Beruflich Dokumente

Kultur Dokumente

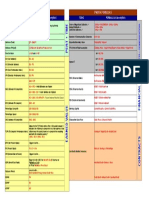

Walk Around Punch List-Towell Shipping Pump

Hochgeladen von

Roshin99Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Walk Around Punch List-Towell Shipping Pump

Hochgeladen von

Roshin99Copyright:

Verfügbare Formate

Sl No DESCRIPTION OF PUNCH ITEM

CATEGORY

(A/B/C)

STATUS EDC REMARKS

1

Painting to be done for all Piping & Weld joints in Suction/

Disharge line

C In progress

2

Painting to be done for all Pipe supports in Suction &

Discharge line

C In progress

3 Flow direction & colour coding to be provided for Piping C

4

Anchor bolts to be provided for all Pipe supports near pump

area on grade slap

A Completed

5

Pipe Support guide to be replaced on Booster pump suction

line

A Completed

1

Grouting to be done for all left out supports in shipping

pump discharge line

A Completed

2

De-shuttering to be done for all left out pipe supports in

shipping pump discharge line

B Completed

3

Pipe Support & Foundation to be provided for 3" Re-

circulation line from T-1202A

C Completed Pahse -II

4 Final Grouting for Booster Pump to be confirmed A Completed

5

All cable enetry to the motor connections to be through a

pipe sleave all the way inside pavement entry. Backfilling

the cables inside pavement withought cable sleaves is not

acceptable. Re-review the design to meet cable entry

standard.

