Beruflich Dokumente

Kultur Dokumente

Construction Techniques

Hochgeladen von

Gelyn MacasiebCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Construction Techniques

Hochgeladen von

Gelyn MacasiebCopyright:

Verfügbare Formate

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

CONSTRUCTION TECHNIQUES

Y. Ito,

Former Senior Vice President and the deputy general manager of the civil engineering

division of TAISEI Corporation, JAPAN

Keywords: Construction techniques and technology, architecture, tunneling, bridge,

river management, dam, offshore, port, foundation, soil improvement, shield tunneling,

earth-retaining excavation

Contents

1. Introduction

2. Development of construction techniques

2.1. Architectural Technology

2.1.1. Super Highrise Building Technology

2.1.2. Seismic Technology

2.1.3. Large Space Technology

2.2. Tunneling Technology

2.2.1. Crushing Techniques of Rock

2.2.2. Muck Transport Technique and Space Supporting

2.3. Bridge Technology

2.3.1. Bridges in Ancient Times

2.3.2. Modern Bridges

2.3.3. Todays Bridges and Future

2.4. River Management Technology

2.5. Dam Technology

2.5.1. Fill Dams

2.5.2. Concrete Dams

2.6. Offshore and Port Technology

2.6.1. Port Technology

2.6.2. Coast Preservation Technique

2.6.3. Facilities Crossing a Strait or a Sea Area

2.7. Foundation Technology

2.8. Soil Improvement Techniques

2.9. Shield Tunneling Technology

2.10. Earth-Retaining Excavation Techniques

Bibliography

Summary

Construction techniques in various kinds of major infrastructures together with their

histories are explained and overviewed. One will see that all these structures are build

not only on the foundations with the state-of-the-art construction techniques but also on

mans never-ending efforts toward improvement, advancement and evolution of the

techniques.

1. Introduction

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

It is considered that ages ago human beings lived in caves or under trees. Then they

would have arranged or removed pebbles to make their entry to the caves easier or

would have cut tree branches and arranged the large branches to make roofs for shelter

from the rain. As they walked on the ground, it became a beaten path. They dug the

ground with stone tools to make traps for animals. As they learned to grow plants, they

would have dug the ground to make water channels and made small bridges by placing

logs over the channels.

These actions contain the basics of construction techniques, namely, digging the ground

or rock, compacting the ground to make a foundation, transporting materials, processing

and assembling various materials to make buildings or structures.

Searching for better living, mankind has refined construction techniques to make it

possible. In other words, construction is a history of mankinds making many mistakes

and overcoming past failures in the process of conquering the harsh nature.

Thus, the desire for better living was one of the major motivations for humans to

develop advanced construction techniques. Development of construction techniques

itself was one of the building blocks of civilization.

In the following chapters, the progress of various kinds of construction techniques is to

be reviewed.

2. Development of Construction Techniques

2.1. Architectural Technology

Primitive structures, or buildings used for people to live and stay, are mainly pit houses,

made up of pits in the ground with roofing. These structures have been unearthed at

various parts of the world. Thousands of years ago, with simple tools which humans

learned to make and use, they constructed dwellings for shelter from rain by making use

of natural materials, such as grass, wood, stone, mud and animal skin. With the

development of civilized society, they came to make buildings that have symbolic

meanings, such as religious, hierarchical, or memorial, beyond the original meaning of

dwellings. Those buildings are temples, palaces and theaters, one of whose

representatives is the pyramids. Depending on natural conditions, under which

civilization it was born, and social conditions, such as thought, religion or hierarchy, a

variety of buildings with various architectural forms have been built around the world.

These buildings expanded their dimensions vertically and laterally as new building

materials and techniques were developed. Good examples are temples and churches

existent in Europe dating back to the middle ages.

The emergence of modern architecture was timed with the industrial revolution in the

19th century in Europe. The industrial revolution accelerated industrialization and

propelled the economy by leaps and bounds. Demands for buildings also drastically

changed, requiring more functional, efficient and economical factories and other

industrial facilities. Reinforced concrete and steel reinforced concrete buildings using

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

such new building materials as steel, cement and glass have become a steady scene. The

demand for dimensional expansion in height and space increased accordingly.

