Beruflich Dokumente

Kultur Dokumente

Aplicatii Cu Polimer Compozite La Masa Mas PDF

Hochgeladen von

CorinaBaitoiuOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aplicatii Cu Polimer Compozite La Masa Mas PDF

Hochgeladen von

CorinaBaitoiuCopyright:

Verfügbare Formate

The application of polymer composites to the table-top machine tool

components for higher stiffness and reduced weight

Sung-Kyum Cho, Hyun-Jun Kim, Seung-Hwan Chang

School of Mechanical Engineering, Chung-Ang University 221, Huksuk-Dong, Dongjak-Gu, Seoul 156-756, Republic of Korea

a r t i c l e i n f o

Article history:

Available online 31 August 2010

Keywords:

Machine tools

Compositemetal hybrid structures

Damping capacity

Structural stiffness

a b s t r a c t

Small machine tools have the inevitable drawback of low structural stiffness caused by a low load-carry-

ing capacity of bearing components. Therefore, mass reduction of the components is advantageous to

ensure high performance of the machine tools. In this study, a small table-top machine tool structure

was designed and fabricated by using carbon/epoxy composites and resin concrete to reduce the weight

of the structure, and enhance the structural stiffness and damping capacity. To determine the specica-

tions of the composite materials nite element analyses and vibration tests were carried out. Several

machine tool components were fabricated and assembled using mechanical joining and adhesive bond-

ing. Our results showed that the re-designed structure was 36.8% lighter, and the structural stiffness was

increased by 16% with higher loss factors (2.823.64%).

2010 Elsevier Ltd. All rights reserved.

1. Introduction

The demand for miniaturized machine tools is growing relative

to conventional machine tools because of the need to save space,

and because of the need for low energy consumption when the

overall size of a manufacturing components are a few millimeters

with micro-scale machining precision, such as a camera lens for

mobile phones. Miniaturized machines have other advantages as

well: rapid and precise motion controls are possible due to low

structural inertia, and they produce low levels of vibration and

heat during machining [13]. One of the weak points of miniatur-

ized machines is their low structural stiffness caused by low bear-

ing capacity and their inadequate structural robustness, which

affects machining precision in products. Many efforts have been

made to address these limitations such as raising the spindle speed

with a low level of runout (below 0.1 lm) [4]. Improvements in

microfactory structural damping and stiffness using new materials

have also been tried. Kim et al. [5] designed and fabricated a light-

weight XY stage for a micro-EDM machine system with brous

composites and PVC foam to increase structural stiffness and

damping capacity, thereby improving the load-carrying capacity

of a stage driven by air bearings. Kim et al. [6] tried to replace a

microfactory machine tool column made of steel with a foam-com-

posite sandwich structure by controlling the stacking angle and

composite thickness. They achieved an increase in stiffness of more

than 50% with a 62% weight reduction. Kim and Chang [7] devel-

oped a friction layer using dry fabrics to increase the damping

capacity and structural stiffness of an aluminumcomposite hybrid

structure that had a 530% damping increment, and applied this to

the spindle holder of a micro-milling machine. To enhance struc-

tural robustness, ber-reinforced composites and resin concrete

have been used in conventional machine structures to improve

damping capacity. Lee et al. [8] and Chang et al. [9] applied

glass/epoxy composite plates to a machine column and a head-

stock to improve structural damping by surface damping treat-

ment. Haranath et al. [10] applied viscoelastic damping layers to

various machine tool structures, such as milling machines, for

damping enhancement. Rahman et al. [11] used resin concretes

to design a linear guide system with high damping, and Kim et

al. [12] studied the mechanical properties of resin concrete accord-

ing to aggregate content with applications to a machine bed. As a

part of enhancing damping characteristics of machine tool struc-

tures a new type of composite material was also investigated using

polymeric mortars with various recycled llers [13].

In this study, a table-top machining center made of stainless

steel and aluminum was re-designed by using polymer-based

ber-reinforced composites and resin concrete to improve struc-

tural stiffness and damping capacity with low structural mass.

The static deection and natural frequencies of the existing metal

system were investigated using nite element analysis. The results

were used as the design basis for the new structure. Two types of

carbon/epoxy composites were used, and the appropriate stacking

angles and thicknesses of the composites were determined by

parametric study and nite element analysis. The damping

capacity of compositeresin concrete hybrid specimens according

0263-8223/$ - see front matter 2010 Elsevier Ltd. All rights reserved.

doi:10.1016/j.compstruct.2010.08.030

Corresponding author. Tel.: +82 2 820 5354; fax: +82 2 814 9476.

E-mail address: phigs4@cau.ac.kr (S.-H. Chang).

