Beruflich Dokumente

Kultur Dokumente

PV 1210 (2004)

Hochgeladen von

Matthew TaylorCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PV 1210 (2004)

Hochgeladen von

Matthew TaylorCopyright:

Verfügbare Formate

Klass.-Nr.

50 21 1 September 2004

Body and Add-on Parts

Corrosion Test

PV

1210

Konzernnorm

Descriptors: corrosion, body, add-on part

Page

Fachverantwortung/Responsibility Normung/Standards (EZTD, 1733)

K-QS-32/2 Frau Dr. Hasse Tel: -42106 Laudien Dr. Eisenberg Wiesner Tel: +49-5361-9-29064 Sobanski

Confidential. All rights reserved. No part of this document may be transmitted or reproduced without the prior written permission of a Standards Department of the Volkswagen Group.

Parties to a contract can only obtain this standard via the responsible procurement department.

VOLKSWAGEN AG

N

o

r

m

v

o

r

A

n

w

e

n

d

u

n

g

a

u

f

A

k

t

u

a

l

i

t

t

p

r

f

e

n

/

C

h

e

c

k

s

t

a

n

d

a

r

d

f

o

r

c

u

r

r

e

n

t

i

s

s

u

e

p

r

i

o

r

t

o

u

s

a

g

e

.

F

o

r

m

F

E

4

1

-

0

1

.

0

3

Changes

The following changes have been made as compared to Test Specification PV 1210, 2001-05:

Referenced standards updated

Previous issues

1981-08; 2001-05

1 Scope

This Test Specification is used for corrosion testing in sample and standard-production tests

conducted on completely painted bodies, body panels, assemblies and components with differing

anti-corrosion coatings.

It serves to monitor and evaluate corrosion behavior or corrosion protection measures of these

parts when exposed to static load.

2 Designation

Corrosion resistance according to PV 1210

3 Test method

3.1 Principle

The test is an alternating cycle consisting of a combination of various climatic and/or corrosion

loads.

A test cycle consists of

4 h salt spray fog test according to DIN 50021-SS,

4 h aging in the DIN 5001423/50-2 standard climate (including cooling-off phase),

16 hours humid aging at elevated temperature, climate according to DIN 50017- KK

(40 3) C; 100% humidity.

After 5 cycles, a 2-day rest phase takes place in the DIN 5001423/50-2 standard climate.

Using this test method, corrosion behavior under static load resulting from salt, humidity and

temperature is evaluated.

Under these defined corrosion conditions, different anti-corrosion coatings can be comparatively

assessed.

A correlation with the corrosion mechanism in actual driving operation is not necessarily possible,

as the types of vehicle damage and corrosion curves are complex and are not completely covered

and reflected by the changing corrosion load.

A short interruption of the test for inspection purposes and/or the removal of test specimens is

permitted. Interrupting the test by changing the test program is not permitted.

T

h

e

E

n

g

l

i

s

h

t

r

a

n

s

l

a

t

i

o

n

i

s

b

e

l

i

e

v

e

d

t

o

b

e

a

c

c

u

r

a

t

e

.

I

n

c

a

s

e

o

f

d

i

s

c

r

e

p

a

n

c

i

e

s

t

h

e

G

e

r

m

a

n

v

e

r

s

i

o

n

s

h

a

l

l

g

o

v

e

r

n

.

Page 2

PV 1210: 2004-09

3.2 Test fixtures

Assemblies, components and test panels can also be tested in suitable single or alternate devices.

The devices must comply with the specifications in DIN 50014, DIN 50017 and DIN 50021.

3.3 Body test

Testing is performed according to Section 3.1. Examples are given in Section 3.6.

In order to carry out a specific evaluation of cavities, the body can be turned.

Before being initially brought into the salt spray test chamber, the body, mounted on the pivoting

frame, is preconditioned in the DIN 5001423/50-2 standard climate, and is then moved into the

test chamber kept at a constant temperature.

3.3.1 Salt spray phase

During the test sequence with rotation, before each salt spray cycle, the body is turned about its

lengthwise axis so that it is positioned as in the following sequence: 0, 45, 135, 225and 315.

