Beruflich Dokumente

Kultur Dokumente

Chapter 3 - Reinforced Concrete

Hochgeladen von

EmanEr0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

322 Ansichten15 SeitenThis document discusses reinforced concrete and steel reinforcement. It begins by defining reinforced concrete as concrete in which steel is embedded to improve tensile strength. The document then covers the basic concepts of reinforced concrete, its use in construction, and the properties of reinforced concrete. Next, it discusses the characteristics, types and properties of steel reinforcement. It concludes by comparing the properties of concrete and steel and how they work together in reinforced concrete, including their roles in resisting tension, compression and shear forces.

Originalbeschreibung:

file

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document discusses reinforced concrete and steel reinforcement. It begins by defining reinforced concrete as concrete in which steel is embedded to improve tensile strength. The document then covers the basic concepts of reinforced concrete, its use in construction, and the properties of reinforced concrete. Next, it discusses the characteristics, types and properties of steel reinforcement. It concludes by comparing the properties of concrete and steel and how they work together in reinforced concrete, including their roles in resisting tension, compression and shear forces.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

322 Ansichten15 SeitenChapter 3 - Reinforced Concrete

Hochgeladen von

EmanErThis document discusses reinforced concrete and steel reinforcement. It begins by defining reinforced concrete as concrete in which steel is embedded to improve tensile strength. The document then covers the basic concepts of reinforced concrete, its use in construction, and the properties of reinforced concrete. Next, it discusses the characteristics, types and properties of steel reinforcement. It concludes by comparing the properties of concrete and steel and how they work together in reinforced concrete, including their roles in resisting tension, compression and shear forces.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 15

IN THIS TOPIC, THE STUDENTS WILL LEARN:

1) THE CHARACTERISTICS OF REINFORCED CONCRETE.

2) THE BASIC KNOWLEDGE OF STEEL

REINFORCEMENT.

3) THE DIFFERENCES BETWEEN CONCRETE AND STEEL.

3.1 BASIC CONCEPT OF REINFORCED

CONCRETE

3.1.1 DEFINE THE REINFORCED CONCRETE

1) Concrete in which steel is embedded in such a manner that the two materials

act together in resisting forces.

2) The reinforcing steelrods, bars, or meshabsorbs the tensile, shear, and

sometimes the compressive stresses in a concrete structure.

3) Plain concrete does not easily withstand tensile and shear stresses caused by

wind, earthquakes, vibrations, and other forces and is therefore unsuitable in

most structural applications.

4) Concrete is strong in compression, but weak in tension, thus adding

reinforcement increases the strength in tension.

5) In reinforced concrete, the tensile strength of steel and the compressive

strength of concrete work together to allow the member to sustain these

stresses over considerable spans.

6) In addition, the failure strain of concrete in tension is so low that the

reinforcement has to hold the cracked sections together.

3.1.2 REINFORCED CONCRETE USED IN CONSTRUCTION

1) Concrete is reinforced to give it extra tensile strength; without reinforcement,

many concrete buildings would not have been possible.

2) Reinforced concrete can encompass many types of structures and components,

including slabs, walls, beams, columns, foundations, frames and more.

3) Reinforced concrete can be classified as precast or cast in-situ concrete.

4) Much of the focus on reinforcing concrete is placed on floor systems.

5) Designing and implementing the most efficient floor system is key to creating

optimal building structures.

6) Small changes in the design of a floor system can have significant impact on

material costs, construction schedule, ultimate strength, operating costs,

occupancy levels and end use of a building.

3.1.3 PROPERTIES OF REINFORCED CONCRETE

1) Reinforced concrete structures are typified by their strength, beauty, bulk and

longevity.

2) It is the material of choice for many structures where these characteristics are

required.

3) For a strong, ductile and durable construction the reinforcement shall have the

following properties:

High strength.

High tensile strain.

Good bond to the concrete.

Thermal compatibility.

Durability in the concrete environment.

In most cases reinforced concrete uses steel rebars that have been inserted

to add strength.

