Beruflich Dokumente

Kultur Dokumente

Case Study Plag

Hochgeladen von

Aamir MalikOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Case Study Plag

Hochgeladen von

Aamir MalikCopyright:

Verfügbare Formate

Name of the Student

Aamir Malik

Program

MBA(G)

Class Roll Number

B-43

Enrollment Number

A0101913169

Name of Faculty guide

Dr. Shalini Trivedi

Case study title Grasim Industries Ltd and VSF -

Expanding a Commodity Market

through Branding and CRM

Student Declaration

I declare (a)That the work presented for assessment is my own, that it has not previously been

presented for another assessment and that my debts (for words, data, arguments and ideas)

have been appropriately acknowledged (b) That the work conforms to the guidelines for

presentation and style set out in the relevant documentation. ( c ) The Plagiarism as taken by

Turnitin is ________ %.

Date : Student

Signature

(Faculty guide name & Signature)

Designation & Department

Abstract

Grasim Industries Ltd. is an overwhelming player in the Indian Viscose Stable Fiber business

and one of the heading players all inclusive. The case starts with a profile of the Indian VSF

market. It then blueprints the effect of changes in the costs of interchange strands, chiefly

cotton and polyester, on the interest for Grasim's VSF. The case portrays in detail the

remarkable business system, 'Benefit past VSF', received by Grasim with the expectation of

pushing the utilization of its VSF and diminishing the effect of value vacillations in substitute

strands. The case diagrams the quality included administrations, and marking and item

improvement activities, that the organization has completed to understand its targets. The

case closes with a discourse on the future prospects of Grasim.

ISSUES

To give experiences into the way of ware markets, and the business for man-made and

different filaments in India

To comprehend the effect of value vacillations of substitute items, on the interest for a ware

item

To like the different issues confronted by makers of ware items, and all the more

particularly, VSF producers

To give experiences into the methods by which a ware item can changed into a marked

item, with more steady request and less probability of substitution

To comprehend the commitment of new item advancement to the development of an

industry

Keywords

Viscose Staple Fiber, Birla, Branding, Value addition, Commodity, Cotton, Polyester,

Substitutes, Price fluctuation, Value chain, Spinners, Knitters , Yarn

There is no such thing as decline. When markets are not moving, there are two things that

you can do - take on competition and see that your offering is better in all ways, and the other

way is to grow your market."

Shailendra K. Jain, President of Grasim Industries Ltd., in 2004.

"Viscose has been underutilized because of a lack of awareness among fashion designers and

end-users. Internationally viscose blended fabrics are extensively used in apparels. This not

the case in India."

- M P Joseph, Secretary General, Association of Man-made Fiber Industry of India

(AMFII),3 in October 2005.

Introduction

In March 2006, Grasim Industries Ltd. (Grasim) reported arrangements to secure a

coordinated manor cum mash plant in Laos to source crude material for its Viscose Staple

Fiber (VSF) creation units in India, Thailand and Indonesia and additionally for future

generation offices.

The report came as an astonishment, showing to industry watchers that Grasim had not

recently succeeded in capturing the decrease in its offers of VSF, however was sure of future

development as well. Grasim began generation of fabric utilizing transported in VSF as a part

of 1950. VSF was then the least expensive accessible fiber and was alluded to as 'the poor

man's cotton'. In 1963, Grasim received a vertical reconciliation methodology and began

delivering it VSF. As an expense sparing measure, the organization even started delivering

significant crude materials (wood mash and burning pop) for VSF in-house. It additionally

created a more eco-accommodating methodology for assembling VSF. These measures,

however fruitful in expanding its deals, were not sufficient to switch the continuous loss of

piece of the pie of its VSF to its substitutes - cotton and polyester filaments.

By the 1990s, a blend of expanding crude material expenses and low polyester and cotton

costs made VSF the costliest fiber. Accordingly, interest for VSF declined quickly.

In 1999, Grasim set out on a forceful showcasing crusade to rescue its VSF business. The

battle did succeed in expanding the interest for VSF to some degree. Be that as it may, in

2002, with the fall in cotton costs, interest for VSF fell once more.

It was at this crossroads that Grasim chalked out a method to lessen the effect of value

variances of substitute strands on interest for its VSF, while in the meantime moving to build

its experience the fiber market.

The system included a few item advancement activities and is accepted to have helped make

esteem for the organization and its clients.

