Beruflich Dokumente

Kultur Dokumente

Lab 4 Contamination Test FAIZUAN

Hochgeladen von

faizuanismail0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

247 Ansichten20 Seitenfree

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenfree

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

247 Ansichten20 SeitenLab 4 Contamination Test FAIZUAN

Hochgeladen von

faizuanismailfree

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 20

1

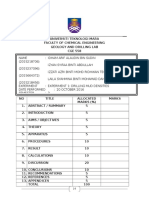

UNIVERSITI TEKNOLOGI MARA

FAKULTI KEJURUTERAAN KIMIA

GEOLOGY AND DRILLING LABORATORY

(CGE 558)

NAME : MOHAMMAD FAIZUAN BIN ISMAIL 2013252638

EXPERIMENT : DRILLING FLUID CONTAMINATION TEST

DATE PERFORMED : 30 OCTOBER 2012

SEMESTER : 3

PROGRAMME/CODE : CGE 558

GROUP : EH2233A

No. Title Allocated marks % Marks %

1 Abstract/Summary 5

2 Introduction 5

3 Aims/Objectives 5

4 Theory 5

5 Apparatus 5

6 Procedure 10

7 Results 10

8 Calculations 10

9 Discussion 20

10 Conclusions 10

11 Recommendation 5

12 References 5

13 Appendices 5

Total 100

Remarks:

Checked by:

2

TABLE OF CONTENT

No Title Pages

1 Abstract 3

2 Introduction 4

3 Objectives 6

4 Theory 7

5 Apparatus 8

6 Procedure 9

7 Result 10

8 Calculations 13

9 Discussion 14

10 Conclusions 17

11 Recommendations 18

12 References 19

13 Appendices 19-20

3

1.0 ABSTRACT

After conduct this experiment, we are able to know the effect of Gypsum to density,

Plastic Viscosity and Yield Point of drilling fluid. Before doing this experiment, we have to

find it properties which are pH and density. To find its pH, we use pH meter while to find its

density, we use mud balance.

We prepare 200 ml of water-based mud in 4 beakers and add different amount of

Gypsum which are 5g, 10g, 15g, and 20g into each of it. By using viscometer, we take the

reading at 600rpm and 300rpm. The difference of the reading is the Plastic Viscosity.

To find the Yield Point, we use formula which is

( p 0.5 N/m (lb/100ft2)

4

2.0 INTRODUCTION

The effects of contamination depend largely upon the mud type and the concentration and

type of contaminating salt. Divalent salts (calcium and magnesium) will have a greater

contaminating effect on water-based muds than mono-valent salts (sodium and

potassium). In general, water-base mud is the most susceptible to contamination of various

types.

Gypsum contamination basically indicated by high viscosity, high flat gels, and increase

fluid floss. An analysis of filtrate will show increase concentrations of both calcium and

sulfates. When drilling small thin anhydride stringers, the mud may be treated with soda ash

or, in some cases, phosphates or sodium carbonates. If massive anhydride encountered, the

mud can either be converted to a gyp mud or to high pH. (J.J. Azar and G. Robello Samuel

2007).

Water-based muds consist of four basic phases which is water, active colloidal solids, inert

solids and chemicals. Water is the continuous phase of any water-based mud. Primary

function of the continuous phase is to provide the initial viscosity which can be modified to

obtain any desirable rheological properties. The second function of the continuous phase is

to suspend the reactive colloidal solids, such as bentonite, inert solids, such as barite. Water

also acts as a medium for transferring the surface available hydraulic horsepower to the bit

on the bottom of the hole. Water is also a solution medium for all conditioning chemicals

which are added to the drilling fluid. In water based muds, clay is added to increase density,

viscosity, gel strength and yield point, and to decrease fluid loss. Clays used in water based

drilling fluids are mainly in three groups:

-Montmorillonites (bentonite)

-Kaolinites

-Illites

5

-gypsum

Chemicals used in water based muds can be grouped according to their functions as:

-Thinners

-Dispersants

-Deflocculants

The most common contaminants to water-based mud systems are:

Gypsum/anhydrite (Ca++)

Cement/lime (Ca++)