Composite Structures 93 (2011) 492501

Contents lists available at ScienceDirect

Composite Structures

j our nal homepage: www. el sevi er . com/ l ocat e/ compst r uct

to the thickness ratio was measured by vibration testing. The com-

positemetal hybrid structures were fabricated and assembled by

adhesive bonding and bolting. A vibration test was carried out to

determine the systems performance, and the results were com-

pared to the existing metal structure.

2. Conguration and materials of the table-top machine

structure

2.1. Components of the existing structure

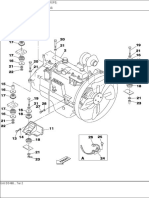

The table-top machining center considered in this study was

composed of a machine base, a machine back plate, a Z stage,

and an XY stage as shown in Fig. 1a. For high structural stiffness,

the machine base and the back plate were made of stainless steel.

The moving parts, such as the XY and Z stages, were made of alu-

minum. A rotary table for the work-piece was installed in the XY

stage, and another rotary table for the spindle system was installed

in the Z stage. The shape and overall dimensions of the original me-

tal structure are shown in Fig. 1a.

2.2. Composite materials used for re-design of the machine structures

To enhance the structural stiffness and damping capacity of the

existing machining center, ber-reinforced composites and resin

concrete were applied to the original metal components. The de-

tails of design modication are summarized in Fig. 1b. Two differ-

ent types of unidirectional carbon/epoxy prepregs (USN125 and

UPN139, SK Chemical, Korea) were used to re-design the machine

back plate and the XY base of the machining center. High modulus

carbon/epoxy prepreg (UPN139), whose maximum modulus is

250 GPa along the ber direction, was applied to the back plate.

The other prepreg (USN125) was applied to the XY base and the

Z-base, replacing an aluminum structure. This increased the stiff-

ness and decreased the weight of the structures. The modulus vari-

ations of the carbon/epoxy prepregs (USN125 and UPN139)

according to the stacking angle were calculated using classical

laminate plate theory (CLPT [14]) for the determination of stacking

angles. For the machine base and the Z-base, resin concrete was ap-

plied to reduce the machine weight and increase the damping

capacity of the structure. The optimal composition of different

types of aggregates for the best mechanical properties (e.g., the

modulus) was proposed in [12]. In our study, only #2 and #3 sand

grit sizes were used, considering the small size of the structures.

The weight ratio between the sand and the epoxy resin was

92.5:7.5 following the research results in [12]. The main material

properties used in this study are summarized in Table 1.

3. Design modication with composite materials

3.1. Structural performance of the existing metal structure

To investigate the structural performance of the existing metal

structure, nite element analyses were carried out to calculate the

maximum static deection due to deadweight, and the natural fre-

quencies and corresponding mode shapes. The commercial nite

element code ANSYS 9.0 was used for the analysis. A xed bound-

ary condition in the Y-direction at the bottom of the machine

structure was imposed on the nite element model as shown in

Fig. 2a. Several other boundary conditions (such as xed in all

directions) were tried, but it was proved using vibration tests that

this condition best simulated the actual behavior of the machine

structure as described in Section 5. We used 19,209 SOLID45 ele-

ments and 30,404 nodes in the model. Because the goal of the anal-

ysis was to determine the exural deformation of the solid parts of

the structure, the air bearings and linear motors of the moving

parts, which were expected to generate rigid body motion of the

structure, were not modeled. Thus, all the moving parts were

merged with the mating stationary parts. Our results showed that

the maximum static deection due to deadweight was 0.465 lm at

the end of the rotary table in the XY stage, as shown in Fig. 2b. The

rst natural frequency was found to be 476.72 Hz (the spindle

bending mode). Two more exural modes were found at the 3rd

mode (596.78 Hz, bending mode of the XY base) and the 5th mode

(1031.70 Hz, twisting mode of the XY base) as shown in Fig. 2c.

The 2nd and 4th modes were found to be due to rigid body motion

caused by X and Z direction free body motion. These results were

used as a basis for the criterion of the re-design using composite

materials.

