Beruflich Dokumente

Kultur Dokumente

Distill Trays

Hochgeladen von

Sanjoy Kr. Dey0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

154 Ansichten2 SeitenDistill Trays

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDistill Trays

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

154 Ansichten2 SeitenDistill Trays

Hochgeladen von

Sanjoy Kr. DeyDistill Trays

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

INTRODUCTION

For more than 25 years, UOP has been a leader in the

supply of high performance trays for distillation,

absorption, stripping, and extraction. UOP trays not

only have outstanding performances but are backed by

broad and documented field experience. UOP distilla-

tion trays provide:

Reduced column diameter in grassroots applications.

Increased capacity from existing columns.

Maximum number of theoretical trays in a given

column height.

Easy scale-up to any diameters.

Fast, simple installation giving short turnaround

times.

Low sensitivity to out-of-levelness.

Minimization or elimination of foaming/fouling.

APPLICATIONS

MD

TM

trays are used for large liquid loads, particularly

when the volumetric ratio between vapor and liquid

rates is low. These situations occur in medium to high

pressure distillation, in absorption and stripping, and in

direct contact heat transfer applications.

MD trays can be used at close tray spacings. They allow

a reduction in both height and diameter of a new column

compared to a column fitted with conventional multi-

pass trays. Vessel shell costs are significantly lowered

by using MD trays. When retrofitting an existing col-

umn with MD trays, a significantly greater number can

be installed, providing increased product purities and

recoveries, as well as reduced reflux ratio for reduced

energy consumption and/or increased column capacity.

The use of MD trays has often reduced the number of

columns needed in difficult separations, such as super-

fractionation of propylene-propane or of xylene isomers.

UOP continues to improve the design of its proprietary

trays to meet specific customer needs. In recent years,

the EEMD

TM

tray and ECMD

TM

tray were developed and

have been installed to achieve specific distillation objec-

tives. Both of these advanced trays are based on the

same operating principles, design philosophies, and

experience as the original MD tray.

UOP also provides other proprietary equipment, including

the MU

TM

tray and Slotted Sieve

TM

tray, for various

applications.

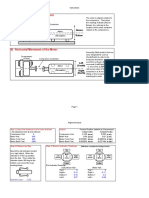

FUNCTIONAL FEATURES OF MD TRAYS

Long total weir length and large downcomer area

provide high liquid handling capability.

No receiving pan area to detract from bubbling area.

90 rotation of downcomers on successive MD

trays promotes lateral mixing and provides easy

scale-up.

Low crest heights over weirs permit close tray

spacings.

Typically, downcomers provide the necessary

structural support up to 30 foot diameters, without

center beams.

Downcomers are supported on a 360 ring, no

bolting bars are required.

Unique downcomer lengths give fast, simple

installation.

Trays can be fabricated with an underflow weir and

vapor seal downcomer options to achieve a large

turndown ratio.

Tray efficiencies range from 70-90% in distillation

service.

Low tray pressure drop of 0.06-0.09 psi.

TURNDOWN

MD trays can generally turn down to 70% of their

design flow rates, particularly when they are used at

UOP Distillation Trays

large tray spacings. The use of sieve decks helps keep

the tray efficiency constant as rates are being turned

down. In columns where a large number of trays are

required, only MD trays can be used at the requisite

close tray spacings. In cases where additional liquid

turndown capability is required, special vapor seal

downcomers can be employed.

GENERAL DESIGN CONSIDERATIONS

The key to MD tray performance is the very large total

weir length provided on each tray. This gives low liquid

loads per unit weir length even at very high total liquid

flow rates. The weir load on MD trays is usually about

1/4 to 1/3 of the weir load on conventional two- or four-

pass trays. The low weir loads on MD trays allow the

use of lower tray spacings at the same capacity factor or

allow a higher capacity factor to be used at the same

tray spacing compared to conventional trays. The result

is a larger number of trays in a given column height and

reduced column diameters. An additional advantage of

MD trays is the absence of receiving pans, because

downcomers terminate above the froth of the tray below.

This provides extra bubbling area, reducing the column

diameter required.

The tray spacing used for MD trays is sometimes deter-

mined by the backup of froth in the downcomer. The

low weir loads on MD trays allow close control over the

froth height on the tray, which is set by the weir height.

As a result, weeping can be prevented with a lower dry

tray pressure drop, further reducing the tray spacing

required.

