Beruflich Dokumente

Kultur Dokumente

Case N Precedent Study of Masjid Jamek

Hochgeladen von

MuiAsmui75%(4)75% fanden dieses Dokument nützlich (4 Abstimmungen)

1K Ansichten48 SeitenThe document provides information about Masjid Jamek, the oldest mosque in Kuala Lumpur, Malaysia. It was designed in 1907 by British architect Arthur Bennison Hubback and completed in 1909. The mosque features a Neo-Moorish architectural style with onion-shaped domes and horseshoe arches. It has also served as the main mosque of Kuala Lumpur before the construction of Masjid Negara in 1965. The document further discusses the mosque's architectural features, surrounding context, users, and accessibility.

Originalbeschreibung:

Report are produce by 3rd Year Architecture Student, IIUM (2014/2015)

Originaltitel

Case n Precedent Study of Masjid Jamek

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document provides information about Masjid Jamek, the oldest mosque in Kuala Lumpur, Malaysia. It was designed in 1907 by British architect Arthur Bennison Hubback and completed in 1909. The mosque features a Neo-Moorish architectural style with onion-shaped domes and horseshoe arches. It has also served as the main mosque of Kuala Lumpur before the construction of Masjid Negara in 1965. The document further discusses the mosque's architectural features, surrounding context, users, and accessibility.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

75%(4)75% fanden dieses Dokument nützlich (4 Abstimmungen)

1K Ansichten48 SeitenCase N Precedent Study of Masjid Jamek

Hochgeladen von

MuiAsmuiThe document provides information about Masjid Jamek, the oldest mosque in Kuala Lumpur, Malaysia. It was designed in 1907 by British architect Arthur Bennison Hubback and completed in 1909. The mosque features a Neo-Moorish architectural style with onion-shaped domes and horseshoe arches. It has also served as the main mosque of Kuala Lumpur before the construction of Masjid Negara in 1965. The document further discusses the mosque's architectural features, surrounding context, users, and accessibility.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 48

PRECEDENT STUDY

MASJID JAMEK, KUALA LUMPUR

ARCHITECTS PROFILE

The architect of Jamek Mosque is Arthur Bennison Hubback. He was born on 13 April 1871 and died on 8 May 1948. He received his education at Fettes College, Edinburgh.

Then, he worked as an architect as well as a soldier ( Brigadier General). In 1895, he is chief draughtsman of Selangor public works department as well as contributed towards

development of Kuala Lumpur. Besides that, he worked on buildings in Malaya and Hong Kong, from mosque to railway stations.

BUILDING PROFILE

Jamek Mosque is located at Jalan Tun Perak, Kuala Lumpur. It covers the project area of 4, 000 sqm out of 10, 000 sqm of site area. This project is started in 1907 and completed in 1909.

Location Plan (N. T. S)

Arthur Bennison Hubback

Site Plan (N. T. S)

HISTORY

Built more than a century ago, Masjid Jamek is one of the countrys oldest mosques. It was officiated by the-then Sultan of Selangor in 1909 two years after construction was completed and served as the

citys main mosque before Masjid Negara was built in 1965.

Located at the confluence of Klang River and Gombak River, the mosque stands on the citys first Malay burial ground. with a capacity of up to 3000 occupants, It was designed by Arthur Benison Hubback and

features Neo-Moorish architectural style reminiscent of colonial buildings in Northern India, distinguished by onion-shaped domes and spires, and horseshoe arches over decorated columns.

Not far from Masjid Jamek across the Gombak River is the equally-historical Sultan Abdul Samad Building, which was designed by the same architect and shares a similar style. An LRT station which connects to

other parts of the city sits right outside the mosque.

ARCHITECTURAL FEATURES

1. Moorish Minarets

There are two red and white striped minarets at the corner which are 26.8m (88ft) high

2. Moghul Influenced Domes

The prayer hall is surmounted by three domes

3. Semi-open Prayer Hall

The prayer hall opens out into a walled courtyard which is now covered

4. Prominent Main Structure

The central dome is 21m (70ft) high

5. Umbrella Shaped Cupolas

Cupolas and minarets that top the brick walls

SURROUNDING CONTEXTS

1. Bumiputra - Commerce Tower

2. Unitar

3. Convent Bukit Nenas

4. Dewan Bandaraya Kuala Lumpur

5. Bank Negara

6. Mahkamah Tinggi Kuala Lumpur

7. Masjid Jamek LRT Station

8. Olympia Tower

9. Maybank Tower

10. Sultan Abdul Samad Building

11. Dataran Merdeka

12. PDRM Bukit Aman HQ

13. Dayabumi Complex

14. Central Market

15. Ancasa Hotel

16. Pudu Sentral

USERS

ACCESSIBILITY

The figure illustrates types of user that used Jamek Mosque for daily usage. As we can see at the figure the

highest, 35%, user of Jamek Mosque is the shoppers who are rest at mosque for a moment before continue

shopping activity.

Besides that, office workers, travelers and hawkers have another 15% respectively. Some of the traveler utilize

the mosque as stopping point. Furthermore, the mosque also gave benefit to the hawkers and the office

workers to have a proper place to pray.

While, the remaining 20% of the users are students and urban residents and community with equal percentage.

FUNCTION AND ZONING

ISSUES AND SOLUTIONS

ISSUE

Limited space for jummah prayer

SOLUTION

Vertical extension of praying hall

instead of horizontal extension

due to the mosque is located at

the urban context.

ISSUE

Beggars

SOLUTION

Provide welfare

Provide work or capital to run any

business which can benefit

themselves and increase countrys

currency.

