Beruflich Dokumente

Kultur Dokumente

M I I N Pli N L L: Timber Products

Hochgeladen von

sourz180 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten1 Seitewood specs

Originaltitel

Timber Products

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenwood specs

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten1 SeiteM I I N Pli N L L: Timber Products

Hochgeladen von

sourz18wood specs

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

186

Table 6.7 Modification factor K12 for compression members (Based on

not for design purposes)

E Ratio of effective length to breadth (rectangular sections)

Gr. stress

1 . 4

3.0 6.0 12.0 18.0 24.0 30.0 36.0 42.0 48.0

600 0.97 0.95 0.90 0.77 0.58

0.41 0.29 0.21 0.16 0.13

800 0.97 0.95 0.90 0.78 0.63 0.48 0.36 0.26 0.21 0.16

1000 0.98 0.95 0.90 0.79 0.66 0.52

0.41

0.30 0.24 0.19

1200 0.98 0.95 0.90 0.80 0.68 0.56 0.44 0.34 0.27 0.22

1400 0.98 0.95 0.90 0.80 0.69 0.58 0.47 0.37 0.30 0.24

1600 0.98 0.95 0.90 0.81 0.70 0.60

0.49 0.40 0.32 0.27

1800 0.98 0.95 0.90 0.81 0.71 0.61 0.51 0.42 0.34 0.29

2000' 0.98 0.95 0.90 0.81 0.71 0.62 0.52

0.44

0.36 0.31

Timber products

Timber products may offer the following advantages over solid timber:

They are competitive in price on account of lower wastage rates; small

sections of the tree, together with defective pieces and off-cuts which

not suitable for solid timber are often perfectly acceptable for timh

products.

Products can be produced in much larger sizes than could be obtained

solid timber - for example, sheets or long lengths.

Defects associated with solid timber can be removed or made I

significant.

Weaknesses and distortion associated with grain can be at least partl

overcome.

Areas in which timber products could cause problems are:

The product can only be as good as the adhesive used in its productio

Some products deteriorate quickly in damp conditions, as might preva

on a building site during construction, or in areas such as kitchens o

bathrooms.

Some adhesives increase wear and tear on cutting tools used f

processing products.

Some timber products are not as aesthetically attractive as their soli

timber counterparts.

Table 6.8 shows some of the timber products available together with main

characteristics and areas for caution. They are widely used in construction,

with materials such as particle board tending to displace others such a

plywood since they can be made with lower grade raw material: BS 566

187

Properties and applications of some timber products

Subdivision

Composition

Applications

Possible

problems

Standard

hardboard

Highly compressed

wood fibres; one

smooth surface

Low cost internal

linings; door skins

Swells in damp

situations

Oil impregnated

External claddings

Risk of damage

Oil tempered

by impact

hardboard

Lower density

Internal linings

Protect from

Medium board

moisture

than hardboards

Higher strength

Decorative

Protect from

Medium density

moisture

fibreboard (MDF)

than medium board

mouldings

Compressed wood

Internal claddings

Irreversible

t 1 1 1 1 1 '

Standard grade

expansion in

"",IN

chipboard

chips; dense

dampcond.

t '()69 Type I

surfaces

Higher strength

Internal floors

As above

Flooring grade

Type 2

Moisture-resistant

Water resistant

Kitchens/bathrooms

flooring grade

Type2/3

II wood

Shutter ply

Crossed coarse

Formwork for concrete. Limited re-use;

I hS66

veneers; water-

Carcassing in timber

proof adhesive

frame construction

Quality veneers

External linings, e.g.

Good veneers

Birch ply

waterproof adhesive

soffit boards

are expensive

45 mm laminates,

Large section straight

Protect from

Ilhtlum Straight

structural members

rain and sun

II, 4169

high-performance

adhesives

Approx. 20 mm

Curved members;

As above

Curved

laminates

portal frames

!lOW includes a specification for the structural use of chiP~art So;e o~~e~

materials have recently been introduced - for example, 'w er .oar d w lC

('omprises thin slices of wood bonded together; and LVL (lammate venee~

lumbar) which comprises strips of wood bonded together to ~ormstructura

. t' s When the benefits of cost and performance are mcluded, such

Izesec Ion. . .

materials have adistinct advantage over sohd equivalents.

