Beruflich Dokumente

Kultur Dokumente

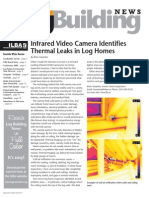

Log Building News Issue No 57

Hochgeladen von

ursindCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Log Building News Issue No 57

Hochgeladen von

ursindCopyright:

Verfügbare Formate

NEWS

SeptemberDecember 2005 Number 57

Agreement Number 40707514

C

hristm

as

is just around

the corner!

Give your employees a

gift that keeps giving

all year round

an ILBA membership.

Keep your employees

interested, enthusiastic

and informed on whats

happening in the world of

log building.

Costing Log Home Shells

by Robert W. Chambers

How much do your handcrafted

shells cost per square foot? Just

give me a simple ballpark gure.

Every customer asks this ques-

tion, and how you answer it can

be life or death for your business.

Four years ago I changed the way

that we cost log shells for my

company, and it has worked well

on more than 100 shells we have

quoted. I wont be going back to

square-foot costing methods. In

this article I will tell you how we

are costing shells, and try to con-

vince you that square-foot costing

has aws that are fundamental

and dangerous.

We cost by the lineal foot of log

used for a project, not the square

foot of space enclosed. And we

know all of our costs by the lineal

foot the cost to buy logs, cost

to transport logs, cost to peel, the

cost to scribe, cost to notch, cost

to reset buildings, overhead. All

these costs are known to us by the

lineal foot of log sold. We nd line-

al-foot costing to be fast, reliable,

and accurate.

If you are perking along nicely

selling a 3200 square foot log

shells for $40 per square foot

(PSF), then I can almost guarantee

that you are losing money selling a

1400 SF shell for $40 PSF. And

thats a problem.

The problem isnt $40 PSF (or

$65, or $35, or any other price

you name); the problem is that

different size shells do not cost the

same per square foot to build.

Small log homes should be selling

for a higher per square foot price

than larger log homes. Please give

me some of your time to show

you why.

Cost & Price

A reminder on the words Ill be

using here: cost means all the

things that your business pays for

which is made up of: 1) All your

direct costs things that you

continued page 18

Dai Onas collage of photos from Allan Mackies 80th birthday party. Read Dais tribute to Allan on page 6.

Inside This Issue

Transition Time at the ILBA

page 2

Chambers Returns as Editor

page 3

Nominees for ILBA Board

of Directors

page 4

B. Allan Mackie Happy

80th Birthday!

page 6

New Job-Costing Software

from ILBA

page 7

ILBA Visits Okanagan

School of Log Building

page 8

Getting a Handle on

Lifting Logs page 10

Advertisers in this issue

page 11

TechTalk page 13

ILBA Conference 2006

page 14

Women in the Industry

page 16

New and Renewing

Members page 21

Classied Ads page 24

2 LogBuildingNews SeptemberDecember 2005

LogBuildingNews

SeptemberDecember 2005

Issue #57

Published six times a year

2005 International

Log Builders Association

P.O. Box 775

Lumby

British Columbia

Canada V0E 2G0

Toll-free: 800-532-2900

Phone: 250-547-8776

Fax: 250-547-8775

www.logassociation.org

Ann Miks, Administrative Assistant

ann@logassociation.org

Log Building News Editor

Robert Chambers

PO Box 283

River Falls, WI

54022 USA

robert@logbuilding.org

Contributors to this issue:

Robert Chambers

robert@logbuilding.org

Dai Yoshito Ona

dai@daizen.com

Ed Shure

ed@timmerhusinc.com

Higgs Murphy

higgs.murphy@sympatico.ca

John Boys

logworks@uniserve.com

John Nininger

john@woodenhousecompany.com

Helen Radomske

info@okslb.ca

Pat Clark

pclark@aboutmontana.net

Cathy Hansen

cathy@logassociation.org

Transition Time at the ILBA

by Ed Shure, President

There are changes at your organization,

the ILBA.

First, the Board of Directors has

changed. In late October, President Jeff

Patterson and Treasurer Martha Patterson

volunteered to retire early when Robert

Chambers, Brian Lloyd and I put our

names forward to help out the ILBA. Brian

and I were voted on to replace Jeff and

Martha, while Robert lls the seat that

became vacant when Mark Fritch departed

the Board.