3.2. Structural design with brous composites and resin concrete

The machine back plate (360 mm 360 mm 35 mm) needs

high stiffness to resist bending and the twisting moments gener-

ated by the load from the XY stage under working conditions,

and also needs high specic stiffness (EI/q) to increase natural fre-

quencies so as to avoid resonance at low frequencies. The machine

base and the Z-base support the compressive forces of the Z-table

and the spindle system generating vibration during machining;

therefore, the Young modulus and damping capacity of the struc-

ture should be considered. By considering these structural require-

ments, a machine back plate was designed using a sandwich

structure composed of a high modulus carbon/epoxy composite

(UPN139) and a stainless steel core to increase structural stiffness

and damping capacity. The aluminum XY base was replaced by

another type of carbon/epoxy composite (USN125) that is lighter

Nomenclature

E Youngs modulus (GPa)

I 2nd moment of inertia of back plate section (m

4

)

b width of back plate cross section (m)

h height of back plate cross section (m)

h stacking angle of composite ()

t thickness of composites (m)

x distance from neutral axis (m)

q mass density (kg/m

3

)

m mass (kg)

V back plate volume (m

3

)

l back plate length (m)

n the number of the composite ply

g loss factor

f frequency (Hz)

H height of beam type specimen (m)

Subscripts

S stainless steel

C composites

R resin concrete

r resonance

1 left-hand half power point

2 right-hand half power point

x longitudinal direction of ber

y transverse direction of ber

S.-K. Cho et al. / Composite Structures 93 (2011) 492501 493

and stiffer, because the original base moves during machining. The

aluminum Z-base was re-designed as a sandwich structure com-

posed of a resin concrete core and a carbon/epoxy composite

(USN125) skin for high damping capacity and light weight. Finally,

the center part of the machine base was dug out and lled with re-

sin concrete for a lighter weight and higher damping structure. The

nal design specication for each component was determined by

evaluation of structural performance using parametric studies

and nite element analyses. The ANSYS SOLID45 and SOLID46 ele-

ments were used for isotropic (stainless steel, aluminum, and resin

concrete) and anisotropic (carbon/epoxy composites) materials,

respectively.

3.3. Machine back plate and XY base applied by composites

The overall dimensions of the composite hybrid components

were the same as those of the metal component dimensions, which

means that as the composite thickness increased, the stainless

steel thickness decreased, thereby keeping the total thickness

constant (see Fig. 3). The stacking angle h, number of ply n, and

the location of composites of the compositestainless steel hybrid

machine back plates (e.g., sandwich or a one-side reinforcement)

were determined by calculating the bending stiffness and specic

bending stiffness according to the composite thickness and stack-

ing angle using the following equations. Eqs. (1) and (2) represent

Fig. 1. System congurations; (a) the components of the table-top machining center, (b) design modication of the structure with composites.

494 S.-K. Cho et al. / Composite Structures 93 (2011) 492501

bending stiffnesses of a sandwich structure and a one-side rein-

forcement, respectively, and Eqs. (3) and (4) are specic bending

stiffnesses for the sandwich structure and the one-side reinforce-

ment case, respectively.

EI

sandwich

E

S

12

fb h 2t

3

g

E

C

12

fb h

3

b h 2t

3

g

1

EI

one-side

E

S

b h t

3

_ _

12

b h t f g x

h t

2

_ _ _ _

2

_

_

_

_

E

C

b t

3

_ _

12

b t h t

t

2

_ _

2

_ _

2

EI

q

_ _

sandwich

E

S

fbh2t

3

gE

C

fbh

3

bh2t

3

g

12

V

fbh2t l q

S

gbh fbh2tg l q

C

3

Table 1

Material properties.

Material Density

(kg/m

3

)

Youngs

modulus

(GPa)

Ply

thickness

(mm)

Loss

factor

(%)

USN125 1550 E

x

= 130 0.125 3.2 (max)

E

y

= 10

UPN139 1620 E

x

= 250 0.132 3.2 (max)

E

y

= 10

Resin concrete [12] 2207 25 2.8

Aluminum 2800 70 0.27

Stainless steel 7750 193 0.16

Fig. 2. Finite element analysis of the existing metal machine tool structure; (a) nite element mesh, (b) maximum deection due to deadweight, (c) exural mode shapes.

S.-K. Cho et al. / Composite Structures 93 (2011) 492501 495

EI

q

_ _

one-side

E

S

b h t

3

12

b h t f g x

h t

2

_ _ _ _

2

_ _

E

C

b t

3

12

b t h t

t

2

_ _

2

_ _

V

fb h t l q

S

g fb h t l q

S

g

4

Based on the plate shape of the machine back plate, it seemed

that bending was the easiest deformation pattern (static deection

and bending vibration mode) of the structure. Thus, the bending

stiffness and specic bending stiffness of the hybrid machine back

plates for several stacking angles and thickness of composite skins

were calculated as shown in Fig. 3cf. Regarding the specic bend-

ing stiffness, because of the nature of brous composites (low den-

sity and high modulus), the specic bending stiffness increased as

Thickness [mm]

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

E

I

[

N

m

2

]

1.2e+5

1.5e+5

1.8e+5

2.1e+5

2.4e+5

2.7e+5

3.0e+5

3.3e+5

3.6e+5

3.9e+5

Thickness [mm]

