Beruflich Dokumente

Kultur Dokumente

IEEE Projects 2014 - 2015 Abstracts - Electrical 08

Hochgeladen von

Final Year Projects 2014Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IEEE Projects 2014 - 2015 Abstracts - Electrical 08

Hochgeladen von

Final Year Projects 2014Copyright:

Verfügbare Formate

www.ingenstech.

com

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

Induction Motor Monitoring And Fault Prevention System Based On

Labview

Abstract

In a normal industrial environment there are lots of machines that operate on different functions.

The proper functioning of these machines is necessary to ensure good productivity and safety. But

failures become inevitable in an environment where there are lots of external parameters that

influence the functioning of the machines. Induction motor is one such machine which is used

extensively from small agricultural fields to large complex industrial houses. They are susceptible to

lots of variations because it is connected to external common power lines. This project aims at

monitoring various parameters of the machines and prevents damage to the machine.

The project aims at monitoring the important parameters of an induction motor substation. The

parameters that are to be monitored are temperature. The project also includes monitoring

parameters like voltage and current frequency. These parameters are taken and given to the ARM

after converting into required formats. The ARM microcontroller transmits the parameters using

suitable medium to a PC that is attached to a level converter.

Further all the obtained data and the control data are displayed on the PC which runs Labview which

is an advanced measurement and automation software. Use of VI has innumerable advantages such

as easy configuration, easy control, variety of data representation, ease of modification, low cost

and a host of others. The user-friendly control panel gives the operator to operate everything in

mouse clicks whereas its robust architecture gives a reliable security and an unmatched accuracy.

The VI has everything in digital so any change can be made with ease. Further a lots of analysis such

as histogram, graphs, etc which are not possible in a conventional software can be plotted on the

screen. As its relatively new and more advanced the project has a good level of advanced concepts.

Existing System

1. In existing method, manual process is employed to enquire the fault identification.

2. Conventional fault identification systems that inform about the fault but do not give

information about which fault happened first.

Proposed System

1. In Proposed system, sensor can be used to monitor the multiple parameters.

2. Use of VI has innumerable advantages such as easy configuration and also easy control,

so any changes can be done easily.

3. In this project, High speed ARM controller is used.

Ingens Tech Private Limited | For Students Use Only | All Rights Reserved

www.ingenstech.com | IEEE Projects 2014 - 2015 abstracts | Final Year Projects

www.ingenstech.com

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

Block Diagram

Temperature

ARM / PIC

A

D

C

U

A

R

T

S

P

I

I

2

C

G

P

I

O

D

A

C

/

P

W

M

Power

& Reset

U

A

R

T

GPIO

ROM

RAM

CLOCK

USB to UART Interface

USB Port

Converter

IC

UART

Interface

Voltage Sensing

PT Diode

Rectifier

LP

Filter

V

Current Sensing

Sensor Diode

Rectifier

LP

Filter

A

Alarm

PC

POWER SUPPLY

Power

Adapter

Reverse

Protection

Voltage

Regulators

Power LED

MACHINE MODULE

Ingens Tech Private Limited | For Students Use Only | All Rights Reserved

www.ingenstech.com | IEEE Projects 2014 - 2015 abstracts | Final Year Projects

www.ingenstech.com

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

w

w

w

.

i

n

g

e

n

s

t

e

c

h

.