Makeup water (Ca++, Mg++)

Solids (added, drilled, active, inert)

Soluble sulfides (HS, S)

Salt/salt water flow (Na+, Cl)

Soluble bicarbonates and carbonates (HCO3, CO3)

Gypsum or (CaSO4 - 2H2O) contains calcium ions (Ca++) which are soluble and it can

flocculate colloidal clays and precipitate large anionic polymers that contain carboxylate

groups, such as an acrylate polymer. The calcium ion tends to replace the sodium ions on

the clay surface through a base exchange, thus causing undesirable changes in mud

properties such as rheology and filtration. It also causes added thinners to the mud system

to become ineffective. On the other hand, some mud types tolerate calcium, in which case

calcium is not considered a contaminant.

6

3.0 OBJECTIVES

To study the effect of contamination of Gypsum (CaSO4-2H20) to the density, Plastic

Viscosity and Yield point of water based mud. This salt commonly encountered during

drilling, completion or work over operations.

7

4.0 THEORY

In preparing a bentonite slurry using fresh water, the bentonite will hydrate and agitation

furnished by a mixer is sufficient to separate the hydrated clay plate lets and result in a

viscosity and gel strength increase, if the bentonite is placed in salty water or water

containing dissolved hardness (calcium or magnesium) the hydration and subsequent

dispersion by agitation is reduced.

A mud is said to be contaminated when a foreign material enters the mud system and

causes undesirable changes in mud properties such as the density, the viscosity, and/or

filtration. In general, water-base mud systems are the most susceptible to contamination of

various types. Mud contamination can result from overtreatment of the mud system with

additives of from material entering the mud during drilling.

8

5.0 APPARATUS

Water-base mud

Gypsum

Mass balance

Mud balance

Viscometer

Beaker

9

6.0 PROCEDURES

1. 200 ml base mud was measured in a beaker.

2. The base mud was tested for weight, Plastic Viscosity, and Yield Point by using

viscometer.

3. The base mud then was contaminated with 5 grams of gypsum.

4. After that, the sample was stirred for 3 minutes. Then, the sample was aged for 15

minutes and was stirred again for 2-3 minutes. Their viscosity, yield point, density,

and pH were determined.

5. Then, another sample of base mud with volume 200ml was prepared.

6. Step 3 & 4 were repeated by using 10, 15, and 20 g Gypsum.

7. The data then were recorded in proper table. Graph of density, Plastic Viscosity, and

Yield Point versus amount of Gypsum added were plotted to see the effect of

Gypsum contamination to the mud properties.

Viscosity

1. Firstly, the viscometer is set up.

2. The rotor bob and mud cup are cleaned.

3. 250 ml of mud are prepared and poured into the mud cup.

4. The experiment is started when the viscometer is switched on at the speed of 600 rpm.

5. The reading on the viscometer is recorded.

6. Steps 4 and 5 are repeated five times using different speed of 300 rpm, 200 rpm, 100 rpm,

6 rpm and 3 rpm.

7. The data is tabulated on the table.

10

7.0 RESULT

Reading Water based

mud

Water-based mud (WBM) + Gypsum (g)

5 10 15 20

Density (ppg) 8.50 8.80 9.00 9.30 9.50

Mud weight

(SG)

163.46 169.23 173.08 178.85 182.69

pH value 8.01 8.97 7.75 7.67 7.43

Viscometer

reading at

600 rpm

27.3 35.0 39.6 45.0 22.5

Viscometer

reading at

300 rpm

24.4 34.7 36.2 34.5 9.4

Plastic

Viscosity, PV

(p)

2.9 0.3 3.4 9.6 13.1

Apparent

Viscosity,

(a)

12.2 17.5 19.8 22.5 11.25

Yield Point,

lb/100 ft

22.95 27.15 34.50 29.7 2.95

11

Graph 1: Density against the amount of Gypsum

Graph 2: Plastic Viscosity (PV) against the amount of Gypsum

y = 0.048x + 8.55

8.7

8.8

8.9

9

9.1

9.2

9.3

9.4

9.5

9.6

0 5 10 15 20 25

D

e

n

s

i

t

y

,

p

p

g

Mass of gypsum, g

Density against mass of gypsum

y- value lines (y-values)

y = 0.892x - 4.55

-5

0

5

10

15

0 5 10 15 20 25

P

l

a

s

t

i

c

v

i

s

c

o

s

i

t

y

P

V

,

(

c

p

)

