavator Hydraulic Systempdf PDFDokument10 SeitenCat 390d Excavator Hydraulic Systempdf PDFSebastian Dube100% (1)

- Hydraulic System 6015B Hydraulic Mining Shovel: Machine - Right Side ViewDokument4 SeitenHydraulic System 6015B Hydraulic Mining Shovel: Machine - Right Side ViewJuan Carlos Inga Vasquez100% (1)

- 797F CMD Field RetrofitDokument21 Seiten797F CMD Field Retrofitsergio conchaNoch keine Bewertungen

- Plano Hidraulico 16m CatDokument2 SeitenPlano Hidraulico 16m CatLuis Ramos100% (2)

- 793 F Electrico PDFDokument8 Seiten793 F Electrico PDFshirley bustos14Noch keine Bewertungen

- Sistema Electrico 785dDokument15 SeitenSistema Electrico 785dFrank Agurto LucianoNoch keine Bewertungen

- Manual de Instalacion VimsDokument121 SeitenManual de Instalacion VimsMartin AlcarazNoch keine Bewertungen

- 950H Hnydra 2 PDFDokument13 Seiten950H Hnydra 2 PDFChrissz Noxd100% (1)

- Esquema Hidráulico CAT D11TDokument2 SeitenEsquema Hidráulico CAT D11TJorge Mendoza0% (1)

- 994K Wheel Loader Electrical SystemDokument8 Seiten994K Wheel Loader Electrical SystemHéctorHernándezDíazNoch keine Bewertungen

- Camion 789DDokument14 SeitenCamion 789Ddinny blanco rojasNoch keine Bewertungen

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument11 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768falahNoch keine Bewertungen

- 994D InglesDokument104 Seiten994D InglesCristian Esteban Correa IrribarraNoch keine Bewertungen

- Hydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionDokument24 SeitenHydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionMiguel Angel RodriguezNoch keine Bewertungen

- 785d Hydraulic PDFDokument2 Seiten785d Hydraulic PDFJPJFNoch keine Bewertungen

- 730E Electric Drive Truck: SafetyDokument109 Seiten730E Electric Drive Truck: Safetyanass100% (2)

- Plano Hidraulico D11TDokument2 SeitenPlano Hidraulico D11TAndrésMoisésRodriguezSuarez100% (4)

- 004 - CAT-6040 - Engine + Pump DriveDokument32 Seiten004 - CAT-6040 - Engine + Pump Drive----100% (1)

- Hydraulic Mining Excavator CAT 6040: 02. UndercarriageDokument20 SeitenHydraulic Mining Excavator CAT 6040: 02. Undercarriage----Noch keine Bewertungen

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument11 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Roberto Antonio Chihuaihuan Araya100% (1)

- Esquema Hidráulico (793D)Dokument2 SeitenEsquema Hidráulico (793D)Oswaldo Ayma VisaNoch keine Bewertungen

- 793F and 793F WTR OEM Hydraulic System Off-Highway Truck: Traction ControlDokument2 Seiten793F and 793F WTR OEM Hydraulic System Off-Highway Truck: Traction Controlpercy de la cruzNoch keine Bewertungen

- Global Service Learning: 950H Wheel Loader, 962H Wheel Loader, and It62H Integrated ToolcarrierDokument63 SeitenGlobal Service Learning: 950H Wheel Loader, 962H Wheel Loader, and It62H Integrated Toolcarriergildercarrascal100% (2)

- Presentacion R1600GDokument53 SeitenPresentacion R1600GJose CarmonaNoch keine Bewertungen

- Uenr6457uenr6457-00 SisDokument2 SeitenUenr6457uenr6457-00 SisHelar W. Cutipa MachacaNoch keine Bewertungen

- D10T Track-Type Tractor Power Train System (Interactive) 212-2749 30082006Dokument14 SeitenD10T Track-Type Tractor Power Train System (Interactive) 212-2749 30082006Med EkahNoch keine Bewertungen

- Plano Hidraulico-7Dokument1 SeitePlano Hidraulico-7RodolfoNoch keine Bewertungen

- D10T Track-Type Tractor Power Train System: Rjg1-UpDokument2 SeitenD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22Noch keine Bewertungen

- RENR8305RENR8305-04 - SIS 777f 1Dokument4 SeitenRENR8305RENR8305-04 - SIS 777f 1gadolineo100% (1)

- 950H Wheel Loader Hydraulic SystemDokument2 Seiten950H Wheel Loader Hydraulic Systemwtn2013100% (16)

- Diagrama Hidraulico D9TDokument2 SeitenDiagrama Hidraulico D9TCristian Valencia100% (1)

- AndresitoDokument25 SeitenAndresitoJoan VasquezNoch keine Bewertungen

- D10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Dokument2 SeitenD10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Roberto Antonio Chihuaihuan Araya100% (2)

- Hydraulic Shematic FonctionDokument10 SeitenHydraulic Shematic FonctionatelierNoch keine Bewertungen