3.3.2 Standard climate aging / humid aging at elevated temperature

During the cooling-off phase and during humid aging at elevated temperature, the body is

positioned horizontally.

3.3.3 Repeating the test cycles

After humid aging at elevated temperature is completed according to Section 3.1, the body is

immediately placed in the salt spray test chamber and turned 90in a clockwise direction to 45,

135, 225or 315, according to the respective test cycle.

3.3.4 Weekend aging

The rest phase entails aging in the DIN 5001423/50-2 standard climate, with the body in

a horizontal position and placed either in a suitable garage/hall or in the test chamber.

3.4 Component test

The required minimum for complete testing is 5 parts.

The components or their sections are tested in accordance with DIN EN ISO 7253 (see Section 4).

Cavities must be exposed to the salt spray fog by cutting/opening of parts. If necessary,

unprotected trim edges must be covered before testing.

3.5 Evaluation

After 15, 30, 60 and 90 cycles, the specimens are evaluated with regard to

Type of corrosion (coating and/or base metal corrosion),

Form of corrosion (surface or edge corrosion),

Time of appearance and development of corrosion,

as well as with regard to additional changes in the anti-corrosion coating such as loss of adhesion

or blistering.

Organic coatings can be evaluated according to DIN EN ISO 4628-1, Table 3.

Page 3

PV 1210: 2004-09

Signs of rust creep on painted sheets can be examined using a non-destructive thermographic

method for quantitative evaluation of the development and spread of defects.

The test is concluded when corrosion grade Ri5 according to DIN EN ISO 4628-3 or corrosion

perforations occur.

The following must be stated in the test report:

Parts examined : e.g., painted sheets

Corrosion protection measures: e.g., paint finish (coating thickness: 96 m, measured

in the sheet center)

Test: Start/end

Evaluation:

Start of base metal corrosion: e.g., after 15 cycles: surface corrosion Ri 2

Blistering: e.g., after 18 cycles: blistering grade 2 (S4)

Adhesion loss: e.g., D = 3 mm

End of test. e.g., after 30 cycles

Notes / remarks

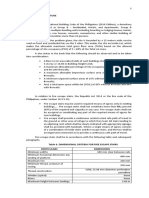

3.6 Examples for week cycle

3.6.1 Example 1

In manufacturing operations from 5:30 a.m. to 10:30 p.m., for one salt spray test chamber and

four chambers for humid aging at elevated temperature (Table 1), change-over times

max. 2 15 minutes per test cycle, throughput eight passenger car bodies.

Table 1

Bodies Salt spray fog test Cooling-off phase Humid aging at

elevated temperature

Weekend aging

A/B 6:00 a.m.-

10:00 a.m., Mo-Fr

10:15 a.m.-

2:15 p.m., Mo-Fr

2:30 p.m.-

5:45 a.m., Mo-Sa

6:00 a.m.-

5:45 a.m., Sa-Mo

C/D 10:00 a.m.-

2:00 p.m., Mo-Fr

2:15 p.m.-

6:15 p.m., Mo-Fr

6:30 p.m.-

9:45 a.m., Mo-Sa

10:00 a.m.-

9:45 a.m., Sa-Mo

E/F 2:00 p.m.-

6:00 p.m., Mo-Fr

6:15 p.m.-

10:15 p.m., Mo-Fr

10:30 p.m.-

1:45 p.m., Mo-Sa

2:00 p.m.-

1:45 p.m., Sa-Mo

G/H 6:00 p.m.-

10:00 p.m., Mo-Fr

10:15 p.m.-

2:15 a.m., Mo-Fr

2:30 a.m.-

5:45 p.m., Mo-Sa

6:00 p.m.-

5:45 p.m., Sa-Mo

Page 4

PV 1210: 2004-09

3.6.2 Example 2

In normal shift, for one salt spray test chamber and two chambers for humid aging at elevated

temperature, throughput: four passenger-car bodies (Table 2)

Table 2

Bodies Salt spray fog test Cooling-off phase Humid aging at

elevated temperature

Weekend aging

A/B 8:00 a.m.-

12:00 p.m., Mo-Fr

12:15 p.m.-

4:15 p.m., Mo-Fr

4:30 p.m.-

7:45 a.m., Mo-Sa

8:00 a.m.-

7:45 a.m., Sa-Mo

C/D 12:30 p.m.-

4:30 p.m., Mo-Fr

4:30 p.m.-

8:30 p.m., Mo-Fr

8:30 p.m.-

11:45 a.m., Mo-Sa

12:00 p.m.-

11:45 a.m., Sa-Mo

4 Note on testing

4.1 Salt spray fog test

The coated bodies, body panels, components and assemblies must be scribed through to the

metallic base material.