Mass of Gypsum , g

Plastic viscosity against Mass of

Gypsum

Y-values

lines (y-values)

12

Graph 3: Yield Point (Yp) against the amount of Gypsum

y = -1.548x + 42.925

0

5

10

15

20

25

30

35

40

0 5 10 15 20 25

Y

e

i

l

d

p

o

i

n

t

,

Y

p

(

l

b

/

1

0

0

f

t

)

mass of gypsum, g

Yeild point against mass of gypsum

y-values

lines (y-value)

13

8.0 CALCULATIONS

1. Apparent viscosity, (a) =600/2 (cp)

For 5g: 10g:

= 35.0 / 2 =39.6/2

= 17.50 cp =19.8 cp

15g: 20g:

= 45.0 / 2 =22.5/2

= 22.5 cp =11.25 cp

2. Plastic viscosity (p) =600300 (cp)

5g: 10g:

= 35.0-34.7 =39.6-36.2

= 0.3 cp = 3.4 cp

15g: 20g:

=45-34.5 = 22.5-9.4

=10.5 cp = 13.1 cp

3. Yield point (yp) =300p 0.5 n/m2 (lb/100 ft2)

5g: 10g:

=34.7-0.3(0.5) =36.2-3.4(0.5)

= 34.55 =34.5

15g: 20g:

=34.5-10.5(0.5) =9.4-13.1(0.5)

= 29.25 =2.85

14

9.0 DISCUSSION

9.1 DENSITY

The term weight is used in connection with mud more often than density, even

though density is the more correct term. This is a consequence of the first attempts to

measure properties of mud. In this experiment, we use mud balance to find the density of

mud. The unit used here is ppg (pound per gallon).

Ideally, a mud weight as low as the weight of water is desired, for optimum drilling

rate sand for minimizing the chances of fracturing the formation. However, in practice, mud

density in excess of two times the density of water may be necessary, to contain abnormal

pressures or to mechanically stabilize unstable formations.

From the data obtained, drilling fluid with amount of Gypsum added are 0g, 5g, 10g,

15g, and 20g have density about 8.50ppg, 8.80ppg, 9.00ppg, 9.30ppg and 9.50ppg

respectively. It is clearly seen from Figure 1 that the value of density in increased when we

increase the amount of Gypsum.

Firstly, we must clean the mass balance before using it. There might be some dust

and dirt inside it. Even it is in small quantity, more or less it will affect our reading. Then,

during finding the density of drilling mud by using mud balance, ensure that the air bubble is

correctly positioned at the centre. While we doing the experiment, we try hardly to put the

bubble at the centre. Because of time constraining, we just take the reading when the

bubble is getting nearer to the centre.

15

9.2 PLASTIC VISCOSITY (PV)

PV is one of the parameter of the Bingham plastic model. PV is the slope of the shear stress/shear

rate line above the yield point.

PV represents the viscosity of a mud when extrapolated to infinite shear rate on the

basis of the mathematics of the Bingham model. YP is also the other parameter of that

model. A low PV indicates that the mud is capable of drilling rapidly because of the low

viscosity of mud exiting at the bit. High PV is caused by a viscous base fluid and by excess

clay. To lower PV, a reduction in solids content can be achieved by dilution of the mud.

However, in this experiment, we added different amount of Gypsum to drilling fluid

so that we will know either the PV is increasing or decreasing when we increase the amount

of Gypsum.

9.3 YIELD POINT (YP)

YP is the yield stress extrapolated to a shear rate of zero. A Bingham plastic fluid

plots as a straight line on a shear rate (x-axis) versus shear stress (y-axis) plot, in which YP is

16

the zero-shear-rate intercept. PV is the slope of the line. From this experiment, YP is

calculated from 300- and 600-rpm viscometer dial readings by subtracting PV from the 300-

rpm dial reading.