ISSUE

Illegal littering

SOLUTION

Provide proper and sufficient

dustbins

ISSUE

Homeless

SOLUTION

Provide welfare as well as basic

shelter

AL- RAJHI GRAND MOSQUE, RIYADH SAUDI ARABIA

INTRODUCTION

Al Rajhi Grand Mosque is one of the most famous and the biggest mosques in Saudi Arabia. It was opened on 12th of Syaaban 1425H. It has a special place in being one of the largest there. However it has

been selected as one of the landmarks in Saudi Arabia to all those who visit it. In addition to that, the mosque has a large overspill area that is used to connect the main entrance with the second entrance on

the highway side.

The mosque area is 13260 m and it can accommodate 18000 male and 2500 female. Besides that, it has dome with diameter of 28.8m, and two minarets with a height of 37m and 55m respectively. In addition,

there has water cooler at each of the columns inside the mosque and it used to be zamzam water.

FACILITIES

1. Library

It is enough for 100 readers. There are four departments inside the library which are Department of Electronic Services, Department of technical procedures, Department of Reference Services and Department

for gifting

2. Halls

For meetings and programmes and it is enough for 150 people also there is halls for special guests.

3. Schools for learning the Quran.

This school is totally focusing on the Quran and they target to have as many as Hafiz of the Quran every year. There are offices and rooms for students to study and have their memorization there.

4. School for learning the Sunnah.

This school is focusing on teaching the Sunnah of the prophet Muhammad PBUH and they have lots of special teachers for that.

5. Place to wash the deceased

It is enough to prepare 11 deceased body without mixing them at one room, so at same time they can prepare 11 body. Also they provide cars and all of the equipment that they need in that place.

6.Toilets and Ablution.

Each side of the masjid got one big space for the toilets.

7. Car parking

It is big enough to cover more than 1000 cars and also they r working to develop it some more.

8.Zakat collection

An office in the main entrance that is opened all days even during night to collect Zakat from people.

9.Bank ( ATM )

The only ATM machines at that area and it is a well done idea by having it there to ease the Muslims way.

10.Sadaqat collection.

Also opened all days and all poor can come there to collect some money and sadaqah.

11.Rooms for generating the money.

They also provide rooms at the back of the masjid to be used for programmes and activities that will be held at the masjid and the collection well go back to the masjid benefits.

12.Rooms for the guest.

These are special rooms for special people and scholars if they come to stay in Riyadh for few days rather than sending them away to a hotel or whatsoever. Also they have the basement for those who cant

speak arabic so during khutba they will have the chance to listen to the translation directly at the basement where else they can pray there13. Praying Hall

Basement for non-arab speakers

Perspective View of Al-Rajhi Mosque

Praying Hall

SYNTHESIS

1. Facilities

From all these facilities we could mention the Special Techniques in the most important among them:

- The separation of entrance for each male and female with toilets provided in each side for each gender.

- A praying hall at the basement where they translate the talks to non- arabic- speakers, also they provide the body language for the deaf people

- 50 rooms are provided for those who are willing to stay overnight (Itikaf) at the masjid where each room can fit two people and toilets are provided inside rooms.

- There is one entrance from each level for the car parking towards the masjid for a smooth connection in order to make it easy for people to reach faster.

2. Material used

The material used is meant to prevent the heat of the day and the noise since the masjid is located on the side of the highway, where one can choose the material that will work the same way. The drinking

water is found in each pillar inside the masjid where we can provide such a thing in our project.

3. A place for washing deceased

Washing deceased will be a good choice to have it in our design if the site was at different place but at the current location it is not wise to have it due to the traffic jam that will happen during praying on them.

4. ATM

Having a bank ATM machine is going to assist the people in having their money while they are rushing to work and passing from there, also it will be one of the reasons that people might think of passing from

our site.

MASJID INDIA

BUILDINGS BACKGROUND

Masjid India is known as the oldest mosque in Kuala Lumpur. It was built around 1863 and financed by Indian Muslim merchants and traders. It was renovated a few times to increase space and improve facilities

to accommodate increasing number of worshipers.

It was initially a small mosque and it was built with bricks and timber. The construction was financed by Indian Muslim merchants who lived and traded around Batu Road (now Jalan Tuanku Abdul Rahman).

There was no piped water facility in the Masjid. Many went to the nearby Klang River for ablution.

HISTORY

1. 1990

To accommodate the rising number of Indian Muslim and other worshippers, an extension was made to the Masjid in 1900.

2. 1939-1952

A wooden annexure was constructed in 1939. Another extension was constructed in 1952.

As the only Indian Muslim Mosque in the town centre, Masjid India had to accommodate Indian Muslims from outside of the town centre. Many of the users came for the Friday prayers. Further extension was

not possible due to space limitation.

3. 1962-1964

In 1962 a committee was formed to build a three storey mosque. The old building was pulled down in 1964. The foundation was laid on 11th September 1962 by His Highness, the Sultan of Selangor. On 29th

June 1964, the Sultan officially opened the new three storey mosque.

Located in the busy commercial centre of the city, the Masjid is used by various Muslim communities, including foreign tourists and businessmen. In the 90s the Masjid was again faced with the problem of

inadequate space and facilities.

4. 1999

In 1999 a massive renovation took place. A basement was constructed to provide more toilets and space for ablution. Additional space for prayers was added above the basement. Separate ablution space and

toilet facilities for women were also provided.

5. 2002

In 2002, the entire mosque building was given a face-lift by cladding polished granite slabs.

Renovation plans have been approved to upgrade the main prayer hall including the mihrab and the mimbar. Work is expected to begin in mid-2008.

More condominiums have been built within walking distance from the mosque. Both local and foreign tourism are also increasing. These have once again created the need for more space and facilities. Many

are performing the Friday congregational prayer in the street. There is no more space for further extension to Masjid India. One solution is to acquire adjacent buildings and make them part of the mosque

One of the recognizable view of Masjid India is its Minaret. It is a unique architectural feature of Islamic mosques which is commonly a tall spire with conical crown on top. The structure serves as visual focal

point and also used to call for a prayer.

