Beruflich Dokumente

Kultur Dokumente

Primary Air in A Boiler

Hochgeladen von

DanielEMOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Primary Air in A Boiler

Hochgeladen von

DanielEMCopyright:

Verfügbare Formate

4.

5-1

RECOVERY BOILER AIR SYSTEMS

Rick A. Wessel, Ph.D.

Advisory Engineer

The Babcock & Wilcox Company

20 South Van Buren Avenue

Barberton, Ohio 44203

INTRODUCTION

This paper presents the equipment and

layout of recovery boiler air systems, and

their purpose. Several arrangements of the

individual air levels are shown along with

the gas flow patterns found in the lower

furnace of recovery boilers. A few of the

problems that are typically encountered will

also be addressed. Slide 1 and Slide 2 are

the title and outline for the presentation.

Slide 3 states the objectives of the recovery

boiler air system. The primary objective is

to supply air to the boiler for complete

combustion of black liquor. Complete

combustion is achieved by a combination of

the three Ts time (residence time),

temperature, and turbulence (mixing). The

second objective is to control the

temperature and chemical environment

around the char bed for good chemical

conversion of the char and smelt. Third is to

minimize carryover of black liquor spray

that can lead to fouling of superheater tube

banks. Fourth is to minimize emissions of

carbon monoxide (CO), nitrous oxides

(NO

x

), total reduced sulfur (TRS), and

sulfur dioxide (SO

2

). The last objective is to

achieve uniform gas flow and temperature

distribution entering the superheater for

reduced fouling, even metal temperatures,

and balanced heat transfer to the steam.

Slide 3

Objectives of Air Systems Objectives of Air Systems

Supply air for complete combustion Supply air for complete combustion

(3 Ts: time, temperature, turbulence) (3 Ts: time, temperature, turbulence)

Control temperature and chemical Control temperature and chemical

environment around char bed environment around char bed

Minimize carryover of black liquor spray Minimize carryover of black liquor spray

Minimize emissions (CO, Minimize emissions (CO, NO NO

x x

, TRS, SO , TRS, SO

2 2

) )

Achieve uniform flow and temperature Achieve uniform flow and temperature

entering entering superheater superheater tube banks tube banks

AIR SUPPLY AND DELIVERY

Slide 4 shows a side elevation of the lower

furnace of a recovery boiler along with its

dissolving tank.

Slide 4

Air System Air System

Components Components

(3 (3- -Levels) Levels)

Primary Primary

Secondary Secondary

Liquor Guns Liquor Guns

Tertiary Tertiary

This boiler has a 3-level air system. The

primary air level is very near the bottom of

the furnace. The secondary air level is about

5 feet above the primary level and 10 to15

feet below the liquor gun level. The tertiary

air level is 10 to 15 feet above the liquor

guns. Most recovery boilers have three

levels of combustion air, but some have two

and a few newer boilers have four or more

levels.

4.5-2

Slide 5 shows just the combustion air

system with the fans, ducting and air

heaters. There is more than one forced draft

fan on most recovery boilers. In this case,

two fans deliver air through large air heaters

located in the ducting to the primary and

secondary air level while a third fan delivers

ambient air to the tertiary level.

Slide 5

Air System Air System

Components Components

Fans Fans

Ducts Ducts

Heaters Heaters

FD

Fan

Ai r

Heater

Air

Duct

Slide 6 presents the two types of fans used

with recovery boilers. Forced draft (FD)

fans deliver combustion air to the furnace.

Induced draft (ID) fans remove the

combustion gases and maintain a slightly

negative draft in the furnace.

Slide 6

Combustion System Fans Combustion System Fans

Forced draft fans deliver combustion air Forced draft fans deliver combustion air

Induced draft fans remove combustion gas Induced draft fans remove combustion gas

Slightly negative draft is maintained in Slightly negative draft is maintained in

furnace ( furnace (- -1 to 1 to - -2 inches H 2 inches H

2 2

O) O)

Firing rate can be limited by fan capacity Firing rate can be limited by fan capacity

Slide 7 shows one arrangement for the

forced draft (FD) fans. Recovery boilers can

be operated with just one combustion air

fan, but most boilers have two or three.

Until recently, the combustion air to all

levels was preheated. Now there are many

applications where unheated air is used

above the liquor gun level. The furnace gas

at this level is nearly 2000F (~1100C) so

air preheating is not required. Cold tertiary

air also increases jet penetration due to its

high density; this promotes mixing of the

flue gases.

