Beruflich Dokumente

Kultur Dokumente

Kinetic Laws of The Chemical Process in The CVD of SiC Ceramics From CH3SiCl3 H2 Precursos PDF

Hochgeladen von

yagami1212120 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

56 Ansichten7 SeitenThe kinetic process of the CVD of silicon carbide from MTS-H2 precursor is investigated. Growth rate measurements as a function of temperature and initial gas phase composition are made. Two kinetic regimes are brought out depending on the temperature. At about 825"c, the deposition of SiC could be rate-limited by the homogeneous decomposition of MTS with an activation energy higher than 300 kJ.mo1-1.

Originalbeschreibung:

Originaltitel

kinetic laws of the chemical process in the cvd of SiC ceramics from CH3SiCl3 H2 precursos.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe kinetic process of the CVD of silicon carbide from MTS-H2 precursor is investigated. Growth rate measurements as a function of temperature and initial gas phase composition are made. Two kinetic regimes are brought out depending on the temperature. At about 825"c, the deposition of SiC could be rate-limited by the homogeneous decomposition of MTS with an activation energy higher than 300 kJ.mo1-1.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

56 Ansichten7 SeitenKinetic Laws of The Chemical Process in The CVD of SiC Ceramics From CH3SiCl3 H2 Precursos PDF

Hochgeladen von

yagami121212The kinetic process of the CVD of silicon carbide from MTS-H2 precursor is investigated. Growth rate measurements as a function of temperature and initial gas phase composition are made. Two kinetic regimes are brought out depending on the temperature. At about 825"c, the deposition of SiC could be rate-limited by the homogeneous decomposition of MTS with an activation energy higher than 300 kJ.mo1-1.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

JOURNAL DE PHYSIQUE IV

CoUoque C3, supplBment au Journal de Physique 11, Volume 3, aoiit 1993

Kinetic laws of the chemical process in the CVD of SiC ceramics from

CH3SiC13-H2 precursor

F. LOUMAGNE, F. LANGLAIS and R. NASLAIN

Laboratoire des Composites Thermoshuchlraux, UMR 47, CNRS-SEP-UBI, Domaine Universitaire,

3 AUke de la Bobtie, 33600 Pessac, France

ABSTRACT - On the basis of growth rate measurements as a function of

temperature and initial gas phase composition, the kinetic process of the CVD of

silicon carbide from MTS-H2 is investigated, particularly under conditions of

rate-control by the chemical reactions. Within specific ranges of dilution ratio

31a15 and total pressure 51PLlOkPa, two kinetic regimes are brought out

depending on the temperature. At about 825"C, the deposition of SiC could be rate-

limited by the homogeneous decomposition of MTS with an activation energy

higher than 300 kJ.mo1-1 and an apparent reaction order of 2.5 with respect to

MTS. At about 92S0C, surface reactions could control the overall kinetic process

with an activation energy of only 160 kJ.mo1-1 and an inhibitor chemisorption of

C1 species which involves a negative reaction order with respect to HCl.

1- INTRODUCTION

Silicon carbide prepared by chemical vapour deposition (CVD) can be integrated in

advanced electronic devices and ceramic matrix composites if specific conditions of

relatively low temperature and low pressure are used [I]. Among the various possible

precursors in both chemical systems Si-C-H and Si-C-H-Cl, the CH3SiC13 (MTS)/H2

gaseous mixture was very often chosen [2-51.

Under these T-P conditions, the kinetic laws which govern the chemical processes

involved i n the CVD of SiC are needed, with a view to understand the deposition

mechanisms and to model both the infiltration of porous substrates (CVI) 16, 73 and the

various phenomena occurring in the CVDJCVI reactors. These kinetic data can only be

acquired experimentally and up to now, very little is known in this field. Kinetic studies

have been carried out under atmospheric pressure and have resulted in (i) activation

energies within a large range of values (70 - 400 kJ.mol-I), depending on the deposition

temperature 18, 93 and (ii) a first order with respect to MTS 193. Under reduced pressure

(P=3.3kPa), a temperature of about 1000C and a ratio ~=PH~/ PMTs between 5 and 20,

Besmann and Johnson have determined an activation energy of 188 kJ.mol-1 and a zero-

order with respect to MTS 1101. The inhibition of the SiC deposition by the HCI by-product

was also evidenced by Besmann et al. for P=100kPa, T=llOOC and 10<ac20 [Ill. On the

other hand, according to thermodynamic calculations, the deposition of silicon carbide

was assumed to result from two successive chemical steps : (1) a homogeneous

decomposition of MTS in hydrogen giving rise to intermediate reactive species and (2) a

heterogeneous reaction between these actual gaseous precursors 1121. A kinetic

Article published online by EDP Sciences and available at http://dx.doi.org/10.1051/jp4:1993373

528 JOURNAL DE PHYSIQUE IV

investigation of the first step, carried out under atmospheric pressure and low

temperatures, revealed a high activation energy of 336 kJ.mo1-1, a first-order with

respect to MTS and a zero-order with respect to hydrogen [13]. At last, very recently, a

study of the growth rate in the MTS/H2 system as a function of total gas flowrate,

temperature and total pressure, has permitted to define accurately the conditions for a

kinetic process controlled by the chemical reactions [14].