ACCESSIBILITY

Basically masjid india located at the center of developed city where people excavate for money. Its

surrounded by developed buildings :-

1) Wisma Kosas

2) Flea market

3) Wet market & Bazaar

4) Medical education advisory sdn bhd

5) Putra lrt station (Masjid jamek)

Notable Landmarks:

o Menara OCBC

o Bazaar along Jalan Melayu

How to get there by LRT: Alight on Masjid Jamek Station. Just go to the right exit going to Jalan Melayu, this is the shortest way to Masjid India

USERS

Malay

Indian (Muslim)

Pakistan

Bangladesh

Indonesian

Shoppers

FUNCTIONS

1. A place for people to rest, especially shoppers

They usually rest at the entrance of the mosque, so its easier for the shoppers who passes by the mosque and have a rest there.

2. A place for praying

Mosque is fulled during solat jumaat

3. Focal for a variety of religious activities and also published and distributed pamphlets

On zakat, fasting and hajj for the benefit of muslim community

4. Free medical checkup every Sunday morning by private doctors (volunteers)

5. Fardhu Ayn classes every day

PLAN

ZONING

SYNTHESIS

1. Very limited spaces for praying area(Especially during solat jumaat)

Do a renovation for extra praying spaces or overspill area

2. There is no enough spaces for renovation due to located in developed area

Make a renovation vertically instead of horizontal

3. Users feel uneasy with the beggars asking for money

Improve the welfare service quality

CASE STUDY

THERMAL COMFORT

THE BROCK ENVIRONMENTAL CENTER:

BUILDING GREEN FOR CLEANER WATERS

INTRODUCTION

The Brock Environmental Center award is winning environmental education programs for being an international model for sustainable building as well as serve as the regional headquarters for the

Chesapeake Bay Foundation.

Joan and Macon Brock of Virginia Beach, who is generous provided a $3.6 million leadership gift toward this, $21 million project, center for the construction and this center is named The Brock

Environmental Center as an honor of them.

The Chesapeake Bay Foundations Brock Environmental Center is targeting LEED Platinum and Living Building Challenge certification for the cost that is donated by them. This will make it the most

environmentally sustainable building in Virginia. The center is located in Virginia Beach at Pleasure House Point on the Lynnhaven River. This 10,000-square foot environmental education facility will

focus on promoting preservation, sustainability, and education. Chesapeake Bay Foundation is raising $10 million for land acquisition and construction of the state-of-the-art Living Building; $5 million

for programs to improve water quality, including advocacy, environmental education, restoration, and outreach; and $5 million to endow the center and its programs.

FUNCTION

The center will provide:

A net zero impact on the surrounding environment

State-of-the-art energy and resource-saving features

An international model for green design and construction

Headquarters to the Chesapeake Bay Foundations award-winning outdoor environmental education programs in Hampton Roads, which provide engaging, hands-on environmental education

opportunities for thousands of teachers, students, citizens, and community leaders annually

Active demonstrations of important restoration projects

Office space for the Chesapeake Bay Foundation, Lynnhaven River NOW, and other local conservation groups

Meeting space for the community

With all aspects of the project meeting the strictest of environmental standards, the Chesapeake Bay Foundation believes the Brock Environmental Center will engage, inform, and inspire the Hampton

Roads Community to solve the Bays challenges in innovative, sustainable, and collaborative ways

3.1.2 INNOVATIVE INDUSTRIAL BUILDING FOR SATELLITE MANUFACTURING IN SAUDI ARABIA

INTRODUCTION

A contemporary production area is used essentially a space of life besides being a place of placing generation construction machines which a highly skilled workforce that uses these machines.

It is basically a space of a high- level creative work (digital machines of high technology) besides being a construction area in the strict sense. Hence, it has to be habitable especially under desert

conditions which is these conditions are naturally harsh towards human beings due to the extreme temperature alterations. This is why such a high technology structure must be safeguarded from

its harsh surrounding environment with the qualities of an "atrium-oasis" which is capable of providing comfort, filtered natural light, plantations and water elements.

It is a space that typologically refers to the structure of a residence with an enclosed yard, which is a classic, archetypical typology we encounter at the meditarrenean and Arabic civilizations.

The proposal tries to handle the main industrial volume, in a clear way, by integrating or eliminating it inside the surrounding sandy environment. Then, selected and intense parts of the whole are

brought out and over the ground, with an exaggeration in shape and height. As a result, they obtain use values - shelter, shades- or symbolism and indication values - administration building,

entrances, final product exit.

The ultimate goal is to give a sculptural quality, compatible with the site's character, to a purely "utilitarian" building-machine. This gesture restores a balance between the technology futurism and

the humane side of daily life. Lastly, on a purely "communicative" level, it enhances the positive surprise of the visitor, as he/she comes from outside- a silent, external space integrated in the natural

environment- to a technologically sophisticated interior, with a symbolic and actual axis or center, the fertile image and reality of an oasis.

The final look of the building must convey the most sophisticated construction technology through the use of cnc technology as well as contemporary synthetic materials, state-of-the art products of

science and research.

The study is about an installation that is developed in an area of 130.000 sq.m.

CONTENT

1. Assumptions

a. An environment that encourages inspiration and creativity

Inventive people are inspired by the sanctity and splendor of nature, the conversation between the past, the present and the future of human civilization. Inspiration and creativity is maximized in a

high quality work environment that ensures positivity, comfort and well-being, where patrimony and state of the art technology are merged. This merging is accomplished with contemporary

translation of traditional cooling techniques of the Near East and oases-patios, as archetypes, that contribute to the positive energy of the industrial space.

b. Functional zones of the facility

This factory is a modern post-industrial production unit. The plant consists of three basic closed types of spaces which are a conventional production area, a transition area, a special production area

(strictly controlled air of scalable purity, test areas, final assembly and integration, packing and delivery ) and a central administration area (management , research and development , reception and

communication).

c. Necessary air conditions and bioclimatic approach

The needs for high standards of air-conditioning and bioclimatic factors are vital in an external environment with temperatures ranging from 8 to 47 degrees Celsius. CAD-CAM procedures of high

accuracy at all stages must be applied and the overall design must ensure minimum functional cost in critical and intensive air-conditioning conditions, in compliance with the L.E.E.D. certification

system.