Slide 7

FD Fans & Air FD Fans & Air

Preheating Preheating

Tertiary Air Tertiary Air

Secondary Air Secondary Air

Primary Air Primary Air

A table of typical air system design

parameters is presented in Slide 8. A two

level air system is common on older boilers

and is the only design which the secondary

air level is located above the liquor guns.

For systems with three or more levels, the

secondary air includes any air injection ports

between the primary air level and the liquor

guns; the tertiary air includes any air

injection ports above the liquor guns.

Slide 8

Typical Air System Designs Typical Air System Designs

Ambient Ambient 15 15 - - 40 40 6 6 - - 20 20 Tertiary Tertiary

200 200 - - 400 400 20 20 - - 50 50 6 6 - - 12 12 Secondary Secondary

200 200 - - 400 400 30 30 - - 40 40 2 2 - - 4 4 Primary Primary 3 3

200 200 - - 400 400 30 30 - - 50 50 4 4 - - 8 8 Secondary Secondary

200 200 - - 400 400 50 50 - - 70 70 2 2 - - 4 4 Primary Primary 2 2

Temp. Temp.

F F

Percent Percent

of Total of Total

Air Flow Air Flow

Static Static

Pressure Pressure

in. H in. H

2 2

O O

Air Air

Levels Levels

Total Total

Number Number

of Levels of Levels

4.5-3

AIR SYSTEM ARRANGEMENTS AND

GAS FLOW IN THE FURNACE

Air port nozzles at the primary, secondary,

and tertiary levels are arranged to distribute

the air, and produce gas flow patterns for

effective mixing and combustion in the

furnace. The smallest element of the air

system is a single air port nozzle for

injecting air into the furnace.

Slide 9 describes the characteristics of a

turbulent jet which emerges from each air

port nozzle on the furnace wall and

penetrates a distance into the furnace. The

jet typically expands with an angle of about

16 degrees as it entrains surrounding gases.

The jet velocity decreases with distance

from the nozzle, and the jet is deflected

upward from gases flowing upward from

below.

Slide 9

0

0.2

0.4

0.6

0.8

1

0 10 20 30 40 50

Distrance from Nozzle, z/Dn

C

e

n

t

e

r

lin

e

V

e

lo

c

it

y

,

V

c

/V

n

Characteristics of Turbulent Jets Characteristics of Turbulent Jets

Jet Penetration Jet Penetration

Jet Expansion Jet Expansion

Gas

Entrainment

Tube

Wall

Velocity

Profile

Windbox

Jet Centerline Air Port

Nozzle

Expansion

Angl e ~16

z =distance fromnozzle

Dn =nozzle diameter

Vc =centerline velocity

Vn =nozzle velocity

Edge of Jet, V/Vc

= 0.2

Slide 10 describes the role of the primary air

in a recovery furnace. Slide 11 presents an

inside view of primary air ports and

discusses their arrangement.

Slide 10

The Role of Primary Air The Role of Primary Air

Primary air controls the char bed perimeter Primary air controls the char bed perimeter

Controls bed burning near primary air ports Controls bed burning near primary air ports

Pushes wall Pushes wall- -shed material away from port shed material away from port

Pressure is important, too low is common problem Pressure is important, too low is common problem

Primary air keeps smelt hot and fluid Primary air keeps smelt hot and fluid

Blowing on a fire increases burning rate and Blowing on a fire increases burning rate and

temperature temperature

Campfire and blacksmith are examples Campfire and blacksmith are examples

Slide 11

Primary Air Arrangement Primary Air Arrangement

Many, small ports on all four walls feed air to Many, small ports on all four walls feed air to

perimeter of the char bed perimeter of the char bed

Isolation dampers control local burning rates Isolation dampers control local burning rates

and bed shape and bed shape

Hot air improves combustion stability Hot air improves combustion stability

Slide 12 describes the role of the secondary

air in a recovery furnace.

Slide 12

The Role of Secondary Air The Role of Secondary Air

Secondary air controls char bed height Secondary air controls char bed height

Jet penetration to center of furnace needed Jet penetration to center of furnace needed

Large ports and high pressure air Large ports and high pressure air required required

Secondary air burns char and volatiles Secondary air burns char and volatiles

Intensive mixing of air and combustion gases Intensive mixing of air and combustion gases

Heat release needed to dry liquor spray Heat release needed to dry liquor spray

Optimized to match liquor firing conditions Optimized to match liquor firing conditions

4.5-4

Slide 13 shows three common arrangements

for the secondary air nozzles. The 4-wall

arrangement is most common on older

boilers, but 2-wall arrangements are used on

most retrofits and new boilers. The

interlaced arrangement in the center of Slide

13 is a 4x3 nozzle pattern. The arrangement

of air nozzles allows sufficient room for jet

expansion without interference from

neighboring jets.