c

o

m

|

Software Tools

LPCXpresso IDE / MPLAB IDE

EAGLE

Orcad

Labview

Embedded C

Hardware Required

ARM LPC11U67 / PIC18F45K22

Current Transformer

Voltage Transformer

Temperature Sensor

PC Interface

Alarm

Ingens Tech Private Limited | For Students Use Only | All Rights Reserved

www.ingenstech.com | IEEE Projects 2014 - 2015 abstracts | Final Year Projects

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- IEEE Projects 2014 - 2015 Abstracts - Sensor 05Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Sensor 05Final Year Projects 2014Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- IEEE Projects 2014 - 2015 Abstracts - PLC 02Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 02Final Year Projects 2014Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- IEEE Projects 2014 - 2015 Abstracts - Sensor 08Dokument4 SeitenIEEE Projects 2014 - 2015 Abstracts - Sensor 08Final Year Projects 2014Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- IEEE Projects 2014 - 2015 Abstracts - Robotics 03Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Robotics 03Ieee Projects 2014Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- IEEE Projects 2014 - 2015 Abstracts - Electrical 07Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Electrical 07Final Year Projects 2014Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- IEEE Projects 2014 - 2015 Abstracts - PLC 06Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 06Final Year Projects 2014Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- IEEE Projects 2014 - 2015 Abstracts - Sensor 02Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Sensor 02Final Year Projects 2014Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- IEEE Projects 2014 - 2015 Abstracts - Sensor 04Dokument4 SeitenIEEE Projects 2014 - 2015 Abstracts - Sensor 04Final Year Projects 2014Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- IEEE Projects 2014 - 2015 Abstracts - Sensor 03Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Sensor 03Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - PLC 05Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 05Final Year Projects 2014Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- IEEE Projects 2014 - 2015 Abstracts - PLC 08Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 08Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Electrical 06Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Electrical 06Final Year Projects 2014Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- IEEE Projects 2014 - 2015 Abstracts - Sensor 01Dokument4 SeitenIEEE Projects 2014 - 2015 Abstracts - Sensor 01Final Year Projects 2014Noch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- IEEE Projects 2014 - 2015 Abstracts - PLC 07Dokument4 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 07Final Year Projects 2014Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- IEEE Projects 2014 - 2015 Abstracts - PLC 04Dokument4 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 04Final Year Projects 2014Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- IEEE Projects 2014 - 2015 Abstracts - PLC 03Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 03Final Year Projects 2014Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- IEEE Projects 2014 - 2015 Abstracts - Zigbee 01Dokument4 SeitenIEEE Projects 2014 - 2015 Abstracts - Zigbee 01Ieee Projects 2014Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- IEEE Projects 2014 - 2015 Abstracts - Electrical 05Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Electrical 05Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Electrical 02Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Electrical 02Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Bluetooth 08Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Bluetooth 08Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - PLC 01Dokument4 SeitenIEEE Projects 2014 - 2015 Abstracts - PLC 01Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Electrical 03Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Electrical 03Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Bluetooth 07Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Bluetooth 07Final Year Projects 2014Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Android Based Robot Using BluetoothDokument3 SeitenAndroid Based Robot Using BluetoothFinal Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Bluetooth 05Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Bluetooth 05Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Bluetooth 03Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Bluetooth 03Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Bluetooth 01Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Bluetooth 01Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Bio Metrics 07Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Bio Metrics 07Final Year Projects 2014Noch keine Bewertungen

- IEEE Projects 2014 - 2015 Abstracts - Bio Metrics 08Dokument3 SeitenIEEE Projects 2014 - 2015 Abstracts - Bio Metrics 08Final Year Projects 2014Noch keine Bewertungen

- IPECS 50 Innstallation ManualDokument58 SeitenIPECS 50 Innstallation ManualpeterNoch keine Bewertungen

- XBee PRO 2 - 4 DigiMeshDokument69 SeitenXBee PRO 2 - 4 DigiMeshRam_G_JesNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Android To Z: A Complete Evolution GuideDokument7 SeitenAndroid To Z: A Complete Evolution GuideVikashclaNoch keine Bewertungen

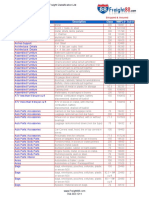

- Freight88 Freight Class CheatsheetDokument11 SeitenFreight88 Freight Class Cheatsheetexamen707160% (5)

- Daftar GedungDokument62 SeitenDaftar GedungDewi SusantiNoch keine Bewertungen

- ERXDokument612 SeitenERXAbdul M MalikNoch keine Bewertungen

- Structural Pruning Guide for Strong, Safe TreesDokument8 SeitenStructural Pruning Guide for Strong, Safe TreeswdarreNoch keine Bewertungen