The purpose of the present contribution is to investigate the influence of (i) the

temperature and (ii) the composition of the gas phase on the deposition rate for 11c155;

3.51P110kPa and two temperatures (i.e. 825 and 925OC) corresponding to different

activation energies. On the basis of a chemical analysis of the deposits, conditions for

pure Si c deposition have been defined and overall kinetic laws proposed.

The deposition experiments have been carried out on graphite substrates i n a

cylindrical hot-wall low pressure vertical reactor heated by radio-frequency induction

(fig. 1) with a large hot isothermal zone and a creeping laminar flow. The growth rate

measurements were performed in-situ with a microbalance (sensitivity of 2.5 pg). The

influence of the partial pressures of MTS and Hz was studied by varying a ratio (one

partial pressure is varied and the other is constant) and pressure P. For HCl and CH4

influence, additional amounts of these species were introduced i n the initial gaseous

mixture. The deposits have been characterized by X-ray diffraction and some of them

analysed by electron probe X-ray microanalysis (EPMA) and electron energy loss

spectroscopy(EELS)

1- Shuboff valve

2- Mass flowmeter

3- Microbalance

4- Microcomputer

5- Silica tubular reactor

6- Susceptor

7- R F. coil

8- Thermocouple

9- Liquid nitrogen trap

10- Pressure sensor

11- Pressure controller

12- Vacuum pump

CH3SiCl3

13- Mass spectrometer

14 Thermwtated bath

Figure 1 : Schematics of the CVD equipment

3- GROWTH KINETICS

3.1- Muence of temperature

The growth rate is plotted in figure 2 as a function of the reciprocal temperature for

Q=2OOsccm, &, P=l and 10kPa. Three domains are evidenced in these plots :

(i) For all conditions, at low temperatures (T < 850 - 900C), the deposition is highly

thermally activated. The activation energy is higher than 300 kJ.mo1-1, which means

that the kinetics is governed by chemical reactions.

(ii) For T>900C, a=3 and P=lkPa and for 850<Tc950C, a=3 and P=lOkPa, the deposition

kinetics is controlled by chemical reactions, but with a lower activation energy,

i.e.160&40kJ.mol-1.

(iii) At high temperatures (T>950C for a=3 and P=lOkPa), the deposition process is not

thermally activated. Mass transfers control the kinetics.

A temperature within each domain corresponding to thermally activated processes

is chosen for the study of the influence of the gas phase initial composition on the growth

rate, i. e. 825 and 925OC.

Figure 2 : Growth rate variations

with reciprocal temperature for Q=200sccm

3.2- Iduence of MTS partial pressure

The variations of the growth rate with MTS partial pressure are reported in a log-

log scale in figure 3 for PH2=4.2kPa and for both temperatures 825 and 925C. In these

experiments, as PMTS increases from 0.8 to 4.2 kPa, the total pressure is raised from 5 to

8.3 kPa, a ratio decreases from 5 to 1 and the total flow rate increases from 200 to 330

sccm (standard.cm3.min-1).

When the deposition kinetics is highly thermally activated (T=825"C), a drastic

influence of MTS content is observed. The growth rate is greatly favoured by an increase

of MTS partial pressure on low PMTS values side (the corresponding apparent reaction

order i s 2.5) and highly inhibited on the high PMTS values side (with an apparent

reaction order of -3). A large maximum is observed between these behaviours

corresponding to an apparent zero order in MTS.

530 JOURNAL DE PHYSIQUE IV

For T=925OC, the growth rate is higher and its variations with PMTS exhibit a

similar behaviour, which is however less pronounced. For low MTS partial pressures,

the growth rate is almost constant (with n=0.1), and for P~~s >2. 5kPa, a reaction order of

-1 is derived.

Figure 3 :Growth rate variations with NlTS partial pressure

fur Pm=4.2kPa and Qtot.=200-330 sccm

3.3- Influence of H2 partial pressure

The growth rate is plotted in figure 4 as a function of H2 partial pressure for

P~~s =1 . 7 k Pa , T=825 and 925OC. P H ~ increases from 1.7 to 8.5 kPa, the total pressure

from 3.4 to 10.2 kPa, a from 1 to 5 and Q from 160 to 480 sccm.