( p 0.5 N/m (lb/100ft2)

YP is used to evaluate the ability of a mud to lift cuttings out of the annulus. A high

YP implies a non-Newtonian fluid, one that carries cuttings better than a fluid of similar

density but lower YP.

However, in this experiment, we added different amount of Gypsum to drilling fluid

so that we will know either the YP is increasing or decreasing when we increase the amount

of Gypsum. Drilling fluid with amount of Gypsum added are , 5g, 10g, 15g, and 20g have YP

about 34.55cP,34.5cP, 29.25cP, and 2.85cP respectively. This is clearly shown at Figure 2.

17

10.0 CONCLUSIONS

Drilling fluid with amount of Gypsum added are 0g, 5g, 10g, 15g, and 20g have

density about 10.3ppg, 10.2ppg, 10.9ppg, 10.9ppg and 10.6ppg respectively. Density of mud

gives huge impact on rate of penetration of drill bit. To slow down the rate of penetration,

add more Gypsum to the mud.

Drilling fluid with amount of Gypsum added are 0g, 5g, 10g, 15g, and 20g have PV for

about 0, 1, 10, 10 and 11 lb/100ft respectively. For better works, reduce the plastic

viscosity of drilling mud. A low PV indicates that the mud is capable of drilling rapidly

because of the low viscosity of mud exiting at the bit.

Drilling fluid with amount of Gypsum added are 0g, 5g, 10g, 15g, and 20g have YP

about 20cP, 22.5cP, 13cP, 17cP, and 15.5cP respectively. For better works during drilling,

increase the yield point of the drilling mud. A high YP mud can carries cuttings better than a

fluid of similar density but lower YP.

18

11.0 RECOMMENDATIONS

1. Clean the outside and inside of mass balance before using it.

2. Start the experiment (mud balance part) early so that can find the density correctly.

3. Crush the Gypsum into powder before add it into mud.

4. Use spatula to clean the beaker when pouring the mud into another container.

19

12.0 REFERENCES

http://www.youtube.com/watch?v=O-6I6kyRXc4 (Plastic Viscosity of Drilling Mud)

Sharma, A. (2011, 10 20). Mud Rheology Test. Retrieved from

http://www.scribd.com/doc/69577132/Mud-Rheology-Test

http://petrowiki.org/Mud_contamination.

Geology and Drilling Laboratory Manual Lab.

http://www.wipertrip.com/drilling-fluids/contamination/332-drilling-fluid-contamination.html

13.0 APPENDICES

Figure 4 Gypsum is being weighed by mass balance Figure 5 pH meter to find pH of drilling mud

20

Figure 6 Mud balance is use to find density of mud Figure 7 200ml mud is prepared in 4 beaker

Figure 8 the mixer

Das könnte Ihnen auch gefallen

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityVon EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleNoch keine Bewertungen

- Drilling Fluid Contamination TestDokument13 SeitenDrilling Fluid Contamination TestHumaira Mirza0% (2)

- Fly Ash Geopolymer Pervious Concrete: A Study of Durability Performance Under Cold-Climate ConditionsDokument7 SeitenFly Ash Geopolymer Pervious Concrete: A Study of Durability Performance Under Cold-Climate ConditionsRosario CornejoNoch keine Bewertungen

- Measuring Density of Mud SamplesDokument11 SeitenMeasuring Density of Mud SamplesCistus AbenNoch keine Bewertungen

- Study Guide For Concrete Batcher (English) - 1Dokument9 SeitenStudy Guide For Concrete Batcher (English) - 1juan jose salazar olveraNoch keine Bewertungen

- COMPACTION TEST REPORTDokument18 SeitenCOMPACTION TEST REPORTOlowoniwa MarvellousNoch keine Bewertungen

- Construction and Building Materials: Dilan Polat, Mustafa GüdenDokument13 SeitenConstruction and Building Materials: Dilan Polat, Mustafa GüdenSeçkin MartinNoch keine Bewertungen