Today, we see cities growing intensively populated, spatially gigantic and more and

more information-oriented. Requests for buildings also become more diversified.

Building technology that makes super highrises and buildings with big spaces

possible has never been more important.

A brief introduction of the advanced building technology is given in the following.

2.1.1. Super Highrise Building Technology

Super highrise buildings are supported by advanced structural analysis techniques and

materials technology. Super highrises towering over 200 m high were once constructed

mainly as steel-frame structures. Now, many super highrises we see today use

reinforced concrete, which excels steel-frame structures in constructibility and

economic efficiency. These buildings owe their structural excellence to the development

of high-strength concrete technology whose strength is several times higher than that of

ordinary concrete. Concrete with very high strength featuring 80 to 130 N/mm

2

is used

in those new buildings under strict quality control. In addition, the CFT method, in

which concrete is filled in steel columns to enhance compressive strength, was

developed to achieve further economic super highrises.

One of the outstanding technological elements that support super highrises is earthquake

resistant engineering, which is to be discussed in the next section. It makes very high

buildings comfortable and safe living space by employing vibration damping structures,

such as braces and reaction-generating pendulums to set off an external force due to

seismic action or wind pressure.

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

Table 1: The world's major super highrise buildings (as of 2005)

One of todays landmark super highrises (Table 1) is TAIPEI 101, the 509 m high

worlds tallest building of steel CFT structure completed in November 2004 in Taipei,

ROC. The worlds highest RC structure is the Petronas Twin Tower of 451.9 m high,

completed in 1997 in Kuala Lumpur, Malaysia. Currently under planning in the UAE is

a building over 700 m high.

2.1.2. Seismic Technology

The conventional standard of earthquake resistance is how to construct a building rigid

enough to resist seismic force (rigid structure) or flexible enough to (flexible structure).

Buildings constructed with either concept will suffer less damage and will not fail in the

face of a major earthquake, but equipment, furnishings and installations inside the

building will receive devastating damage.

The state-of-the-art building engineering concept aims at control and mitigation of

seismic force itself that acts on the building in order to reduce vibration and protect the

building as well as what is inside. These techniques are categorized into two types,

vibration control and seismic isolation.

A vibration-controlled structure is designed to set off seismic force by giving a counter

force in the opposite direction and is categorized into active and passive control

depending on how to set off seismic force. Active damping controls vibration energy by

giving a reaction force generated with, for instance, computer-controlled hydraulic

power after detecting seismic vibration with sensors. Passive damping absorbs vibration

energy with inertial force generated by, for instance, pendulums. Vibration damping is

The world's major super highrise buildings (as of 2005)

name location height stories completion

1. Taipei 101 Taipei, R.O.C. 509m 101 1998

2. Pet r onas Tower ?, ? Kualalumpur, Malaysia 452m 88 1998

3. Sears Tower Chicago, USA 442m 110 1974

4. Jin Mao Tower Shanghai, China(PRC) 421m 88 1998

5. Two International Finance Center Hongkong, China(PRC) 412m 88 2003

6. CITIC Plaza Guangzhou, China(PRC) 391m 80 1997

7. Shun Hing Square Shenzhen, China(PRC) 384m 81 1996

8. Empire State Building New York, USA 381m 102 1931

9. Central Plaza Hongkong, China(PRC) 374m 78 1992

10. Bank of China Tower Hongkong, China(PRC) 367m 70 1990

11. Emirates Office Tower Dubai, UAE 355m 54 2000

12. The Centre Hongkong, China(PRC) 350m 69 1998

13. Tuntex&Chein-Tai Tower Kaohsiung, R.O.C. 348m 85 1998

14. Aon Center Chicago, USA 346m 80 1973

15. John Hancock Center Chicago, USA 344m 100 1969

16. Burj al Arab Hotel Dubai, UAE 321m 69 1998

17. Baiyoke Sky Hotel Bangkok, Thailand 320m 90 1998

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

an indispensable technology for todays super highrises.

A seismic isolation structure has an isolation layer, in which rubber or sliding bearings

are installed to absorb and reduce seismic force transmission to floors above the

isolation layer for vibration mitigation. The isolation layer is generally set on the

foundation, but some buildings have it among the middle-height floors depending on the

building shapes. This technique is effective especially for low- to mid-rise buildings.