Two P H ~ domains are observed. For P~2c4kPa (a<2.5), hydrogen favours the

deposition rate, the apparent reaction order with respect to Ha being 2.5 at 825OC and 0.6

at 925OC. For higher Hz partial pressures, the growth rate is no more influenced by this

parameter.

1 Pm Wa) 5 10

F3gure 4 : Growth rate variations with Hz partial pressure

forPMT,=l.7kPa and Q=160-480sccm

3.4- Iduence of CH4 p d a l pressure

Figure 5 represents the variations of the growth rate with the partial pressure of

CH4 (which is added to the initial gas mixture) for P~Ts =l kPa, P~2=4kPa. As P C H ~ is

increased from 0.2 to 1 kPa, the total pressure increases from 5.2 to 6 kPa and the total

flow rate from 200 to 240 sccm. If the addition of methane to the gas phase does not

modify the growth rate for T=925OC, a very slight decrease is observed at low temperature

(T=825"C).

3.5- Influence of HCl partial pressure

0.1

1

B

a

E

V

0.01:

8

E

0

F

8

w

0.001

For P~Ts =l kPa, P~2=4kPa, T=825 and 925OC, the growth rate is drawn i n figure 6

versus HC1 partial pressure. For T=925"C, HC1 is added to the initial gas phase with a

partial pressure rising fiom 0.15 to 0.5 kPa, which increases the total pressure from 5.15

to 5.5 kPa. For T=825OC, PHC~ is raised from 0.05 to 0.1 kPa.

While at low temperature (825OC), additional HC1 does not seem to influence the

growth rate, for T=92EiC, an important inhibitor effect is observed with an apparent

reaction order of -2.5. Nevertheless, as HCl content increases in the initial gas mixture,

this inhibition decreases more and more.

- I

T-925"C

- - - - I

n=O

-

- T=825"C

n = - 0.2

A

A *

- I

Figure 6 : Growth rate variations with H a partial pressure

f a PMTs=lkPa, Pm=4kPa and Q=200-220sccm

0.1

P,Wa)

1 2

Figure 5 : Growth rate variations with CH4 partial pressure

for PMTs=lkPa, Pm=4kPa and Q=200-240sccm

532 JOURNAL DE PHYSIQUE IV

4 ANALYSIS OF THE DEPOSlT

On the basis of X-ray diffraction, EPMA and EELS analyses, it has been shown that

for 800<T<950C and a=5, an increase of the total pressure from 5 to 20 kPa favours a

silicon excess (60 - 70 Si at.%) and a very poor crystallization state. On the other hand, for

P=2OkPa and a=5, an increase of the temperature from 950C to llOOC favours a

stoichiometric p-silicon carbide well crystallized with a high textural effect in the <I l l >

direction. At last, for the low temperatures (T<950C) and the low pressures (PGkPa), a

decrease of the dilution ratio from 5 to 3 does not seem to modify the composition of the

deposit which remains P-Sic.

5- DISCUSSION - KINETIC LAWS

The results presented in sections 3 and 4 permit to specify the kinetic process of

pure Si c deposition from MTS/H2 system under conditions favourable to a rate control by

the chemical reactions. Within the dilution ratio and total pressure range defined by

31a15 and 5<PslOkPa, two temperature ranges are shown with different reactional

mechanisms.

In the range of relatively low temperatures, a previous investigation of the gas

phase by mass spectrometry analysis has evidenced a high activation energy of about 350

kJ.mo1-1 for the homogeneous decomposition of NITS [141, in accordance with the value

reported by Burgess and Lewis for P=100kPa and 7001T1850C [13]. For a temperature of

about 825"C, the CVD process could be controlled by the MTS homogeneous

decomposition. The apparent reaction order of 2.5 with respect to MTS is higher than

that previously reported 1131. A zero-order is observed for the other species Ha, CH4 and

HC1. As a result, the kinetic law for the formation of Si c can be written as follows for

3-15; 5QllOkPa and T = 825C :

R = ko exp (-Ea/RT) PMTS2.5 (1)

with Ea > 300 kJ.mo1-1.

Due to this high order with respect to MTS, an increase of its initial partial pressure

favours the homogeneous decomposition of MTS giving rise to reactive intermediate

species, e.g. Sic12 or Sic13 as silicon source species, CH3 as carbon precursor and HCl.