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34

E

I

[

N

m

2

]

1.2e+5

1.5e+5

1.8e+5

2.1e+5

2.4e+5

2.7e+5

3.0e+5

3.3e+5

3.6e+5

3.9e+5

Thickness [mm]

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

E

I

/

[

N

k

g

/

m

]

E

I

/

[

N

k

g

/

m

]

20

40

60

80

100

120

140

160

180

200

220

240

Thickness [mm]

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34

20

40

60

80

100

120

140

160

180

200

220

240

a

c

e

b

d

f

Fig. 3. The compositestainless steel hybrid machine back plate; (a) sandwich structure, (b) one-side reinforcement structure, (c) bending stiffness of sandwich structure

w.r.t. stacking angle and thickness of the composite, (d) bending stiffness of one-side reinforcement structure w.r.t. stacking angle and thickness of the composite, (e) specic

bending stiffness of sandwich structure w.r.t. stacking angle and thickness of the composite, (f) specic bending stiffness of one-side reinforcement structure w.r.t. stacking

angle and thickness of the composite.

496 S.-K. Cho et al. / Composite Structures 93 (2011) 492501

the stacking angle decreased, and the thickness increased for both

of the hybrid structures. However, for the bending stiffness (EI), the

stacking angles below 15, which have a higher Youngs modulus

than that of stainless steel, ensured better results. According to

the calculation results it was found that the sandwich machine

back plate with a [5]

n

stacking sequence had the most effective

performance even though [0]

2n

had the best result with a view-

point of Youngs modulus itself. The stacking sequence of [0]

2n

is

vulnerable to transverse fracture under impact conditions and

the machining process because it is very brittle in the transverse

direction (90). The required thickness of the composite was deter-

mined to be 10 mm, which means the number of ply, n, was 39 be-

cause the bending stiffness saturated near this value (Fig. 3c).

Using these results ([5]

39

), a nite element analysis was carried

out to determine the maximum static deection of the newly de-

signed structure with the same model as the metal structure, as

shown in Fig. 2a. From the analysis results, it was found that the

maximum deection due to deadweight was 0.419 lm, which

was 9.9% lower than that of the metal structure.

To determine the stacking sequence of the composite XY base

made of carbon/epoxy composite (USN 125), a nite element anal-

ysis was carried out according to the stacking angle, keeping the

same specication for the sandwich machine back plate ([5]

39

)

as previously determined. The analysis results showed that the

maximum static deection was 0.393 lm (15.5% lower than that

of the metal structure) when the stacking sequence of the compos-

ite XY base was [5]

80

(20 mm thick). From a modal analysis of

the new structure, it was found that the compositemetal hybrid

machine back plate and composite XY base had the same exural

vibration modes (1st, 3rd, and 5th modes) as the metal structures

with frequencies of 499.61 Hz, 672.86 Hz, and 1065.5 Hz, which

were 5%, 13%, and 3.2% higher than the frequencies of the metal

structure, respectively.

3.4. Z-base and machine base

The aluminum Z-base was re-designed using resin concrete and

a carbon/epoxy composite (USN125) to enhance damping capacity

with light weight, as shown in Fig. 4a. A pair of 10 mm-thick alu-

minum plates was applied at the top of the Z-base to assemble a

linear motion guide. The overall size of the composite Z-base was

the same as the aluminumZ-base. The stacking angle and the num-

ber of ply of composite prepregs were determined through nite

element analysis by checking the maximum deection due to the

weight of the Z-table and the spindle system, and the damping

capacity. The stacking sequences of the skin composites were

examined for [0/90]

n

and [h]

n

where h varied from 0 to 90 at

15 intervals, and the thickness of the composite skin ranged from

1 mm to 8 mm. The nite element analysis showed that even the

most effective composite Z-base applied by the composite with

[90]

48

(composite thickness was 6 mm) had a higher maximum

deection (0.0478 lm) than that of the aluminum Z-base

(0.020 lm) as shown in Fig. 4b. However, this level of deection

seemed too small to affect system performance to an appreciable

Thickness [mm]

1 2 3 4 5 6 7 8

D

e

f

l

e

c

t

i

o

m

[

m

]

0.0

2.0e-8

4.0e-8

6.0e-8

8.0e-8

1.0e-7

1.2e-7

1.4e-7

Thickness ratio [%]

0.10 0.15 0.20 0.25 0.30 0.35 0.40

L

o

s

s

f

a

c

t

o

r

[

%

]

0

1

2

3

4

5

a b

c d

Fig. 4. The composite Z-base; (a) conguration of the composite Z-base made of a resin concrete and a carbon/epoxy prepreg and aluminum beam, (b) the maximum

deection due to deadweight of Z-table w.r.t. stacking angle and thickness of composite skin, (c) the compositeresin concrete hybrid specimen for vibration test, (d) the

measured and calculated loss factors of the compositeresin concrete hybrid specimens.