High liquid loads on conventional trays often result in

foaming and a reduction of efficiency from vapor

entrainment through the downcomers. MD trays largely

avoid these problems by the use of low liquid velocities

across the tray, without costly and cumbersome antifoam

additions.

Because of the short flow path length,

MD trays operate only slightly above

point efficiency. However, experience

has shown that because of the adverse

effects found on conventional trays, the

tray efficiencies of MD trays and con-

ventional multipass trays are usually

comparable.

COMMERCIAL EXPERIENCE

UOP trays have been proven to increase

separation performance, reduce capital

and operating costs, and/or increase

column capacity in a wide range of

applications. They are particularly

effective for:

Medium to high pressure distillation (MD tray,

ECMD tray, EEMD tray)

Medium to large diameter columns (Slotted Sieve

tray, MD tray, ECMD tray, EEMD tray)

Difficult, low relative volatility separations (Slotted

Sieve tray, MD tray, ECMD tray, EEMD tray)

Heat pumping applications (Slotted Sieve tray, MD

tray, ECMD tray, EEMD tray)

Low pressure and vacuum distillation (Slotted

Sieve tray)

Heavily liquid loaded absorbers and strippers (MD

tray, ECMD tray)

Low interfacial tension extraction systems (MU tray)

UOP 4217-36 1103PTE0Bx

2004 UOP LLC. All rights reserved.

The information in this document should not be construed as a representation for

which UOP assumes legal responsibility, or an authorization or recommendation to

practice a patented invention without a license.

UOP LLC

13105 NW Freeway, Suite 600

Houston, Texas 77040-6312, U.S.A.

Phone: +1-713-744-2800

www.uop.com

MD Tray Applications

Acetic acid/ water Cryogenic separations Glycols dehydration heat

separations transfer applications

Acetone/water Debutanizers Heavy water production

separations

Acetylene absorbers Deethanizers Xylenes separation

Acid gas absorbers & Demethanizers Phenol/cresol separation

strippers

Acrylonitrile Dichlorobenzene Propylene/propane splitters

absorbers & strippers purification

Butadiene absorbers Ethylbenzene-xylene Stabilizers

splitters

Butane splitters Ethylene-ethane Tetraethylene glycol strippers

splitters

Cresol/xylenols Ethylene oxide Vinyl acetate purification

purification absorbers & strippers

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Solutions Manual Principles Chemical Engineering Processes Material Energy Balances 2nd Edition Ghasem PDFDokument85 SeitenSolutions Manual Principles Chemical Engineering Processes Material Energy Balances 2nd Edition Ghasem PDFNivar selevanay75% (4)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- CH 2Dokument63 SeitenCH 2Arbanah Muhammad82% (11)

- Material BalanceDokument26 SeitenMaterial BalanceSai Krishna Lakkavajjala0% (1)

- Engine ReviewerDokument41 SeitenEngine ReviewerArturo John Mark Mata100% (3)

- Ofd en WebDokument6 SeitenOfd en WebSanjoy Kr. DeyNoch keine Bewertungen

- A) Vertical Movement of The Motor: Compressor (Fixed)Dokument3 SeitenA) Vertical Movement of The Motor: Compressor (Fixed)Sanjoy Kr. DeyNoch keine Bewertungen

- Control Valve Training MaterialDokument36 SeitenControl Valve Training MaterialSanjoy Kr. DeyNoch keine Bewertungen

- Fundamentals of CompressorDokument16 SeitenFundamentals of CompressorSanjoy Kr. DeyNoch keine Bewertungen

- Fans & BlowersDokument7 SeitenFans & BlowersSanjoy Kr. DeyNoch keine Bewertungen

- Welding: Debasis Mitra Inspection DepartmentDokument31 SeitenWelding: Debasis Mitra Inspection DepartmentSanjoy Kr. DeyNoch keine Bewertungen

- Optimize Distillation ColumnsDokument16 SeitenOptimize Distillation Columnscrnewsom100% (3)

- Multipass Tray DesignDokument12 SeitenMultipass Tray DesignAyoun Ul HaqueNoch keine Bewertungen

- Steps To Check SKF BearingsDokument1 SeiteSteps To Check SKF BearingsSanjoy Kr. DeyNoch keine Bewertungen

- Pump AlignmentDokument1 SeitePump AlignmentSanjoy Kr. Dey100% (1)