2.1.3. Large Space Technology

The worlds oldest large-space building extant today is the Pantheon, constructed in the

beginning of the 2nd century in Rome to enshrine Roman gods. Today, large space is

very much sought after in various buildings, including railroad stations, airports, halls,

stadiums and commercial complexes.

Large space technology is generally categorized into techniques of structure,

erection and simulation.

The structural technique concerns with structures to support the roofs of large spaces.

Regular plans so far proposed include a 3D truss structure composed of triangles, a

semi-sphere shaped geodesic dome structure developed by Richard Buckminster Fuller,

a beam string structure using pretensioned cables, and a membrane structure in which a

roof is supported by enhancing internal pressure of a building over external pressure. An

increasing number of newly built stadiums have their roofs capable of opening and

closing, which shows that more and more complicated mechanisms are used for large-

space facilities. The openable mechanism is also diversifying into sliding, folding and

rotating types.

The erection technique considers how to construct the long-span roofs of large spaces

which obtain sufficient strength when the entire roof structure is completed. The basic

concepts are the temporary-support method and the lift-up method. In the standard

procedure of temporary supporting, temporary supports and scaffolds are formed first to

assemble each part of a roof at its position, after the entire roof assembling is completed

and the required strength of the roof structure is confirmed, then those temporary

installations are dismantled. In the procedure for lifting-up, on the other hand, the whole

roof structure assembling is finished on the ground level and the required strength of the

roof is confirmed. Then hydraulic jacks are set to columns, and the entire roof is lifted

up with computer control. Although it depends on the scale and the structure, the lift-up

method features quicker and safer construction and can save cost more.

The finds ways to accurately ensure environmental comfort, such as air-conditioning

and lighting, for large spaces. Computational simulation is conducted for temperature,

humidity, air current, illumination intensity and acoustics under the expected conditions

assuming various shapes of roofs with open or close state, thus a high level of comfort

and energy saving in actual structures are realized.

2.2. Tunneling Technology

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

Tunnel construction usually involves crushing of rock to remove it out of the tunnel,

and supporting of the excavated space. According to this definition, tunneling

technology generally covers crushing of rock, transport and removal of muck, and

supporting an excavated space.

2.2.1. Crushing Techniques of Rock

From time immemorial holes have been dug in the ground with chisels, hammers,

shovels and pickaxes. In some ruins of ancient people, deer horns were unearthed,

which were probably used as pickaxes. In around the 8th century BC, people in todays

Persia started construction of irrigation canals, which were called qanat, using

pickaxes and shovels. The qanats ran without supports for 5 to 10 km and sometimes

went as far as 70 km because the route was chosen following the ground firm enough

for nonsupport excavation. Tunnels for military roads or water supply were also built in

Roman days, by manual digging. When they encountered hard rock, they tried to

slacken the rock by heating it up with fire and cooling it down with water. After

gunpowder was invented, it was used to explode the rock into pieces, although it was in

the latter half of the 19th century that modern blasting technique was developed with the

invention of dynamite and development of rock drills.

Figure 1. The Mont Cenis tunnel

from : Le Tunnel Ferroviaire Du Frejus

Improvement of machines to dig tunnels was accelerated when the Industrial Revolution

promoted expansion of the railroad network and the construction of long tunnels for

railroad over the Alps was started. Alfred Nobel invented dynamite in 1866 and the

blasting cap in 1867. Improvement of rock drills started in the early part of the 19th

century with a rotary drill using steam developed by Richard Trevithick in 1813, and a

hammer drill by the Singer Brothers in 1838. Browton made use of compressed air in

1844, and a compressed air hammer drill that rotates a chisel to hit and break rock was

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

then developed by Fowl in 1851. In 1861, Germain Sommeiller started to use improved

drilling machines and he built the Mont Cenis tunnel (Figure 1) in the Alps between

Italy and France in 1870. In 1897, J . G. Rheiner invented the water liner method, in

which compressed air is sent through hollow steel chisels to the drilled hole bottom and

blow off crushed muck to remove. Combined use of the improved rock drills and

dynamite led the construction of the Simplon Tunnel to its completion, a 20 km long

transalpine tunnel connecting Italy and Switzerland, in 1905.