A Completed

6 Balance Cable Trench to be backfilled inside DPS A Completed

1

Cable Tag to be Provided for ESD Valve & All left out Field

Instruments

A Completed

2 Route marker to be provided for all UG cables C

3

Proper cable tray installation required to avoid any tripping

hazards all around the pump pavements

B Completed

4

Earthing to be done for Junction box near booster &

shipping pump

A Completed

5

Anchor bolts for name plate stands near booster pump to

be replaced with uniformly

B

6

Cross bracing support to be provided for 4no's name plate

supports near booster pump

C

7

Earthing to be provided for booster & shipping pump Skids

with Earth Boss

A Completed

8 Instrument Tubing to be completed for Instrument air line A Completed

9

All under ground laying cables, edge to be properly covered

inside DPS

A to confirm

1 Earthing to be provided for all Ladder A Completed

2

Cable tray to be cutted for cable opening near the HVAC

side

A Completed

3

Plug/Cover to be provided for all smoke detectors unused

outlets below the building

B Completed to confirm

4

Cable tag to be provided for all cables under the S.G

Building

A Completed

5

All temporary cable tie to be replaced with permanent

metallic coated cable Tie's

A Completed

6

Colour coding/tape to be provided for all main power cables

under the S.G Building

A Completed

UPGRADE OF CRUDE OIL EXPORT FACILITIES AT DPS

SHIPPING & BOOSTER PUMP: MECHANICAL PUNCH POINTS

SHIPPING & BOOSTER PUMP: CIVIL PUNCH POINTS

SHIPPING & BOOSTER PUMP: E&I PUNCH POINTS

SWITCH GEAR BUILDING: E&I PUNCH POINTS

7 All temporary cables to be removed under the S.G Building A Completed

8 Louver location to be verified A Completed

9 Broken Shroud covers to be replaced in LV Panels C Completed

10

Smoke detector to be confirmed in corrider not installed to

be provided

B Pending

11 Lights to be installed in office room A Completed

12 Earth pit depth to be clarified A Completed

13

Additional Cable sleeves to be removed under the S.G

Building

B Completed

14

All Short length bolt to be replaced with proper size in

transformer

A Completed

15

Socket to be provided for transformer oil filtration calbe &

Properly aligned

B Completed

16 All the loose bolts to be properly tightened in transformer A Completed

17 Earthing to be provided for Handrails B Completed

18 S. G Wall Single socket to be Replaced with Double Socket A As per dwg

19 Earthing to be done for S.G Door A Not required

20

4 no's of bolt to be provided for HV cable box cover in

transformer

A Completed

1

Final Painting to be completed for Steps/Corrider in S.G

Building

A Completed

2 All loose fencing areas to be properly tigtened B Completed

3 Touch up paint to be done for all welded areas in fencing C

4

Checker Plates to be provided for all cutout opening inside

S.G Building

A Completed

5

Finish Painting to be confirmed on HVAC Ducting as not

enough

C

6

Additional coat of painting to be done for All hand rails in

S.G Building

C

7

Grating and Gravels to be provided on the Transformer

foundation bund wall

A Completed

8 Transformer wall top side to be smooth finished C Completed

9

Transformer inside wall opennings to be blanked off before

filling with gravel stones

A Completed

10

emergency door to be paint agine with dark red colour

as normal practice instead of light red color.

C

1 Route marker to be provided for HV & LV cables C

2

Cable Tag to be provided for HV & all left out cables in

ODCB 5 & ODCB 6

A Completed

3

Permanent metallic coated cable tie to be provided for all

cables in ODCB 5 & ODCB 6

B Completed

4

Name plate sticker to be provided for

ODCB 5 & ODCB 6

B Completed

5 Check nut to be provided for ODCB 5 and 6 Foundation bolt A Completed

6 Tag to be provided for isolators C Completed

7

Earthing Cable, size 35 to be replaced with size 70 for ODCB

5 & ODCB 6

A Completed

8

Plugging to be done for all un-used holes in isolator ODCB 5

& ODCB 6

B Completed

9 Clamp to be provided for all isolator cables B Completed

1

House Keeping to be carried out all around the work place

area Inside DPS

A

2

Grout cement kept near shipping pump location to be

removed

A Completed

SWITCH GEAR BUILDING: CIVIL PUNCH POINTS

POWER PLANT: ODCB PUNCH POINTS

HSE : PUNCH POINTS

3 House Keeping to be carried out all around the S.G Building A

Note:

Category A: Before Pre-commissioning

Category B: Before commissioning

Category C : Before Handover

Das könnte Ihnen auch gefallen

- Installation of Underground Drainage Piping: ChecklistDokument1 SeiteInstallation of Underground Drainage Piping: Checklistakash nairNoch keine Bewertungen

- Praveen Piping Field ResumeDokument5 SeitenPraveen Piping Field ResumeprvnpgNoch keine Bewertungen

- Cosasco Access FittingsDokument2 SeitenCosasco Access FittingsE_Rodriguez20Noch keine Bewertungen

- Field Welding Inspection ManualDokument40 SeitenField Welding Inspection ManualrosennmNoch keine Bewertungen

- ITPDokument1 SeiteITPmaani7zeroNoch keine Bewertungen

- Subcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoDokument1 SeiteSubcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoAzwan SunlineNoch keine Bewertungen

- Upvc SubmittalDokument52 SeitenUpvc Submittalraja bharathi0% (1)

- Ms For Upvc Above Ground r1Dokument29 SeitenMs For Upvc Above Ground r1VibinNoch keine Bewertungen

- SAIC-M-1003Location, Depth of TrenchBoreholes & Elevation For Types I - V Fences InspectionDokument3 SeitenSAIC-M-1003Location, Depth of TrenchBoreholes & Elevation For Types I - V Fences InspectionAbuAhmedQuaziNoch keine Bewertungen

- Fire Pump 5 JanDokument4 SeitenFire Pump 5 JanMarco CetiNoch keine Bewertungen

- 26 24 16.00 40-1 Submittal Review SheetDokument6 Seiten26 24 16.00 40-1 Submittal Review SheetLuisSalinasNoch keine Bewertungen

- Basics of Pressure Piping For Junior EngineersDokument36 SeitenBasics of Pressure Piping For Junior Engineersتدریس زبان ESLNoch keine Bewertungen

- A Review of The Pressure Transient Effects On Water Distribution Main FailuresDokument15 SeitenA Review of The Pressure Transient Effects On Water Distribution Main FailuresSuranji RathnayakaNoch keine Bewertungen

- PipingDokument54 SeitenPipingakhilsyam21Noch keine Bewertungen

- Basics of Nitrogen Purging: Siswanto YDokument22 SeitenBasics of Nitrogen Purging: Siswanto Ydiaccessltd_17172961100% (2)