5 Referenced standards

*)

DIN 50014 Climates and Their Technical Application, Standard Climates

DIN 50017 Atmospheres and their Technical Application; Condensation Water Test

Atmospheres

DIN 50021 Spray Tests with Different Sodium Chloride Solutions

DIN EN ISO 4628-1 Paints and Varnishes Evaluation of Degradation of Coatings

Designation of Quantity and Size of Defects, and of Intensity of Uniform

Changes in Appearance; Part 1: General Introduction and Designation

System

DIN EN ISO 4628-3 Paints and Varnishes Evaluation of Degradation of Coatings

Designation of Quantity and Size of Defects, and of Intensity of Uniform

Changes in Appearance; Part 3: Assessment of Degree of Rusting

DIN EN ISO 7253 Paints and Varnishes Determination of Resistance to Neutral Salt

Spray (Fog)

*)

In this section, terminological inconsistencies may occur as the original titles are used.

Das könnte Ihnen auch gefallen

- 1997 Uniform Code For The Abatement of Dangerous BuildingsDokument19 Seiten1997 Uniform Code For The Abatement of Dangerous BuildingsMatthew Taylor100% (1)

- Engineered Coating SDokument2 SeitenEngineered Coating SHo Bach100% (1)

- GMW 3044-0405Dokument5 SeitenGMW 3044-0405GilmarasanNoch keine Bewertungen

- Certification Roadmap 11-30-16Dokument1 SeiteCertification Roadmap 11-30-16Cristian Gavilanes MontoyaNoch keine Bewertungen

- Worldwide Engineering Standards: Neutral Salt Spray (NSS) TestDokument4 SeitenWorldwide Engineering Standards: Neutral Salt Spray (NSS) Testjorgesalg100% (2)

- API RP 1102 SpreadsheetDokument5 SeitenAPI RP 1102 Spreadsheetdrramsay100% (4)

- E M5083 2016-NDokument7 SeitenE M5083 2016-NPongsan57% (7)

- Organic Coat GMW 14670 PDFDokument4 SeitenOrganic Coat GMW 14670 PDFYosua Dimas Agus SriyantoNoch keine Bewertungen

- ICBO Mechanical Code-97Dokument185 SeitenICBO Mechanical Code-97Matthew Taylor100% (1)

- TL - 260 - en 2015Dokument11 SeitenTL - 260 - en 2015hand42100% (1)

- TL211 Paint Coatings On Exterior Plastic Parts RequirementsDokument9 SeitenTL211 Paint Coatings On Exterior Plastic Parts RequirementsFrancesco VignaliNoch keine Bewertungen

- ATE N 553 81.09 (En)Dokument11 SeitenATE N 553 81.09 (En)Miguel QueirosNoch keine Bewertungen

- EX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFDokument3 SeitenEX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFEd RiNoch keine Bewertungen

- GMW14671 (Dec 2016)Dokument5 SeitenGMW14671 (Dec 2016)Ashley Wiley100% (2)

- TL 212 en 2021 06Dokument9 SeitenTL 212 en 2021 06David DomokosNoch keine Bewertungen

- TL 226 en 2018Dokument13 SeitenTL 226 en 2018Michal BílekNoch keine Bewertungen

- Trim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. ScopeDokument11 SeitenTrim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. Scopeerik0007Noch keine Bewertungen

- Worldwide Engineering Standards: Stone Impact Resistance of CoatingsDokument6 SeitenWorldwide Engineering Standards: Stone Impact Resistance of CoatingsAlondra CVNoch keine Bewertungen

- VW50180 en 2000-07-01Dokument3 SeitenVW50180 en 2000-07-01Bruno BrasseurNoch keine Bewertungen