Slide 13

Secondary Air Arrangements Secondary Air Arrangements

4 4- -wall air jet wall air jet

arrangement arrangement

2 2- -wall wall

full interlace full interlace

2 2- -wall partial wall partial

interlace interlace

Small

Jet

Large

Jet

The flow pattern which is shown in Slide

14, is the result of a Computational Fluid

Dynamics (CFD) calculation. The small

arrows indicate the gas velocities at the

secondary air level, and the color indicates

the gas speed. The velocity vectors confirm

that the jets interlace effectively for a 4x3

pattern in a furnace that is nearly square.

Slide 14

Flow Pattern for a Full Interlace Flow Pattern for a Full Interlace

Slide 15 shows a similar result for a 2-wall

partial interlace arrangement which uses a

pattern of large jets opposed by small jets in

a similar interlace configuration. There is

slightly less penetration of the large jets

with this arrangement because some of the

flow is diverted to the small jets, but the two

flow patterns are otherwise similar.

Slide 15

Flow Pattern for Partial Interlace Flow Pattern for Partial Interlace

Slide 16 lists several secondary air port

arrangements that are commonly used in

recovery boilers. These arrangements will

be discussed further after describing the

tertiary air level.

Slide 16

Alternate Secondary Air Arrangements Alternate Secondary Air Arrangements

Single level, full Single level, full- - or partial or partial- -interlace interlace

(front/rear walls, or side walls) (front/rear walls, or side walls)

Multiple (2 Multiple (2- -3) levels, full interlace 3) levels, full interlace

(vertically aligned ports) (vertically aligned ports)

Rotary firing (swirling flow) Rotary firing (swirling flow)

4.5-5

Slide 17 describes the role of the tertiary air

in a recovery furnace. Reducing conditions

in the lower furnace improve smelt

reduction and reduce NO

x

emissions.

Oxidizing conditions in the upper furnace

reduce CO and TRS emissions and minimize

corrosion of furnace wall tubes.

Slide 17

The Role of Tertiary Air The Role of Tertiary Air

Tertiary air completes mixing and burning Tertiary air completes mixing and burning

of combustible gases (CO, H of combustible gases (CO, H

2 2

S, etc.) S, etc.)

Jet penetration to center of furnace needed Jet penetration to center of furnace needed

Large ports with high pressure air required Large ports with high pressure air required

Tertiary air is essential for staged Tertiary air is essential for staged

combustion combustion

Reducing conditions in lower furnace Reducing conditions in lower furnace

Oxidizing conditions in upper furnace Oxidizing conditions in upper furnace

Slide 18 shows two air nozzle arrangements

at the tertiary air level. The interlace pattern

here is a 4x3 configuration. This pattern, or

a 5x4 pattern, is typically used at the tertiary

level. The concentric tertiary air on the right

is a modification of a tangential pattern used

by one vendor; this produces rotating gas

flow in the upper furnace and is known to

cause and unbalanced flow and temperature

distribution entering the superheater. The

interlaced arrangement produces more

balanced conditions in the upper furnace.

Slide 18

Tertiary Air Arrangements Tertiary Air Arrangements

Interlaced Tertiary Air Interlaced Tertiary Air Concentric Tertiary Air Concentric Tertiary Air

Slide 19 lists several tertiary air port

arrangements that are commonly used in

recovery boilers.

Slide 19

Alternate Tertiary Air Arrangements Alternate Tertiary Air Arrangements

Single level, full interlace (front/rear walls) Single level, full interlace (front/rear walls)

Multiple (2 Multiple (2- -4) levels, full interlace 4) levels, full interlace

(vertically aligned ports) (vertically aligned ports)

Two separate levels, 10 to 20 feet apart Two separate levels, 10 to 20 feet apart

(upper most level (upper most level - - quaternary air) quaternary air)

Concentric tertiary air, or tangential Concentric tertiary air, or tangential

tertiary air (swirling flow) tertiary air (swirling flow)

Newer boiler designs and retrofits have

demonstrated certain advantages for more

than 3 levels of air, particularly for units

firing high solids liquor. As previously

mentioned, multiple air levels can be used to

supply secondary air, tertiary air, or both.