Background Note:

Grasim was a piece of the Aditya Vikram (A.v) Birla Group established by Shiv Narayan

Birla (SN) in the late nineteenth century. A part of the Marwari4 group in Pilani, Rajasthan,

SN began exchanging cotton in Bombay (Mumbai).

The cotton business stretched quickly. In 1919, Ghanshyam Das Birla (GD), SN's grandson,

went to Kolkata, to set up a jute business. GD later set up units in aluminum, bond,

chemicals, materials, and fiber commercial ventures. He was likewise eagerly included in

India's opportunity battle and was a nearby partner of Mahatma Gandhi. Grasim was made on

August 25, 1947 at Gwalior in Madhya Pradesh by G.d. The organization was set up to

produce fabrics. Amid that period, most material plants utilized cotton fiber. At the point

when British India was parceled, the vast majority of the cotton-delivering ranges went to

Pakistan, with the come about that the Indian material industry confronted a genuine crude

material deficiency. Grasim searched for plan B to cotton, and decided to utilize VSF, which

was likewise the least expensive fiber accessible at the time.

It initiated generation of fabrics utilizing VSF foreign from Europe. In 1954, Grasim set up a

plant to create VSF in India surprisingly at Nagda in Madhya Pradesh, in this manner

accomplishing significant retrograde reconciliation.

In 1962, Grasim began a different building division to fabricate plant and hardware for VSF

generation. In later decades, Grasim manufactured all its plants utilizing indigenous

innovation and supplies.

In 1963, Grasim set up a VSF plant at Mavoor, Kerala which turned into the first to utilize

bamboo as crude material. Creation at the plant initiated in 1968.

In 1972, a totally indigenous plant was fabricated at Harihar, Karnataka that made utilization

of mash from eucalyptus trees. The plant utilized in-house engineering for creating wood

mash through a creative oxygen dying methodology which lessened the utilization of

chlorine.

VSF: Fluctuating Fortunes

Generally, the costs of substitute strands had regularly had an effect on the interest for VSF.

The interest for VSF was grinding away's top in the 1960s, when it summoned a piece of the

pie of 20% in the worldwide fiber market. Through the years, this had declined slowly.

Throughout the decades, the creation expense of VSF had climbed consistently, owing to

taking off crude material (particularly wood mash) costs and the exceptionally control

concentrated nature of the generation process. In the 1990s, the low cost of cotton and falling

polyester costs made VSF the costliest fiber, bringing on a decrease in its piece of the pie. In

the 1990s, VSF's worldwide piece of the pie had contracted to 4%...

Service Beyond VSF:

In 2002, Grasim started execution of its 'Administration past VSF' methodology. The

organization had the accompanying goals:

- to give complete answers for its clients' fiber related needs,

- to guarantee most extreme client fulfillment bringing about higher client maintenance,

- to attain higher deals by making clients build the use of VSF in their yarn,

- to completely use its creation limit, and

- to increase piece of the pie from cotton and polyester.

Offering Value Added Services to the Entire Value Chain

Grasim accepted that the business could be broadened just on the off chance that it worked

with each section of the VSF worth chain. Thusly, the organization executed the

Administration past VSF' procedure to blanket the whole VSF worth chain. It supported the

use of VSF by spreading data with respect to the key properties of the fiber. It gave a few

administrations to the different elements in the material quality chain which included article

of clothing producers, weavers, knitters, fabric getting done with/garmenting units, material

specialized experts, merchants/executors, processors, and significant purchasing

houses/operators who sourced fabric/piece of clothing supplies...

Product Development Initiatives

Grasim perceived that its endeavors to augment the business sector for its VSF would be

useless unless new applications and items were brought out customarily. Item improvement

in VSF was basically nonexistent as contrasted with different strands which normally turned

out in fresher forms. Subsequently, alongside its procurement of worth included

administrations, Grasim tried exertions to present more current variations of VSF...

Other Efforts

Grasim acknowledged that the business could be increased just if it worked with each one

segment of the VSF worth chain. In this way, the association executed the 'Organization past

VSF' system to cover the entire VSF worth chain. It upheld the utilization of VSF by

spreading information as for the key properties of the fiber. It gave a couple of organizations

to the diverse components in the material quality chain which included piece of attire makers,

weavers, knitters, fabric accomplishing with/garmenting units, material particular specialists,

traders/agents, processors, and critical buying houses/administrators who sourced fabric/bit of

apparel supplies...

The Impact of 'Service Beyond VSF'

Grasim saw that its tries to increase the business division for its VSF would be pointless

unless new applications and things were brought out usually. Thing change in VSF was

fundamentally nonexistent as appeared differently in relation to distinctive strands which

typically turned out in fresher structures. Accordingly, close by its acquisition of worth

included organizations, Grasim attempted efforts to present more present varieties of VSF...

Outlook

Grasim acknowledged that the business could be increased just if it worked with each one

segment of the VSF worth chain. In this way, the association executed the 'Organization past

VSF' system to cover the entire VSF worth chain. It upheld the utilization of VSF by

spreading information as for the key properties of the fiber. It gave a couple of organizations

to the diverse components in the material quality chain which included piece of attire makers,

weavers, knitters, fabric accomplishing with/garmenting units, material particular specialists,

traders/agents, processors, and critical buying houses/administrators who sourced fabric/bit of

apparel supplies...

Grasim saw that its tries to increase the business division for its VSF would be pointless

unless new applications and things were brought out usually. Thing change in VSF was

fundamentally nonexistent as appeared differently in relation to distinctive strands which

typically turned out in fresher structures. Accordingly, close by its acquisition of worth

included organizations, Grasim attempted efforts to present more present varieties of VSF...

Das könnte Ihnen auch gefallen

- Group 5 (Denim-Men)Dokument84 SeitenGroup 5 (Denim-Men)Mukund VermaNoch keine Bewertungen

- China HousingMarketDokument31 SeitenChina HousingMarketshashankgowdaNoch keine Bewertungen

- Banking Law Syllabus Atty VeraDokument2 SeitenBanking Law Syllabus Atty VeraLawrence Villamar100% (1)

- Indian Stock MarketDokument60 SeitenIndian Stock Marketmokshasinchana100% (1)

- Price 2022-D - 1669879424Dokument19 SeitenPrice 2022-D - 1669879424Moses SilvaNoch keine Bewertungen

- Champo Carpets: Improving Business-To-Business Sales Using Machine Learning AlgorithmsDokument5 SeitenChampo Carpets: Improving Business-To-Business Sales Using Machine Learning AlgorithmsSKNoch keine Bewertungen

- CPP Form (New License)Dokument4 SeitenCPP Form (New License)Kopil uddin NishanNoch keine Bewertungen

- TIR Vardhman, Budhni (29 Dec 2020)Dokument36 SeitenTIR Vardhman, Budhni (29 Dec 2020)Keshav AnandNoch keine Bewertungen

- VF Brands Case AnalysisDokument9 SeitenVF Brands Case AnalysisKaran TrivediNoch keine Bewertungen

- Makakalikasan SSG Ppa Accomplishment Report Template EditedDokument4 SeitenMakakalikasan SSG Ppa Accomplishment Report Template Editedjunapoblacio100% (3)

- Project ReportDokument79 SeitenProject ReportranaNoch keine Bewertungen

- Case Study - An Incredible Way Of Learning: Management, #1Von EverandCase Study - An Incredible Way Of Learning: Management, #1Noch keine Bewertungen

- History of The Organization: Assignment TemplateDokument4 SeitenHistory of The Organization: Assignment Templatethqqwidie qddqNoch keine Bewertungen

- Grasim HR ReportDokument22 SeitenGrasim HR ReportTushar NagoriNoch keine Bewertungen

- Part-A 1.industry Profile: A Study On Consumer Awareness of Kara Skincare Wet WipesDokument64 SeitenPart-A 1.industry Profile: A Study On Consumer Awareness of Kara Skincare Wet WipesSarva ShivaNoch keine Bewertungen

- Grasim Industries: Viscose Staple Fibre Sector: Grasim Has The Following Overseas Joint Venture CompaniesDokument2 SeitenGrasim Industries: Viscose Staple Fibre Sector: Grasim Has The Following Overseas Joint Venture CompaniesRajat SharmaNoch keine Bewertungen

- Project On Effectiveness of Training Program OF Grasim Industries Limited Staple Fibre DivisionDokument52 SeitenProject On Effectiveness of Training Program OF Grasim Industries Limited Staple Fibre Divisiondave_sourabhNoch keine Bewertungen

- A Project Report On Reduction of Fabric Faults in Casual Shirting DepartmentDokument23 SeitenA Project Report On Reduction of Fabric Faults in Casual Shirting DepartmentranaNoch keine Bewertungen

- Managerial Aptitude Assignment 3Dokument5 SeitenManagerial Aptitude Assignment 3najla fedawiNoch keine Bewertungen

- Champo Carpets Improving Business-To-Business Sales Using Machine Learning AlgorithmsDokument5 SeitenChampo Carpets Improving Business-To-Business Sales Using Machine Learning Algorithmsjoshir878Noch keine Bewertungen

- Textile IndustryDokument8 SeitenTextile IndustryAarav AggarwalNoch keine Bewertungen

- Solarvastra Is Renewable Energy-Powered Sustainable Fashion A Real Market Opportunity CEEW 2021Dokument26 SeitenSolarvastra Is Renewable Energy-Powered Sustainable Fashion A Real Market Opportunity CEEW 2021keshav.mundhraNoch keine Bewertungen

- CoverDokument103 SeitenCoverankitag_49Noch keine Bewertungen

- Industrial Profile:: Birth of Textile Industry in IndiaDokument68 SeitenIndustrial Profile:: Birth of Textile Industry in IndiaSagar SagiNoch keine Bewertungen

- Individual Assignment Merger of Birla Aditya Birla Nuvo Ltd. and Grasim Industries LTDDokument7 SeitenIndividual Assignment Merger of Birla Aditya Birla Nuvo Ltd. and Grasim Industries LTDMokshita VajawatNoch keine Bewertungen

- Project On Brand Positioning of Vimal Suitings PDFDokument60 SeitenProject On Brand Positioning of Vimal Suitings PDFsudhirNoch keine Bewertungen

- GrasimDokument1 SeiteGrasimTrisha PorwalNoch keine Bewertungen

- Yash Arora ReportDokument110 SeitenYash Arora ReportShan AtrayNoch keine Bewertungen

- Arvind Mills Re-Evaluating ProfitabilityDokument10 SeitenArvind Mills Re-Evaluating ProfitabilityPooja Bilkha0% (1)

- Project On Brand Positioning of Vimal SuitingsDokument60 SeitenProject On Brand Positioning of Vimal SuitingsSanjay839100% (3)

- Document4 2 Copy Copy 3Dokument6 SeitenDocument4 2 Copy Copy 3mnrwillers0305047Noch keine Bewertungen

- B2B Project Report - Group9Dokument15 SeitenB2B Project Report - Group9Vaibhav RajNoch keine Bewertungen

- IndexDokument14 SeitenIndexVijayKumar NishadNoch keine Bewertungen

- Mike Morris: Globalisation, China, and Clothing Industrialisation Strategies in Sub-Saharan AfricaDokument19 SeitenMike Morris: Globalisation, China, and Clothing Industrialisation Strategies in Sub-Saharan AfricaManjusha NairNoch keine Bewertungen

- Imran BlackbookDokument8 SeitenImran BlackbookManisha YadavNoch keine Bewertungen

- Arvind ReportDokument17 SeitenArvind Reportaneri31791100% (1)

- Proj ReportDokument40 SeitenProj Reportshriya_bupathNoch keine Bewertungen

- MGT541 - Group2 - Final AssignmentDokument21 SeitenMGT541 - Group2 - Final AssignmentParth ThakerNoch keine Bewertungen

- Garment IndustryDokument37 SeitenGarment IndustryPuneet TandonNoch keine Bewertungen

- Chapter - 1: Introduction of GrasimDokument66 SeitenChapter - 1: Introduction of GrasimLovish SharmaNoch keine Bewertungen

- Birla Afrid EditedDokument25 SeitenBirla Afrid EditedMohammed AfridNoch keine Bewertungen

- Customer Satisfaction Study For The Drivers of Sodium Salphet at Grasim Industries Ltd. by Gaurav Soral - MarketingDokument59 SeitenCustomer Satisfaction Study For The Drivers of Sodium Salphet at Grasim Industries Ltd. by Gaurav Soral - MarketingVinod PandeyNoch keine Bewertungen

- Sapphire Textile Mills LimitedDokument8 SeitenSapphire Textile Mills LimitedPaul ConstanteNoch keine Bewertungen

- Aditya Birla Nuvo LTD.: The Company's Business Location IncludesDokument12 SeitenAditya Birla Nuvo LTD.: The Company's Business Location IncludesMokshita VajawatNoch keine Bewertungen

- NandyDokument10 SeitenNandyNandhini PriyaNoch keine Bewertungen

- Arvind Mills Internship DocumentDokument68 SeitenArvind Mills Internship DocumentniftshikhaNoch keine Bewertungen