Under these conditions of low temperature (T=825"C), for relatively low initial partial

pressure of MTS, the extent of homogeneous decomposition is low and the deposition of

Si c is kinetically controlled by the production of the actual source species such as SiC12,

SiC13, CH3 ... The growing surface is not saturated in chemisorbed species and the

intermediates react on the surface more rapidly than they are formed in the

homogeneous phase. As PMTS is going on increasing (lla12), reactive species are

formed more and more rapidly, particularly HCl which is produced by both the

homogeneous and heterogeneous reactions. The inhibitor chemisorption of C1 species

can limit in this case the deposition rate, which possibly explains the important negative

order of -3 observed for PMTS 2 3 kPa, as shown in figure 3.

For higher temperatures (900Q1950C), the activation energy (i.e. 160 kJ.mo1-1) is

markedly lower than that for the MTS homogeneous decomposition. It means that this

reaction is turned rapid and i s no more limiting the Si c deposition process. Under the

previously defined conditions, i.e. 31a15; 5QllOkPa and T=925"C, the apparent reaction

orders with respect to MTS, Hz and CH4 are zero (nil orders with respect to MTS and H2

are in accordance with that obtained by Bessmann and Johnsontl03) and the order with

respect to HC1 is negative, varying from -2.5 to -0.6, which results in the following kinetic

law :

1

R = kIo exp (- E t a / R T ) y

(2)

l + p ~ ~ l

with = 5.105mg min-1 cm-2 Pan, Ea = 160 + 40 k~. mol -1 and 2.52nS0.6.

This kinetic behaviour shows t hat t he MTS dissociation has provided enough

reactive intermediates to saturate the surface. The inhibition effect of HCl, i n accordance

with Besmann et al. results [ I l l , which decreases as PHC~ raises, confirms t he

heterogeneous limitation of the overall kinetic process. The decrease of the growth rate

when PMTS increases above 3 kPa can also be explained on the basis of inhibitor

chemisorption of C1 species favoured by increasing the total pressure.

CONCLUSION

This work is a first approach to the kinetic laws of Sic vapour deposition from

CH3SiC13-H2 precursors, determined in specific ranges of temperatures, total pressures

and dilution ratios. For each chemically controlled domain, the limiting step and a set of

kinetic data have been derived. A more advanced paper with tentative mechanisms

fitting the given kinetic laws will follow.

ACKNOWLEDGEMENTS

The authors wish to thank Dr. S. Schamm (CEMES-LOE, CNRS, Toulouse) for her

contribution to the EELS analyses and both DRET (French Ministry of Defense) and SEP

for their financial support through a grant to F.Loumagne.

1- J. SCHLICHTING, Powder Metall. Int., 12, 3 (1980) 141 and 12, 4 (1980) 196.

2- K. MINATO and K. FUKUDA, J. Nucl. Mater., 149 (1987) 233.

3- P. TSUI and K.E. SPEAR, Mat. Sci. Res., 17 (1984) 371.

4 M.G. SO and J.S. CHUN, J. Vax. Sci. Technol., 6 (1988) 5.

5- K. BRENNFLECK, E. FITZER, G. SCHOCH and M. DIETRICH, Proc. 9th Int. Conf.

on CVD, Pennington, Mc D. Robinson et al., eds., The Electrochem. Soc. (1984) 649.

6 R. FEDOU, F. LANGLAIS and R. NASLAIN, J. Mat. Synth. and Proc., 1,1(1993).

7- R. FEDOU, F. LANGLAIS and R. NASLAIN, J. Mat. Synth. and Proc., 1, 2 (1993).

8- L.M. IVANOVNA and A.A. PLETIOUCHKINE, Izvest. Akad. Nank. SSSR, Neorg.

Mater. 4, 7 (1968) 1089.

9- T.M. BESMANN, B.W. SHELDON and M.D. KASTER, Surf. Coat. Technol., 43/44

(1990) 167.

10- T.M. BESMANN and M.L. JOHNSON, Proc. Int. Symp. on Ceramic Materials and

Components for Engines (Las Vegas, NV, 19881, V.J. Tennery, ed., Am. Ceram.

Soc., Westerville, OH, 1989.

11- T.M. BESMANN, B.W. SHELDON, T.S. MOSS I11 and M.D. KASTER, J. Am.

Ceram. Soc., 75,lO (1992) 2899.

12- F. LANGLAIS and C. PREBENDE, Proc. 11th Int. Conf. on CVD, K.E. Spear and

G.W. Cullen, eds., The Electrochem. Soc., Pennington, (1990) 686.

13- J.N. BURGESS and T.J. LEWIS, Chem. Ind. (1974) 76.