- Water Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileDokument2 SeitenWater Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileNiwled UyNoch keine Bewertungen

- GS P&D Archsd 2012Dokument127 SeitenGS P&D Archsd 2012Andy Lee100% (1)

- Expert Review of Water System Pipeline Breaks - LADWP - 2009Dokument186 SeitenExpert Review of Water System Pipeline Breaks - LADWP - 2009yanichik20Noch keine Bewertungen

- Baseline Schedule Narrative PDFDokument8 SeitenBaseline Schedule Narrative PDFRohit JaiswalNoch keine Bewertungen

- Presentation FRP 06Dokument10 SeitenPresentation FRP 06Mohamed BouchouatNoch keine Bewertungen

- CPVC-PVC Tuberias y FittingsDokument64 SeitenCPVC-PVC Tuberias y FittingsJuan Acuña100% (1)

- Costing of PipelinesDokument29 SeitenCosting of PipelinesShankar Jha100% (1)

- F913 Gaskets For Joining Plastic PipeDokument5 SeitenF913 Gaskets For Joining Plastic Pipelepm30Noch keine Bewertungen

- 10.1 Construction ScheduleDokument104 Seiten10.1 Construction Schedulesanthoshtm 76Noch keine Bewertungen

- Standard Groove SpecificationsDokument5 SeitenStandard Groove SpecificationsDavid SalgueroNoch keine Bewertungen

- W G Ss 001Dokument44 SeitenW G Ss 001didi9696Noch keine Bewertungen

- Work Procedure For CCB Installation of Raised Floor 2Dokument13 SeitenWork Procedure For CCB Installation of Raised Floor 2ResearcherNoch keine Bewertungen

- Abbreviations in PipingDokument12 SeitenAbbreviations in PipingADITYA_PATHAKNoch keine Bewertungen

- P&id SeminarDokument30 SeitenP&id SeminaryasirvazhikkadavuNoch keine Bewertungen

- SleeveDokument16 SeitenSleeveengsamerhozinNoch keine Bewertungen

- Wps FormatDokument2 SeitenWps FormatParminder SinghNoch keine Bewertungen

- Sede Abu Dhabi Transmission & Dispatch Company (TRANSCO) : Water Supply System For Fujairah Distrbution NetworkDokument7 SeitenSede Abu Dhabi Transmission & Dispatch Company (TRANSCO) : Water Supply System For Fujairah Distrbution NetworkMoataz MedhatNoch keine Bewertungen

- HDPE Pipe and Fitting Materials Fusion Joining and Installation 1Dokument8 SeitenHDPE Pipe and Fitting Materials Fusion Joining and Installation 1Mohamed ElsayedNoch keine Bewertungen

- Plumbing - Check List - FlatDokument3 SeitenPlumbing - Check List - FlatMd AbdulNoch keine Bewertungen

- E&I Tool Box ContentsDokument1 SeiteE&I Tool Box ContentsChandan RayNoch keine Bewertungen

- Checklist For Technical Evaluation (Contract Review) of Infrastructure ContractsDokument7 SeitenChecklist For Technical Evaluation (Contract Review) of Infrastructure Contractskerwin jayNoch keine Bewertungen

- Inspection Request: Report #: RE/INRQ/ Date: 24-Sep-17 Page: 1 of 1Dokument1 SeiteInspection Request: Report #: RE/INRQ/ Date: 24-Sep-17 Page: 1 of 1mansih457Noch keine Bewertungen

- Pmbok Formulas Pmbok Formulas: Topic FORMULA (Or Description) Topic FORMULA (Or Description)Dokument1 SeitePmbok Formulas Pmbok Formulas: Topic FORMULA (Or Description) Topic FORMULA (Or Description)jpcdellNoch keine Bewertungen

- Weld CalculationDokument5 SeitenWeld CalculationTAUFIKNoch keine Bewertungen

- Dots in ASME B36.10 Under Schedule TableDokument5 SeitenDots in ASME B36.10 Under Schedule TableIbrahim BashaNoch keine Bewertungen

- Piping DownloadDokument15 SeitenPiping DownloadJason RogersNoch keine Bewertungen