The intermediation of the atria in the overall functional structure comes to fulfil this approach which is completed with the use of shades and elements of water, which take advantage of the wind

directions during the critically hot periods of the year.

d. Size of the proposed industrial facility

International practice and experience from similar facilities illustrate a size ranging from 10000 to 100000 sq.m. of closed production areas and it depends on the size of the satellites to be produced.

The proposed facility consists of 25000 sq.m of closed and 26000 sq.m of semi-open spaces. The exact decision of its size requires a more detailed report of the facility's needs.

e. Proposed location on site

The site is a few kilometers outside the city center of Riyadh, on an almost flat tableland of 1000 acres. In this area there are already some facilities of relevance, which are placed on an absolute axis

of North-South.

The criteria used for placing the building onto the site, are the optimal utilization of climatic conditions in the area with soft N, NW and NE winds, the maximum flatness of the site-a factor which

favors scalability - and the minimum annoyance of existing buildings and uses.

2. Preliminary study

a. Functional structure of the facility

The individual functions are established in the building with the conscious choice of sovereign compositional elements: a central North-South axis and a secondary East-West axis, which is the

axis of the building's potential scalability. These two axes form a cross, where all functions of the building, the stop and the circulation areas revolve around them, with the rational intermediation

of the atria this entire layout increases the status, the stability and rationality of the whole composition. It is the main rule that constitutes it and allows the subsequent integration of morphological

exceptions/deviations, which further enhance, rather than disturb, the equilibrium of the whole.

b. The shell typology

The shell typology of the complex follows certain rules that distinguish but at the same time unite the several parts that constitute it. The conventional production area houses the conventional

production process with an archetypical form, a "cave" which is like structure that becomes one with the natural landscape of the sand.

The environmental test areas, the clean rooms and the assembly accommodate the perfectly technologically sophisticated and state of the art production process , with a form borrowed from the

mature industrial period , from that which was back then, about 100 years ago, the latest technology, from that which was the first great enterprise of man to explore the sky .Namely, the image of

a Zepellin fuselage. With this partial image of a Zepelin fuselage, covered with titanium foils- a typical space material - we express today's human ambition, trying maybe to imply its limits , its splendor

and at the same time, its corruptibility.

The north-south axis, the link (the backbone) of the building is signaled by the flow of a "ribbon" that unfolds, housing the major circulations.

The office building has a distinct character, with the heliport on the roof signaling the "head" of the whole enterprise, the transparent glass outer casing of the offices which is the coexistence of two

curved shapes , an ellipse and a circle (inner atrium) with a golden ratio relationship in their development , four enormous horizontal shaders which protrude at least ten meters, protecting the glass

casing from the sun, and the trollis of the shaders ,that have received a shrub planting. The need for technological and environmental efficiency are embedded in the counterpoint of the roughness

of the technological construction that converses with the natural elements.

3. Building structure

Prefabricated composite construction

The building structure is composed by prefabricated elements. The ground and structure interaction entails a geotechnical study that will provide correct data for the structural design and project

budget optimization. High strength structural steel S355JR is considered to be the appropriate material for the environment use. For flooring areas the composite solution will be applied, which

requires steel deck and high strength concrete C 30/37.Spaceframes are considered appropriate for column-free areas and cellular beams for E&M installations. The B.I.M. application for advanced

and accurate fabrication allows for all prefabricated elements to be transported by containers from any available fabrication plant and to be easily installed on site.

4. E&M

The electric and mechanical installations such as plumbing installations, fire protection systems, cranes, heating ,ventilating & air conditioning HVAC Systems and electrical systems on the site must

be in conformance with local and international standards and regulations of "clean spaces" requirements and the manufacturing procedure. The design must be easy to construct, economical and

adaptable and the structures must be common for all system networks

5. Bioclimatic design

The application of bioclimatic technology reassures the appropriate audio-visual thermal behaviour of the building, while minimizing the energy consumption for heating and cooling by 70%.This is

achieved by placing shades for the glass building, e-low windows , natural ventilation, plantation, geothermal power system through air and water, solar panels, water cascades and an appropriate

choice of materials.

6. Construction methods and materials

The materials and construction methods have different qualities. It depends on the nature of each space. The roofs for the conventional industrial spaces are made of aluminium

matchboard suspended ceiling in white colour, with vinyl topping for the high purity spaces, and drywall constructions with integrated conceiled lighting for the office spaces.

The internal partitions for the conventional industrial spaces are made of prefabricated aluminium partitions with double soundproofing glazing or soundproofing vinyl panels with certified

partitions depending on the purity grades for the high purity spaces in thickness depending on the particular requirements of each space as well as with soundproofing glazing with internal BLINDS

and drywall partitions for the office spaces.

The floors for the conventional industrial spaces are made of special resin self- levelling flooring and with wooden pre polish flooring for the office spaces. The outer casing was treated differently in

order to attain the desirable insulation and thermal conditions and provide bioclimatic qualities. While, the external roofs for the conventional industrial spaces have three layers that consist of

especially prefabricated sand plates (final external layer), prefabricated soundproofing aluminium panels and lastly, air vacuum .The roofs at the high purity spaces are made from a layer of

titanium or titanium zinc sheet coating (external layer), a layer of prefabricated soundproofing aluminium panels and air vacuum. At the office zone, the building is topped with a green roof.

The handling of the outer shell is completed with the outer casing which is made from prefabricated soundproofing aluminium panels at the industrial spaces and aluminium curtain walls with

double e-low glazing and integrated remote controlled blinds at the patios and office areas.

7. 3D Models

Conventional production area- raw material entrance.

Test bay area-clean rooms- final assembly- product exit.