The Board has elected me President

(a position that I am hoping is temporary),

and John Boys as Treasurer. Pat Clark

remains Vice President. We welcome

Robert back for a while as Log Building

News editor, and all the Committees and

Chairs are listed on page 27.

Three past-presidents (John, Robert

and I) have

been added to

the Board, and

this experience

and strength

will help us with

the nancial and governance issues that

we have right now. Frankly, I am very

optimistic that things are looking up.

Brian Lloyd, as many old-timers will

remember, was at the head of our out-

standing and successful 1993 conference

at Yellowstone, and Brian co-chairs our

Montebello 2006 Conference Committee

with Linda Bourdage. We are lucky to have

their talents and experience added to our

efforts.

The staff has changed. We feel fortunate

that Ann will remain at the ILBA offices.

Cathy Hansen, currently on sick leave, and

Robrt Savignac have been let go by the

Board. It is hard to imagine how volun-

teers can ll their shoesbut we are going

to try to do our best. Our current budget

simply does not allow us to keep them on.

Cathy and Robrt have been, in many

ways, the faces, the voices, and the heart

of the ILBA during their tenure, and we

will miss them, their talents, and their hard

work.

We will need to rely on our members to

take up stronger volunteer roles in the

foreseeable future. If you get a call from us

asking you to step up to the plate, please

consider it a serious, and seriously needed,

job that must be lled.

We need you to join, pay your dues, and

to upgrade your membership. A log build-

ing company really should not coast by on

an individual membership. Log building

companies should pay company dues

its only right. And, of course, we will treat

you like company!

This week I sent the ILBA a check for

$100, a donation on top of my estimated

Montebello conference fees of $800. I

encourage you to do the samecommit-

ment builds condence.

The 2006 Conference in Montebello is a

make or break event for the ILBA. We ask

all our members to attend. We promise a

good one, and we need you there. We

need your support, we need your money,

and we need your opinion. Without a big

success at Montebello, success at the ILBA

will be difficult. You can help us guarantee

a bright future.

I feel strongly that the changes we have

made in the past few weeks will ensure

that the ILBA will remain a world leader in

log home organizations. We have a long

history of supplying leadership to the edu-

cation of log builders that is unmatched.

Expect to see a number of good new ini-

tiatives, products, and services being

offered to you in the next 6 to 12 months.

This is not the time to step backI

intend to help the ILBA to step upa chal-

lenging goal in a time of transition. And

the new ILBA Board, the Committees, and

the staff have committed to do exactly

that. We also need your supportyour

positive and helpful advice, your volunteer

time, and your membership dues.

I am very optimistic that things are

looking up.We need your positive advice, your

volunteer time, and your membership dues.

Number 57 LogBuildingNews 3

Nat ural l y Perf ect

with Sansin Timber-Tec.

Protect your logs for less

Sansin Timber-Tec is an industrial-strength wood primer designed to protect your logs against.

surface staining and weathering even before they leave your yard. Sansin Timber-Tec is.

specially formulated for application to green as well as seasoned timber, so you can enjoy the.

peace of mind that comes from knowing your logs will be protected from the elements at every.

stage of construction. Call 1-877-SANSIN-1 to nd out how you can protect your logs for less.

*Offer ends April 30, 2005

BUY

5

PAILS

of Sansin Timber-Tec

GET

1

PAIL FREE

P R OT E CT Y OUR L OGS F OR L E S S S

LI MI TED TI ME OFFER

*

20% FREE MATERI AL!

www.sansi n.com

1- 877- S ANS I N - 1

Hello again, team.

I am back as Log Building

News editor for a while, and am

looking forward to bringing you

some great articles and news.

I have to admit that for the past

several years I have really

enjoyed getting LBN in the mail-

box, and having only one job:

reading it!

I like the new look of LBN

its really fresh, and I dont plan

any changes. Cathy and Robrt

have done a super job, I think.

But the type of articles we print may change just a littleafter all

I have a weakness for certain log building themes. First, I like

technical, nuts-and-bolts building stuff. Tech Tips. Tools, jigs,

new ways of doing old things, ways to make our jobs easier,

faster, or better.