Slide 20 lists the advantages of multi-level

air systems and cautions that these designs

may promote combustion instability on the

char bed or corrosion in the upper furnace.

Slide 20

Multi Multi- -level Air Systems level Air Systems

Advantages of multi Advantages of multi- -level secondary and level secondary and

tertiary air systems tertiary air systems

Reduced fouling by carryover Reduced fouling by carryover

Better mixing and emissions control Better mixing and emissions control

Potential disadvantages Potential disadvantages

Difficult to control char bed combustion Difficult to control char bed combustion

at low at low- -medium solids medium solids

Accelerated corrosion by reducing gases Accelerated corrosion by reducing gases

reaching above composite tube line reaching above composite tube line

4.5-6

Slide 21 describes how an air system

arrangement is selected for a particular

boiler design and operation. Any one

combination of the previously described

arrangements may not work on all boilers.

Slide 21

Selecting An Arrangement Selecting An Arrangement

The best arrangement depends on The best arrangement depends on

furnace design, liquor properties, furnace design, liquor properties,

spray conditions, and firing rate spray conditions, and firing rate

Arrangement is optimized by CFD and Arrangement is optimized by CFD and

combustion modeling combustion modeling

Performance is demonstrated by field Performance is demonstrated by field

testing and operating experience testing and operating experience

Engineers must consider the boiler design,

liquor properties, spray conditions and firing

rate to determine the best arrangement.

CFD and combustion modeling of the

recovery furnace is the most common

approach to optimize the air system

arrangement. Field testing and operating

experience is the ultimately the most reliable

means to demonstrate air system

performance.

AIR SYSTEM PROBLEMS

Two of the problems encountered with

recovery boiler air systems are their

inflexibility once installed, and their need

for frequent port cleaning. This is described

in Slide 22.

Slide 22

Air System Operating Problems Air System Operating Problems

Air delivery systems are inflexible Air delivery systems are inflexible

P proportional to square of flow P proportional to square of flow

Limits recovery boiler turndown Limits recovery boiler turndown

Port velocity control dampers increase Port velocity control dampers increase

flexibility flexibility

Air ports need frequent cleaning Air ports need frequent cleaning

Automatic port rodders improve performance Automatic port rodders improve performance

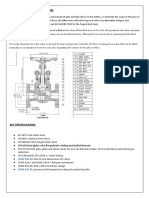

Slide 23 describes the two common types of

dampers. A louver damper can be used in

the air delivery duct to adjust the air flow

and pressure to the windbox that houses an

individual air port or a group of air ports.

The illustration in Slide 23 shows another

type of damper that is located immediately

upstream of the air port nozzle. The velocity

damper controls the nozzle area, and allows

higher velocity and pressure over a wider

range of total air flow rates. The velocity

damper increases the flexibility of the air

delivery system.

Slide 23

Air Port Dampers Air Port Dampers

Louver damper Louver damper

Adjusts flow rate Adjusts flow rate

pressure and velocity pressure and velocity

decrease with flow rate decrease with flow rate

Velocity damper Velocity damper

Adjusts air port nozzle Adjusts air port nozzle

area and flow rate area and flow rate

Maintains higher pressure Maintains higher pressure

and velocity and velocity

Velocity Damper

Velocity Damper

Slide 24 shows an automatic port cleaning

system. The black liquor char and inorganic

salts cause deposits on the walls of the lower

furnace. The air ports can become

constricted or clogged with deposits and

4.5-7

must be cleaned periodically. The traditional

method is hand rodding of the ports. The

diagram in Slide 24 illustrates one of several

designs for cleaning the ports automatically.

Slide 24

Automatic Port Cleaning Automatic Port Cleaning

E

x

te

n

d

e

d

E

x

te

n

d

e

d

R

e

t

r

a

c

t

e

d

There are several other potential design

problems with recovery boiler air systems.

These are described in Slide 25.

Slide 25

Air System Design Problems Air System Design Problems

Insufficient fan capacity for increased loads Insufficient fan capacity for increased loads

Duct size, length, and bends can limit flow Duct size, length, and bends can limit flow

Duct flow is not always uniform Duct flow is not always uniform

Duct arrangement can affect nozzle flow Duct arrangement can affect nozzle flow

Boiler supports limit duct/nozzle placement Boiler supports limit duct/nozzle placement

Slide 26 shows one example of the type of

problem that can be encountered in air duct

and air nozzle design. In this case, the

nozzle in the top of the slide is not being fed

uniformly. This causes improper air flow

through the nozzle and therefore poor

furnace operation. The lower nozzle

arrangement shows an inexpensive

modification used to solve this problem.