Aerial view

Entrance for employees

Northeastern general view.

Northeastern view of the office building.

Southern view of the office building.

Visitors' and office building entrance

Visitors floor and heliport View of the atrium from the visitors

entrance

8. General plans

Level-3 70, entrances, handling, auxiliary spaces, parking lot, geothermal installations. Level 0, 00 production areas, research and development area.

This preliminary study was assigned to us in October 2011. It was delivered by the end of November 2011 in Dubai.

The study was designed by the following groups:

Architectural design : Andreas Kyranis architects

SYNTHESIS

LIGHT PIPES/LIGHT CHANNEL

INTRODUCTION

Light pipes or Light tube are physically structured used for transporting or distributing natural or artificial light for the purpose of illumination. In their application to day lighting, they are also often called

tubular day lighting devices, sun pipes, sun scopes, or daylight pipes. In other words, light tube or light pipes refer to a tube or pipe to channels daylight into areas normally lacking of natural light.

The light pipes may be divided into two types which are the flexible and rigid systems.

COMPONENT

1. Light pipes

It is more effective if the clear plastic domes are installed on a south facing roof to gain the maximum amount of daylight. Light pipes are highly effective at delivering light into internal and badly lit spaces

making it particularly useful for bathrooms, stairs, corridors and any dark areas.

2. Clear roof domes

Clear domes are available in unbreakable polycarbonate or impact resistant modified acrylic. They are available in several different sizes depending on the amount of light required and can be located on flat

or pitched roofs.

3. Insulating light pipe

The outside of the light pipe must be insulated to prevent condensation occurring where it passes through an unheated space, like a loft. It is important that the light pipe's joints and offset bends are also

insulated.

4. Diffusers for lights tube

The light pipe system uses a mirrored tube that reflects natural daylight transferring it to a room or dark area inside. When the light reaches the end of the tube, it can be evenly diffused by a translucent ceiling

fixture and light the room.

5. Light pipe - horizontal applications

Although mainly used in roof applications, clear plastic dome lights can be used for horizontal applications and fixed to an external wall. This configuration is particularly useful for providing daylight into

basements. The light can be transferred horizontally at the top of an external wall of a basement. Alternatively, a 90 degree offset can be used to discharge the light through the basement ceiling.

6. Maintenance of light pipe

Because of its shape, the clear plastic dome is self-cleaning and it eliminates damaging condensation. The sun tube assembly is sealed and therefore requires no maintenance. Light pipe generally has a life

expectancy of 35 years.

THE PROCESS

The light pipe conveys the daylight which gets into the light pipes through the clear dome mounted onto the roof. Afterward, the suns rays

reflected from the walls of the flexible, reflective pipes are directed downwards onto the light diffuser. The diffuser fitted into the ceiling

spreads the light, evenly illuminating the whole interior.

INSTALLATION

Step 3 Step 4

Step 5 Step 6 Step 7 Step 8

Step 1 Step 2

Step 9 Step 10 Step 11 Step 12

Step 13 Step 14

LONDON 2012 HANDBALL ARENAS COPPER- THE COPPER BOX

BUILDINGS PROFILE

It is named The Copper Box as suitable as the function of this building which is sports arena building and located at City, London, United Kingdom. This building covers the area of 15,500m/170,000ft and

also completed in March 2011. Make Architects and ARUP, consulting engineer, put efforts into this building for their client which is Olympic Delivery Authority/London Legacy Development Corporation for

the purpose of leisure market sector.

LIGHT PIPES FOR DAYLIGHTING

Arup Lighting has ensured that no artificial lighting will be needed for 60 per cent of the year. The plan was to use light pipes, so daylight analyses were carried out to check that they could deliver the 200-lux

minimum requirement for playing community and school sport in the arena.

Calculations predicted that 88 large light pipes would provide enough daylight for nearly two-thirds of the year. For darker days, the light pipes are backed up by artificial lighting.

The lighting team worked with manufacturers to develop the larger modified pipes they needed 1.5m across, instead of the standard 600mm diameter which were low glare but retained the architects

desire to conceal the lightweight structure of the steelwork supporting the roof.

The solution required close co-ordination between the lighting team, the architect and the structural engineer. The pipes provide a notional ceiling at 14m above the field of play.

Lighting pipes on the roof can decrease electricity costs by 40 percent.

Backup electric lights will only switch on temporarily when photo-sensors in the roof detect a sudden loss of sunlight during the day, such as when a dark cloud passes over.

SYNTHESIS

SOUND BARRIER

PAVILLION 21 MINI OPERA SPACE

BUILDINGS PROFILE

Pavillion 21 Mini Opera Space is completed within three years which is from 2008 to 2010. It is located at Munich, Germany. The architect in charged for this project is Coop Himmelb (L) AU Wolf D. Prix

& Partner and built for The Free State of Bavaria represented by The Bavarian State Opera Munich, Germany.

SOUNDSCAPING

The first thing that has to be taken into account is the thing that is fixed in drawings which show the basic concept of the Pavilion to introduce elements which are on the one hand the spatial

transformation of sound sequences, and which on the other hand develop sound reflecting and absorbing properties through their pyramid-like shape: Soundscaping.

The strategy to achieve soundscaping comprises three steps: Firstly, to realize the shielding effect between square and street, secondly, to shape the geometry of the Pavilion in such a way that the

surface deflects noise, and thirdly, to design the surface of the Pavilion in such a way that it reflects and absorbs sound.

In order to implement the objectives of the interior spatial acoustics, the interior wall and ceiling surfaces were integrated with a combination of perforated absorbing and smooth reflecting sandwich

panels. The flooring of the Pavilion is carried out as a reflecting even stage floor. Sound reflecting, parallel wall and ceiling surfaces are avoided and are therefore tilted or skewed.

BB CENTER E

BUILDINGS BACKGROUND

Seven-storey administrative E building is one of objects of so called BB Center and encloses a planned protection shield against negative effects of transport for residential buildings that are planned.