- VW2.8.1 en 2009-12-01Dokument17 SeitenVW2.8.1 en 2009-12-01mehmet ustunNoch keine Bewertungen

- WSS M8P16 BDokument16 SeitenWSS M8P16 Berik0007Noch keine Bewertungen

- Worldwide Engineering Standards: Tape Adhesion Test For Paint FinishesDokument3 SeitenWorldwide Engineering Standards: Tape Adhesion Test For Paint FinishesRicardo Bavasso100% (1)

- PV 1303Dokument10 SeitenPV 1303tufantasma100% (2)

- A Research Paper On DormitoriesDokument5 SeitenA Research Paper On DormitoriesNicholas Ivy EscaloNoch keine Bewertungen

- TL 260 Engl 20040501 PDFDokument4 SeitenTL 260 Engl 20040501 PDFAniruddha HawalNoch keine Bewertungen

- GMW 8-2008Dokument9 SeitenGMW 8-2008Clauco Tiago Seno RoqueNoch keine Bewertungen

- F 22 - 13Dokument5 SeitenF 22 - 13Azize Razam100% (1)

- Worldwide Engineering Standards: Corrosion Performance SpecificationDokument8 SeitenWorldwide Engineering Standards: Corrosion Performance SpecificationAkmal Nizametdinov100% (1)

- PV 3952 (2002)Dokument4 SeitenPV 3952 (2002)Matthew Taylor100% (2)

- PV 3952 (2002)Dokument4 SeitenPV 3952 (2002)Matthew Taylor100% (2)

- m3018 en - 2008 08Dokument16 Seitenm3018 en - 2008 08Ronaldo Rodrigues100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryVon EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNoch keine Bewertungen

- GMW14671 - Organic Coating UnderbodyDokument4 SeitenGMW14671 - Organic Coating UnderbodyYosua Dimas Agus SriyantoNoch keine Bewertungen

- Standard Test Method For Impact Resistance D2794Dokument3 SeitenStandard Test Method For Impact Resistance D2794vasu_suvaNoch keine Bewertungen

- GMW 14829 PDFDokument3 SeitenGMW 14829 PDFEd Ri100% (2)

- R 021 R 2 A 1 eDokument24 SeitenR 021 R 2 A 1 egsuoag100% (1)

- Iso 1463 2004 PDFDokument4 SeitenIso 1463 2004 PDFGerardo Rivera50% (2)

- Gravimetric Determination of Condensable Components: Group StandardDokument6 SeitenGravimetric Determination of Condensable Components: Group Standardthiagomcasimiro100% (1)

- PR308 - 2+00+en - Invecchiamento BMWDokument10 SeitenPR308 - 2+00+en - Invecchiamento BMWAnonymous 8Z2HZ5JP7100% (1)

- N67F CM-ZN-2 - 5001.110.016 - NormDokument22 SeitenN67F CM-ZN-2 - 5001.110.016 - Normgokul100% (1)

- Hand Out To Borbet GMBH: Coating Adhesion TestDokument8 SeitenHand Out To Borbet GMBH: Coating Adhesion Testferhat aydoganNoch keine Bewertungen

- Iso 11997-1 - 2005Dokument8 SeitenIso 11997-1 - 2005Khin Khin Thaw100% (2)

- VW 13750 enDokument16 SeitenVW 13750 enNatan1912100% (1)

- Automotive Specification List PDFDokument14 SeitenAutomotive Specification List PDFGilmarasanNoch keine Bewertungen

- D271389 F' PDFDokument13 SeitenD271389 F' PDFReza AbdolahiNoch keine Bewertungen

- Scope TestsDokument4 SeitenScope TestsGonzalo TelleríaNoch keine Bewertungen

- International Standard: Paints and Varnishes - Cross-Cut TestDokument20 SeitenInternational Standard: Paints and Varnishes - Cross-Cut TestBehrooz75% (4)

- May 2021 Examination Diet School of Mathematics & Statistics ID5059Dokument6 SeitenMay 2021 Examination Diet School of Mathematics & Statistics ID5059Tev WallaceNoch keine Bewertungen

- STJLR 51 5254Dokument7 SeitenSTJLR 51 5254akomocar100% (1)