- Constructing Cross Passages in Varied GeologyDokument22 SeitenConstructing Cross Passages in Varied GeologyParasuram BonangiNoch keine Bewertungen

- BoQ GRP Pipe Contructor 20180918Dokument8 SeitenBoQ GRP Pipe Contructor 20180918Mohammad SyeduzzamanNoch keine Bewertungen

- Laboratory Exercise 1: Using An Altera Nios II SystemDokument12 SeitenLaboratory Exercise 1: Using An Altera Nios II SystemNam TômNoch keine Bewertungen

- Concrete Mix Design M20 GradeDokument4 SeitenConcrete Mix Design M20 GradeSyerifaizal Hj. MustaphaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Desalination BOQDokument7 SeitenDesalination BOQDishantha PrasadNoch keine Bewertungen

- Accelerate With Ibm Storage CSM UpdateDokument36 SeitenAccelerate With Ibm Storage CSM UpdateufukozdemirNoch keine Bewertungen

- Vb-Audio Cable: Case StudyDokument8 SeitenVb-Audio Cable: Case StudyROMAN RODOLFO AREVALO RODRIGUEZNoch keine Bewertungen

- Final Report - Pdf-Urban Village PDFDokument30 SeitenFinal Report - Pdf-Urban Village PDFReswannaApsalNoch keine Bewertungen

- Operation Manual Telairity SD HD Encoder Setup Manual-EDokument65 SeitenOperation Manual Telairity SD HD Encoder Setup Manual-ETechne Phobos100% (2)

- Division 04: Brick Works, Patent Stone in Floor and Fancy Screen Block WorkDokument3 SeitenDivision 04: Brick Works, Patent Stone in Floor and Fancy Screen Block Workamit dasguptaNoch keine Bewertungen

- IO SummaryDokument8 SeitenIO SummaryVineeth VKNoch keine Bewertungen

- IS 15301: Installation and Maintenance of Fire Fighting Pumps - Code of PracticeDokument13 SeitenIS 15301: Installation and Maintenance of Fire Fighting Pumps - Code of Practiceashwani100% (1)

- Central Vista, New DelhiDokument21 SeitenCentral Vista, New DelhiAbhinav NarainNoch keine Bewertungen

- Mscit 102Dokument2 SeitenMscit 102api-3782519Noch keine Bewertungen

- BLD-ELEC Standard Data For Electrical Items In BuildingsDokument115 SeitenBLD-ELEC Standard Data For Electrical Items In BuildingsrokiahhassanNoch keine Bewertungen

- 74HC165 8-Bit PISO Shift RegisterDokument10 Seiten74HC165 8-Bit PISO Shift Registeroscar_ceja_02Noch keine Bewertungen

- Two Years of Jet-Grouting in British ColumbiaDokument10 SeitenTwo Years of Jet-Grouting in British ColumbiaabbidubbiNoch keine Bewertungen

- Command Line Reference Az Filetype PDFDokument2 SeitenCommand Line Reference Az Filetype PDFTinaNoch keine Bewertungen

- Certificate of Product Approval: TRIMO D.O.ODokument2 SeitenCertificate of Product Approval: TRIMO D.O.Oprimoz1Noch keine Bewertungen

- 12 Steps To Success (UK) - 1 PDFDokument1 Seite12 Steps To Success (UK) - 1 PDFAndreea JurgeNoch keine Bewertungen

- Building ServicesDokument49 SeitenBuilding ServicesGireendraNoch keine Bewertungen

- How To Configure NetBackup For Granular Restore Technology (GRT) Backups of Exchange Server 2010 On Windows 2008 and Windows 2008 R2Dokument2 SeitenHow To Configure NetBackup For Granular Restore Technology (GRT) Backups of Exchange Server 2010 On Windows 2008 and Windows 2008 R2William RojasNoch keine Bewertungen

- RBD-17 09 2020Dokument137 SeitenRBD-17 09 2020hishamndtNoch keine Bewertungen