Second, I enjoy the money side of things. Log building is a

challenging and honorable craft, and it is also a great opportuni-

ty to make money. So, starting with my cover article in this issue,

expect to see more articles on businessand especially on

improving prots, cutting costs, increasing sales, and more.

Third, I like to explore other log building traditions, and in

other places or at other times. Whenever I have been overseas I

have learned something about log building, and LBN is a good

place to share our experiences. If youve seen something that

you think wed all learn something from, please send it to me.

As always, I do need your helpyour photos, thoughts, letters,

ideas, tools. Look around your yard, or your computer desktop,

and contact me! My email is <Robert@LogBuilding.org>. It can

be difficult to reach me by phone, so please try email rst. I do

have a spam lter, so you may get an email reply with simple

instructions on how to get your email delivered to me. I hope

you dont mind!

The focus of LBN will be on log building, of course. Theres

plenty of good advice out there, and once in a while we may

include articles that are a little off topic. But Log Building News

is the official newsletter of a log building organization whose

mission is education. I take that responsibility seriously, and so, I

will be publishing as much log building news as I can nd.

My best, Robert W. Chambers, Editor

Chambers Returns as LBN Editor

4 LogBuildingNews SeptemberDecember 2005

John Boys

I have been an active

and enthusiastic con-

tributor to the ILBA

both on and off the

board of directors

since 1984. I also

served as president of

the association from

1996 through 2001.

My chief satisfaction in participating in

the ILBA is the sense of camaraderie and

openness that typies our association.

At this time I seek election to the board

motivated by a concern for the long term

strength of our association. Weve grown

from a grassroots organization run by

members into a more sophisticated crea-

ture run by a full time office. It is critical to

the future of our association to bring back

the spirit of member involvement. I believe

it needs to start with the elected members

of our board.

To accomplish this I feel we need to

develop clear roles and expectations for

directors and a mentoring program for

new directors this would help those new

to the board understand our mandate, and

give them the tools to make effective con-

tributions.

As a board, we need to more fully under-

stand and act on our mandate; this

includes reviewing and taking scal respon-

sibility as well as dening our core activities

and ensuring the following services and

undertakings are a priority:

Involvement in Code Issues including

ICC. This is vital to the health of our indus-

try and I will continue to advocate strong

ILBA participation.

Education: We need plan our future

undertakings and build upon our core

assets: The Log Building Standards, LBN

and The Log Span Tables.

Member Services and Benets: Our

Construction Contract is another example

of past endeavors by an active and com-

mitted board. Other projects developed to

further our cause and benet the member-

ship include Land to Lock-Up and The Jig

Book. I am currently working with Dai Ona

to develop a pricing/customer manage-

ment program for sale to members.

Conference: A strong conference is critical

to our future growth. It is a great forum for

the exchange of information and with the

strong support of members and Sponsors

also generates a big chunk of our operating

revenue.

From my perspective the up-coming year

is going to require a big effort that needs

member support. If you are willing to be

called on for contributions and want to

ensure and participate in dening the

future of our association cast your vote

for meI will be calling.

Jay Driesen

My interest in log

building started while I

was still associated

with the engineering

team of the double

hung window depart-

ment of Pella Windows

at their home plant in

Pella, Iowa. Our family built our personal

milled log home in 1990 and proceeded to

travel the country building other milled log

homes for home owners who purchased

their materials from a milled log home pro-

ducer. We soon realized that we desired to

produce and build the most beautiful hand

crafted log homes which; however,

required property with space and location

to enable this venture. Due to the passing

of my father in the fall of 1999, the oppor-

tunity presented itself by utilizing one of

the farmsteads by Sioux Falls, SD near

Inwood, Iowa. After doing some initial

preparation on the farmstead, we sold our

Pella, IA log home and relocated to the

farmstead in the fall of 2000. Two days

after arriving we experienced the sudden

and untimely death of my wife and chil-

drens mother in an auto accident. But we

persevered and nished setting up the pro-

duction capabilities of our company, Rustic

Home Builders, according to plans and are

currently manufacturing and producing

high end log homes and related compo-

nents.