1) :

4) However, reinforced concrete structures have several shortcomings which may

preclude it as a building material, including:

a) It needs mixing, casting and curing, all of which affect the final strength of

concrete.

b) The cost of the forms used to cast concrete is relatively high.

c) It has low compressive strength as compared to steel (the ratio is about 1:10

depending on material) which leads to large sections in columns/beams of

multistory buildings cracks develop in concrete due to shrinkage and the

application of live loads.

3.2 STEEL REINFORCEMENT

3.2.1 INTRODUCTION

1. A rebar (short for reinforcing bar), also known as reinforcing steel, reinforcement steel, or

a deformed bar, is a common steel bar, and is commonly used as a tensioning device in

reinforced concrete and reinforced masonry structures holding the concrete in

compression.

2. It is usually formed from carbon steel, and is given ridges for better mechanical anchoring

into the concrete.

3. Concrete is very strong in compression, but has almost no strength in tension. To

compensate for this inequity in concrete's behavior, rebar steel are placed into it to

support the heavy loads.

4. Masonry structures and the mortar holding them together have close to the properties of

concrete, and as well have a limited ability to carry a tensile load.

5. Some masonry blocks and bricks are made with strategically placed spaces to allow for

rebar steel, which is then grouted into place. This is what is known as reinforced masonry.

3.2.2 CHARACTERISTIC OF STEEL REINFORCEMENT

1. Rebar steel have a series of ridges that bind it automatically to the concrete with

friction, but it can still be pulled out of the concrete with enough force, an

occurrence that often comes before a collapse of the building.

2. To prevent such a failure, rebar is either deeply inserted into surrounding structural

areas, or bent and hooked at the ends which locks it around the rebars and concrete.

3. Rebar steel that are made of unfinished steel make it easy to rust.

4. Rust causes very harsh internal pressure on the surrounding concrete, leading to

cracking, splintering and finally structural failure.

5. This is a noticeable problem where the concrete is exposed to salt water, or in bridges

built in areas where roadways are salted in winter, or in marine applications.

6. Stainless steel rebar may be used in these occurrences at greater initial cost, but

drastically lowers the cost for the servicing life of the project.

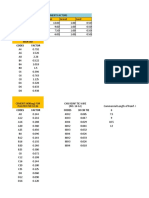

3.2.3 TYPES OF STEEL REINFORCEMENT

1. Reinforcing bars are produced in three (3) grades:

a) Hot Rolled Mild Steel which have a yield strength by 250 N/mm

2

.

b) Hot Rolled High Yield Steel have a yield strength by 460 N/mm

2

.

c) Cold Worked High Yield Steel have a yield strength by 460 N/mm

2

.

2. Hot-rolled mild steel usually has a smooth surface. Therefore, this type of steel is bent

easily and requires a small radius. For example, wire bonding steel poles or small logs.

3. Hot rolled high yield steel is steel with a carbon content of more than mild steel. It is

manufactured with a rough surface that overlap.

4. Cold Worked High Yield Steel have overlapping surface-shaped spindles, also known as

"deformed bar..

5. Bar for reinforcement are available with diameters of 6, 8, 10, 12, 16, 20, 25, 35 and 40

mm.

6. Type of steel reinforcement are indicated by the code R for mild steel and Y for the high

yield steel.

3.2.3 PROPERTIES OF STEEL REINFORCEMENT

1. All reinforcement shall be clean and free from rust, oil, grease, paint or layers of other

steel before it is placed in the concrete.

2. Reinforcement used should be compatible with the latest British Standard (BS)

specification for the design of the structure.

3. The reinforcement should not be heated or burned.

4. All the reinforcement defects such as bent, twisted, cracked and others, if they are in need

of repair, shall be made in cold condition.

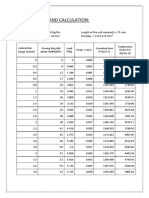

3.2.3.1 MINIMUM DISTANCE BETWEEN STEEL BARS

1. Reinforcement distance in structural members is important because if too close, it is

difficult for the compression work to be done.