Position of the building in the immediate vicinity of a large scale thoroughfare also requires a solution enabling to eliminate traffic noise reflection from its envelope to the houses on the opposite side

of the road.

THE BROKEN FACADE

A broken faade is designed facing the source of noise. Its moulding was defined by the specific highway curve and the ramp from Vyskocilova (street) in order to prevent reverberation of noise

generated by cars passing by towards the above-mentioned houses on the opposite side of the highway.

Project specifics lay in the solution of noise reflection that became its principal architectonic motive, reacting to physical principles of noise reflection. The designed geometry allows areas of this special

envelope to bounce noise away either to the grassed slope between the highway and the ramp naturally absorbing it, or diverting it at a large angle upwards and diffusing it in the open space high

above.

So the facade system treats mainly those parts of the envelope that cannot be attenuated glazed ribbons of windows and the rest of full areas that are not able to absorb noise. The prevailing main

full area of the facade is designed with perforation as sound absorbing.

The Broken Faade Facing the Source of Noise

Sound-absorbing perforated steel plates soundscaping

Solid faade sections are designed as thermally insulated with perforated sheet panels finished by metallic coloured powder coat set in front. Perforation (diameters and cc distances of holes)

A system of fixing eyes for anchorage of the faade cleaning and maintenance staff is designed within the faade system. The acoustic facade forms a hypotenuse of a triangular concept of the building;

the remaining two side facing inwards to the area are designed as fully glazed with irregular horizontal articulation. The envelope is designed using a system modular faade; the additional areas on the

ground floor and faade of the bay above the entrance are standard framing with additional cladding of solid areas by aluminium coated sheet and Larson composite panels.

Full parts of the envelope are designed as warmed-up facade with a set-off cladding made of perforated sheet boards, metallic powder coated. Sheet perforations were again chosen in cooperation with

an acoustic professional. The sheets are anchored to the bearing grid with bolts. The grid also drains water off the envelope area. With respect to the perforation the mineral acoustic and thermal

insulation are protected with waterproofing foil on the whole area. Jambs with window spandrels and niches for exterior louvers are made with exact surrounds made of Larson composite aluminium

panels. Parapets are made in similar way and faces of the set-off wall on both ends of the building. To clean and maintain the facade there is a system of eyes on the cladding to anchor service staff.

Acoustic facade forms a hypotenuse of the building triangular concept; two remaining facades facing inwards the area are designed as all-glazed envelopes with irregular horizontal rasterization. The

envelope is made in the element facade system additional; areas in the parterre and oriel facade above the entrance are made as a standard stick system facade where full areas are clad with varnished

aluminium sheet and Larson composite panels.

ARMADILLO HOUSE/ FORMWERKZ ARCHITECTS

BUILDINGS PROFILE

The architects in charged for this building is Formwerkz Architechs and it is located at Singapore. Alan Tay and Whei Huong as the design team start this project area of 380 sqm in 2012. The photographs

is taken by Jeremy San.

BUILDINGS BACKGROUND

The 2-1/2 storey corner terrace house in Singapore, is flanked on its long western face by a Category 3 road with a traffic crossing and a highway viaduct. The site is polluted with noise arising out of the

on-coming traffic at 2 different speeds and its accompanying privacy issues due to its close proximity to the main thoroughfares. The site tapers from the front to the back, with its longest face exposed

to the heat of the western sun and the front facing a road intersection. The client wanted a house that can adapt to the expanding needs of a multi-generation family and called for a sustainable design

that can mediate the extremely unfavorable site condition while minimizing its energy demand from air-conditioning.

The overarching, environmental need to combat the traffic noise and western sun without resorting to a fully air-conditioned and walled-in design became the driving

force of the concept. A key strategy was to create a huge basement to locate the main living space, the master en-suite and part of the garden below grade. The

basement is a natural shadow zone in relation to the sound path of the adjacent traffic. It is possible to open to the environment with the most minimum noise impact.

Shielded from the western sun, it is also the most shaded and coolest part of the house.

Perspective View of Armadillo House

Above ground, we envisioned the house to be an armadillo where the skin of the building along the western face is designed to be impervious to the harsh environment. The use of glazing along this

face is limited to a narrow horizontal band, a meter above grade, sufficiently shaded by the garden and boundary walls.

On the upper floors, indirect daylight penetrates the interior space through the full height glazing on the southern face of the segmented volumes. Mechanical Fans are installed on the rooftop to induce

a stack effect, drawing air from the basement to the upper floors via the double volume in the basement and the open raiser stairs that connects the upper floor.

SYNTHESIS

Das könnte Ihnen auch gefallen

- Case Study of MosquesDokument18 SeitenCase Study of MosquesAWahyoon-i TheeyassNoch keine Bewertungen

- Masjid Wilayah ArticalDokument24 SeitenMasjid Wilayah ArticalAaYoyo100% (1)

- Local Mosque Design Standards and Case StudiesDokument29 SeitenLocal Mosque Design Standards and Case StudiesRawan Alsamairi100% (1)

- Archisc Masjid (SR)Dokument12 SeitenArchisc Masjid (SR)Hafizi KamilNoch keine Bewertungen

- Slide 10 - Malay MosqueDokument52 SeitenSlide 10 - Malay MosqueMuhammad Suhaimi100% (1)

- Cyberjaya MosqueDokument86 SeitenCyberjaya Mosquemohammed abbas100% (1)

- Question 1: What Do You Think About The People Stated AboveDokument6 SeitenQuestion 1: What Do You Think About The People Stated Abovesharusli100% (1)

- The Industrialised Building System IBSDokument12 SeitenThe Industrialised Building System IBSMuhammad Asyari Mohammad Shah100% (2)

- Mosque StandartDokument20 SeitenMosque StandartHarimurti WijNoch keine Bewertungen