Having had early experience and involve-

ment with a farm organization in the

1970s, I could see the necessity of organi-

zation and involvement with the ILBA. It is

truly sad to witness the many and various

log homes being built that are decient in

so many ways. The ILBA and it's past lead-

ership has achieved a great milestone in

developing the Log Building Standards that

have come to be the industry wide bench-

mark. The Log Building Standards must

continue to be held forth to the entire

industry as the standard for all log con-

struction along with continuing education

Nominees for ILBA Board of Directors

Number 57 LogBuildingNews 5

for builders and their employees. Some

areas of further association work may be in

facilitating the procedures with all involved

in the log home sales and production. The

Log Building Standards have been set forth,

training in building has been and is being

accomplished for all involved, and I feel we

need to continue to build and develop our

association on the great foundation work

already in place. What further services can

be rendered to association members and

their clients in the whole process of log

structure production? However the associa-

tion deals with many of the future issues

that face the industry, one fact is para-

mount with that being the integrity and

honesty of the association and it's leader-

ship. As a late comer to the association I

"take my hate off" to the early members

and their leadership in organizing what we

have to day. As your director from our

unique location bordering South Dakota

and the upper Midwest I would cherish

and seek out the input of the many associ-

ation members regarding their needs and

serve those needs as your servant director

to the best of my ability.

Todigan Hodson

My name is Todigan

Hodson, the rst log

home I constructed

came in a kit I assem-

bled like pieces of lego

at the age of 3 or 4.

My father has built log

homes since I was

crawling and, having grown up in the

industry, I have always found the construc-

tion intriguing. I cut my rst log when I

was considered old enough to safely han-

dle a chainsaw. In the last 10 years, I

worked towards becoming a lead hand in

the construction and reassembly of our

projects, and I now manage the company.

I graduated in 2002 from the University

of Alberta with a degree in Forest

Management, and going into University

knew that I would be a business owner.

With this goal in mind, I have supplement-

ed my degree with business courses to help

me become a success. To be a successful

business owner, I feel you must become

intimately familiar with industry standards,

successes, and failures so that you can

make informed business decisions. For this

reason, I have been

attending the ILBA con-

ferences for the last three

years, and have been

ooded with a wealth of

information. I have

become more informed

and more involved with

some of the current polit-

ical issues facing the

industry, so that my

knowledge of the indus-

try may continue to

grow.

I am young, focused

and ambitious, wanting

to be involved with the

further advancement or

our industry, and feel

that I would be an asset

to the board of directors.

I will bring a fresh, edu-

cated, and hands on

opinion to the group and

look forward to getting

to know the members

better.

Jean Rodrigue

My name is Jean

Rodrigue. I have been

working with wood all

my life. I got some

saw dust in my blood.

I set up my cabinet-

terie shop in 1972

making high quality

solid wood furniture and stairs. Doing this

for 25 years full time I got a little tired of it

so I decided to lock the door and look for

something different. Six months later I dis-

covered log building and just jumped in.

Since 1998 I have built 42 log houses. I

believe ILBA is part of my success and I

want to join the Board of Directors to work

at my best for the interest of all ILBA mem-

bers.

Dan Wait

I was born and raised

on a dairy farm in cen-

tral Wisconsin, thus

you can understand

my passion for football

and the Green Bay

Packers. I helped my

father, Jerry construct

his dream home in the early 80s. Frontier

Builders, Inc. formed in 1966. In 1997 I

attended Great Lakes School of Log

Building 10-day Full Scribe class. I then

built my rst cabin. I read everything that I

could get my hands on regarding log

home construction. My back ground in

farming serves me well in the log building

industry with the long hours and the

unique problems encountered.

I attended my 1st international AGM in

1993 at Yellowstone and was in awe. I

came home, excited to try some of the

new things I had learned. I have attended

as many as possible since and come home

invigorated. I have a great respect for the

organization, its goals and its many ne

members.

I took over Frontier Builders from my

father in 2000 and now know what he

meant when he said, just wait till you sit

in this chair. I could not have had a better

teacher or mentor.

My wife Mary, our three children, and I

co-exist with 2 horses, 3 cattle, several cats

and dogs as I am also a hobby farmer.