- Optimization in The Use of Cement Additives: Effect of Gypsum Dehydration On The Reactivity of Performance EnhancersDokument5 SeitenOptimization in The Use of Cement Additives: Effect of Gypsum Dehydration On The Reactivity of Performance EnhancersVaibhav KhodakeNoch keine Bewertungen

- View Free ArticleDokument3 SeitenView Free Articlegdevi80Noch keine Bewertungen

- Research in Progress-J.canulDokument17 SeitenResearch in Progress-J.canulerosNoch keine Bewertungen

- Accepted Manuscript: Materials LettersDokument7 SeitenAccepted Manuscript: Materials LettersYeluri Sesha ChoudaryNoch keine Bewertungen

- 8.21 Strength, Sorptivity and Carbonation of Geopolymer ConcreteDokument6 Seiten8.21 Strength, Sorptivity and Carbonation of Geopolymer ConcreteSulchan Purnama SaputraNoch keine Bewertungen

- Test Report of MetakaolinDokument14 SeitenTest Report of MetakaolinAbdul Falahitawan UfalNoch keine Bewertungen

- Effects of Mix Composition On The Sulfate Resistance of Blended CementsDokument5 SeitenEffects of Mix Composition On The Sulfate Resistance of Blended CementsTarek ChikerNoch keine Bewertungen

- LAB L4 (Determination of Dry Density)Dokument14 SeitenLAB L4 (Determination of Dry Density)Sahrizanea Nurizmisa100% (1)

- Drilling Lab 1 FullDokument14 SeitenDrilling Lab 1 FullIdham Arif100% (1)

- Catalytic Effect of Trace Excess Water On The Rate of Gel ShrinkageDokument9 SeitenCatalytic Effect of Trace Excess Water On The Rate of Gel ShrinkagefacevidyaNoch keine Bewertungen

- Standard Proctor Compaction Test ResultsDokument11 SeitenStandard Proctor Compaction Test Resultsakmal hazimNoch keine Bewertungen

- Mohamad Taslin Shah Bin IbramshahDokument11 SeitenMohamad Taslin Shah Bin IbramshahTaslinNoch keine Bewertungen

- IOSRJEN (WWW - Iosrjen.org) IOSR Journal of EngineeringDokument6 SeitenIOSRJEN (WWW - Iosrjen.org) IOSR Journal of EngineeringIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- Geopolymer Concrete With Fly Ash: NalloydandbvranganDokument12 SeitenGeopolymer Concrete With Fly Ash: NalloydandbvranganJoel ulrich Ndengue mballaNoch keine Bewertungen

- Rafeet Et Al - FinalDokument44 SeitenRafeet Et Al - FinalCarlonNoch keine Bewertungen

- G4 Exp5Dokument9 SeitenG4 Exp5Naresh GanisonNoch keine Bewertungen

- To Study The Effects of Acid Rain On LimestoneDokument21 SeitenTo Study The Effects of Acid Rain On Limestonepkkalai112Noch keine Bewertungen

- Comparitive Study On Flyash Based Geopolymer Concrete WithDokument32 SeitenComparitive Study On Flyash Based Geopolymer Concrete Withjs kalyana ramaNoch keine Bewertungen

- Petrofisik Analisis Limestone From Banjarejo Village and Potentially To Be Reservoir RockDokument11 SeitenPetrofisik Analisis Limestone From Banjarejo Village and Potentially To Be Reservoir RockAditya Ryu ArzoNoch keine Bewertungen

- Waste Management: Chea Chandara, Khairun Azizi Mohd Azizli, Zainal Arifin Ahmad, Etsuo SakaiDokument5 SeitenWaste Management: Chea Chandara, Khairun Azizi Mohd Azizli, Zainal Arifin Ahmad, Etsuo SakaiTrí Thông PhạmNoch keine Bewertungen

- Durability Study of Low Calcium Fly Ash Geopolymer ConcreteDokument7 SeitenDurability Study of Low Calcium Fly Ash Geopolymer Concretethisisatest402003Noch keine Bewertungen

- Improvements in The Strength and Water Penetrability of Low Calcium Fly Ash Based Geopolymer ConcreteDokument8 SeitenImprovements in The Strength and Water Penetrability of Low Calcium Fly Ash Based Geopolymer ConcretemolivinewibisanaNoch keine Bewertungen