S.-K. Cho et al. / Composite Structures 93 (2011) 492501 497

degree. On the other hand, the composite Z-base was able to en-

hance the damping capacity by reducing vibration amplitude (see

Fig. 4d) caused by the spindle operating at high speed.

To investigate the damping capacity of the compositeresin

concrete hybrid structure, vibration tests of the hybrid beam (see

Fig. 4c) were carried out. The stacking angle and thickness ratio

(H

C

/H) shown in Fig. 4c were controlled. Loss factor g was mea-

sured using half-power bandwidth and calculated using Eq. (5)

after applying an impact to the specimen suspended by a string.

g

f

2

f

1

f

r

5

Fromthe test results, it was found that the loss factor of the sand-

wich beamincreased as the stacking angle of the composite skin in-

creased, but it decreased as the thickness ratio increased, as shown

in Fig. 4d. This trend was in good agreement with the theoretical

result (surface damping treatment [15]) expressed in Eq. (6).

g

R

g

C

E

C

E

R

8

H

C

H

_ _

3

12

H

C

H

_ _

2

6

H

C

H

_ _

_ _ 1 6

From the preceding analysis and test results, the composite

stacking angle and the thickness were determined to be 90 and

6 mm; therefore, the stacking sequence was [90]

48

.

The stainless steelresin concrete hybrid machine base was also

analyzed to determine the maximum deection due to the weight

of the Z stage and an air spindle. The surface area of the resin con-

crete was the same as the bottom area of the Z-base. The analysis

results revealed that the deection had an almost uniform distri-

bution with a maximum value of 2.93 nm, whereas the stainless

steel machine base had a maximum value of 0.325 nm. Even

though the newly designed machine base had higher static deec-

tion than that of the metal machine base, the level of deection

was quite low so it did not seem to affect much the machine per-

formance because the target machining precision of the machine

tool was level of a few micrometers.

Fig. 5. The fabrication process of composite structures; (a) assembly of the hybrid machine back plate and the XY-base, (b) the compositeresin concrete Z-base, (c) the

metalresin concrete hybrid machine base.

498 S.-K. Cho et al. / Composite Structures 93 (2011) 492501

4. Fabrication of metalcomposite hybrid structures

4.1. Machine back plate and XY base made of carbon/epoxy

composites

The hybrid machine back plate was composed of a 15 mm-thick

stainless steel core and 10 mm-thick carbon/epoxy composite

skins ([5]

39

, UPN139), as described in Section 3.3. The cured com-

posite skins and the stainless steel core were treated with abrading

papers and cleaned using acetone. For bonding, epoxy adhesives

(DP460, 3 M) were applied to the surfaces at room temperature

for 24 h. After the bonding process was completed, bolt holes

and tabs were machined to allow assembly with other parts such

as the XY base (see Fig. 5a).

The 20 mm-thick composite XY base was fabricated using a

carbon/epoxy composite ([5]

80

, USN125) with the same shape

and size as the aluminum structure. A central rectangular hole

(170 mm 140 mm) was machined in the composite XY base

by water jet cutting (see Fig. 5a). Both of the composite structures

were fabricated by vacuum bag-degassing molding with the rec-

ommended cure cycles, as shown in Fig. 6a and b. The fabricated

machine base and the XY base were assembled by adhesive bond-

ing and mechanical fastening methods with ten bolts, as shown in

Fig. 5a. As a result, the hybrid machine back plate and composite

XY base showed 46.9% and 45.5% weight reductions, respectively.

4.2. Z-base and the machine base made of resin concrete

By considering previous research results [12], sands with #2

and #3 grit sizes were used to fabricate the resin concrete struc-

ture. The weight ratio between the sand and the epoxy resin for

casting YD-114F epoxy and D-230 hardener with a mixing ratio

of 7:3 was 92.5:7.5. The sands were washed out to eliminate impu-

rities by water and dried well. Four molds for the resin concrete

beams and another mold for the plate were prepared, and the resin

concrete was lled into the mold and rammed for compaction

(Fig. 5b). The materials were cured in an autoclave at 60 C and

0.4 MPa for 6 h as shown in Fig. 6c. The cured resin concrete beams

and plate were wrapped with carbon/epoxy prepregs (USN125)

with the stacking sequence of [90]

48

(6 mm thick). The structures

were put into molds and cured in an autoclave using the cure cycle

shown in Fig. 6b. The cured compositeresin concrete structures

were bonded using an epoxy adhesive (DP 460, 3 M) and nally a

pair of aluminum beams were bonded at the top of the structure

for assembling linear motion guide rails. After the bonding process,

to adjust the atness and the straightness of the composite Z-base,

the aluminum beams were precisely processed using a milling ma-

chine. The mass of the structure was reduced from 7.5 kg to 4.6 kg,

a 38.7% weight reduction.