The dawn of the 20th century saw the debut of a jumbo, which is equipped with many

large compressed air rock drills. In 1970, hydraulic rock drills emerged, which provide

enhanced drilling performance with higher pressure and greater hammering rotation

than those of compressed air drills. The latest models of rock drills are excellent in

various functions as well as in improved performance of drilling. Some are equipped

with angle sensors and hydraulic sensors to ensure parallel drilling, accuracy in

positioning and setting of angles. Computer-aided jumbos (Figure 2) equipped with an

automatic drilling management system have also been developed and widely used due

to improvement of the automation techniques.

Figure 2. Computer-aided jumbo

courtesy : ATLAS COPCO Corporation (Tokyo, J APAN)

2.2.2. Muck Transport Technique and Space Supporting

Crushed stone, called muck or debris, used to be moved out of a tunnel with manual

labor and animal force, such as horses and cows. After the invention of the locomotive,

rails were built in tunnels so as to move muck out of them with trolleys in tow by

locomotives.

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

courtesy : RAILWAY TECHNICAL RESEARCH INSTITUTE (Tokyo, J APAN)

courtesy : SANKAIDO Corporation (Tokyo, J APAN)

Figure 3. Block excavation of tunneling

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

Figure 4. Timber supports of tunneling

courtesy : SANKAIDO Corporation (Tokyo, J APAN)

After the WW2, steel supports became dominant. As steel supports are stronger than

timber ones, they can maintain a larger space and thus allow the use of larger machines

for drilling. When tunnels with large cross-section are excavated, muck is moved out by

large dump trucks or containers (Figure 5). In long tunnels where blasting is used, the

use of belt conveyors (Figure 6) together with crusher equipment for removal of muck

has become popular.

courtesy : SHIN CATERPILLAR MITSUBISHI LTD. (Tokyo, JAPAN)

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

courtesy : TAISEI Corporation (Tokyo, J APAN)

Figure 5. Large dump trucks or containers

courtesy : TAISEI Corporation (Tokyo, J APAN)

Figure 6. Belt conveyors

A new concept of tunneling supports, named the New Australian Tunneling Method

(NATM), was introduced in the 1960s, in which the natural ground itself is to support

the tunnel space through a combined use of sprayed concrete and rock bolts. This new

method is based on the ideas that natural ground itself can support the tunnel space and

that timely actions (changes) should be made to the tunnel support by measureing and

monitoring the behavior of the natural ground.

The idea of excavating the entire cross-section of a rock tunnel with a tunneling

machine instead of blasting was born in Italy in the middle of the 19th century. It was in

1952 when a machine close to todays TBM in terms of mechanism was produced and

applied to a drainage canal tunneling project for the Oahe Dam, South Dakota, U.S.A. It

was in those days that the rock tunneling technique using TBM (Figure 7) started to

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

develop in the USA as well as in Europe. In the USA and Europe, where the ground was

suitable for TBM tunneling, application of TBM rapidly increased, and technical

standards were upgraded in the fields of excavation speed, applicability to various types

of geology, and upsizing. TBM was thus more recognized and appreciated eventually.

In the 1990s, an improved version of TBM tuned to softer ground was developed.

Incorporating new functions, TBM has gradually increased the applicable range of

geology type. Today, TBM is frequently used to drill pilot tunnels for road tunnels,

large water channel tunnels and railroad tunnels of over 8m in diameter. The worlds

largest TBM of 12.8m in diameter, has also been in use for drilling two-lane road

tunnels.

(diameter : 8.3)

(diameter : 12.84)

courtesy : TAISEI Corporation (Tokyo, J APAN)

Figure 7. TBM (Tunnel Boring Machine)

U

N

E

S

C

O

E

O

L

S

S

S

A

M

P

L

E

C

H

A

P

T

E

R

S

CIVIL ENGINEERING Vol. I - Construction Techniques - Y. Ito

Encyclopedia of Life Support Systems (EOLSS)

-

-

-

TO ACCESS ALL THE 43 PAGES OF THIS CHAPTER,

Visit: http://www.eolss.net/Eolss-sampleAllChapter.aspx

Bibliography

A. Ghali and A. M. Neville, (1978), Structural Analysis (A Unified Classical and Matrix Approach),

Chapman and Hall, London. [This is a good text in the same approach that readers can study in parallel to

this section].