- Protech Bearing Isolator Seal TheoryDokument8 SeitenProtech Bearing Isolator Seal TheorySanjoy Kr. DeyNoch keine Bewertungen

- Is.10512.2003 0Dokument13 SeitenIs.10512.2003 0Enrique Alejandro OvandoNoch keine Bewertungen

- Petrochemical 1Dokument68 SeitenPetrochemical 1AnilKumarNoch keine Bewertungen

- Distillation Optimization-Vapor RecompressionDokument5 SeitenDistillation Optimization-Vapor RecompressionChem.EnggNoch keine Bewertungen

- Correct FCC Tower RevampDokument8 SeitenCorrect FCC Tower RevampAlessio ScarabelliNoch keine Bewertungen

- Final Evaluation Final DraftDokument67 SeitenFinal Evaluation Final DraftshubhNoch keine Bewertungen

- MT Lab Mini Project Groups - 3!2!2022Dokument6 SeitenMT Lab Mini Project Groups - 3!2!2022Pavan ChinnaNoch keine Bewertungen

- Lab 1 CE 2015Dokument60 SeitenLab 1 CE 2015Doaa BadarnehNoch keine Bewertungen

- Salt Volatilisation ExperimentDokument7 SeitenSalt Volatilisation ExperimentjamesilluminareNoch keine Bewertungen

- Energy Efficiency and Integration in The Refining andDokument215 SeitenEnergy Efficiency and Integration in The Refining andjk.jackycheokNoch keine Bewertungen

- Reboiler: Types of ReboilersDokument5 SeitenReboiler: Types of ReboilersMigueAngelPFNoch keine Bewertungen

- Koch GlitschDokument36 SeitenKoch Glitschdeepanagha100% (1)

- Absorber-Stripper System Design For Biogas PurificationDokument20 SeitenAbsorber-Stripper System Design For Biogas Purificationkaye100% (1)

- Production of Biodiesel From Waste Oil Via Catalytic DistillationDokument15 SeitenProduction of Biodiesel From Waste Oil Via Catalytic Distillationali abdulrahman al-ezziNoch keine Bewertungen

- The Role of Statistics in EngineeringDokument42 SeitenThe Role of Statistics in EngineeringMohammed Abushammala50% (2)

- Lect12 Recycle Bypass PurgeDokument13 SeitenLect12 Recycle Bypass Purgechandro57Noch keine Bewertungen

- Extraction of Essential Oils From Citrus By-Products Using Microwave Steam DistillationDokument12 SeitenExtraction of Essential Oils From Citrus By-Products Using Microwave Steam DistillationKiesa Mae LeenNoch keine Bewertungen

- Equilibrium Stage Processes - Docx CetDokument25 SeitenEquilibrium Stage Processes - Docx CetPortia ShilengeNoch keine Bewertungen

- Agrifood Bioethanol Drying-Cooling ProcessesDokument5 SeitenAgrifood Bioethanol Drying-Cooling ProcessesCY LeeNoch keine Bewertungen

- Purificiation and Characterisation of Organic CompoundsDokument15 SeitenPurificiation and Characterisation of Organic CompoundsHari BabuNoch keine Bewertungen

- AspenPlusPetroleumV7 1 StartDokument45 SeitenAspenPlusPetroleumV7 1 StartLuis Eduardo Plazas100% (1)

- Modeling Oil and Petroleum EvaporationDokument12 SeitenModeling Oil and Petroleum EvaporationkozareclaNoch keine Bewertungen

- Aspentech Catalogo 1 20Dokument20 SeitenAspentech Catalogo 1 20Dany ReyesNoch keine Bewertungen

- Spirits in India PDFDokument3 SeitenSpirits in India PDFMUKESH KUMARNoch keine Bewertungen

- Ulva Lactuca As BiofertilizerDokument6 SeitenUlva Lactuca As BiofertilizerSherlice Rom - BelistaNoch keine Bewertungen

- Barnstead - Corning MegaPure Water Purification Stills and Spare Parts - BARNSTEAD WATERDokument7 SeitenBarnstead - Corning MegaPure Water Purification Stills and Spare Parts - BARNSTEAD WATERcountry boyNoch keine Bewertungen

- Rule of Thumb PapDokument12 SeitenRule of Thumb PapafifahNoch keine Bewertungen