Das könnte Ihnen auch gefallen

- 15mm Kahrs Techspec OriginalDokument2 Seiten15mm Kahrs Techspec OriginalMohammed Mustafa AliNoch keine Bewertungen

- Aluminium Plastic Composite PanelDokument9 SeitenAluminium Plastic Composite PanelFrankie ChanNoch keine Bewertungen

- Baison 1Dokument24 SeitenBaison 1mohanty_anantakumar6332Noch keine Bewertungen

- PETg Data SheetDokument4 SeitenPETg Data SheetVikram BorkhediyaNoch keine Bewertungen

- Tech Handbook - Bison BoardsDokument51 SeitenTech Handbook - Bison BoardsRaj Mani0% (1)

- Engineered TimberDokument14 SeitenEngineered TimberNaar Muhendislik100% (1)

- Mechanical GalvDokument11 SeitenMechanical GalvMehman NasibovNoch keine Bewertungen

- BISON PANEL Product GuideDokument24 SeitenBISON PANEL Product Guideg_periwal_pune9635Noch keine Bewertungen

- Properties of WWCBDokument4 SeitenProperties of WWCBninashiroNoch keine Bewertungen

- Know Your Associate 0Dokument12 SeitenKnow Your Associate 0sarveshrathiNoch keine Bewertungen

- Pattern Design StandardsDokument12 SeitenPattern Design StandardsaniruddhahNoch keine Bewertungen

- Ar2101cabinetrypowerpoint PDFDokument55 SeitenAr2101cabinetrypowerpoint PDFRaymond Gregg TanNoch keine Bewertungen

- BCM Block BoardDokument34 SeitenBCM Block BoardNidhi JoshiNoch keine Bewertungen

- Monitor BSP Folder e 2013 01Dokument3 SeitenMonitor BSP Folder e 2013 01MIlos AndricNoch keine Bewertungen

- CHAD Tech Manual AAC EcoPanel V3.outputDokument68 SeitenCHAD Tech Manual AAC EcoPanel V3.outputbadar_tsaniNoch keine Bewertungen

- Medium and High Density FibreboardDokument43 SeitenMedium and High Density FibreboardSakhi JalanNoch keine Bewertungen

- GluamDokument13 SeitenGluamMadelline Joy RitaritaNoch keine Bewertungen

- Boism PanelDokument24 SeitenBoism PanelhipreyashNoch keine Bewertungen

- Limit States Design With Hyspan and HybeamDokument6 SeitenLimit States Design With Hyspan and HybeamTuroyNoch keine Bewertungen

- Internal Cladding Installation GuidelinesDokument7 SeitenInternal Cladding Installation GuidelinesShajit KumarNoch keine Bewertungen

- Market Sorvey On PlywoodDokument19 SeitenMarket Sorvey On PlywoodEduardo MafraNoch keine Bewertungen

- Ineos Polypropylene Processing GuideDokument18 SeitenIneos Polypropylene Processing GuideLe Toan100% (1)

- Marco Full Product CatalogDokument54 SeitenMarco Full Product Catalogjonathan1479Noch keine Bewertungen

- Bu Suelos GBDokument33 SeitenBu Suelos GBGhenoiu PaulNoch keine Bewertungen

- TDA Domestic Decking Guide Aug 2013Dokument22 SeitenTDA Domestic Decking Guide Aug 2013Anonymous uuKGF5rAWNoch keine Bewertungen

- Best Metal Casting DesignDokument71 SeitenBest Metal Casting DesignVijay Pawar100% (2)

- Sheetrock Gypsum Panels Installation GuideDokument26 SeitenSheetrock Gypsum Panels Installation Guidew_christopher_miller@gmail_comNoch keine Bewertungen