Alan J ennings, (1977), Matrix Computation for Engineers and Scientists, J ohn Wiley and Sons. [A good

background book for matrix formulations and many exercises to work on]

J .E. Gordon, (1978), "Structures or Why Things Dont Fall Down", Pelican Books. [The author explains

the importance and properties of different structures in a way that will appeal to everyone.]

M.G. Salvadori and R.A. Heller (1963), "Structure in Architecture", Prentice-Hall [This presents

comprehensive discussions of the load carrying mechanisms of various structural types without using

sophisticated equations.]

W. Kanok-Nukulchai, (2002), Analysis Interpretive Computer package - 1993 Version, Asian Institute of

Technology. [This is the manual of a symbolic programming tool that can be used to perform some

exercises].

W. Kanok-Nukulchai, (2002), Computer Methods of Structural Analysis, Lecture note, School of Civil

Engineering, Asian Institute of Technology, Pathumthani, Thailand. [A comprehensive notes of discrete

structural analysis from which the structural analysis section is extracted from].

Das könnte Ihnen auch gefallen

- A5v1 5-20120611 Underground Cable System Design ManualDokument178 SeitenA5v1 5-20120611 Underground Cable System Design ManualPeng Keong LeongNoch keine Bewertungen

- Tunnel Ventilation System: PKG.-14, Mumbai - Nagpur Expressway Presented byDokument19 SeitenTunnel Ventilation System: PKG.-14, Mumbai - Nagpur Expressway Presented bybalabhaviniNoch keine Bewertungen

- Anna University - Conduct-of-Examination-ManualDokument34 SeitenAnna University - Conduct-of-Examination-ManualC Pazhanimuthu100% (1)

- Architecture For ND 1Dokument184 SeitenArchitecture For ND 1Kenzo Movies100% (1)

- Sample-Question-Paper - Building Planning and DrawingDokument7 SeitenSample-Question-Paper - Building Planning and DrawingPrasad ArsulNoch keine Bewertungen

- Disaster Management An OverviewDokument17 SeitenDisaster Management An OverviewNilesh RanaNoch keine Bewertungen

- Engineering Drawing 1Dokument49 SeitenEngineering Drawing 1Thorne Adam Danor100% (1)

- Training ReportDokument47 SeitenTraining ReportPasindu MalshanNoch keine Bewertungen

- Introduction To Computer Aided ManufacturingDokument6 SeitenIntroduction To Computer Aided ManufacturingitzgayaNoch keine Bewertungen

- Digital Literacy Level 6-Assessors GuideDokument12 SeitenDigital Literacy Level 6-Assessors GuideNjoka Samuel KNoch keine Bewertungen

- Ce 223 Construction Technology Nots 2011.2012Dokument109 SeitenCe 223 Construction Technology Nots 2011.2012orodizodanieloNoch keine Bewertungen

- Drafting Sanitary and Plumbing Layouts in CADDokument15 SeitenDrafting Sanitary and Plumbing Layouts in CADmico alilayaNoch keine Bewertungen

- Engineering Drawing GuideDokument50 SeitenEngineering Drawing GuideBhuwan JoshiNoch keine Bewertungen

- Industry 4.0 Group 4Dokument12 SeitenIndustry 4.0 Group 4Shepherd NhangaNoch keine Bewertungen

- FKE S3 1011 BUKU LOG Amalan KejuruteraanDokument80 SeitenFKE S3 1011 BUKU LOG Amalan Kejuruteraanng soo keeNoch keine Bewertungen

- Proposal For WsuDokument23 SeitenProposal For WsuGoftaye Techane GemedaNoch keine Bewertungen

- Networking of PC PDFDokument5 SeitenNetworking of PC PDFMourougapragash SubramanianNoch keine Bewertungen

- Student Internship Programme Report: Name Amizzuddin Bin MD Amin Class AE4 (01) Matrix Number 1200243BDokument15 SeitenStudent Internship Programme Report: Name Amizzuddin Bin MD Amin Class AE4 (01) Matrix Number 1200243B아미주딘 아민Noch keine Bewertungen

- GNS 202 Communication in English IIDokument24 SeitenGNS 202 Communication in English IIOreoluwa OmiyaleNoch keine Bewertungen