2. Cause of that, the required concrete strength is not reached.

3. If the distance too long, the possibility of shear failure will occur.

4. Therefore, practical codes in CP 110 have suggested the following:

a) Individual Bar Horizontal distances not less than H

agg

= maximum aggregate size.

b) Pairs Bar Horizontal distances not less than H

agg

+ 5 mm. Vertical

distances not less than 2/3 H

agg

. If the bar is paired side by side, the vertical

distance must be not less than H

agg

+ 5 mm.

c) A Group of Bar Horizontal and vertical distances not less than H

agg

+ 15

mm.

3.2.4 ADVANTAGES OF STEEL REINFORCEMENT

a) Steel reinforcement is easy to place.

b) It minimizes random cracking.

c) Curling and displacement can be minimized with steel reinforced concrete.

d) Steel reinforcement reduces and controls crack width.

e) It can increases reserve strength of concrete slab up to 16 %.

f) Steel reinforcement saves costs over lifespan of the concrete slab.

3.3 DIFFERENCES STEEL & CONCRETE

3.3.1 COMPARISON BETWEEN STEEL AND CONCRETE

Tensile Tegangan.

Compression Mampatan.

Shear Ricihan.

PROPERTIES CONCRETE STEEL

Tensile Strength WEAK GOOD

Compression

Strength

GOOD BETTER

(Slender Steel will Bend & Loose)

Shear Strength AVERAGE GOOD

Durability GOOD WILL CORRODE IF NOT PROTECTED

Fire Resistant GOOD WEEK

(To Lose Strength Rapidly at High Temperature)

3.3.2 THE REINFORCEMENT USED DUE TO TENSION & COMPRESSION FORCE

1) If the load is applied in the center

of plane, bending will occurs.

2) When bending occurs, the surface

of the plane is compress due to

the COMPRESSION FORCE

and the bottom is a state of

stretcher caused by TENSION

FORCES.

3) Max. force is occurred in the arch

bottom of bending surface.

4) If plane is made without the

rebar, it will crack and

eventually collapse.

5) Adding the rebar at bottom plane

can prevent the plane from

collapse.

3.3.3 THE REINFORCEMENT USED DUE TO SHEAR FORCES

A shear load is a force that tends to produce a

sliding failure on a material along a plane that is

parallel to the direction of the force.

Shear strength of a plane is held in a plane that is

connected between the compression force of

concrete & steel tension force.

One way to overcome this shear is inclined to the

steel rebar to the right angle (90) of the crack.

Rebar in the longitudinal plane is to withstand

bending and to resist shear especially if it is

combined with metal fasteners (see Figure A)

The most effective method to overcome this

problem is to have a 45 bend bar across the

plane which crack is expected to grow.

3.3.3.1 CANTILEVER BEAM (BALAK JULUR)

3.3.3.2 SIMPLY SUPPORTED BEAM (BALAK TERIKAT)

A cantilever is a beam supported on only one

end. The beam carries the load to the

support where it is resisted by compression

and tension stresses.

Simply supported is beam that supported on

both ends. Normally, reinforcement is

provided in the compression & tension zone.

A, C and E have a tensile stress.

B, D and M has a compressive stress.

3.3.3.3 CONTINUOUS BEAM (BALAK SELANJAR)

i. A continuous beam is a structural component that provides resistance to bending

when a load or force is applied.

ii. These beams are commonly used in bridges.

iii. A continuous beam has more than two points of support along its length.

iv. These are usually in the same horizontal plane, and the spans between the

supports are in one straight line.