6 LogBuildingNews SeptemberDecember 2005

F

F

l

l

a

a

t

t

d

d

e

e

c

c

k

k

T

T

R

R

A

A

I

I

L

L

E

E

R

R

S

S

B BR RI I T TI I S SH H C CO OL LU UM MB BI I A A T TR RA AI I L LE ER R

250-765-7779

Toll Free 1-800-668-1068 Fax 250-765-6724 www.bctrailer.com Email: info@bctrailer.com

897 Stremel Road, Kelowna, BC V1X 5E6

Wardhaul Trailers have been manufactured in the heart

of the Okanagan Valley since 1996 and are second to

none when it comes to quality workmanship, value and

durability.

4, 5, 6 and 7 ft. widths and

102" width

Suppliers of Interstate, Pace

American, Royal, and Trailtech

SALES

SERVICE

RENTALSDaily, Weekly,

Monthly

LEASING

B. Allan Mackie Happy 80th Birthday!

by Dai Yoshito Ona

In a April, Allan and I were on a way to

Germany, and we stopped in Toronto for

the transit, where Allans daughter Nadina

came to see us. Big hug between father

and daughtershe is really proud of her

father. Allan is going to be 80 years old

but is still working just like the rest of us.

At this time, we were running a 7-

month course at Chase, BC, and the tem-

perature got to minus 35 degrees, then

we were heading to Germany for other

course. No day to rest at all. This time we

had talked about getting together for

Allans birthday.

By word of mouth, a lot of people came

long way to celebrate his Happy 80th

birthday. I have been celebrating Allans

birthday each year for ten years because

we have been running course in this time

of season. This year, Allan wanted to stay

at home and get to the next project.

So I drove to his home 8,000 km

drive round trip. It was long drive. I was

thinking about the past on the way to his

place, the time I have spent with him, 13

years we have seen every year, and all the

fun. On the way back to BC, I was think-

ing about the future. For my future plan,

after seeing Allan, I am not worried now,

as I was before.

Driving to his home, it took three and

half days and I drove all night because I

had big gift for him on my trailer. I had to

ll the tank 11 times to get there. On the

way back, it was easy and we took 6 days

seeing the country and driving in the day

time. It was very hard for my kids. When

we got close to home, where the scenery

gets familiar, I thought my kids would be

excited, but both kids started to cry. Allan

made this trip over ten times every year

that he came to my place. I think his butt

is very thick.

People came all over the place. Staff

from Korean school, staff from Japanese

school and Hans from the Germany

school. Graduated students also came. I

know we would get a lot of people if we

told them what we were doing.

Allan told me people are connected for

economic reasons. People have relation-

ships because we gets some kind of bene-

t. I think he is right. Most of the time this

applied. But what about this time? I think

people are also connected not just because

it benets themselves. There were many

people who came, helped and left. They

would not except anything in return. Will

this happen to me? I guess it will depend

on how I do for others.

Allan is my only teacher. He taught me

what a house is for, he told me how things

were done in an age when I was not in

this world. He also taught me that we can

expect to have fun for a long time.

But he is really my friend. I have had

Number 57 LogBuildingNews 7

New Job-Costing Software

from ILBA

Training Sessions at Montebello!

LogWorksHelper1.0 is a major new effort by the ILBA to develop a pricing and

construction management tool for log builders. It is built on a series of easy to

use Excel spreadsheets. You put in basic information about a particular building

project, and the program will output the information that you need to price and

track the progress of your projects.

Output includes: log lineal footage, log volume, waste, piecework count,

estimate of hours, gasket count, shipping weight, staining coverage.

LogWorksHelper automatically generates documents such as price quotes,

contracts, change orders, purchase orders, and more. It will be available for sale

before the Montebello conference, and training workshops will be held during

the conference. If you are interested, please indicate by emailing

program@logworks.ca and put pricing-1 in the subject line of your email.

Samples from the LogWorksHelper

software, which automatically

generates price quotes, contracts,

change orders, purchase orders,

and more, and will be available

from the ILBA at the Montebello

Conference.

many hard times in a past, just like every-

body. Every time when I had him beside me,

he gave me courage to face trouble, and I

got over it every time.