14 F. LOUMAGNE, F. LANGLAIS and R. NASLAIN, to be published.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Analysis of Buckling of Piles Fully Embedded in Ground According To Finite Element MethodDokument5 SeitenAnalysis of Buckling of Piles Fully Embedded in Ground According To Finite Element Methodctlim88Noch keine Bewertungen

- Jib Cranes 20875644 Colour CatalogueDokument30 SeitenJib Cranes 20875644 Colour Cataloguepsingh1996Noch keine Bewertungen

- Chebyshev PolynomialsDokument19 SeitenChebyshev PolynomialssofiavictorNoch keine Bewertungen

- Heat Transfer Types and EquationsDokument10 SeitenHeat Transfer Types and EquationsRAVEENA RAVINoch keine Bewertungen

- 5200 Shelves and Components, Part 1 of 2 PDFDokument266 Seiten5200 Shelves and Components, Part 1 of 2 PDFalek nowalNoch keine Bewertungen

- Elementarysurvey PDFDokument167 SeitenElementarysurvey PDFStanley OnyejiNoch keine Bewertungen

- 09-The Synthesis and Analysis of AspirinDokument12 Seiten09-The Synthesis and Analysis of AspirinJeffrey Lee100% (2)

- $binder 1Dokument156 Seiten$binder 1fchem11Noch keine Bewertungen

- Science Sample Papers 2Dokument7 SeitenScience Sample Papers 2api-281429068Noch keine Bewertungen

- ConvectionDokument4 SeitenConvectionFaheem Fiaz ChohanNoch keine Bewertungen

- Part Number 26-84: Illustrated Parts BreakdownDokument90 SeitenPart Number 26-84: Illustrated Parts BreakdownJesus OliverosNoch keine Bewertungen

- TOP 10 PAKISTANI SCIENTISTSDokument5 SeitenTOP 10 PAKISTANI SCIENTISTSabsarNoch keine Bewertungen

- MV Drop TestDokument5 SeitenMV Drop Testrajinipre-1Noch keine Bewertungen

- Introduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialDokument8 SeitenIntroduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialAYAUWU LOVEDAYNoch keine Bewertungen

- Program in Mathcad to Thin Rectangular PlatesDokument12 SeitenProgram in Mathcad to Thin Rectangular PlatesPedro Luis Garcia VillegasNoch keine Bewertungen

- BKI Vol2 - Section38Dokument5 SeitenBKI Vol2 - Section38Erwin Paulian SihombingNoch keine Bewertungen

- 11 HW ChemistryDokument6 Seiten11 HW ChemistryJ BalanNoch keine Bewertungen

- Shell Horizontal Butt-Weld Minimum RequirementsDokument16 SeitenShell Horizontal Butt-Weld Minimum RequirementsBTENoch keine Bewertungen

- Suntech STP225-20 WD 225Wp ENDokument2 SeitenSuntech STP225-20 WD 225Wp ENmax2503Noch keine Bewertungen

- Computer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. ScharerDokument6 SeitenComputer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. Scharerdaimon_pNoch keine Bewertungen

- SCH 305Dokument34 SeitenSCH 305Qwin NajyaNoch keine Bewertungen

- Rheopecty: Confusion Between Rheopectic and Dilatant FluidsDokument2 SeitenRheopecty: Confusion Between Rheopectic and Dilatant Fluidsengineer bilalNoch keine Bewertungen

- Torque NotesDokument3 SeitenTorque NotesKudzai MashayaNoch keine Bewertungen

- Autonics TK DatasheetDokument24 SeitenAutonics TK DatasheetHoang Anh0% (1)

- MCR 3U5 CPT Part 2Dokument4 SeitenMCR 3U5 CPT Part 2Ronit RoyanNoch keine Bewertungen

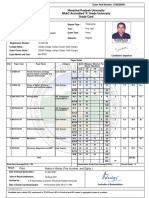

- Serial Number:1920110212668 Exam Roll Number Grade CardDokument2 SeitenSerial Number:1920110212668 Exam Roll Number Grade Cardsimran vaidNoch keine Bewertungen

- Boardwork No.1 and 2Dokument9 SeitenBoardwork No.1 and 2John Nalog100% (1)

- Linear equations worksheet solutionsDokument4 SeitenLinear equations worksheet solutionsHari Kiran M PNoch keine Bewertungen

- Orbital Velocity Formula - Solved Example With EquationsDokument5 SeitenOrbital Velocity Formula - Solved Example With Equationsmohamad magdyNoch keine Bewertungen

- Learning Objectives-2: Uniform MotionDokument7 SeitenLearning Objectives-2: Uniform MotionBryanHarold BrooNoch keine Bewertungen