- Amenability of A Plant Slimy Tails To A Nil Waste Process For ReuseDokument7 SeitenAmenability of A Plant Slimy Tails To A Nil Waste Process For ReuseravibelavadiNoch keine Bewertungen

- Moisture Influence On Compressive Strength of Ternary Gypsum-Based BindersDokument5 SeitenMoisture Influence On Compressive Strength of Ternary Gypsum-Based BindersIS AANoch keine Bewertungen

- No 2Dokument11 SeitenNo 2Sotu KdaptNoch keine Bewertungen

- Compressive Strength Comparison of Concrete Made With Aggregates From Different Sources and Using Stone DustDokument24 SeitenCompressive Strength Comparison of Concrete Made With Aggregates From Different Sources and Using Stone DustShubham KauravNoch keine Bewertungen

- 045 Tempest2009Dokument17 Seiten045 Tempest2009Manish ShashikantNoch keine Bewertungen

- Effect of AgingDokument13 SeitenEffect of AgingShadrachNoch keine Bewertungen

- Mud viscofying improves rheology and filtrationDokument12 SeitenMud viscofying improves rheology and filtrationعلي عباس جاسم غليمNoch keine Bewertungen

- Properties of Geopolymer Bricks Made With Flyash ADokument6 SeitenProperties of Geopolymer Bricks Made With Flyash ARubhini SNoch keine Bewertungen

- Water TreatmentDokument45 SeitenWater TreatmentSarim ChNoch keine Bewertungen

- Production of Refractory Chamotte Particle-Reinforced Geopolymer CompositeDokument6 SeitenProduction of Refractory Chamotte Particle-Reinforced Geopolymer CompositeAri RangelNoch keine Bewertungen

- Cement & Concrete Composites 29 (2007) 224–229: Workability and strength of coarse high calcium fly ash geopolymerDokument6 SeitenCement & Concrete Composites 29 (2007) 224–229: Workability and strength of coarse high calcium fly ash geopolymerAndrew PiNoch keine Bewertungen

- Basic Drilling Fluid CourseDokument63 SeitenBasic Drilling Fluid CourseAhmed Salah KhalifaNoch keine Bewertungen

- 04-Section 04 Pilot Testing & ContaminationsDokument17 Seiten04-Section 04 Pilot Testing & ContaminationsLazharNoch keine Bewertungen

- Vincent Arthur - Group 5 - Experiment 2Dokument11 SeitenVincent Arthur - Group 5 - Experiment 2Vincent ArthurNoch keine Bewertungen

- Journal 1Dokument7 SeitenJournal 1nagarjunNoch keine Bewertungen

- Deflocculation of Concentrated Aqueous Clay Suspensions With SodDokument5 SeitenDeflocculation of Concentrated Aqueous Clay Suspensions With SodkhosrosaneNoch keine Bewertungen

- Paper ASP PetrofacDokument12 SeitenPaper ASP Petrofacbagus yosan setiawanNoch keine Bewertungen

- Behaviour of Geopolymer Reinforced Concrete BeamsDokument84 SeitenBehaviour of Geopolymer Reinforced Concrete BeamsHarish T S Gowda100% (1)

- Long-term aging performance of asphalt compositionsDokument9 SeitenLong-term aging performance of asphalt compositionsNatalia KovalovaNoch keine Bewertungen

- Colombian Soil Stabilized With Geopolymers For Low Cost RoadsDokument9 SeitenColombian Soil Stabilized With Geopolymers For Low Cost RoadsPaula AlejandraNoch keine Bewertungen

- International Journal of Engineering Research and DevelopmentDokument7 SeitenInternational Journal of Engineering Research and DevelopmentIJERDNoch keine Bewertungen

- Experiment No 5Dokument6 SeitenExperiment No 5Kirby CamposanoNoch keine Bewertungen

- Fly Ash-Based Geopolymer Lightweight Concrete Using Foaming AgentDokument13 SeitenFly Ash-Based Geopolymer Lightweight Concrete Using Foaming AgentpulendralkNoch keine Bewertungen