The B. Allan Mackie School of Log

Building is where many log builders started

a new life. I tried to keep this school going

and I have been doing this every year. We

still get many inquiries for the course. I dont

know how long I can keep this going. It will

be big loss if we let this school go. I really

wish that some public organization would

take over this school and continue what

Allan has started.

8 LogBuildingNews SeptemberDecember 2005

We are lucky to be located near enough to

the ILBA office to allow a presentation to

our students. Robrt Savignac arrived, rst

coming to the house for a meal of elk

chops compliments of Del and Jarret

Radomske, and Robrt brought his

appetite! Then it was off to the classroom

for the presentation.

In his usual high spirits and exuberance

for the industry his presentation left no

one in doubt about his passion for the

Craft of Log Building and his dedication to

the ILBA.

Robrt gave an insightful overview of

how the Association initiates and explores

ways to get the log building message out

to the log building world, ways to involve

the membership, and encourage new

members. His PowerPoint presentation,

complete with great photographs, compli-

mented his comments. Throughout the

presentation the themes that he struck

most were the advantages of becoming a

member; opportunities to meet other like-

minded people at the conferences and

rendezvous, the exchange of ideas, oppor-

tunities to learn more through Association

workshops with the ongoing endeavour to

promote education as offered by the

Association.

Robrt commented to the students that

the ILBA is member-driven and has the

richness of being an International Associ-

ation. That the Association is about shar-

ing of history, knowledge and invention,

and as a result The Standards were

developed, and many other contributions

that have been made through the ener-

gies of members; scientic research, jigs,

lots of jigs, the various publications that the

association has available to its members.

The ILBA is founded on: education,

design, engineering, research and testing,

and there was also mention of safe build-

ing practices and log building being

green for the value added nature of

handcrafting with logs. And he mentioned

regional log building associations as well

as the Timber Framers Guild. It was a

good couple of hours and a presentation

that the students

found very worth-

while.

The students who

attend our classes

have often com-

pleted extensive

research on the

subject and many

are looking to enter

into the log build-

ing industry. We do

have some owner-

builders, too, but

then that is almost

every student just

as in the past, eh!

The students enthu-

siastic response to

Robrts presenta-

tion brought ques-

tions. Do you live

in a log house?

What type of join-

ery is that? All

thought the presen-

tation was great and appreciated Robrt

coming.

There are usually a few memberships

that result from the presentation and that

lets us know that having the ILBA do a

presentation is very worthwhile. Many

thanks, to Robrt for giving our students

the opportunity to hear about the

Association.

ILBA Visits Okanagan School of Log Building

by Helen Radomske

Number 57 LogBuildingNews 9

10 LogBuildingNews SeptemberDecember 2005

Getting a Handle on Lifting Logs

by John Nininger

Handling logs for a living keeps us trying new things to make

the process easier and safer. Today we use a variety of metal

tongs and exible slings to get a good hold on each log before

lifting it up.

The closest thing that Ive found to a pair of strong, gentle

hands to grab each carefully-chosen log and transport it safely

are the non-marring log lifting tongs made for us by Wayne

Sparshu and originally designed by Alan Mackie (Photo 1). This

stainless-steel-lined, scissor-action design is good for unloading

new logs, and excels at moving them around the yard, and dis-

mantling the completed log walls before loading the logs onto

trailers.

But, slings are our rst choice for loading trailers and assem-

bling the log shell (re-stacking) on the owners foundation. For

pre-building the log walls in the yard we use both tongs and

slings: tongs are quicker and easier; slings are better for con-

trolled rolling and multiple picks. We nd that slings are better

for oor and roof-system logs than the tongs.

Log tongs are extremely quick to put on and get off the logs,

and to re-position for a near-perfectly balanced pick. Slings leave

very faint marks, if any, on only the heaviest of our relatively soft

White Pine logs.

Every tool has its limits, of course. They are:

1) Tongs cant pick small logs diameters of 7 (20cm) or

less. Sparshus tongs were designed for logs up to 16" (40cm)

diameter. Larger logs are damaged by the rounded points of the

tong arms because the radius of the arms is too small, and pre-

vent it from holding or squeezing the log gently. To overcome

this limitation we built an oversized set of tongs based on the

same design but with larger radius and heavier parts (Photo 2).