- Rubber Research Institute of MalaysiaDokument41 SeitenRubber Research Institute of MalaysiaTommy TanNoch keine Bewertungen

- Assignment Panggung BDokument17 SeitenAssignment Panggung BAina AnuarNoch keine Bewertungen

- Case Study StaircaseDokument19 SeitenCase Study StaircaseBishop Yen0% (3)

- HISTORY II (Mag)Dokument40 SeitenHISTORY II (Mag)Abdi Mohamed Abdi MireNoch keine Bewertungen

- Project 2 Site AnalysisDokument77 SeitenProject 2 Site AnalysisAmirul Hakim SabriNoch keine Bewertungen

- Hisham Al BakriDokument21 SeitenHisham Al BakriRamsrajNoch keine Bewertungen

- Faculty of Architecture, Planning and Surveying Bachelor in Building Surveying (Ap229)Dokument17 SeitenFaculty of Architecture, Planning and Surveying Bachelor in Building Surveying (Ap229)Eja Alif100% (2)

- Pam Buidling Integration and Performance 1 PDFDokument11 SeitenPam Buidling Integration and Performance 1 PDFKei Wern Chan0% (1)

- Modular Coordination IbsDokument5 SeitenModular Coordination IbsCik Mia100% (1)

- The Adoption of Industrialised Building System IBS Construction in Malaysia The History Policies Experiences and Lesson LearnedDokument8 SeitenThe Adoption of Industrialised Building System IBS Construction in Malaysia The History Policies Experiences and Lesson LearnediwereNoch keine Bewertungen

- Kampung Admiralty - A Mix of Public Facilities - UrbanNextDokument7 SeitenKampung Admiralty - A Mix of Public Facilities - UrbanNextkohvictorNoch keine Bewertungen

- Provision of By-Laws 34A of The Uniform Building Bylaws (UBBL)Dokument1 SeiteProvision of By-Laws 34A of The Uniform Building Bylaws (UBBL)Safwan Salleh100% (1)

- Taipei 101: Building Case StudyDokument19 SeitenTaipei 101: Building Case StudyTanuj BhardwajNoch keine Bewertungen

- Building ServicesDokument31 SeitenBuilding ServicesFarHany ZaInyNoch keine Bewertungen

- TM Tower HistoryDokument34 SeitenTM Tower HistoryJustin Pau50% (2)

- CASE STUDY Green BuildingDokument17 SeitenCASE STUDY Green BuildingSathis WaranNoch keine Bewertungen

- Report Praktikal 2020Dokument30 SeitenReport Praktikal 2020Zul HafrizNoch keine Bewertungen

- Case Study MosqueDokument12 SeitenCase Study Mosquelal Muhammad Junejo0% (1)

- Petronas Twin Towers: High Rise Building-I Submitted To: Submitted By: Ar. ShikhaDokument16 SeitenPetronas Twin Towers: High Rise Building-I Submitted To: Submitted By: Ar. Shikhaaanchal jainNoch keine Bewertungen

- Green Building PBLDokument11 SeitenGreen Building PBLsofea1121Noch keine Bewertungen

- Building Services Jaya MallDokument163 SeitenBuilding Services Jaya MallJulie Tan100% (3)

- Mokuzai Kaikan NIKKEN SEKKEI LTD OfficeDokument2 SeitenMokuzai Kaikan NIKKEN SEKKEI LTD OfficeWika NurikaNoch keine Bewertungen

- Case StudyDokument23 SeitenCase StudyMUHAMMAD NURNAJMINoch keine Bewertungen

- DeconstructivismDokument5 SeitenDeconstructivismnithyaebNoch keine Bewertungen

- Rumah LimasDokument8 SeitenRumah Limassyaqirah_topNoch keine Bewertungen

- Full Report Final CENTRAL MARKET CONSERVATION STUDYDokument34 SeitenFull Report Final CENTRAL MARKET CONSERVATION STUDYmohd qisti94% (16)

- Assignment IBSDokument13 SeitenAssignment IBSEsya Iman0% (1)

- OKU-Malaysian Standard NewDokument9 SeitenOKU-Malaysian Standard NewRafi' RamliNoch keine Bewertungen

- Structure Design EsaimenDokument14 SeitenStructure Design EsaimensyahidatulNoch keine Bewertungen

- Interior Design Studio (Zarin Tasnia, Id - 1601111600233)Dokument19 SeitenInterior Design Studio (Zarin Tasnia, Id - 1601111600233)zarin tasniaNoch keine Bewertungen

- CT Assignment TAIPEI 101Dokument12 SeitenCT Assignment TAIPEI 101Samantha Lim Ai PeiNoch keine Bewertungen

- Penang10 - Khoo KongsiDokument6 SeitenPenang10 - Khoo Kongsimohd qistiNoch keine Bewertungen

- Energy EfficientDokument89 SeitenEnergy EfficientHIMA MiniNoch keine Bewertungen

- Glasgow's Riverside Museum of Transport and TravelDokument20 SeitenGlasgow's Riverside Museum of Transport and TravelAlvera SerapainNoch keine Bewertungen

- MPCC Case StudyDokument47 SeitenMPCC Case StudyAbhinav SrivastavaNoch keine Bewertungen

- Setia City Convention Center LatestDokument23 SeitenSetia City Convention Center LatestFadila Abdul Hak100% (1)

- 15 Chapter 5Dokument21 Seiten15 Chapter 5Nurul Husna Mohd KamilNoch keine Bewertungen

- Front Page PDFDokument1 SeiteFront Page PDFDaniel FaizNoch keine Bewertungen

- Cost Implication On Design and Method of Building ElementsDokument4 SeitenCost Implication On Design and Method of Building ElementsAzmirul HanifNoch keine Bewertungen

- Ooi Poh EanDokument22 SeitenOoi Poh EanAnita VkNoch keine Bewertungen

- Kohinoor SquareDokument5 SeitenKohinoor SquareAmar NeethiNoch keine Bewertungen