- EXP 5 Full ReportDokument19 SeitenEXP 5 Full ReportSaravin SelhvaduraiNoch keine Bewertungen

- Jar TestDokument7 SeitenJar TestWanShanuzieNoch keine Bewertungen

- Standard Proctor TestDokument6 SeitenStandard Proctor TestnattydreadfathelahNoch keine Bewertungen

- RigidDokument23 SeitenRigidMadhu MadhuNoch keine Bewertungen

- Experimental Study On Slag-Based Composite Admixture: Ri Hua Zhang, Xian Jun GuoDokument5 SeitenExperimental Study On Slag-Based Composite Admixture: Ri Hua Zhang, Xian Jun GuoJHON WILMAR CARDENAS PULIDONoch keine Bewertungen

- JETIR2301396Dokument8 SeitenJETIR2301396karthicfinconNoch keine Bewertungen

- Design of Concrete To Resist CarbonationDokument13 SeitenDesign of Concrete To Resist CarbonationEliott ThommesNoch keine Bewertungen

- Assignment 1 Reservoir EngineeringDokument5 SeitenAssignment 1 Reservoir EngineeringfaizuanismailNoch keine Bewertungen

- Casing and Bit SizeDokument1 SeiteCasing and Bit SizefaizuanismailNoch keine Bewertungen

- CGE416-UPSTREAM Business PerspectiveDokument83 SeitenCGE416-UPSTREAM Business PerspectiveHumaira MirzaNoch keine Bewertungen

- ICP LaaaaDokument9 SeitenICP LaaaaFatimah Zahra Ab RahmanNoch keine Bewertungen

- Casing DataDokument6 SeitenCasing DatafaizuanismailNoch keine Bewertungen

- Dean StarkDokument15 SeitenDean Starkfaizuanismail100% (1)

- Drilling Fluids Engineering GuideDokument51 SeitenDrilling Fluids Engineering GuidefaizuanismailNoch keine Bewertungen

- Lab 4 Contamination Test FAIZUANDokument20 SeitenLab 4 Contamination Test FAIZUANfaizuanismailNoch keine Bewertungen

- THIN SECTION AND PETROGRAPHY ExperimentDokument17 SeitenTHIN SECTION AND PETROGRAPHY Experimentfaizuanismail100% (1)

- 31380112Dokument5 Seiten31380112Pedro Luis Choque MamaniNoch keine Bewertungen

- A-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemDokument44 SeitenA-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemBadiNoch keine Bewertungen

- Whiting (CalciumCarbonate) MSDSDokument6 SeitenWhiting (CalciumCarbonate) MSDSrinda_indaNoch keine Bewertungen

- Acoustic Louver - Beta Dubai PDFDokument20 SeitenAcoustic Louver - Beta Dubai PDFMohamed YaserArafatNoch keine Bewertungen

- KHKKKDokument39 SeitenKHKKKdaney67299Noch keine Bewertungen

- 3LW - Types and Properties of Aviation OilsDokument10 Seiten3LW - Types and Properties of Aviation OilsZouhair ElmNoch keine Bewertungen

- 55 IChO 2023 Preparatory Problems v1Dokument158 Seiten55 IChO 2023 Preparatory Problems v1Shraddha Deshmukh-KelkarNoch keine Bewertungen

- Catalog: Flanged Safety Relief Valves Series 526 CCDokument12 SeitenCatalog: Flanged Safety Relief Valves Series 526 CCSuelen SobrinhoNoch keine Bewertungen

- 01 Well Cementing - Day 1 PDFDokument131 Seiten01 Well Cementing - Day 1 PDFام فاطمة البطاط100% (1)

- Insulating Flange Kits DatasheetDokument4 SeitenInsulating Flange Kits DatasheetAndry RimanovNoch keine Bewertungen

- Measuring Methods of Acoustic Properties and Influence of Physical Parameters On Natural Fibers: A ReviewDokument21 SeitenMeasuring Methods of Acoustic Properties and Influence of Physical Parameters On Natural Fibers: A Reviewraja dhiefNoch keine Bewertungen