- Design Package Deliverable S 90Dokument5 SeitenDesign Package Deliverable S 90Viet Nguyen HungNoch keine Bewertungen

- Typical Project SequenceDokument10 SeitenTypical Project SequenceGeetha_jagadish30Noch keine Bewertungen

- Water Distribution CodeDokument62 SeitenWater Distribution CodePipeline EngineerNoch keine Bewertungen

- Scaffold ChecklistDokument5 SeitenScaffold ChecklistMohamed GhariebNoch keine Bewertungen

- Abu Dhabi Crude Oil Pipeline Project Habshan - Fujairah: Post Weld Heat Treatment ProcedureDokument12 SeitenAbu Dhabi Crude Oil Pipeline Project Habshan - Fujairah: Post Weld Heat Treatment ProcedureSubrata PatraNoch keine Bewertungen

- Method Statement For Installation of Electric Water Heater - Method Statement HQDokument5 SeitenMethod Statement For Installation of Electric Water Heater - Method Statement HQGwenn AsprerNoch keine Bewertungen

- ITP InstrumentationDokument9 SeitenITP InstrumentationzhangyiliNoch keine Bewertungen

- Piping and Pipeline Engineering: Full DescriptionDokument4 SeitenPiping and Pipeline Engineering: Full Descriptiontunlinoo100% (1)

- Volksbolts Additional Options Stainless S Visit Our Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale LinksDokument12 SeitenVolksbolts Additional Options Stainless S Visit Our Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale LinksAllan EscobarNoch keine Bewertungen

- VD V013 ZPM Pro 1507Dokument105 SeitenVD V013 ZPM Pro 1507abdulNoch keine Bewertungen

- Form Leak Test Report DD 101005Dokument5 SeitenForm Leak Test Report DD 101005Thiri HtetNoch keine Bewertungen

- Pipe & Pipe FittingsDokument10 SeitenPipe & Pipe FittingsSalim BakhshNoch keine Bewertungen

- How To Write A Welding Procedure Specification (WPS)Dokument5 SeitenHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Material ControlDokument32 SeitenMaterial ControlbonaNoch keine Bewertungen

- Punch Points - Phase-1 Dated 11-Dec-19Dokument14 SeitenPunch Points - Phase-1 Dated 11-Dec-19Goutam HotaNoch keine Bewertungen

- Preliminary Acceptance Test - Pat Civil Works (RT/GF)Dokument7 SeitenPreliminary Acceptance Test - Pat Civil Works (RT/GF)Shah Ahammadullah AshrafNoch keine Bewertungen

- SR No Action Point BuildingDokument4 SeitenSR No Action Point BuildingnikunjNoch keine Bewertungen

- Acceptance Sheet - ModelDokument17 SeitenAcceptance Sheet - ModelHassan Mody TotaNoch keine Bewertungen

- Test Record For Overcurrent - Earth Fault - Prot Relay-Induction TypeDokument1 SeiteTest Record For Overcurrent - Earth Fault - Prot Relay-Induction TypeRoshin99Noch keine Bewertungen

- Inspection Report For Field WeldDokument1 SeiteInspection Report For Field WeldRoshin99Noch keine Bewertungen

- Diff-Limit State & Working StressDokument2 SeitenDiff-Limit State & Working StressRoshin99100% (1)

- Footings Soil PressureDokument8 SeitenFootings Soil Pressuredeepakram04Noch keine Bewertungen

- Tank Test CertificatesDokument1 SeiteTank Test CertificatesRoshin99Noch keine Bewertungen

- FootingDokument5 SeitenFootingMohammad Tawfiq Wara100% (4)

- Insp Record For Install Accept Safeguarding SystemDokument1 SeiteInsp Record For Install Accept Safeguarding SystemRoshin99Noch keine Bewertungen

- IR For Cable Tray & LaddersDokument1 SeiteIR For Cable Tray & LaddersSchwihdi ZakNoch keine Bewertungen

- WeldingDokument1 SeiteWeldingVinothNoch keine Bewertungen

- Inspection Record For Cabinets - ConsolesDokument2 SeitenInspection Record For Cabinets - ConsolesRoshin99Noch keine Bewertungen