Das könnte Ihnen auch gefallen

- Drainage Criteria Handbook Swan April 2022Dokument58 SeitenDrainage Criteria Handbook Swan April 2022Noriel GarciaNoch keine Bewertungen

- Learning Level-1,2: Development of Building FormsDokument33 SeitenLearning Level-1,2: Development of Building FormsSaad HafeezNoch keine Bewertungen

- Example of Mix DesignDokument3 SeitenExample of Mix DesignRam Narendra Nath100% (1)

- Calculating Labour, Plant & Unit RatesDokument13 SeitenCalculating Labour, Plant & Unit RatesKarl AttardNoch keine Bewertungen

- QUANT Sis BunmiiiiiDokument20 SeitenQUANT Sis BunmiiiiinaconnetNoch keine Bewertungen

- CIE 332: Measuring Building & Civil WorksDokument40 SeitenCIE 332: Measuring Building & Civil WorkskingNoch keine Bewertungen

- Finsih BOQDokument15 SeitenFinsih BOQAfrath_nNoch keine Bewertungen

- Quantity Survey & Estimation: Engr. Shad MuhammadDokument50 SeitenQuantity Survey & Estimation: Engr. Shad MuhammadOsama AnjumNoch keine Bewertungen

- Near East University: Electrical Installation Design EE400Dokument167 SeitenNear East University: Electrical Installation Design EE400Cristian JaramilloNoch keine Bewertungen

- The Standard Method of MeasurementDokument99 SeitenThe Standard Method of MeasurementCharles NdunguNoch keine Bewertungen

- Civil Works Cost Estimating GuidanceDokument6 SeitenCivil Works Cost Estimating GuidancebharathaninNoch keine Bewertungen

- Journal 5cd1743c69584 PDFDokument14 SeitenJournal 5cd1743c69584 PDFMis A MilliNoch keine Bewertungen

- Financials 2008Dokument5 SeitenFinancials 2008Joyce PascuaNoch keine Bewertungen

- Final 3Dokument10 SeitenFinal 3Om BankarNoch keine Bewertungen

- Gantt-Chart O365 LDokument8 SeitenGantt-Chart O365 LAngie GuerreroNoch keine Bewertungen

- Unit 1 Estimation and ValuationDokument42 SeitenUnit 1 Estimation and ValuationPrashant Mani PaudelNoch keine Bewertungen

- EP 1110 1 8 - Vol - 02Dokument540 SeitenEP 1110 1 8 - Vol - 02aryesNoch keine Bewertungen

- Small Buildings Structural GuidanceDokument85 SeitenSmall Buildings Structural GuidanceMihnea CostacheNoch keine Bewertungen

- Embankment Calculation Using C3DDokument25 SeitenEmbankment Calculation Using C3DPriyeshBabarNoch keine Bewertungen

- PV-Technology CourseDokument32 SeitenPV-Technology Courseokollo johanNoch keine Bewertungen

- Failures Due To ShearDokument70 SeitenFailures Due To ShearEr Saurabh Shah100% (1)

- Spreadsheet Modelling Full SmallDokument67 SeitenSpreadsheet Modelling Full Smallskshimla1Noch keine Bewertungen

- Boq Format For Residential BuildingDokument45 SeitenBoq Format For Residential BuildingitsmimigamingNoch keine Bewertungen

- Formula Geometric Sequence: F I N F P F N I F P A PDokument24 SeitenFormula Geometric Sequence: F I N F P F N I F P A PMabrook SattarNoch keine Bewertungen

- CH 3 Quantity Surveying 23 Vs Ex DraftDokument50 SeitenCH 3 Quantity Surveying 23 Vs Ex DraftRobel WendwesenNoch keine Bewertungen

- Storm Water Drainage GuidelinesDokument16 SeitenStorm Water Drainage GuidelinesSeeni GovindNoch keine Bewertungen

- Engineering Fundamentals Laboratory: ME 372 Word Processing NoteDokument46 SeitenEngineering Fundamentals Laboratory: ME 372 Word Processing NoteOmar SaleemNoch keine Bewertungen

- Lecture 4-Concrete WorksDokument24 SeitenLecture 4-Concrete WorksSyakir SulaimanNoch keine Bewertungen

- HB 2.2-2003 Australian Standards For Civil Engineering Students Structural EngineeringDokument8 SeitenHB 2.2-2003 Australian Standards For Civil Engineering Students Structural EngineeringSAI Global - APACNoch keine Bewertungen