For a light weight machine base with high damping, the original

stainless steel machine base was machined to make a cavity

(310 250 30 mm

3

) at the center of the structure as shown in

Fig. 5c. The resin concrete was lled into this cavity. The curing

process was the same as that used for the compositeresin con-

crete Z-base. The fabricated hybrid machine base had a 28.4%

weight reduction, reducing the mass from 49.6 kg to 35.5 kg.

All the fabricated machine components and the original compo-

nents, such as the linear motion guide blocks and Z-table, were

assembled using adhesive bonding or mechanical joining with

bolts. The Z-base was bonded to the machine base with epoxy

adhesive (DP 460, 3 M), and other metal components were assem-

bled by bolted joints as shown in Fig. 7a. Metal components includ-

ing the X and Y tables and the Z-table were assembled after the

linear motion guides were mounted (Fig. 1b). The linear motors

and air bearings were not assembled because our research scope

was limited to the re-design of structural components for high

stiffness, high damping, and light weight.

5. Performance evaluation

The existing metal machine tool structure had been assembled

with non-contact driving components such as air bearings and a

linear motion guide attached by linear motors. These driving com-

ponents have complex behaviors when they move and vibrate,

which makes the analysis and test results complex. Therefore, in

this study, only the non-moving parts, as shown in Fig. 7a, were

Fig. 6. Cure cycles of composites; (a) carbon/epoxy prepreg (UPN 139), (b) carbon/

epoxy prepreg (USN 125), (c) resin concrete.

S.-K. Cho et al. / Composite Structures 93 (2011) 492501 499

considered. The disassembly of the existing metal machine struc-

ture was technically difcult, so an indirect evaluation was carried

out. For the compositemetal hybrid structure (Fig. 7a), nite ele-

ment modal analyses (Fig. 7c) and vibration tests were performed

to nd the resonant frequencies of the structure. The calculated

resonant frequencies were compared with the test results to deter-

mine the accuracy of the nite element analysis (see Fig. 7e). Next,

the metal structure with the same assembly conguration as the

hybrid structure was analyzed using the same nite element mod-

el (Fig. 7c) as the hybrid structure. Finally, the analyzed resonant

frequencies and their mode shapes for the two systems were com-

pared to evaluate the systems performance indirectly.

From the analysis and test results, it was found that the three

main frequencies had slight errors compared with the test results,

as summarized in Table 2. These small errors might be caused by

the simple boundary condition (displacement restriction in Y-

direction at the bottom of the machine) and the assumption of a

perfect bonding condition in the nite elements. The analysis re-

sults revealed that the compositemetal hybrid structure had a

1216% higher structural stiffness.

The loss factor was also evaluated using the vibration test, cal-

culating the half-power bandwidth at the resonant frequencies.

The loss factors ranged from 2.82% to 3.64% (see Fig. 7e and Table

2), which is a higher damping capacity relative to ordinary welded

or bolted metal structures [8]. The vibration test and nite element

analysis of the metal structure with a different system congura-

tion (the Z-table was not able to be disassembled for technical

reasons, see Fig. 7b and d) was also tried, but the amplitude of

the frequency response function (FRF) were quite low (see Fig. 7e

and f) because of the air bearings between the Z-base and the

Fig. 7. The assembled compositesmetal hybrid machine tool structure and its performance; (a) fabricated compositemetal hybrid machine tool structure, (b) metal

machine tool structure, (c) nite element model for compositesmetal hybrid machine tool structure, (d) nite element model for metal machine tool structure, (e) result of

vibration test and modal analysis for the fabricated compositemetal hybrid machine tool structure, (f) result of vibration test and modal analysis for metal structure.

500 S.-K. Cho et al. / Composite Structures 93 (2011) 492501

Z-table. The air bearing system seems to have attenuated much of

the system vibration, and the higher mass reduced the natural fre-

quencies. The mode shapes estimated by the nite element model

(Fig. 7d) were the same as the hybrid structure (Fig. 7c), and the

test and analysis resonant frequency values were in relatively good

agreement (Fig. 7f), which shows that the analysis results are rea-

sonable. The system mass was measured for both systems, and the

total compositemetal system showed a 36.8% weight reduction.