- PV - 1210 - EN 14482 - Corrosion Test PDFDokument5 SeitenPV - 1210 - EN 14482 - Corrosion Test PDFAniruddha HawalNoch keine Bewertungen

- PV 1200 (2004) Environmental Cycle Test (+80/-40C)Dokument2 SeitenPV 1200 (2004) Environmental Cycle Test (+80/-40C)Matthew Taylor100% (1)

- PV 1200 (2004) Environmental Cycle Test (+80/-40C)Dokument2 SeitenPV 1200 (2004) Environmental Cycle Test (+80/-40C)Matthew Taylor100% (1)

- D27 1327 - Ind.F - en - Resist. Imersão em ÁguaDokument9 SeitenD27 1327 - Ind.F - en - Resist. Imersão em Águaclaudio5475Noch keine Bewertungen

- PV 1425 (2008) Lubricating Oil Corrosivity TestDokument4 SeitenPV 1425 (2008) Lubricating Oil Corrosivity TestMatthew TaylorNoch keine Bewertungen

- VW 13750 - 2014-05 - enDokument21 SeitenVW 13750 - 2014-05 - enHarold_katzerNoch keine Bewertungen

- TL 52288Dokument6 SeitenTL 52288Thiago TorresNoch keine Bewertungen

- Harmonized Document: Fluids Resistance To VariousDokument8 SeitenHarmonized Document: Fluids Resistance To VariousJuliano Depetris100% (1)

- D1014Dokument5 SeitenD1014manox007Noch keine Bewertungen

- BS en Iso 06272-2-2011Dokument14 SeitenBS en Iso 06272-2-2011محمد مقلد0% (1)

- Iso 9227 2017Dokument11 SeitenIso 9227 2017Dineshkumardivya100% (2)

- TL 52622 enDokument43 SeitenTL 52622 enmakineci_67Noch keine Bewertungen

- Smartor manualENDokument148 SeitenSmartor manualENPP043100% (1)

- Wss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Dokument5 SeitenWss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Fab CarvalNoch keine Bewertungen

- WSS M16J19 BDokument10 SeitenWSS M16J19 BJuan Angel DechimaNoch keine Bewertungen

- Worldwide Engineering Standards: Tape Adhesion Test For Paint FinishesDokument9 SeitenWorldwide Engineering Standards: Tape Adhesion Test For Paint FinishesAkmal NizametdinovNoch keine Bewertungen

- VW 13750 Englisch Superficial TratamentDokument16 SeitenVW 13750 Englisch Superficial Tratamentrgi178Noch keine Bewertungen

- A10 0156 (Rev. C 2014.09) EN - TEST OR MEASUREMENT REPORTS WRITINGDokument14 SeitenA10 0156 (Rev. C 2014.09) EN - TEST OR MEASUREMENT REPORTS WRITINGDiego Camargo100% (2)

- Operating Salt Spray (Fog) Apparatus: Standard Practice ForDokument11 SeitenOperating Salt Spray (Fog) Apparatus: Standard Practice ForFelipeMoriNoch keine Bewertungen

- Rust Protection by Metal Preservatives in The Humidity CabinetDokument9 SeitenRust Protection by Metal Preservatives in The Humidity CabinettoanvmpetrologxNoch keine Bewertungen

- PV PV PV PV 1210 1210 1210 1210 Salt Salt Salt Salt Spray Spray Spray Spray Test Test Test Test Standard Standard Standard StandardDokument5 SeitenPV PV PV PV 1210 1210 1210 1210 Salt Salt Salt Salt Spray Spray Spray Spray Test Test Test Test Standard Standard Standard StandardJose BresciaNoch keine Bewertungen

- Astm D3972-09Dokument7 SeitenAstm D3972-09Matthew TaylorNoch keine Bewertungen

- Asme 1325-18 (2007)Dokument1 SeiteAsme 1325-18 (2007)Matthew TaylorNoch keine Bewertungen

- Case 1192-1 Ni-Cu-Al Bolting Material, SB-164 Modified Section VIII, Division 1Dokument1 SeiteCase 1192-1 Ni-Cu-Al Bolting Material, SB-164 Modified Section VIII, Division 1Matthew TaylorNoch keine Bewertungen