- DAE Civil Technology PDFDokument225 SeitenDAE Civil Technology PDFprincesaleem100% (1)

- Abu Bakar-Electrical EngrDokument2 SeitenAbu Bakar-Electrical EngrUsama FarooqiNoch keine Bewertungen

- Icmtech PDFDokument38 SeitenIcmtech PDFom prakash vermaNoch keine Bewertungen

- Intro To Construction Drawings NCCERDokument46 SeitenIntro To Construction Drawings NCCERsteverich2k6Noch keine Bewertungen

- PROJECT TERM PAPER-parasDokument8 SeitenPROJECT TERM PAPER-parasShivi GargNoch keine Bewertungen

- Ce 301: Professional PracticeDokument24 SeitenCe 301: Professional PracticeRidwan Bin AlamNoch keine Bewertungen

- What Is Materials EngineeringDokument2 SeitenWhat Is Materials EngineeringIrinaNoch keine Bewertungen

- Aberra Bekele ThesisDokument147 SeitenAberra Bekele Thesisdanielalemayehu100% (2)

- Building Technology 0Dokument30 SeitenBuilding Technology 0Tichaona MutukumiraNoch keine Bewertungen

- QTO Tutorial PDFDokument11 SeitenQTO Tutorial PDFJanesha100% (1)

- Mitigating Risks For Large-Scale ProjectsDokument21 SeitenMitigating Risks For Large-Scale ProjectsRoland NicolasNoch keine Bewertungen

- Building ServicesDokument49 SeitenBuilding ServicesVarunPatyal67% (3)

- Graphical PresentationsDokument12 SeitenGraphical PresentationsJay Bryson RuizNoch keine Bewertungen

- Nisar's Resume PDFDokument1 SeiteNisar's Resume PDFnisar ahamedNoch keine Bewertungen

- Measurement of Tool WearDokument4 SeitenMeasurement of Tool WearSourav KayalNoch keine Bewertungen

- ES 114ea Engineering DrawingsDokument3 SeitenES 114ea Engineering DrawingsMelchor Jaramilla OronosNoch keine Bewertungen

- Debre Markos University: College of TechnologyDokument39 SeitenDebre Markos University: College of TechnologyLij Davis100% (1)

- Amendments to Education Building GuidelinesDokument70 SeitenAmendments to Education Building GuidelinesSinh luong vuNoch keine Bewertungen

- Enterprenurship 1Dokument122 SeitenEnterprenurship 1olure100% (2)

- UT Construction Design Standards ManualDokument51 SeitenUT Construction Design Standards ManualRajnish Mishra0% (1)

- Quantity Surveying: Chapetr - 4Dokument25 SeitenQuantity Surveying: Chapetr - 4Dani JuraNoch keine Bewertungen

- NICMAR-Safety & EnvironmentDokument44 SeitenNICMAR-Safety & EnvironmentAjay Malik100% (2)

- Civil Engineering FYP GuidelinesDokument10 SeitenCivil Engineering FYP GuidelinesBright MuzaNoch keine Bewertungen

- Guidelines For Writting Project Thesis ReportDokument18 SeitenGuidelines For Writting Project Thesis ReportDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Tutorial Autocad 2007Dokument26 SeitenTutorial Autocad 2007hbfmecNoch keine Bewertungen

- Building Construciton Sample Exit Exam QuestionsDokument156 SeitenBuilding Construciton Sample Exit Exam QuestionsascendancyyfirisaNoch keine Bewertungen

- SCOPE of Works For A Building ConstructionDokument5 SeitenSCOPE of Works For A Building ConstructionlemersonlNoch keine Bewertungen

- Basic Industrial Training Mercedes Benz Company Building ProjectDokument8 SeitenBasic Industrial Training Mercedes Benz Company Building ProjectSachitra Priyashan GovinnaNoch keine Bewertungen

- Grade - 10 - Civil Engineering - Engineering Drawing IIDokument53 SeitenGrade - 10 - Civil Engineering - Engineering Drawing IIBhuwan BhusalNoch keine Bewertungen

- Preparing for ConstructionDokument55 SeitenPreparing for ConstructionOliver Del CarmenNoch keine Bewertungen