- Concrete Placement RecordDokument1 SeiteConcrete Placement RecordRoshin99100% (1)

- Insp & Test Recds For Outgoing Units-LV SwitchgearDokument2 SeitenInsp & Test Recds For Outgoing Units-LV SwitchgearRoshin99Noch keine Bewertungen

- Inspection Record For Switch HousesDokument1 SeiteInspection Record For Switch HousesRoshin99Noch keine Bewertungen

- Inspection Record For Air Ducting System: Items To InspectDokument1 SeiteInspection Record For Air Ducting System: Items To InspectSchwihdi ZakNoch keine Bewertungen

- Insp Record For Block WorkDokument1 SeiteInsp Record For Block WorkRoshin99Noch keine Bewertungen

- Inspection Record For GatesDokument1 SeiteInspection Record For GatesRoshin99Noch keine Bewertungen

- Record of Vessel TestsDokument1 SeiteRecord of Vessel TestsRoshin99Noch keine Bewertungen

- Instion Test Record-PaintingDokument1 SeiteInstion Test Record-PaintingkeronsNoch keine Bewertungen

- Insp Record For Block WorkDokument1 SeiteInsp Record For Block WorkRoshin99Noch keine Bewertungen

- Incoming Equipment Inspection RecordDokument1 SeiteIncoming Equipment Inspection RecordRoshin99Noch keine Bewertungen

- Continuity Test Record For Earthing Conductor For EquipmentDokument1 SeiteContinuity Test Record For Earthing Conductor For EquipmentRoshin99Noch keine Bewertungen

- Inspection & Test Record Control Valve Pre-InstallationDokument1 SeiteInspection & Test Record Control Valve Pre-InstallationRoshin99Noch keine Bewertungen

- Site Engineering Query (SEQ)Dokument1 SeiteSite Engineering Query (SEQ)Roshin99Noch keine Bewertungen

- Certificate For Mech Completion - Ready For Start UpDokument1 SeiteCertificate For Mech Completion - Ready For Start UpRoshin99Noch keine Bewertungen

- Report For Quality Audit PDFDokument1 SeiteReport For Quality Audit PDFRoshin99Noch keine Bewertungen

- Inspection Record For Air Handling Units: Record No.: - Page 1 of 2Dokument2 SeitenInspection Record For Air Handling Units: Record No.: - Page 1 of 2Schwihdi ZakNoch keine Bewertungen

- Insp & Test Record Underground Piping PDFDokument1 SeiteInsp & Test Record Underground Piping PDFRoshin99Noch keine Bewertungen

- Site Engg Query & Status ReportDokument1 SeiteSite Engg Query & Status ReportRoshin99Noch keine Bewertungen

- Insp & Test Records of Switching Units-HV - SwitchgearDokument3 SeitenInsp & Test Records of Switching Units-HV - SwitchgearRoshin99100% (2)

- Manual KW950 E Iss 09 Rev01Dokument25 SeitenManual KW950 E Iss 09 Rev01Эдуард Щаев100% (1)

- Hex Rb750gr3 UgDokument5 SeitenHex Rb750gr3 UgAgus MytechNoch keine Bewertungen

- Wiring Information: Installation Instructions (English)Dokument4 SeitenWiring Information: Installation Instructions (English)MaxcolocoNoch keine Bewertungen

- Landis Chainstitch Mckay Stitcher: Instructions To OperatorsDokument18 SeitenLandis Chainstitch Mckay Stitcher: Instructions To OperatorsWilberth FrancoNoch keine Bewertungen

- w990 Brochure 04 04 2019 PDFDokument32 Seitenw990 Brochure 04 04 2019 PDFcriistiianNoch keine Bewertungen

- JSK 42 Repair ManualDokument42 SeitenJSK 42 Repair ManualKelvin HindsNoch keine Bewertungen

- NEW Atlanta DWV 2019 - 0 PDFDokument2 SeitenNEW Atlanta DWV 2019 - 0 PDFjansenrosesNoch keine Bewertungen