Slide 26

Windbox Windbox

Flow Problems Flow Problems

Isolation Damper Isolation Damper

Air Port Opening Air Port Opening

Before Modification Before Modification

After Modification After Modification

Flow problems can also be generated by

other equipment in the delivery ducts. The

velocity vectors in Slide 27 show the very

non-uniform flow pattern that is generated

by one type of damper arrangement. If this

damper were near an elbow or nozzle, air

delivery could be very non-uniform and

intermittent.

Slide 27

Damper Flow Problems Damper Flow Problems

Slide 28 shows 4-wall and 2-wall secondary

air arrangements with significant jet

interference. The air jets cannot traverse the

furnace without crashing into opposing jets,

and being deflected away from a path of free

penetration. For the two-wall secondary air

arrangement, the air nozzles are too tightly

spaced for the jets to expand and form an

effective interlace.

4.5-8

Slide 28

4 4- -wall Secondary wall Secondary

Air Arrangement Air Arrangement

Jet Interference Jet Interference

2 2- -wall Secondary wall Secondary

Air Arrangement Air Arrangement

Interference

Inter-

ference

Gas flow channeling is shown in Slide 29,

which is the result of significant jet

interference at the secondary or tertiary

levels. A plume of high upward velocity is

formed which travels up the furnace, with

gas recirculation along the walls. This

channel is usually not steady, and can move

around between the center and any of the

corners depending on slight differences in

flow and pressure on each wall of the

furnace.

Slide 29

Gas Flow Gas Flow

Channeling Channeling

Ai r Nozzles

Char bed

Gas

Recirculation

High

Velocity

Plume

Gas flow channeling can result in severe

carryover fouling in the upper furnace and

insufficient gas mixing to destroy TRS gases

that are released in the lower furnace

reducing zone.

SUMMARY

Slides 30 and 31 summarize the main points

from this introduction to recovery boiler air

system design and operation.

Slide 30

Implications for RB Air Systems Implications for RB Air Systems

Total quantity of air is most important Total quantity of air is most important

Impacts thermal efficiency, reduction, emissions Impacts thermal efficiency, reduction, emissions

Vertical distribution and pressure are next Vertical distribution and pressure are next

Impacts char bed stability, carryover, emissions Impacts char bed stability, carryover, emissions

Air nozzle arrangement is third Air nozzle arrangement is third

Impacts channeling, carryover, temperature Impacts channeling, carryover, temperature

distribution into superheater, emissions distribution into superheater, emissions

Slide 31

Implications for RB Air Systems Implications for RB Air Systems

Recovery boiler air systems can limit Recovery boiler air systems can limit

firing capacity and performance firing capacity and performance

Velocity dampers increase flexibility Velocity dampers increase flexibility

Variations in firing conditions and firing rate Variations in firing conditions and firing rate

Fine tuning possible Fine tuning possible

Ports require frequent cleaning for good Ports require frequent cleaning for good

operation of recovery boiler operation of recovery boiler

FURTHER READING

Adams, T. N., General Characteristics of

Kraft Black Liquor Recovery Boilers,

Chapter 1 of Kraft Recovery Boilers,

Adams, T. N., Ed., TAPPI Press, Atlanta,

GA, pp. 1-38 (1997).

J ones, A. K., Recovery Boiler Air Supply

and Gas Flows, Chapter 7 of Kraft Recovery

Boilers, Adams, T. N., Ed., TAPPI Press,

Atlanta, GA, pp. 181-214 (1997).

Das könnte Ihnen auch gefallen

- Volvo 1998 V70 S70 C70 Parts-CatalogueDokument1.176 SeitenVolvo 1998 V70 S70 C70 Parts-CatalogueEero Aho88% (16)

- Safety Valve Setting BoilerDokument2 SeitenSafety Valve Setting BoilerkrishnaNoch keine Bewertungen

- Ic Engine Varable Valve Timing and Lift Control System Assignment 1 Bsme0116303 Section BDokument32 SeitenIc Engine Varable Valve Timing and Lift Control System Assignment 1 Bsme0116303 Section BAbdullah Khan100% (1)

- Asme B16.5Dokument11 SeitenAsme B16.5jacquesmayol100% (1)