- Excel ReportDokument31 SeitenExcel ReportHari PrakashNoch keine Bewertungen

- Sanitary Rate Analysis 2020Dokument26 SeitenSanitary Rate Analysis 2020Harsshal WankedeNoch keine Bewertungen

- Unconfined Compression Test On Soil Stabilisation With Lime: Fig. Shear Stress Failure PlaneDokument7 SeitenUnconfined Compression Test On Soil Stabilisation With Lime: Fig. Shear Stress Failure PlaneAnonymous X3aejJNoch keine Bewertungen

- MSExcel 101Dokument12 SeitenMSExcel 101DaveNoch keine Bewertungen

- Compressive Strength TestDokument2 SeitenCompressive Strength TestUltimate BoyNoch keine Bewertungen

- An Assignment On Microsoft Excel PDFDokument10 SeitenAn Assignment On Microsoft Excel PDFRoger PrimoNoch keine Bewertungen

- Using Spreadsheets, Selection Sets, and COGO ControlsDokument19 SeitenUsing Spreadsheets, Selection Sets, and COGO ControlsipcNoch keine Bewertungen

- 4ar8 - STD - Pa1 - Alomia, Gabriel PDFDokument4 Seiten4ar8 - STD - Pa1 - Alomia, Gabriel PDFGABRIEL ANGELO ALOMIANoch keine Bewertungen

- Reinforcement DetailsDokument18 SeitenReinforcement Detailsmoussa66Noch keine Bewertungen

- Solar Panel Experiment Tests Power Flow and EfficiencyDokument45 SeitenSolar Panel Experiment Tests Power Flow and Efficiencyfiraol kasahunNoch keine Bewertungen

- Units and Unit Conversions Important For ENES 100Dokument4 SeitenUnits and Unit Conversions Important For ENES 100haseebriaz383Noch keine Bewertungen

- Quantity EstimateDokument59 SeitenQuantity EstimateJohn Christopher JusayanNoch keine Bewertungen

- PMBOK 5th Edition, Chapter 7Dokument42 SeitenPMBOK 5th Edition, Chapter 7mhdstatNoch keine Bewertungen

- Creating and Editing Shapefiles in ArcMapDokument4 SeitenCreating and Editing Shapefiles in ArcMapFernando PizarroNoch keine Bewertungen

- Hec-Ras River Analysis System: User's ManualDokument0 SeitenHec-Ras River Analysis System: User's ManualSocrates Palomino GamboaNoch keine Bewertungen

- Modelling With SpreadsheetsDokument6 SeitenModelling With SpreadsheetsGiacomoNoch keine Bewertungen

- ThesisDokument104 SeitenThesisKastur ChakrabortyNoch keine Bewertungen

- Bid Prices: Items of Work Quantity Unit Materials Labor Unit Cost Amount Unit CostDokument17 SeitenBid Prices: Items of Work Quantity Unit Materials Labor Unit Cost Amount Unit CostCarlo FloresNoch keine Bewertungen

- Thesis Software Development PDFDokument92 SeitenThesis Software Development PDFMr ProfessorNoch keine Bewertungen

- TLO3 REINFORCING BARS NNNNDokument26 SeitenTLO3 REINFORCING BARS NNNNBilly Joe Breakfast TalaugonNoch keine Bewertungen

- What is the Critical Path Method (CPMDokument8 SeitenWhat is the Critical Path Method (CPMKhafid Nur IkhsanNoch keine Bewertungen

- Pengujian Unconfined Compression TestDokument2 SeitenPengujian Unconfined Compression Testuven sanjayNoch keine Bewertungen

- CIV 413 Structural Steel Design LectureDokument61 SeitenCIV 413 Structural Steel Design LectureحمدةالنهديةNoch keine Bewertungen

- ACI (Absolute Volume) MethodDokument5 SeitenACI (Absolute Volume) Methodjyothis_joy77Noch keine Bewertungen

- Repaire and RectifyDokument13 SeitenRepaire and RectifyDawit Awash100% (3)

- Quantity Surveying: Chapetr - 4Dokument25 SeitenQuantity Surveying: Chapetr - 4Dani JuraNoch keine Bewertungen