- Product Data Sheet: Product Description Product Description Product Description Product DescriptionDokument3 SeitenProduct Data Sheet: Product Description Product Description Product Description Product DescriptionVaittianathan MahavapillaiNoch keine Bewertungen

- SOBM Calculation SheetDokument15 SeitenSOBM Calculation SheetChintan GohelNoch keine Bewertungen

- CNG Cylinder Inspection FormDokument1 SeiteCNG Cylinder Inspection FormYUGENDRANNoch keine Bewertungen

- Mechanical Properties of Engineered Materials Mechanical EngineeringDokument584 SeitenMechanical Properties of Engineered Materials Mechanical EngineeringEnis Sevim100% (12)

- Electrosil CoatingDokument4 SeitenElectrosil Coating69x4100% (1)

- Everything You Need to Know About Thermoplastic PolyethyleneDokument3 SeitenEverything You Need to Know About Thermoplastic PolyethyleneJoan M. EspelimbergoNoch keine Bewertungen

- Aircraft Hangar Lighting Fixture ScheduleDokument10 SeitenAircraft Hangar Lighting Fixture ScheduleWaleed Abd El-HamiedNoch keine Bewertungen

- Masterseal Traffic 1330 TdsDokument3 SeitenMasterseal Traffic 1330 TdsSolomon AhimbisibweNoch keine Bewertungen

- Chemkin PDFDokument44 SeitenChemkin PDFmohamedIGCMONoch keine Bewertungen

- Outokumpu Stainless Steel Wall Chart PDFDokument1 SeiteOutokumpu Stainless Steel Wall Chart PDFcnaren67Noch keine Bewertungen

- 4-Settlement of Shallow FoundationsDokument63 Seiten4-Settlement of Shallow FoundationsENoch keine Bewertungen

- The Analysis and Prevention of Failure in Railway AxlesDokument10 SeitenThe Analysis and Prevention of Failure in Railway AxlesAnonymous PufNjgNoch keine Bewertungen

- Dow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in PolyethyleneDokument1 SeiteDow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in Polyethylenefengshaohua_gmailNoch keine Bewertungen

- Hydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterDokument1 SeiteHydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterJUNIORNoch keine Bewertungen

- 2011 Exam GeotechnicalDokument9 Seiten2011 Exam GeotechnicalAhmed AwadallaNoch keine Bewertungen

- Large Steam GeneratorDokument12 SeitenLarge Steam GeneratorChe AguilarNoch keine Bewertungen

- ASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012Dokument18 SeitenASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012omar quiñonesNoch keine Bewertungen

- Cds Photoconductive Cells: 3Mm Cds Photosensitive ResistorDokument5 SeitenCds Photoconductive Cells: 3Mm Cds Photosensitive Resistor21xim21Noch keine Bewertungen

- Platinum Silicone Paint Base: Product OverviewDokument2 SeitenPlatinum Silicone Paint Base: Product OverviewGrace LNoch keine Bewertungen

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideVon EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideBewertung: 2 von 5 Sternen2/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryVon EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNoch keine Bewertungen

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Pipeline Integrity: Management and Risk EvaluationVon EverandPipeline Integrity: Management and Risk EvaluationBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastVon EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastBewertung: 4.5 von 5 Sternen4.5/5 (76)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionVon EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesVon EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesBewertung: 4 von 5 Sternen4/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationVon EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisVon EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNoch keine Bewertungen

- Fire in the Night: The Piper Alpha DisasterVon EverandFire in the Night: The Piper Alpha DisasterBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesVon EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNoch keine Bewertungen

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsVon EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsBewertung: 5 von 5 Sternen5/5 (1)

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilVon EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilNoch keine Bewertungen

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingVon EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNoch keine Bewertungen

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsVon EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNoch keine Bewertungen

- Subsea Valves and Actuators for the Oil and Gas IndustryVon EverandSubsea Valves and Actuators for the Oil and Gas IndustryBewertung: 5 von 5 Sternen5/5 (1)

- Compression Machinery for Oil and GasVon EverandCompression Machinery for Oil and GasKlaus BrunBewertung: 4 von 5 Sternen4/5 (4)