They work very well on any size log from 7" to 26" (66cm)

diameter (at the balance point). We used very wide stainless lin-

ers to make them even more gentle to the wood surface of

large and heavy logs. These tongs are more cumbersome

because of their size and weight, so unless we are lifting large

logs, we will use the Sparshu tongs.

2) Tongs must be dropped low enough onto the log that they

are below the widest part of the log that is being picked up

this is necessary for the tongs to grab and stay closed. Tough to

do when there is not enough space (5" to 6" either side)

between the logs to get the tongs intofor example when logs

are on trucks. We have found that it helps to un-hook the tongs

so they are in the closed position. This way they slip down over

the log and require the least clear space either side. And some-

times you have to lift one end of the log high enough (3' to

6'1m to 2m) to get a short, stout beam under it. With the log

propped up, then the tongs can drop down around it for pick-

ing (Photo 3). This is still often easier than using slings in a tight

spot and is used most often when unloading new logs off the

trucks.

3) Very freshly peeled logs (slippery with sap or slime), and

heavily ice-coated logs can slide out of the tongs if not carefully

balanced to within about 5 degrees of level (Photo 4). Since its

quick and easy to re-position the tongs on the log for a bal-

anced pick, its worth doing. Safety comes rst, men. Wayne

suggested roughing up the liner with small bumps, but we

found the indentations in the wood were more of an issue than

the sliding logs. All logs should be carefully balanced before lift-

1 Sparshu tongs in use, hanging from

lifting slings.

2 Our oversize tongs with extra wide

stainless linings.

3 In a tight spot, we lift one end of the

log enough to put a timber under it,

and then we re-grab it with the tongs.

4 Make sure the load is balanced by rst

lifting only a little.

1

2

3

4

Number 57 LogBuildingNews 11

Advertisers in This Issue

Accutech . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

British Columbia Trailer . . . . . . . . . . . . . . . . . . 6

CBR Products . . . . . . . . . . . . . . . . . . . . . . . . 23

Dietrichs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Emseal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Good Shepherd Wool Insulation . . . . . . . . . . 26

GRK Fasteners . . . . . . . . . . . . . . . . . . . . . . . . 19

Insulspan Corporation . . . . . . . . . . . . . . . . . . . 5

J. Rouleau & Associates . . . . . . . . . . . . . . . . . 26

Log & Cottage Show . . . . . . . . . . . . . . . . . . 16

Log Home Design Ideas/Log Home Living . . 28

Log Home Store . . . . . . . . . . . . . . . . . . . . . . 26

Nicola Log Works . . . . . . . . . . . . . . . . . . . . . . 9

Pat Wolfe Log Building . . . . . . . . . . . . . . . . . 26

Perma-Chink Systems Inc. . . . . . . . . . . . . . . . 17

RCM Cad Design & Drafting . . . . . . . . . . . . 26

Riverside Forest Products . . . . . . . . . . . . . . . . 12

Roto-Clip Inc. . . . . . . . . . . . . . . . . . . . . . . . . 17

Schroeder Log Home Supply . . . . . . . . . . . . . 8

Summer Beam Books . . . . . . . . . . . . . . . . . . 26

The Continental Products Company . . . . . 4/11

The Sansin Corporation . . . . . . . . . . . . . . . . . . 3

Timber Framers Guild . . . . . . . . . . . . . . . . . . 26

Wayside Press . . . . . . . . . . . . . . . . . . . . . . . . 26

ing to ensure easier swinging from one end and more accurate

placement with the crane. Contrary to common belief, balanc-

ing a log is not easier or better with a greater distance between

lifting points.

Contrary to common belief, balancing a log does is not easier

or better with a greater distance between lifting points.

We lift each log just a foot or so and evaluate its balance. If

both log ends dont rise clear of any supports than it is immedi-

ately set back down and the load is completely released from

the tongs. With the tongs hanging freely by just an inch or two,

they are moved along the log toward the end that was low and

lifted again. This procedure is repeated until a nearly perfect bal-

ance is achieved. This procedure goes quickly, and often the

tongs can be slid along just by the crane operatorwithout a

man at the tongs.

For setting short log pieces under 4' that cant be picked by

the Sparshu tongs we use a single non-marring lifting tong of

an earlier design that never gained the condence of my crew

when lifting larger logs.