- Boe Exam Paper Feb 2012Dokument9 SeitenBoe Exam Paper Feb 2012saurabhshineNoch keine Bewertungen

- Globe Valve Bs 1873 and Api 602: ASME B16.10Dokument7 SeitenGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNoch keine Bewertungen

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDokument7 SeitenIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNoch keine Bewertungen

- Why Air Vent Should Be Closed Maintaining 2kg/cm 2 Drum Level Pressure at Starting of Boiler Operation?Dokument2 SeitenWhy Air Vent Should Be Closed Maintaining 2kg/cm 2 Drum Level Pressure at Starting of Boiler Operation?Ashish KapoorNoch keine Bewertungen

- Boiler Questions BtechDokument5 SeitenBoiler Questions BtechRishav Raj100% (1)

- Mill Reject SystemDokument22 SeitenMill Reject SystemgangatharanNoch keine Bewertungen

- Boiler Emergencies - 2017Dokument10 SeitenBoiler Emergencies - 2017RAJKUMAR100% (1)

- Afbc Boiler Light Up ProcedureDokument4 SeitenAfbc Boiler Light Up ProcedurepurvgargNoch keine Bewertungen

- A Diagnostic Study in A Husk Fired Boiler For A Power PlantDokument44 SeitenA Diagnostic Study in A Husk Fired Boiler For A Power Plantparthi20065768Noch keine Bewertungen

- Furnace or Fired Heater 3Dokument13 SeitenFurnace or Fired Heater 3Nia Syafiqq100% (1)

- Coc Oral Exam Preparation (Part - 17) : Boiler Safety ValveDokument3 SeitenCoc Oral Exam Preparation (Part - 17) : Boiler Safety ValveshashankrawatNoch keine Bewertungen

- Inspections and Survey Procedures in Auxiliary BoilerDokument16 SeitenInspections and Survey Procedures in Auxiliary BoilerkrishnaNoch keine Bewertungen

- Top 50 Boiler Information Booster Question Answers - ASKPOWERPLANTDokument19 SeitenTop 50 Boiler Information Booster Question Answers - ASKPOWERPLANTRaju MaityNoch keine Bewertungen

- IR CFBC Cold Start Up ProcedureDokument15 SeitenIR CFBC Cold Start Up ProcedureJose Angie CabreraNoch keine Bewertungen

- Boiler Water TreatmentDokument38 SeitenBoiler Water TreatmentMahmoud MahmoudmNoch keine Bewertungen

- C&I in CFBC-1Dokument25 SeitenC&I in CFBC-1Prudhvi RajNoch keine Bewertungen

- Boiler Start-Up & Shut-DownDokument42 SeitenBoiler Start-Up & Shut-DownBurhan Khan100% (1)

- Types and Functions, Constructional Details,: Air Pre HeatersDokument77 SeitenTypes and Functions, Constructional Details,: Air Pre HeatersBala VigneshNoch keine Bewertungen

- User Requirement SpecificationDokument14 SeitenUser Requirement SpecificationDoan Chi Thien86% (7)

- Failure of Boiler Tubes Due To EROSIONDokument9 SeitenFailure of Boiler Tubes Due To EROSIONShiVa20155244Noch keine Bewertungen

- 2.1 Boiler Surveys (2013)Dokument58 Seiten2.1 Boiler Surveys (2013)Diegos44Noch keine Bewertungen

- Boiler Question and AnswersDokument9 SeitenBoiler Question and AnswersAnup JhaNoch keine Bewertungen

- 34 - 244Dokument208 Seiten34 - 244rohithunni100% (1)

- MotorDokument48 SeitenMotorHernan CuevasNoch keine Bewertungen

- Boiler Operation EngineerDokument10 SeitenBoiler Operation EngineerSarah Frazier100% (2)

- Troubleshooting Boiler OperationDokument5 SeitenTroubleshooting Boiler OperationRahul ChandrawarNoch keine Bewertungen

- "Boiler Tube Failures": Project ReportDokument30 Seiten"Boiler Tube Failures": Project ReportmdjanNoch keine Bewertungen

- Boiler Light UpDokument19 SeitenBoiler Light Upabbutalibb5407100% (1)

- Boiler Efficient, Safe & Emergency OperationDokument51 SeitenBoiler Efficient, Safe & Emergency OperationShambhu MehtaNoch keine Bewertungen

- Presentation On Steam Turbine Operation by S ChandDokument36 SeitenPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- Boiler Protection AND InterlocksDokument54 SeitenBoiler Protection AND InterlocksSarah Frazier100% (1)