- Blow Mould DesignDokument75 SeitenBlow Mould DesignKamal Krishna Kashyap100% (1)

- 3D Laminates: HistoryDokument5 Seiten3D Laminates: Historysukavasi1973Noch keine Bewertungen

- bs1088 Marine Plywood StandardDokument3 Seitenbs1088 Marine Plywood StandardSubrata ParaiNoch keine Bewertungen

- Alternative Wall TechnologiesDokument9 SeitenAlternative Wall TechnologiesSACHIDANANDA SNoch keine Bewertungen

- Long Span BeamsDokument9 SeitenLong Span BeamsraktalNoch keine Bewertungen

- Id-Pradeeppoddarwst Pw-Priyanka Slide 1Dokument6 SeitenId-Pradeeppoddarwst Pw-Priyanka Slide 1Pradeep PoddarNoch keine Bewertungen

- Alternative Wall Technologies-Sandwitch PanelsDokument14 SeitenAlternative Wall Technologies-Sandwitch PanelsDiya MakanurNoch keine Bewertungen

- Wall Panel DetailsDokument20 SeitenWall Panel Detailsdebbie89_myloves100% (1)

- Engineered Hardwood FloorDokument8 SeitenEngineered Hardwood FloorRachel IngramNoch keine Bewertungen

- Data Sheet Heradesign Fine - EnglDokument2 SeitenData Sheet Heradesign Fine - EnglYoudont CareatallNoch keine Bewertungen

- Quality Aspects of Hydrogen Annealead Steel Strip - eDokument8 SeitenQuality Aspects of Hydrogen Annealead Steel Strip - eHaluk Pulatsü100% (1)

- Injection Molding Design GuidelinesDokument28 SeitenInjection Molding Design GuidelinesVinay Kumar KumarNoch keine Bewertungen

- Lectures CompositeDokument5 SeitenLectures CompositeMuhammad AhmedNoch keine Bewertungen

- Timber Product Stage 1Dokument68 SeitenTimber Product Stage 1Ayush GuptaNoch keine Bewertungen

- Division 6 Wood and PlasticsDokument6 SeitenDivision 6 Wood and PlasticsRuellyn CagaisNoch keine Bewertungen

- Wood Cement BoardDokument15 SeitenWood Cement BoardpiangphetNoch keine Bewertungen

- Eb 8Dokument7 SeitenEb 8SyedjamelNoch keine Bewertungen

- Vboard BrochureDokument2 SeitenVboard BrochureAmit Abhishek TopnoNoch keine Bewertungen

- KS1000 RW Panel UK Roof Poduct Data SheetDokument6 SeitenKS1000 RW Panel UK Roof Poduct Data SheetThe Lone GunmanNoch keine Bewertungen

- Rett0022 PB Purmo UkDokument183 SeitenRett0022 PB Purmo UkPeanut d. DestroyerNoch keine Bewertungen

- Extrusion and DrawingDokument19 SeitenExtrusion and DrawingBatuhan YildizNoch keine Bewertungen

- Tech Handbook.137130458Dokument51 SeitenTech Handbook.137130458wakil74Noch keine Bewertungen

- Aeng 261 - Paes 320Dokument47 SeitenAeng 261 - Paes 320lennahfe19100% (1)

- Masonite Timber Beam DataDokument13 SeitenMasonite Timber Beam DatascribdsquaredNoch keine Bewertungen

- NIFT DE Vertical ExtnDokument45 SeitenNIFT DE Vertical Extnexecutive engineer1Noch keine Bewertungen

- Painting, Furniture Finishing and Repairing - A Compilation of Helpful Articles for Craftsmen, Home Owners, Painters and HandymenVon EverandPainting, Furniture Finishing and Repairing - A Compilation of Helpful Articles for Craftsmen, Home Owners, Painters and HandymenNoch keine Bewertungen