- Isp565: Data Mining Assingment 2: NO. Name Matric NoDokument21 SeitenIsp565: Data Mining Assingment 2: NO. Name Matric NoYana AliNoch keine Bewertungen

- Bahrain World Trade CenterDokument3 SeitenBahrain World Trade CenterIrfie SantosoNoch keine Bewertungen

- RES614 Part A and Part B CFAP225 5B Group 1Dokument110 SeitenRES614 Part A and Part B CFAP225 5B Group 1umairhakim30100% (1)

- Traditional Mosque in MalaysiaDokument37 SeitenTraditional Mosque in MalaysiaMohd Hafiefi Md RezalNoch keine Bewertungen

- About Jaekel House, LagosDokument2 SeitenAbout Jaekel House, LagosTope Adeniyi100% (1)

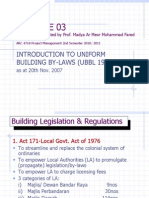

- Introduction To Uniform Building By-Laws (Ubbl 1984) : As at 20th Nov. 2007Dokument19 SeitenIntroduction To Uniform Building By-Laws (Ubbl 1984) : As at 20th Nov. 2007wfng770% (1)

- Masjid Lendu Vcs 128Dokument9 SeitenMasjid Lendu Vcs 128Nur NinaNoch keine Bewertungen

- SUMMER 2019-20: Art & Architecture 4Dokument5 SeitenSUMMER 2019-20: Art & Architecture 4Jubayet BariNoch keine Bewertungen

- Architecture Culture & History 2 (Arc 60203)Dokument64 SeitenArchitecture Culture & History 2 (Arc 60203)Tan Wing HoeNoch keine Bewertungen

- Teks InggrisDokument2 SeitenTeks InggrisGyan RakhmandaNoch keine Bewertungen

- Adh Dialectical JournalDokument4 SeitenAdh Dialectical Journalapi-521174998Noch keine Bewertungen

- Demonstration MethodDokument16 SeitenDemonstration Methodfrankie aguirreNoch keine Bewertungen

- TTG Basic Rules EngDokument1 SeiteTTG Basic Rules Engdewagoc871Noch keine Bewertungen

- Class Program 2019 2020Dokument2 SeitenClass Program 2019 2020Cristy Gongon100% (5)

- (Essential Histories) Waldemar Heckel - The Wars of Alexander The Great-Osprey PDFDokument97 Seiten(Essential Histories) Waldemar Heckel - The Wars of Alexander The Great-Osprey PDFJorel Fex100% (3)

- Sanskrit LessonsDokument195 SeitenSanskrit LessonsSuganya100% (1)

- SF3300Dokument2 SeitenSF3300benoitNoch keine Bewertungen

- Monkey Shine - ScriptDokument4 SeitenMonkey Shine - Scriptapi-583045984Noch keine Bewertungen

- 2007 - Q1 NewsletterDokument20 Seiten2007 - Q1 NewsletterKisara YatiyawelaNoch keine Bewertungen

- LAAG4 Elementary Row Operations-3Dokument14 SeitenLAAG4 Elementary Row Operations-3Kamran AliNoch keine Bewertungen

- Early China 2aDokument4 SeitenEarly China 2aapi-205540374Noch keine Bewertungen

- Contoh Soal TOEFL PBTDokument3 SeitenContoh Soal TOEFL PBTiwanNoch keine Bewertungen

- Comparative Analysis of Severe Pediatric and Adult Leptospirosis in Sa o Paulo, BrazilDokument3 SeitenComparative Analysis of Severe Pediatric and Adult Leptospirosis in Sa o Paulo, BrazilShofura AzizahNoch keine Bewertungen

- Technology in EducationDokument3 SeitenTechnology in EducationDinesh MadhavanNoch keine Bewertungen

- WWW Foboko Com Sentence Dictionary English UnderstandDokument12 SeitenWWW Foboko Com Sentence Dictionary English UnderstandEnkhee WefweeNoch keine Bewertungen

- The Scopes TrialDokument10 SeitenThe Scopes Trialapi-607238202Noch keine Bewertungen

- Vocabulary ListDokument2 SeitenVocabulary List謝明浩Noch keine Bewertungen

- Chapter02 AnglesDokument40 SeitenChapter02 Angleslen16328100% (1)

- Who Should Take Cholesterol-Lowering StatinsDokument6 SeitenWho Should Take Cholesterol-Lowering StatinsStill RageNoch keine Bewertungen

- Cinderella: From The Blue Fairy Book of Andrew LangDokument7 SeitenCinderella: From The Blue Fairy Book of Andrew LangnizamianNoch keine Bewertungen

- Final Exam1-Afternoon SessionDokument40 SeitenFinal Exam1-Afternoon SessionJoshua Wright0% (1)

- How To Write A ThesisDokument14 SeitenHow To Write A ThesisPiyushNoch keine Bewertungen

- Icivics MontesquieuDokument3 SeitenIcivics Montesquieuapi-32806152578% (9)

- MAT 120 NSU SyllabusDokument5 SeitenMAT 120 NSU SyllabusChowdhury_Irad_2937100% (1)

- Gein, EdDokument10 SeitenGein, Edpetru_k1Noch keine Bewertungen

- Jurnal Q1 PDFDokument29 SeitenJurnal Q1 PDFSepti DamayantiNoch keine Bewertungen

- Constitutional Law Sem 5Dokument5 SeitenConstitutional Law Sem 5Ichchhit SrivastavaNoch keine Bewertungen

- Figures of Speech StylisticsDokument11 SeitenFigures of Speech StylisticsCarmie Lactaotao DasallaNoch keine Bewertungen

- Elitmus PapersDokument21 SeitenElitmus Papersanon_879320987Noch keine Bewertungen

- Reading Activity - A Lost DogDokument3 SeitenReading Activity - A Lost DogGigsFloripaNoch keine Bewertungen