- Flue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1Dokument56 SeitenFlue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1ASHIL PRABHAKARNoch keine Bewertungen

- Phase II Boiler QuestionsDokument12 SeitenPhase II Boiler QuestionsNithin VargheseNoch keine Bewertungen

- FURNACE Operations Rev2Dokument41 SeitenFURNACE Operations Rev2Lakhvinder Singh100% (8)

- Boiler License Exam GuideDokument45 SeitenBoiler License Exam GuideAhmed GomaaNoch keine Bewertungen

- Double Mechanical Seals, Tandem ArrangementDokument10 SeitenDouble Mechanical Seals, Tandem ArrangementViwek MertiyaNoch keine Bewertungen

- Optimize Fired Heater Operations To Save MoneyDokument8 SeitenOptimize Fired Heater Operations To Save Moneyyogitadoda100% (2)

- Forced Draft Fan: by Justice. A. OfugaraDokument37 SeitenForced Draft Fan: by Justice. A. OfugaraobisonandlawNoch keine Bewertungen

- Ferrocare LVDH Oil Cleaning MachineDokument2 SeitenFerrocare LVDH Oil Cleaning Machinessheart_mindNoch keine Bewertungen

- CFBC & PFBC TechnologyDokument18 SeitenCFBC & PFBC TechnologyomiitgNoch keine Bewertungen

- Smart Soot Blower SystemDokument8 SeitenSmart Soot Blower SystemidigitiNoch keine Bewertungen

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDokument10 SeitenEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNoch keine Bewertungen

- The Indian Boilers Act 1923Dokument16 SeitenThe Indian Boilers Act 1923Anand Swami100% (1)

- MH BOE 2014 Paper 1 SolutionDokument15 SeitenMH BOE 2014 Paper 1 SolutionPratima MondalNoch keine Bewertungen

- Boiler Startup and Shutdown ProcedureDokument57 SeitenBoiler Startup and Shutdown Procedurea.jainNoch keine Bewertungen

- Water QualityDokument21 SeitenWater QualityLakshmi NarayanNoch keine Bewertungen

- Drum Level CompensationDokument8 SeitenDrum Level CompensationSmriti PrasadNoch keine Bewertungen

- Flue Gas AnalysisDokument12 SeitenFlue Gas AnalysisMadhavanIceNoch keine Bewertungen

- Pump Manual - Single Plunger AmbicaDokument24 SeitenPump Manual - Single Plunger AmbicaHimTex /JaswinderNoch keine Bewertungen

- Boiler Inspector TRAINING - 2021Dokument8 SeitenBoiler Inspector TRAINING - 2021SUNIL BABURAO GAVADENoch keine Bewertungen

- MH BOE 2016 Paper 2 SolutionDokument9 SeitenMH BOE 2016 Paper 2 SolutionKamleshNoch keine Bewertungen

- CBD IbdDokument2 SeitenCBD Ibdpremk20100% (5)

- Cheema Boiler Limited: Presented To: MR - Deepak Bhandari (Dokument32 SeitenCheema Boiler Limited: Presented To: MR - Deepak Bhandari (angenious100% (1)

- BOE Exam (Enginering Drawing Symbols) : IBCI (Indian Best Coaching Institute)Dokument11 SeitenBOE Exam (Enginering Drawing Symbols) : IBCI (Indian Best Coaching Institute)gangarao0% (1)

- AFBC Boiler Cold Start-Up ProcedureDokument3 SeitenAFBC Boiler Cold Start-Up ProcedurekiranNoch keine Bewertungen

- Daily Maintenance BoilerDokument3 SeitenDaily Maintenance BoilerAppleuk SudarNoch keine Bewertungen

- Recovery Boiler Air Systems - Rick Wessel, PH.DDokument16 SeitenRecovery Boiler Air Systems - Rick Wessel, PH.Dsony setyawanNoch keine Bewertungen

- Components of HVAC Systems: Indoor Fan (Blower)Dokument17 SeitenComponents of HVAC Systems: Indoor Fan (Blower)monoj5859Noch keine Bewertungen

- Module 5 CombustorDokument11 SeitenModule 5 CombustorKevin MangroliyaNoch keine Bewertungen

- Third Class SampleDokument40 SeitenThird Class Sampleshanmugam17Noch keine Bewertungen

- 4.1.10,11 Draft SystemDokument3 Seiten4.1.10,11 Draft SystemSergio IvánNoch keine Bewertungen