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerVon EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerBewertung: 4 von 5 Sternen4/5 (1)

- Family Handyman Quick & Easy ProjectsVon EverandFamily Handyman Quick & Easy ProjectsFamily HandymanNoch keine Bewertungen

- A Guide to Making Wooden Furniture and Furnishings for the KitchenVon EverandA Guide to Making Wooden Furniture and Furnishings for the KitchenNoch keine Bewertungen

- The Disabled in The Caribbean - Huggins, J. 243-478-1-SMDokument12 SeitenThe Disabled in The Caribbean - Huggins, J. 243-478-1-SMsourz18Noch keine Bewertungen

- Tvet & General EducationDokument27 SeitenTvet & General Educationsourz18Noch keine Bewertungen

- Forests and Climate Change Working Paper 13Dokument39 SeitenForests and Climate Change Working Paper 13sourz18Noch keine Bewertungen

- 2008.ackeepaper Jamaica - JournalDokument20 Seiten2008.ackeepaper Jamaica - Journalsourz18Noch keine Bewertungen

- Economic Sociology PDFDokument296 SeitenEconomic Sociology PDFsourz18Noch keine Bewertungen

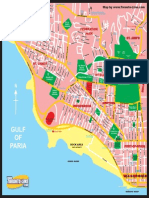

- Gulf OF Paria: Federation Park Federation ParkDokument1 SeiteGulf OF Paria: Federation Park Federation Parksourz18Noch keine Bewertungen

- Appedix D: The Pulse Width Modulatio: Figure 122: Six-Pulse PWM Pulsing Generation SchemeDokument2 SeitenAppedix D: The Pulse Width Modulatio: Figure 122: Six-Pulse PWM Pulsing Generation Schemesourz18Noch keine Bewertungen

- Janouras Catalogue 2010Dokument36 SeitenJanouras Catalogue 2010sourz18Noch keine Bewertungen

- PHYSICS CSEC - CPO Workbook - (4.0) Skill and PracticeDokument173 SeitenPHYSICS CSEC - CPO Workbook - (4.0) Skill and Practicesourz18Noch keine Bewertungen

- 3D Paper Heart: HEART BOX © Minieco - Co.uk. To Be Used For Non-Commercial Purposes Only. Do Not Link Directly To PDFDokument1 Seite3D Paper Heart: HEART BOX © Minieco - Co.uk. To Be Used For Non-Commercial Purposes Only. Do Not Link Directly To PDFsourz18Noch keine Bewertungen

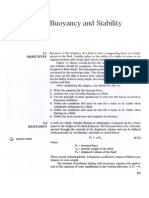

- Applied Fluid Mechanics - 05 Bouyancy and StabilityDokument29 SeitenApplied Fluid Mechanics - 05 Bouyancy and Stabilitysourz1875% (4)

- Applied Fluid Mechanics - 02 Viscosity of FluidsDokument19 SeitenApplied Fluid Mechanics - 02 Viscosity of Fluidssourz18100% (1)

- DaneMorton Gittens ABDokument1 SeiteDaneMorton Gittens ABsourz18Noch keine Bewertungen

- AutoCAD Civil 3D 2012 Essentials p2Dokument55 SeitenAutoCAD Civil 3D 2012 Essentials p2dobridorinNoch keine Bewertungen

- Restorative ResinsDokument71 SeitenRestorative ResinsAhmed DolaNoch keine Bewertungen

- 0304 S9 AbsDokument8 Seiten0304 S9 AbsbangsNoch keine Bewertungen

- Blank Boq - Finishing (II) - Hiland ParkDokument13 SeitenBlank Boq - Finishing (II) - Hiland ParkUTTAL RAYNoch keine Bewertungen

- Composition of Steels PDFDokument5 SeitenComposition of Steels PDFNitin SharmaNoch keine Bewertungen

- Pervious Concrete Construction - Methods and Quality ControlDokument14 SeitenPervious Concrete Construction - Methods and Quality ControlARVIND SINGH RAWATNoch keine Bewertungen