- Steering System: Systems OperationDokument12 SeitenSteering System: Systems Operationhidekel crafort vinicioNoch keine Bewertungen

- Cat 450E Backhole Loader Hydraulic SystemDokument4 SeitenCat 450E Backhole Loader Hydraulic Systemwords2zhigang_612545100% (3)

- Differential Gear: Construction and WorkingDokument4 SeitenDifferential Gear: Construction and WorkingParmar DivyangNoch keine Bewertungen

- ME2203 KOM SyllabusDokument1 SeiteME2203 KOM SyllabusrkumaravelanNoch keine Bewertungen

- Dls 16 eDokument12 SeitenDls 16 eseaqu3stNoch keine Bewertungen

- Transmission Shift Control Solenoids - ST19309: Parts ListDokument8 SeitenTransmission Shift Control Solenoids - ST19309: Parts ListCASE ETRANS100% (1)

- TRHC 80-600-750Dokument5 SeitenTRHC 80-600-750Sukron Nursalim100% (1)

- Exercise 1: Bongac, Wyler C. Canam, Glendale G. Olaya, Altheia Lynn VDokument5 SeitenExercise 1: Bongac, Wyler C. Canam, Glendale G. Olaya, Altheia Lynn VAltheia Lynn Velasco OlayaNoch keine Bewertungen

- Base de Valvulas Iso DuplomaticDokument12 SeitenBase de Valvulas Iso DuplomaticEduardo CramerNoch keine Bewertungen

- Liquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFDokument30 SeitenLiquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFHidroil Neuquen SrlNoch keine Bewertungen

- Hydraulic Training 19052021Dokument61 SeitenHydraulic Training 19052021Imad100% (2)

- Sce MaticDokument2 SeitenSce Matictyok sajaNoch keine Bewertungen

- Variable Displacement Vane Pump Variable Displacement Vane PumpDokument4 SeitenVariable Displacement Vane Pump Variable Displacement Vane PumpRonaldNoch keine Bewertungen

- Describe The Differences Between The Following. Include Diagrams. A. Open Center Hydraulic CircuitDokument7 SeitenDescribe The Differences Between The Following. Include Diagrams. A. Open Center Hydraulic CircuitMohammad UsmanNoch keine Bewertungen

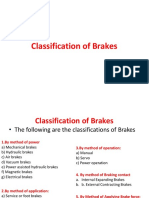

- 5 Classification of Brakes 160217042825Dokument39 Seiten5 Classification of Brakes 160217042825manipsg100% (1)

- MissionDokument420 SeitenMissionAlejandro ZanellaNoch keine Bewertungen

- Serv1852 TXT6Dokument38 SeitenServ1852 TXT6Noel Olvera100% (2)

- Band BrakeDokument17 SeitenBand Brakeocy12Noch keine Bewertungen

- Gambar 10 Clutch: Nomor Refere Nomor Part Nama Part KeteranganDokument1 SeiteGambar 10 Clutch: Nomor Refere Nomor Part Nama Part KeteranganDevii AryaNoch keine Bewertungen

- UnimecDokument43 SeitenUnimecayavuzbvsNoch keine Bewertungen

- 963C Caterpillar Systems Operation.Dokument63 Seiten963C Caterpillar Systems Operation.Baron KasoziNoch keine Bewertungen

- 4HP24 PDFDokument4 Seiten4HP24 PDFAbbode HoraniNoch keine Bewertungen

- Dreadnought Type 2 in 1 Brake EjectorDokument10 SeitenDreadnought Type 2 in 1 Brake EjectorVikk SuriyaNoch keine Bewertungen

- Planar Mechanisms 1Dokument6 SeitenPlanar Mechanisms 1Aryan Rai0% (1)

- KladivarDokument107 SeitenKladivaranta77Noch keine Bewertungen

- Making Such A Change To Assure Type 2 Performance. Please Consult SiemensDokument1 SeiteMaking Such A Change To Assure Type 2 Performance. Please Consult SiemensPawan kumarNoch keine Bewertungen

- ME2203 Subject Notes PDFDokument34 SeitenME2203 Subject Notes PDFRakeshkumarceg100% (1)

- 6R140 VacTestGuideDokument4 Seiten6R140 VacTestGuideJose Andres HuertaNoch keine Bewertungen

- Catalogue Maximator Valves Fittings and Tubings 05 2011Dokument62 SeitenCatalogue Maximator Valves Fittings and Tubings 05 2011willianNoch keine Bewertungen

- Technical Drawing PDFDokument170 SeitenTechnical Drawing PDFLazzarus Az GunawanNoch keine Bewertungen

- Control Valves: by Hans D. BaumannDokument17 SeitenControl Valves: by Hans D. BaumannAida PerezNoch keine Bewertungen

- ME138P E02 Report 1 Group 2Dokument82 SeitenME138P E02 Report 1 Group 2Anthony FajardoNoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen