Beruflich Dokumente

Kultur Dokumente

Cie 326 HW 3

Hochgeladen von

aumi77Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cie 326 HW 3

Hochgeladen von

aumi77Copyright:

Verfügbare Formate

Khondoker Alam

CIE 326

Due 2/27/14

HW 6

5.1) The three geological classifications of rocks are igneous, sedimentary and metamorphic. Igneous:

Formed from hardening or crystallizing molten material, magma through volcanic action.

Sedimentary: Coalesce from deposits of disintegrated existing rocks or inorganic remains of marine

animals.

Metamorphic: Form from igneous or sedimentary rocks that are drawn back into the earths crust and

exposed to heat and pressure, re-forming the grain structure.

5.2 One desirable aggregate characteristic of Portland concrete is to have round, smooth aggregate to

improve the workability of the fresh concrete during mixing (this is because the stability if the concrete

is from the cementing action and aggregate interlock). Another characteristic that is important is the

aggregates ability to resist weathering, or durability. This is important because the aggregate needs to

resist the pressure from water freezing in voids. A third characteristic is toughness, so that the aggregate

will not disintegrate, crush, or degrade when being mixed into the concrete. Absorption is also

important Portland cement concrete because moisture trapped in the voids is not available to react with

the cement and improve the workability of plastic concrete. A final characteristic is the specific gravity of

the aggregate in the concrete mix design.

5.3) One desirable aggregate characteristic of Asphalt concrete is to have angular and rough particles

because the stability of asphalt concrete is mostly in the aggregate interlock. These aggregate have to

meet an angularity and texture requirement, the angularity and texture of fine particles is another

characteristics of Asphalt concrete that should be considered, as there is a specific gradation needed for

fine particles. Another desirable characteristic is the adsorption of water because adsorbed asphalt is

not available to act as a binder, therefore, low adsorption aggregates are desirable for asphalt concrete.

The aggregates should also have the same strength and modulus as the concrete so the strength is

uniform throughout. Finally, aggregate must be able to withstand the force of mixing the asphalt

concrete and not disintegrate; this is called toughness.

5.4) The standard specifications for fine aggregates in New York are, fine aggregate shall consist of

natural sand or manufactured sand, all fine aggregates shall consist of hard, strong, durable particles,

which are free from a coating or any injurious material and injurious amounts of class, loam, or other

deleterious substances. Fine aggregate shall not contain substances, which when mixed in Portland

cement concrete, produce an unacceptable level of chloride ions in the final product.

5.5) a. in Portland cement concrete, round and smooth aggregate is preferred in order to increase the

workability of the cement. This is because the stability of PCC is mostly developed by the cementing

action of the cement and by the aggregate interlock.

b. Angular and rough particles are preferred to increase stability in the field and reduce rutting. This is

because the stability of HMA is mostly developed by the aggregate interlock only.

5.6) a) Saturated surface-dry condition of aggregates is when the aggregates voids are filled with

moisture but the main surface area of the aggregate particles is dry.

b) Absorption of aggregates is defined as the moisture content in the SSD condition. Moist aggregates

have moisture content in excess of the SSD condition.

c) Free water aggregates is the difference between the actual moisture content of the aggregate and the

moisture content in the SSD condition.

d) The moisture captured in the voids in the aggregates is not available.

5.31) The fineness modulus of aggregate measures the fine aggregates gradation and it is used mostly

for Portland cement concrete mix design.

5.39) Alkali-silica reactivity is the reaction between the active silica in the aggregate and the alkalis in the

cement. This is the most common reaction with cement in concrete, and is common in humid and warm

climates. This reaction causes excessive expansive, cracking, and pop-outs in the concrete. Ways to

minimize ASR is limiting the alkali content of the cement and but keeping the concrete as dry as

possible.

5.40) Typical deleterious substances in aggregate that affect Portland cement concrete include organic

impurities, coal, lignite, clay lumps, friable particles, soft particles, low density material, and particles

smaller than 0.075mm. Coal lignite and low-density materials can reduce durability and may cause pop-

outs or stains. Clay clamps, friable particles, and soft particles result in pop-outs, reduce durability and

wear resistance. Small particles weaken the bond between the cement and aggregate and may increase

water materials requirements. Organic impurities can delay settling and hardening, reduce strength

gain, and can cause deterioration.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- WSET Level 2 中级葡萄酒品尝教材Dokument83 SeitenWSET Level 2 中级葡萄酒品尝教材凱日本Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Sci Quiz Gr. 4Dokument50 SeitenSci Quiz Gr. 4Kristine Barredo81% (16)

- Grade 4 Science Review States of WaterDokument2 SeitenGrade 4 Science Review States of WaterQuake Garen100% (13)

- Essentials for College Dorm Room ChecklistDokument3 SeitenEssentials for College Dorm Room Checklistaumi77Noch keine Bewertungen

- Adrian TrailsDokument3 SeitenAdrian Trailsaumi77Noch keine Bewertungen

- 2013 Lab ManualDokument92 Seiten2013 Lab Manualaumi77Noch keine Bewertungen

- Practice Exam For Exam3 CHE116Dokument10 SeitenPractice Exam For Exam3 CHE116aumi77Noch keine Bewertungen

- Man Overboard Rescue TurnDokument3 SeitenMan Overboard Rescue TurnPolly O'NedelchevaNoch keine Bewertungen

- Standard of Shore Connection PDFDokument5 SeitenStandard of Shore Connection PDFrameshprtNoch keine Bewertungen

- CEC 150 (K)Dokument4 SeitenCEC 150 (K)I'am PhilNoch keine Bewertungen

- (15200485 - Journal of Physical Oceanography) The Red Sea - A Natural Laboratory For Wind and Wave ModelingDokument21 Seiten(15200485 - Journal of Physical Oceanography) The Red Sea - A Natural Laboratory For Wind and Wave ModelingLinh CrystalNoch keine Bewertungen

- Technical English SampleUnit CB2 PDFDokument6 SeitenTechnical English SampleUnit CB2 PDFXavi AlonsoNoch keine Bewertungen

- Official SSC CHSL Question Paper 19th Jan 2017 Tier I With Answer KeyDokument24 SeitenOfficial SSC CHSL Question Paper 19th Jan 2017 Tier I With Answer Keynidhi tripathiNoch keine Bewertungen

- Yokdil Fen Deneme SinaviDokument22 SeitenYokdil Fen Deneme SinaviYaşar YılmazNoch keine Bewertungen

- Hydrology Principles Analysis DesignDokument477 SeitenHydrology Principles Analysis DesignDen Baguse DonieNoch keine Bewertungen

- Fastclass Test02bDokument5 SeitenFastclass Test02bSebastian2007Noch keine Bewertungen

- R 41031022015Dokument8 SeitenR 41031022015GokulSubramanianNoch keine Bewertungen

- Activity Guide and Evaluation RubricDokument2 SeitenActivity Guide and Evaluation Rubrickarina meriñoNoch keine Bewertungen

- Perlite - Water Absorption - C549.617045-1Dokument4 SeitenPerlite - Water Absorption - C549.617045-1mn4webNoch keine Bewertungen

- Glossary of Geographical TermsDokument33 SeitenGlossary of Geographical Termscleophil_yontingNoch keine Bewertungen

- Sanyo RefrigeratorsDokument3 SeitenSanyo Refrigeratorspratikhire9Noch keine Bewertungen

- Vega Atlantic CrossingDokument6 SeitenVega Atlantic Crossingjoswas100% (2)

- San Mateo Daily Journal 12-05-18 EditionDokument28 SeitenSan Mateo Daily Journal 12-05-18 EditionSan Mateo Daily JournalNoch keine Bewertungen

- Boiler Material and Typical ApplicationsDokument1 SeiteBoiler Material and Typical Applicationsmtbecerrap100% (1)

- Direct U2..QuotesDokument216 SeitenDirect U2..Quotessameh1311Noch keine Bewertungen

- PDS Hempadur 45883Dokument2 SeitenPDS Hempadur 45883Fredy Xavier DomínguezNoch keine Bewertungen

- IndiaDokument2 SeitenIndiaDan McNicollNoch keine Bewertungen

- FloodA USER GUIDE TO THE FLOODS REPORTING SCHEMAS: A USER GUIDE TO THE FLOODS REPORTING SCHEMASsSchemaUserGuide - v3.0Dokument105 SeitenFloodA USER GUIDE TO THE FLOODS REPORTING SCHEMAS: A USER GUIDE TO THE FLOODS REPORTING SCHEMASsSchemaUserGuide - v3.0Vangelis RavelNoch keine Bewertungen

- Moving AveragesDokument8 SeitenMoving AveragesRenuka SushilNoch keine Bewertungen

- Mystery Lesson - Tag - Revision and ReflectionDokument8 SeitenMystery Lesson - Tag - Revision and Reflectionapi-323796185Noch keine Bewertungen

- MV SSI BRILLIANT Daily Report 04 - 12.11.2023Dokument16 SeitenMV SSI BRILLIANT Daily Report 04 - 12.11.2023DanielNoch keine Bewertungen

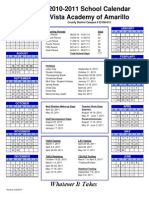

- 2010-2011 Calendar AmarilloDokument1 Seite2010-2011 Calendar AmarilloResponsiveEdNoch keine Bewertungen

- MSC Thesis - Gert Cool - 4100093 - Floating LiDAR Technology - 07september2016Dokument136 SeitenMSC Thesis - Gert Cool - 4100093 - Floating LiDAR Technology - 07september2016lpczyfansNoch keine Bewertungen

- DMV Practice Test: 25 QuestionsDokument6 SeitenDMV Practice Test: 25 QuestionsMadhesi Sah100% (1)