- Silres KX: Silicone Resin SolutionDokument2 SeitenSilres KX: Silicone Resin SolutionurianufmNoch keine Bewertungen

- Raychem e CatalogDokument99 SeitenRaychem e Catalogarifayee-1Noch keine Bewertungen

- FRP Tank Specifications PDFDokument5 SeitenFRP Tank Specifications PDFRagh100% (1)

- Embodied Energy Computations in BuildingsDokument6 SeitenEmbodied Energy Computations in BuildingsVijay KapoorNoch keine Bewertungen

- Catalogo Parker CAT 4660 PDFDokument420 SeitenCatalogo Parker CAT 4660 PDFpelcarNoch keine Bewertungen

- FORTA - Product Family 4CsDokument2 SeitenFORTA - Product Family 4CsSamiNoch keine Bewertungen

- Introduction To SimplexDokument14 SeitenIntroduction To SimplexMujahid Mehdi100% (1)

- HdpeDokument33 SeitenHdpeThiruThirunavukkarasuNoch keine Bewertungen

- Catalog BoltDokument61 SeitenCatalog BoltJulius AdomėnasNoch keine Bewertungen

- M Pi 170Dokument10 SeitenM Pi 170reza329329Noch keine Bewertungen

- Effect of Aggregate Properties On Asphalt Concrete MixesDokument18 SeitenEffect of Aggregate Properties On Asphalt Concrete MixesNgabirano B. JuliusNoch keine Bewertungen

- FLOWTITE GRP Pipe Systems - For Bridge - and Tunnel Drainage - enDokument24 SeitenFLOWTITE GRP Pipe Systems - For Bridge - and Tunnel Drainage - enraji357Noch keine Bewertungen

- MoS BrickworkDokument4 SeitenMoS BrickworkIvan DjordjicNoch keine Bewertungen

- TPG MPLADS Estimate To Print - Xls 05-12-2015Dokument12 SeitenTPG MPLADS Estimate To Print - Xls 05-12-2015sasidharkatari91572Noch keine Bewertungen

- ASTM 3M Products (2009) PDFDokument14 SeitenASTM 3M Products (2009) PDFmtcengineeringNoch keine Bewertungen

- Payne EffectDokument31 SeitenPayne EffectrajchemengNoch keine Bewertungen

- Comparative Study of GFRP Rebar and Steel Rebar Used in Concrete SectionsDokument6 SeitenComparative Study of GFRP Rebar and Steel Rebar Used in Concrete SectionsGRD JournalsNoch keine Bewertungen

- Porous Asphalt Association Guidance DocumentDokument10 SeitenPorous Asphalt Association Guidance DocumentwillypraviantoNoch keine Bewertungen

- 2012 San Diego Regional Supplement To GreenbookDokument83 Seiten2012 San Diego Regional Supplement To GreenbookridlasNoch keine Bewertungen

- 1 08-04-2014 - Summer Training Finl List WebDokument4 Seiten1 08-04-2014 - Summer Training Finl List Webravikr95Noch keine Bewertungen

- Xuper Nucleotec 2222Dokument2 SeitenXuper Nucleotec 2222jose amad nolazcoNoch keine Bewertungen

- C1140 PDFDokument3 SeitenC1140 PDFMyriam Carrera100% (2)

- Schmetz Needle ChartDokument2 SeitenSchmetz Needle Chartsamking838Noch keine Bewertungen

- Catalogue - Floor Trims GuideDokument57 SeitenCatalogue - Floor Trims GuideFloorkitNoch keine Bewertungen

- 1-A Colored Substance That Is Spread Over A Surface and Dries To Leave A Thin Decorative or Protective Coating. Decorative or Protective CoatingDokument60 Seiten1-A Colored Substance That Is Spread Over A Surface and Dries To Leave A Thin Decorative or Protective Coating. Decorative or Protective Coatingjoselito lacuarinNoch keine Bewertungen