- VDG 14Dokument5 SeitenVDG 14AONLANoch keine Bewertungen

- Important HVAC Interview Questions: 1) What Is The Unit of Heat?Dokument10 SeitenImportant HVAC Interview Questions: 1) What Is The Unit of Heat?Junaid KhanNoch keine Bewertungen

- Installation of Electrical, Instrument & Telecommunication: Norsok StandardDokument20 SeitenInstallation of Electrical, Instrument & Telecommunication: Norsok StandardvvNoch keine Bewertungen

- VW MKIV Brake Fluid Flush DIY PDFDokument12 SeitenVW MKIV Brake Fluid Flush DIY PDFcloantafNoch keine Bewertungen

- Instruction: Type AKS 4100/4100U Coaxial D14 VersionDokument12 SeitenInstruction: Type AKS 4100/4100U Coaxial D14 VersionVasti Diaz AguilarNoch keine Bewertungen

- Unit 5 Special Electr UmasnkarDokument3 SeitenUnit 5 Special Electr UmasnkarvlkumashankardeekshithNoch keine Bewertungen

- Dynapac CC950 Dynapac CC950: Double Drum Vibratory Rollers Double Drum Vibratory RollersDokument2 SeitenDynapac CC950 Dynapac CC950: Double Drum Vibratory Rollers Double Drum Vibratory RollersNadir MohamedNoch keine Bewertungen

- CC CCCC: Y Y Y YyDokument24 SeitenCC CCCC: Y Y Y YyRavi KantNoch keine Bewertungen

- Non-Contact Water Level Monitoring Using Labviewwith Arduino and Ultrasonic SensorDokument5 SeitenNon-Contact Water Level Monitoring Using Labviewwith Arduino and Ultrasonic SensorMidzie PedroNoch keine Bewertungen

- r56 Dme Failure Question - Mini Cooper ForumDokument9 Seitenr56 Dme Failure Question - Mini Cooper Forumjohn larson100% (1)

- 17 Termografia de PV Con Flir Tau 640 y Drone PDFDokument2 Seiten17 Termografia de PV Con Flir Tau 640 y Drone PDFOscar ChilcaNoch keine Bewertungen

- 2ME705-4-Hydraulic and Pneumatic SystemsDokument2 Seiten2ME705-4-Hydraulic and Pneumatic SystemsDev Chauhan100% (1)

- High Density Mono Perc Module: CS1H-325 - 330 - 335 - 340MSDokument2 SeitenHigh Density Mono Perc Module: CS1H-325 - 330 - 335 - 340MSMicu RãzvanNoch keine Bewertungen

- Topic: Identify The Front and Rear Panel Controls and Ports On A PC, Cases, Cooling, Cables and ConnectorsDokument29 SeitenTopic: Identify The Front and Rear Panel Controls and Ports On A PC, Cases, Cooling, Cables and ConnectorsKkr0% (1)

- 8-Bit Xmega A Microcontroller Xmega A ManualDokument445 Seiten8-Bit Xmega A Microcontroller Xmega A Manualpunisher454Noch keine Bewertungen

- Everdigm EHB30Dokument28 SeitenEverdigm EHB30ALI RAZAVI100% (1)

- LCM S24064GSF 1134121Dokument5 SeitenLCM S24064GSF 1134121Mitchell DanielsNoch keine Bewertungen

- Mir250 User Guide 1.4 - enDokument224 SeitenMir250 User Guide 1.4 - envictor.ciudad.carpelNoch keine Bewertungen

- TL783 RegulatorDokument5 SeitenTL783 RegulatorVenkatesh KarriNoch keine Bewertungen

- Service Manual: CFD-S36Dokument50 SeitenService Manual: CFD-S36london335Noch keine Bewertungen

- 2FB4 PCDokument55 Seiten2FB4 PClingeshsaikumar030Noch keine Bewertungen

- Kitchen Appliances: Profile No.: 123 NIC Code: 27504Dokument13 SeitenKitchen Appliances: Profile No.: 123 NIC Code: 27504Subrahmanya Prasad NelabhotlaNoch keine Bewertungen

- VAR Catalogue UkDokument72 SeitenVAR Catalogue Ukgeisbrian1Noch keine Bewertungen