- History 4 IN 1Dokument185 SeitenHistory 4 IN 1Malack ChagwaNoch keine Bewertungen

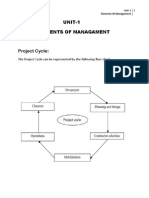

- UNIT-1 Elements of Managament: The Project Cycle Can Be Represented by The Following Flow ChartDokument27 SeitenUNIT-1 Elements of Managament: The Project Cycle Can Be Represented by The Following Flow ChartShashank SinghNoch keine Bewertungen

- Sample - Macau International Airport PDFDokument104 SeitenSample - Macau International Airport PDFChin Xue KeiNoch keine Bewertungen

- Towards Energy Efficient Buildings MauritiusDokument5 SeitenTowards Energy Efficient Buildings MauritiuslordrtNoch keine Bewertungen

- CE404 Civil Engineering Project ManagementDokument2 SeitenCE404 Civil Engineering Project Managementshalu R F100% (1)

- 962 PDFDokument36 Seiten962 PDFdipNoch keine Bewertungen

- Repaire and RectifyDokument13 SeitenRepaire and RectifyDawit Awash100% (3)

- Unesco - Eolss Sample Chapters: Construction TechniquesDokument12 SeitenUnesco - Eolss Sample Chapters: Construction TechniquesVijayaNoch keine Bewertungen

- Unesco - Eolss Sample Chapters: Construction TechniquesDokument12 SeitenUnesco - Eolss Sample Chapters: Construction TechniquesSaurabh BaghelNoch keine Bewertungen

- Earthquake-Proofed Buildings: March 30, 2011 EflreaderDokument2 SeitenEarthquake-Proofed Buildings: March 30, 2011 EflreaderSaynett Strahalm DenekenNoch keine Bewertungen

- High Rise BuildingDokument4 SeitenHigh Rise BuildingMel FNoch keine Bewertungen

- 100 More of The World's Best HousesDokument352 Seiten100 More of The World's Best HousesGelyn MacasiebNoch keine Bewertungen

- Building Practice NotesDokument10 SeitenBuilding Practice NotesGelyn MacasiebNoch keine Bewertungen

- Theology in Stone - ChurchesDokument390 SeitenTheology in Stone - ChurchesAryadne Albuquerque100% (3)

- Community Development PlanningDokument37 SeitenCommunity Development PlanningGelyn MacasiebNoch keine Bewertungen

- BD LST CBP 2012 2QDokument4 SeitenBD LST CBP 2012 2QGelyn MacasiebNoch keine Bewertungen

- BP 344 Accessibility LawDokument22 SeitenBP 344 Accessibility Lawmoonstardolphins100% (2)

- BP 220 Socialized and Economic Housing 2Dokument2 SeitenBP 220 Socialized and Economic Housing 2moonstardolphins91% (11)

- Unesco - Eolss Sample Chapters: Construction TechniquesDokument0 SeitenUnesco - Eolss Sample Chapters: Construction TechniquesGelyn MacasiebNoch keine Bewertungen

- Sparks TOD Mixed-Use and Commercial Design ManualDokument39 SeitenSparks TOD Mixed-Use and Commercial Design ManualGelyn MacasiebNoch keine Bewertungen

- A Book of House PlansDokument166 SeitenA Book of House PlansGelyn Macasieb100% (4)

- Community Development PlanningDokument37 SeitenCommunity Development PlanningGelyn MacasiebNoch keine Bewertungen

- Theology in Stone - ChurchesDokument390 SeitenTheology in Stone - ChurchesAryadne Albuquerque100% (3)

- Architectural AcousticsDokument8 SeitenArchitectural AcousticsEric ThompsonNoch keine Bewertungen

- Hotel Classification StandardsDokument41 SeitenHotel Classification StandardsGelyn MacasiebNoch keine Bewertungen

- Accommodation EstablishmentsDokument30 SeitenAccommodation EstablishmentsGelyn MacasiebNoch keine Bewertungen

- Structural Developments in Tall BuildingsDokument19 SeitenStructural Developments in Tall BuildingsKaaviya RajarethinamNoch keine Bewertungen

- Roof Slab SystemDokument42 SeitenRoof Slab SystemGelyn Macasieb100% (1)