- Creating A Lookup Table: (Includes Excel VLOOKUP Example File)Dokument64 SeitenCreating A Lookup Table: (Includes Excel VLOOKUP Example File)leslieDulleNoch keine Bewertungen

- Group 2 Structural and Construction Engineering Management Report Day 1Dokument57 SeitenGroup 2 Structural and Construction Engineering Management Report Day 12ne1 BlackjackNoch keine Bewertungen

- Topic 3Dokument25 SeitenTopic 35p6zzgj4w9Noch keine Bewertungen

- RCC and SteelDokument12 SeitenRCC and SteelSHAHID THAKURNoch keine Bewertungen

- What Is Steel Reinforcement? Why Is It Required in A Concrete Structure?Dokument11 SeitenWhat Is Steel Reinforcement? Why Is It Required in A Concrete Structure?Rabish ANoch keine Bewertungen

- MethodDokument2 SeitenMethodEmanErNoch keine Bewertungen

- 358S 6Dokument8 Seiten358S 6Raqib MohammedNoch keine Bewertungen

- ReportDokument11 SeitenReportEmanErNoch keine Bewertungen

- Construction MaterialsDokument52 SeitenConstruction MaterialsNikom KraitudNoch keine Bewertungen

- ConclusionDokument2 SeitenConclusionEmanErNoch keine Bewertungen

- CC206 - Bab 2 BIDokument45 SeitenCC206 - Bab 2 BIAdron LimNoch keine Bewertungen

- Unit 7 - Construction SafetyDokument2 SeitenUnit 7 - Construction SafetyEmanErNoch keine Bewertungen

- UC Test Determines Clay StrengthDokument13 SeitenUC Test Determines Clay StrengthMuhammad LutfiNoch keine Bewertungen

- Slope and Deflection at 5m Using Macaulay's MethodDokument2 SeitenSlope and Deflection at 5m Using Macaulay's MethodEmanErNoch keine Bewertungen

- Concrete Materials & Mixtures GuideDokument52 SeitenConcrete Materials & Mixtures GuideEmanErNoch keine Bewertungen

- Engineering Survey 2: Measuring Distance OpticallyDokument48 SeitenEngineering Survey 2: Measuring Distance OpticallyEmanErNoch keine Bewertungen

- Lecture On Circular CurvesDokument43 SeitenLecture On Circular CurvesAnonymous s6xbqCpvSW100% (2)

- A1 TensileTest 2003Dokument14 SeitenA1 TensileTest 2003Itzmichael EzNoch keine Bewertungen

- CC206 LDokument8 SeitenCC206 Lejot79Noch keine Bewertungen

- Tensile Testing LaboratoryDokument20 SeitenTensile Testing LaboratoryGirish ViswanathanNoch keine Bewertungen

- Senarai Kursus JKADokument7 SeitenSenarai Kursus JKAEmanErNoch keine Bewertungen

- Compacting Factor TestDokument4 SeitenCompacting Factor TestEmanErNoch keine Bewertungen

- Structural Mechanics and Strength of Materials LabDokument78 SeitenStructural Mechanics and Strength of Materials LabEmanErNoch keine Bewertungen

- Precast ConcreteDokument11 SeitenPrecast ConcreteTuan Mejar Syed SyeshNoch keine Bewertungen

- Precast ConcreteDokument11 SeitenPrecast ConcreteTuan Mejar Syed SyeshNoch keine Bewertungen

- ANSYS Stress Analysis of Impeller Blade at Various RPMDokument13 SeitenANSYS Stress Analysis of Impeller Blade at Various RPMcena3135Noch keine Bewertungen

- AS 1056.1-1991 Storage Water Heaters - General RequirementsDokument43 SeitenAS 1056.1-1991 Storage Water Heaters - General RequirementsChetan ChopraNoch keine Bewertungen

- Handbook of Practical Gear DesignDokument7 SeitenHandbook of Practical Gear DesignPooria1989Noch keine Bewertungen