6. Conclusion

In this paper, carbon/epoxy composites and resin concrete were

applied to a table-top machine tool structure to enhance structural

stiffness and damping capacity, and reduce weight. A composite

stainless steel hybrid back plate, a carbon/epoxy XY base, a com-

positeresin concrete Z-base, and a resin concrete machine base

were designed and fabricated. The types of composites and stack-

ing sequences for brous composites were determined by nite

element analyses with respect to structural stiffness and damping

capacity. The newly fabricated hybrid structure showed a 36.8%

weight reduction and the structural stiffness was increased by up

to 16% based on our modal analysis results with higher damping

capacity (with a loss factor ranging from 2.82% to 3.64%). However,

system performance needs to be examined more precisely by driv-

ing tests, checking machining quality after installing all the driving

components such as air bearings and linear motors, and mounting

all the related components such as the rotary table and Z-table,

which were not accomplished in this study.

Acknowledgements

This research was supported by the Chung-Ang University Re-

search Grants in 2010. The authors extend special thanks to Dr.

Jong-Kweon Park and Dr. Seung-Kook Ro of the Intelligent Machine

Systems Research Centre, KIMM for their thoughtful help during

this research.

References

[1] Kawahara N, Suto T, Hirano T, Ishikawa Y, Kitahara T, Ooyama N, et al.

Microfactories; new applications of micromachine technology to the

manufacture of small products. Microsyst Technol 1997;3:3741.

[2] Kussul E, Baidyk T, Ruiz-Huerta L, Caballero-Ruiz A, Velasco G, Kasatkina L.

Development of micromachine tool prototypes for microfactories. J Micromech

Microeng 2002;12(6):795812.

[3] Okazaki Y, Mishima N, Ashida K. Microfactory-concept, history, and

developments. J Manuf Sci Eng Trans ASME 2004;126:83744.

[4] Ehmann KF, Sung H, Yoon HS. Development of a micro-spindle for micro/meso-

scale machine tool (mMT) applications. In: Proceedings of the 3rd

international workshop on microfactory technology (IWMT/3). Jeju, 2324

August, 2007. p. 138.

[5] Kim DI, Jung SC, Lee JE, Chang SH. Parametric study on design of composite

foamresin concrete sandwich structures for precision machine tool

structures. Compos Struct 2006;75:40814.

[6] Kim JH, Lee JE, Chang SH. Robust design of microfactory elements with high

stiffness and high damping characteristics using foamcomposite sandwich

structures. Compos Struct 2008;86(13):2206.

[7] Kim JH, Chang SH. Design of l-CNC machining centre with carbon/epoxy

compositealuminum hybrid structures containing friction layers for high

damping capacity. Compos Struct 2010;92(9):212836.

[8] Lee DG, Chang SH, Kim HS. Damping improvement of machine tool columns

with polymer matrix ber composite materials. Compos Struct

1998;43:15563.

[9] Chang SH, Kim PJ, Lee DG, Choi JK. Steelcomposite hybrid headstock for high

precision grinding machines. Compos Struct 2001;53(1):18.

[10] Haranath S, Ganesan N, Rao BVA. Dynamic analysis of machine tool structures

with applied damping treatment. Int J Mach Tool Manuf 1987;27:4355.

[11] Rahman M, Mansur MA, Lee LK, Lum JK. Development of a polymer

impregnated concrete damping carriage for linear guideways for machine

tools. Int J Mach Tool Manuf 2001;41:43141.

[12] Kim HS, Park KY, Lee DG. A study on the epoxy resin concrete for the ultra-

precision machine tool bed. J Mater Process Technol 1995;48:64955.

[13] Bignozzi MC, Saccani A, Sandrolini F. New polymer mortars containing

polymeric wastes part 2: dynamic mechanical and dielectric behaviour.

Compos Part A Appl Sci 2002;33:20511.

[14] Lee DG, Suh NP. Axiomatic design and fabrication of composite

structures. New York: Oxford University Press; 2006.

[15] Nashif AD, Jones DIG, Henderson JP. Vibration damping. New York: John Wiley

and Sons; 1985.

Table 2

Analysis and test results for the models presented in Fig. 7a and b.