- PB VWL 709 ChryslerDokument32 SeitenPB VWL 709 ChryslerMatthew TaylorNoch keine Bewertungen

- PV 1058 (2010)Dokument4 SeitenPV 1058 (2010)Matthew TaylorNoch keine Bewertungen

- SRM OverviewDokument37 SeitenSRM Overviewbravichandra24Noch keine Bewertungen

- MS Y7 Spelling Bee Memo & List 21 22Dokument9 SeitenMS Y7 Spelling Bee Memo & List 21 22Muhammad Akbar SaniNoch keine Bewertungen

- Differential Association Theory - Criminology Wiki - FANDOM Powered by WikiaDokument1 SeiteDifferential Association Theory - Criminology Wiki - FANDOM Powered by WikiaMorningstarAsifNoch keine Bewertungen

- Coding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringDokument14 SeitenCoding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringBahar UğurdoğanNoch keine Bewertungen

- Biogas Technology Suppliers Directory 2018: Internati NalDokument6 SeitenBiogas Technology Suppliers Directory 2018: Internati NalRazvan PetricaNoch keine Bewertungen

- Strata Ene 2023Dokument8 SeitenStrata Ene 2023gabyNoch keine Bewertungen

- Timing Chain InstallationDokument5 SeitenTiming Chain InstallationToriTo LevyNoch keine Bewertungen

- Consumer Behaviour ProjectDokument43 SeitenConsumer Behaviour ProjectMuhammad UsmanNoch keine Bewertungen

- Lab Science of Materis ReportDokument22 SeitenLab Science of Materis ReportKarl ToddNoch keine Bewertungen

- Vocabulary: Activity 1Dokument18 SeitenVocabulary: Activity 1Aurora GonzalezNoch keine Bewertungen

- Al Kindi AssingmentDokument9 SeitenAl Kindi AssingmentMuhammad Sirajuddin MazlanNoch keine Bewertungen

- CAT 438 3kk Esquema ElectricoDokument2 SeitenCAT 438 3kk Esquema ElectricocasigreNoch keine Bewertungen

- Recruitment and SelectionDokument50 SeitenRecruitment and SelectionAmrita BhatNoch keine Bewertungen

- IUK Routemap - GovernanceDokument27 SeitenIUK Routemap - GovernanceTom RedwayNoch keine Bewertungen

- (LS 1 English, From The Division of Zamboanga Del SurDokument17 Seiten(LS 1 English, From The Division of Zamboanga Del SurKeara MhieNoch keine Bewertungen

- COCapplication08rev Working SampleDokument34 SeitenCOCapplication08rev Working SampleTanya HerreraNoch keine Bewertungen

- Quotation Request Form: Customer DetailsDokument1 SeiteQuotation Request Form: Customer DetailsAmanda RezendeNoch keine Bewertungen

- SAGC Compliance Awareness-Grid UsersDokument66 SeitenSAGC Compliance Awareness-Grid Userskamal_khan85Noch keine Bewertungen

- Brittan Bradford ResumeDokument2 SeitenBrittan Bradford Resumeapi-574584381Noch keine Bewertungen

- Examen Inglés de Andalucía (Ordinaria de 2019) (WWW - Examenesdepau.com)Dokument2 SeitenExamen Inglés de Andalucía (Ordinaria de 2019) (WWW - Examenesdepau.com)FREESTYLE WORLDNoch keine Bewertungen

- International Trade SyllabusDokument3 SeitenInternational Trade SyllabusDialee Flor Dael BaladjayNoch keine Bewertungen

- Aljotronic Control 2Dokument30 SeitenAljotronic Control 2Fuzzbuddy100% (1)

- Catalog ITEM - Pdf4a3667894b315Dokument552 SeitenCatalog ITEM - Pdf4a3667894b315Domokos LeventeNoch keine Bewertungen

- (Checked) 12 Anh 1-8Dokument9 Seiten(Checked) 12 Anh 1-8Nguyễn Khánh LinhNoch keine Bewertungen

- 1.1. CHILLER 1.2. Centrifugal: 5.2.hrizontalDokument2 Seiten1.1. CHILLER 1.2. Centrifugal: 5.2.hrizontalShah ArafatNoch keine Bewertungen