- Catalogue ACDelco RemanEnginesDokument90 SeitenCatalogue ACDelco RemanEnginesphamnhatlinh467Noch keine Bewertungen

- Sa 2696 1Dokument1 SeiteSa 2696 1siddiq alviNoch keine Bewertungen

- Sheet Metal OperationsDokument27 SeitenSheet Metal OperationsbmvinayNoch keine Bewertungen

- Catalogo Aurora PneumaticDokument84 SeitenCatalogo Aurora PneumaticSam MarmorNoch keine Bewertungen

- Your First Day Lifeguarding: How To Vacuum and Backwash A PoolDokument4 SeitenYour First Day Lifeguarding: How To Vacuum and Backwash A PoolMattMonroeNoch keine Bewertungen

- Product Information: Diesel Extra LD 15W40Dokument2 SeitenProduct Information: Diesel Extra LD 15W40movie hunterNoch keine Bewertungen

- Ade 12 Physics Exercise 6 Page 135 144Dokument48 SeitenAde 12 Physics Exercise 6 Page 135 144Hope AlforqueNoch keine Bewertungen

- Tutorial 7 MomentumDokument4 SeitenTutorial 7 Momentumapi-3827354Noch keine Bewertungen

- Air Intake Calculations For Ventilation of WarehousesDokument4 SeitenAir Intake Calculations For Ventilation of WarehousesAkhtar Bahram100% (1)

- Genie Scc755psDokument2 SeitenGenie Scc755psWellington Xavier Pazmiño RodríguezNoch keine Bewertungen

- Compresor Atlas Copco GA30Dokument16 SeitenCompresor Atlas Copco GA30Florin Maria Chirila100% (1)

- AM1101 Structures KSDokument62 SeitenAM1101 Structures KSKnowledge MiningNoch keine Bewertungen

- Design Handbook IRC112Dokument111 SeitenDesign Handbook IRC112zulfekharNoch keine Bewertungen

- Wei Gong Lattice Tower Design of Offshore Wind Turbine Support Structures v0Dokument135 SeitenWei Gong Lattice Tower Design of Offshore Wind Turbine Support Structures v0Sachin Sithik50% (2)

- Rail Transportation Safety Investigation Report R21C0070Dokument7 SeitenRail Transportation Safety Investigation Report R21C0070CTV CalgaryNoch keine Bewertungen

- BS en 12334-2001Dokument14 SeitenBS en 12334-2001Udit Kumar SarkarNoch keine Bewertungen

- B-3801 IOM - Rev - 2011-09-02 (1) MidlandDokument23 SeitenB-3801 IOM - Rev - 2011-09-02 (1) MidlandLucas MonteNoch keine Bewertungen

- Hazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanDokument7 SeitenHazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanFaisal AkhterNoch keine Bewertungen

- Figure R4-1: Vacuum Column FlowsheetDokument18 SeitenFigure R4-1: Vacuum Column Flowsheetnico123456789Noch keine Bewertungen

- RVX Upgrade Ps 100 7 Ea4Dokument8 SeitenRVX Upgrade Ps 100 7 Ea4Mark HydeNoch keine Bewertungen

- PV-SAE Installation Guide EN Web 1 1Dokument20 SeitenPV-SAE Installation Guide EN Web 1 1Adam KaczmarekNoch keine Bewertungen

- LAB 2 Free N Force VibrationDokument8 SeitenLAB 2 Free N Force Vibrationmohdanis53yahoocomNoch keine Bewertungen

- Accelerator Ap PsDokument2 SeitenAccelerator Ap PsRazvan RaduNoch keine Bewertungen

- Ducato 290 Handbook 05-15 PDFDokument387 SeitenDucato 290 Handbook 05-15 PDFDaniNoch keine Bewertungen

- Best Practice Manual-Fluid PipingDokument43 SeitenBest Practice Manual-Fluid Pipingapi-3869476100% (1)

- Smokevent Calculation..Dokument2 SeitenSmokevent Calculation..Karthy GanesanNoch keine Bewertungen