- 1.1 Importance of The Spinning Sector 1.2 Research Objectives 1.3 Benefits of The Study 1.4 LimitationsDokument23 Seiten1.1 Importance of The Spinning Sector 1.2 Research Objectives 1.3 Benefits of The Study 1.4 LimitationsArsalan HamidNoch keine Bewertungen

- Mudra Fabrics Private LimitedDokument70 SeitenMudra Fabrics Private LimitedPrashanth PBNoch keine Bewertungen

- Ferdous Custom Made Tailors Fabrics Fashions New CDokument7 SeitenFerdous Custom Made Tailors Fabrics Fashions New Cdarshilsolanki.mba22Noch keine Bewertungen

- (Head of Textile) : Submitted ToDokument77 Seiten(Head of Textile) : Submitted ToDivya Thakur100% (1)

- Indian Ray OneDokument96 SeitenIndian Ray Oneધ્રુવ પટેલNoch keine Bewertungen

- Arvind IntershipDokument52 SeitenArvind IntershipAnurag MosanNoch keine Bewertungen

- Vardhman ReportDokument18 SeitenVardhman ReportRaj Kumar100% (1)

- Siyarams RoughDokument38 SeitenSiyarams RoughASHISH BHUWANIANoch keine Bewertungen

- Arvind MillsDokument9 SeitenArvind MillsPradeep Kumar PandeyNoch keine Bewertungen

- ProjectDokument11 SeitenProjectsatyarthsinghNoch keine Bewertungen

- Grasim Industry Ltd.Dokument20 SeitenGrasim Industry Ltd.Neha ShelkeNoch keine Bewertungen

- Arvind MillsDokument4 SeitenArvind MillsYardenKalinto0% (1)

- Working Capital and Company Tex Til Company Mafatlal PDFDokument14 SeitenWorking Capital and Company Tex Til Company Mafatlal PDFKaran ParmarNoch keine Bewertungen

- MAP Report For MBADokument57 SeitenMAP Report For MBAMaulik TankNoch keine Bewertungen

- Customer Feedback of Fabrics With Reference To Mayur Suitings and Shirtings TaxtilrsbwDokument85 SeitenCustomer Feedback of Fabrics With Reference To Mayur Suitings and Shirtings TaxtilrsbwJitendra VirahyasNoch keine Bewertungen

- Lalbhai Group - ArvindDokument4 SeitenLalbhai Group - Arvindvinoth_17588Noch keine Bewertungen

- Marketing Pro CoirDokument23 SeitenMarketing Pro Coirlamiya laljiNoch keine Bewertungen

- Company Grasim ProfileDokument48 SeitenCompany Grasim ProfileNitu Saini100% (1)

- Garima 1Dokument82 SeitenGarima 1Parshant GargNoch keine Bewertungen

- Fast Fashion, Fashion Brands and Sustainable ConsumptionVon EverandFast Fashion, Fashion Brands and Sustainable ConsumptionNoch keine Bewertungen

- Gaming:: Observation in Nehru Place MarketDokument4 SeitenGaming:: Observation in Nehru Place MarketAamir MalikNoch keine Bewertungen

- 5ca58ICICI Securities JCP Planning Session RegistrationDokument5 Seiten5ca58ICICI Securities JCP Planning Session RegistrationAamir MalikNoch keine Bewertungen

- Objectives and Functions: Statutory Body Government of India Ministry of Micro, Small and Medium Enterprises KhadiDokument2 SeitenObjectives and Functions: Statutory Body Government of India Ministry of Micro, Small and Medium Enterprises KhadiAamir MalikNoch keine Bewertungen

- Journal Student Chapter DetailsDokument1 SeiteJournal Student Chapter DetailsAamir MalikNoch keine Bewertungen

- Amity Business School: Capital StructureDokument7 SeitenAmity Business School: Capital StructureAamir MalikNoch keine Bewertungen

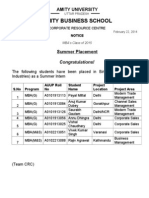

- 0 B 0 F 9 NoticeklnDokument1 Seite0 B 0 F 9 NoticeklnAamir MalikNoch keine Bewertungen

- Amity Business School: MBA Legal Aspects of Business Ms. Shinu VigDokument20 SeitenAmity Business School: MBA Legal Aspects of Business Ms. Shinu VigAamir MalikNoch keine Bewertungen