- Air Breathing Propulsion Unit-2Dokument54 SeitenAir Breathing Propulsion Unit-2api-271354682Noch keine Bewertungen

- 2022-2 Spindle MultiphyicsDokument81 Seiten2022-2 Spindle Multiphyics潘季宏Noch keine Bewertungen

- AISC SCM2013 - Designexample Chapter H Design of Members For Combined Forces and TorsionDokument30 SeitenAISC SCM2013 - Designexample Chapter H Design of Members For Combined Forces and TorsionriodejaneiryeoNoch keine Bewertungen

- Aerator PremiumDokument10 SeitenAerator PremiumvijaykumarnNoch keine Bewertungen

- Statics of Rigid Bodies: Chapter 3: Equilibrium of A ParticleDokument23 SeitenStatics of Rigid Bodies: Chapter 3: Equilibrium of A ParticleRyan Philip CatapangNoch keine Bewertungen

- Adps 08 2 N CDokument1 SeiteAdps 08 2 N CmaximilianoNoch keine Bewertungen

- MaxiTrip Manual V1.02Dokument27 SeitenMaxiTrip Manual V1.02xuzebinNoch keine Bewertungen

- Muhammad Hanif Hidayat - 33120016 - LT2A - English Script PresentationDokument2 SeitenMuhammad Hanif Hidayat - 33120016 - LT2A - English Script PresentationMuhammad Hanif HidayatNoch keine Bewertungen

- Plano Explosivo & Partes y Piezas Wmf-m160gbDokument18 SeitenPlano Explosivo & Partes y Piezas Wmf-m160gbCatalina GonzalezNoch keine Bewertungen

- NJIT Module-Liquid Mixing Fundamentals-ArmenanteDokument233 SeitenNJIT Module-Liquid Mixing Fundamentals-Armenanteacas35Noch keine Bewertungen

- Novalt16: Setting A New Standard For 16 MW Class Turbines in Mechanical Drive and Power Generation ApplicationsDokument8 SeitenNovalt16: Setting A New Standard For 16 MW Class Turbines in Mechanical Drive and Power Generation ApplicationsDan PascaruNoch keine Bewertungen

- Home Work 17 SolutionsDokument6 SeitenHome Work 17 Solutions洪健勛Noch keine Bewertungen

- Stress Analysis and Creep Life Prediction of Hydrogen Reformer Furnace TubeDokument14 SeitenStress Analysis and Creep Life Prediction of Hydrogen Reformer Furnace TubeVijay KadliNoch keine Bewertungen

- Regulador AxialDokument12 SeitenRegulador Axialluis_d_mNoch keine Bewertungen

- Force & Laws of Motion Numericals SolutionDokument10 SeitenForce & Laws of Motion Numericals SolutionViji GowriNoch keine Bewertungen

- Kyko Fan Stirling JDW CompletDokument3 SeitenKyko Fan Stirling JDW CompletNam Hoang50% (2)

- 1st Quarter - SCIENCE 8-WEEK 1-2Dokument6 Seiten1st Quarter - SCIENCE 8-WEEK 1-2MICAH NORADANoch keine Bewertungen

- Parafusos Com Gargantachapter 3Dokument7 SeitenParafusos Com Gargantachapter 3Miguel QueirosNoch keine Bewertungen

- Analysis and Design of Prestressed Deck Slab Bridge With IRC 112-2011Dokument6 SeitenAnalysis and Design of Prestressed Deck Slab Bridge With IRC 112-2011Anonymous b9fkTYfEoRNoch keine Bewertungen

- Research: John W. HutchinsonDokument25 SeitenResearch: John W. HutchinsonskcNoch keine Bewertungen

- Part 4 Mesin FluidaDokument23 SeitenPart 4 Mesin FluidaARFAI020797Noch keine Bewertungen

- Modeling An Air-Cooled Gas Turbine of The Integrated Gasification Combined Cycle in Aspen PlusDokument6 SeitenModeling An Air-Cooled Gas Turbine of The Integrated Gasification Combined Cycle in Aspen Plusdafer_daniNoch keine Bewertungen

- B-191 Operationmanual en A LowresDokument28 SeitenB-191 Operationmanual en A LowresDinhtrung TruongNoch keine Bewertungen

- Wood's Powr-Grip Guide To Maintenance, Troubleshooting, and RepairDokument4 SeitenWood's Powr-Grip Guide To Maintenance, Troubleshooting, and Repairkamikadze7Noch keine Bewertungen