Modes Natural frequency (Hz) Mode shape Loss factor

g (%)

Analysis Experiment

Fig. 7a Fig. 7b Fig. 7a Fig. 7b

Hybrid

structure

Metal

structure

% Hybrid

structure

Metal

structure

% Hybrid

structure

Metal

structure

1 397 342 16" 346 264 31" 354 236 In-plane rotation in Y-dir. 3.64

2 690 595 16" 596 469 27" 658 396 Back plate bending 3.10

3 1169 1049 12" 911 888 3" 1133 826 Back plate twisting 2.82

S.-K. Cho et al. / Composite Structures 93 (2011) 492501 501

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 312B PDFDokument2 Seiten312B PDFJesus Carhuamaca Pascual92% (13)

- UNIT 2 - PhysicsDokument38 SeitenUNIT 2 - PhysicsPpx XdNoch keine Bewertungen

- Fishing TechnologyDokument64 SeitenFishing TechnologyK K Verma100% (2)

- LPHX 55000 - FlowserveDokument12 SeitenLPHX 55000 - FlowserveAldy Dankers100% (1)

- E 993 KatalogDokument488 SeitenE 993 KatalogGigi DuruNoch keine Bewertungen

- Physical Chemistry-Problems and Solutions-1 - MiesslerDokument836 SeitenPhysical Chemistry-Problems and Solutions-1 - MiesslerAKHILA MNoch keine Bewertungen

- CTMS Example - Motor Position Control ModelingDokument4 SeitenCTMS Example - Motor Position Control ModelingKartik DetrojaNoch keine Bewertungen

- COMPLETE Report (Braking Department)Dokument30 SeitenCOMPLETE Report (Braking Department)Dinie Abdullah ZamawiNoch keine Bewertungen

- Guo 2005Dokument16 SeitenGuo 2005Taha SerwerNoch keine Bewertungen

- Check List RodilloDokument2 SeitenCheck List RodilloDarwin Supò100% (1)

- Chapter 9-Hydroelectric Plant PDFDokument118 SeitenChapter 9-Hydroelectric Plant PDFsindyNoch keine Bewertungen

- CASE CX460 Crawler Excavator Parts Catalogue Manual PDFDokument31 SeitenCASE CX460 Crawler Excavator Parts Catalogue Manual PDFfjjsekfksemm100% (1)

- Retrofitting of Reinforced Concrete BuildingsDokument44 SeitenRetrofitting of Reinforced Concrete BuildingsKrupakl Gowda100% (8)

- WL 835H Liugong Heavy DutyDokument13 SeitenWL 835H Liugong Heavy Dutyrusydi raushan fikriNoch keine Bewertungen

- Gear Backlash - KHK GearsDokument11 SeitenGear Backlash - KHK Gearsmarcio_soutoNoch keine Bewertungen

- Lasac. Assignment 4. Ce43s4Dokument9 SeitenLasac. Assignment 4. Ce43s4Karyme MendezNoch keine Bewertungen

- DR Ashok K Jain Former Professor IIT Roorkee PDFDokument43 SeitenDR Ashok K Jain Former Professor IIT Roorkee PDFAtul Kumar EngineerNoch keine Bewertungen

- Máy SliceDokument15 SeitenMáy SliceHoang NguyenNoch keine Bewertungen

- A Mini Project On Design of Flexible PavementDokument94 SeitenA Mini Project On Design of Flexible Pavementsohail irfanNoch keine Bewertungen

- Tu RBO8Dokument1 SeiteTu RBO8AnkurTripathiNoch keine Bewertungen

- 2600, 2400, 2300 FOGGERS: User'S ManualDokument2 Seiten2600, 2400, 2300 FOGGERS: User'S Manualver_at_work100% (1)

- 3408 Timing GeaarsDokument4 Seiten3408 Timing Geaarsmanu luvungaNoch keine Bewertungen

- Turbo ChargerDokument28 SeitenTurbo ChargerCharles ChivengahNoch keine Bewertungen

- The Concrete Producer Article PDF - Comparing The Options For Cooling ConcreteDokument4 SeitenThe Concrete Producer Article PDF - Comparing The Options For Cooling Concretearangar1100% (1)

- ARI ARMATUREN - Ball Float Steam Trap CONADokument15 SeitenARI ARMATUREN - Ball Float Steam Trap CONArahimi mohamadNoch keine Bewertungen

- Forged Valves - Operation & Maintenance ManualDokument16 SeitenForged Valves - Operation & Maintenance ManualKoolkrayzeh KLNoch keine Bewertungen

- BS en 14620-4 2006Dokument34 SeitenBS en 14620-4 2006Quat Le DinhNoch keine Bewertungen

- Physics I Problems PDFDokument1 SeitePhysics I Problems PDFBOSS BOSSNoch keine Bewertungen

- XT125R 2007Dokument57 SeitenXT125R 2007Oren BuskilaNoch keine Bewertungen

- F2500W 03 en PDFDokument338 SeitenF2500W 03 en PDFElliel Paes Luvison100% (4)