- The Product Launch of Tenso-1Dokument24 SeitenThe Product Launch of Tenso-1Aamir MalikNoch keine Bewertungen

- Aaker Brand Equity ModelDokument3 SeitenAaker Brand Equity ModelAamir MalikNoch keine Bewertungen

- Amity Business School: MBA, Semester 2 Legal Aspects of Business Ms. Shinu VigDokument20 SeitenAmity Business School: MBA, Semester 2 Legal Aspects of Business Ms. Shinu VigAamir MalikNoch keine Bewertungen

- Aaker Brand Equity ModelDokument3 SeitenAaker Brand Equity ModelAamir MalikNoch keine Bewertungen

- 1923 Baragwanath The Ballarat Goldfield, Memoir 14 - pt-2Dokument143 Seiten1923 Baragwanath The Ballarat Goldfield, Memoir 14 - pt-2Yuri Vladimir Ordonez LamaNoch keine Bewertungen

- Sanjeev Kr. YadavDokument3 SeitenSanjeev Kr. YadavSahil KumarNoch keine Bewertungen

- The Rotary Club of Payson: Today... September 18th Is..Dokument2 SeitenThe Rotary Club of Payson: Today... September 18th Is..api-35893633Noch keine Bewertungen

- Channel ManagementDokument8 SeitenChannel Managementsajid bhattiNoch keine Bewertungen

- The Surplus Economy: and The Battle of BrandingDokument8 SeitenThe Surplus Economy: and The Battle of Brandinga4yNoch keine Bewertungen

- Air India Analyst ReportDokument14 SeitenAir India Analyst ReportRicha100% (1)

- Manifest Trigana Air YulyzanataDokument16 SeitenManifest Trigana Air YulyzanataRendi WibowoNoch keine Bewertungen

- Intergovernmental Organizations (Igos) and Their Roles and Activities in Security, Economy, Health and EnvironmentDokument9 SeitenIntergovernmental Organizations (Igos) and Their Roles and Activities in Security, Economy, Health and EnvironmentAMPONIN EUNICENoch keine Bewertungen

- Assignment On BelgiumDokument21 SeitenAssignment On Belgiumgalib gosnoforNoch keine Bewertungen

- IssuesDokument30 SeitenIssuesJessy BascoNoch keine Bewertungen

- Market Drivers - Currencies: Today's Comment Today's Chart - EUR/USDDokument5 SeitenMarket Drivers - Currencies: Today's Comment Today's Chart - EUR/USDMiir ViirNoch keine Bewertungen

- Congress Policy Brief - CoCoLevyFundsDokument10 SeitenCongress Policy Brief - CoCoLevyFundsKat DinglasanNoch keine Bewertungen

- Special Contracts Case MatDokument294 SeitenSpecial Contracts Case Matsheryl sebastianNoch keine Bewertungen

- NTSE MAT Solved Sample Paper 1 PDFDokument17 SeitenNTSE MAT Solved Sample Paper 1 PDFAlmelu AvinashNoch keine Bewertungen

- Alice's Adventures in WonderlandDokument2 SeitenAlice's Adventures in WonderlandDavid SaguaNoch keine Bewertungen

- Production Possibility Frontiers, OC, MarginalismDokument4 SeitenProduction Possibility Frontiers, OC, Marginalismyai giniNoch keine Bewertungen

- Xury, Friday and The Nineteenth-Century Racialisation of EnslavementDokument6 SeitenXury, Friday and The Nineteenth-Century Racialisation of EnslavementIan ChenNoch keine Bewertungen

- Mint E-Paper 2Dokument23 SeitenMint E-Paper 2Parthasarathi MishraNoch keine Bewertungen

- Chapter 1 Introduction To Human Resource ManagementDokument31 SeitenChapter 1 Introduction To Human Resource Managementnorlaily arshad100% (1)

- Coins PH Buy SellDokument10 SeitenCoins PH Buy Selljoshann251Noch keine Bewertungen

- GS - Outlook For 2023Dokument56 SeitenGS - Outlook For 2023Aaron WangNoch keine Bewertungen

- Research Paper Electric Vehicles (Autorecovered)Dokument3 SeitenResearch Paper Electric Vehicles (Autorecovered)AryanNoch keine Bewertungen

- Imp WebsitesDokument21 SeitenImp WebsitesMeenakshi S. RajpurohitNoch keine Bewertungen

- Mindquest Rules 2024Dokument6 SeitenMindquest Rules 2024carrybabaahmmmNoch keine Bewertungen