Because our only piece of lifting equipment is a tower crane,

we are limited to how much room we have to spread logs out.

Winter time usually sees us stacking 50' (15m) logs in a criss-

cross pattern as new logs come in (30 to 60 minutes per load to

unload), sometimes up to 6 or 7 layers high.

When peeling season arrives (April/May) we

spread out the pile for peeling and bumping

(rough smoothing). Then they either get re-

stacked in piles, or stored one-layer-deep in

the racks. In one to two hours a log pile of

50 or more logs is spread out by two men,

one at the crane, using radio controls. Its

fast, safe and fun (on a nice day!).

For operations where the tongs are too cumbersome, they are

quickly unhooked from the spreader cable hooks. From the

hook on the cranes main rope, two wire ropes about 14 -feet

(4.2m) long go down and through the spreader bar, which is 4-

feet long (the same length as the width of our tongs). Each of

these spreader cables has a hook, and on these hooks we set lift-

ing slings of various lengths. Often, we have one 3', one 6', one

9', and one 12' (1m, 2m, 3m, & almost 4m) sling on each

spreader hook (Photo 5).

The tongs are hung from the 9' slings, which leaves the 12'

slings free for lifting a log end, or another log. When not being

used, the 12 slings are clipped up and out of the way. Or, when

we remove the tongs, the slings are now used by themselves,

Contrary to common belief, balancing a log

is not easier or better with a greater distance

between lifting points.

continued next page

12 LogBuildingNews SeptemberDecember 2005

Divisions at Lumby, Armstrong, Kelowna,

Wineld, Williams Lake and Ashcroft

Meeting your log building

requirements with beam

logs and all species of

house logs.

Contacts:

Clive Powell 250-550-7233

Shirley Taylor 250-547-9802

Clint Dyck 250-547-9802

choked around a

log, or clipped with

a shackle/carabiner/

snap hook onto

another sling that is

already on a log.

With the multi layers

of slings to hang

logs from, plus the

spreader hooks, up

to ve logs can be

lifted in one pick and

placed one at a time

on the building

(Photo 6).

This system is simi-

lar to a rigging

method called a

daisy-chain. The

main difference

being that in a daisy-

chain each piece is

hanging from the

slings of the piece

above it which even-

tually puts the entire

load on the top pair

of slings. It wouldnt

take long to over-

load those top slings.

Our system provides

individual slings for

each piece so that

the each load is

taken directly by the

spreader cable

hooks.

Once the shell is

completed at our

yard, we use log

tongs to dismantle

and spread out the

logs for gasketing.

When fully closed the tongs are still 6" or so apart (this amount

is adjustable) which prevents damaging the scribed edge of the

lateral groove.

Once the shell is taken apart, a pair of 7-foot long, 1" nylon,

endless loop slings are placed on every single piece of log in

the shell, where they are to remain until they are placed on the

foundation (yes, this requires a lot of slings). The logs are then

lifted, 4 or 5 at a time, and loaded on the trailers, again in

reverse-order of how they will come off.

Once at the foundation, the logs are lifted for the last time

and stacked, corner by corner, up to the headers. The headers

are lifted and set, sometimes two at a time, and the stacking

continues. Floor joists, purlins, rafters and most any of the differ-

ent pieces can be lifted in multiple picks (daisy-chain). The only

limitations are the load capacity of the crane and the height of

the boom.

Most of the slings can be pulled out of from between the

stacked logs by hand, but this must be done immediately after

each log is set on the wall. Occasionally one end of a log needs

to be looped with a sling and lifted to get its trapped sling

released. There was one sling that somehow got looped onto a

purlin log and was never noticed until the crane had left. That

one had to be cut free.

When its time to clean up, we throw on three or four of the

old-time skid tongs (the ones with sharp points, like ice tongs)

and pick up three or four log end cut offs at a time and ll a

wagon that gets hauled away by a local farmer who heats his

whole farm with our scraps using an outdoor furnace.

Combining the merits of all of these log holding contraptions

has proven the most benecial way to go. But that doesnt

mean we wont stop looking for better ways and tools to do the

job. Why it was just the other day we got talking about big

magnets and wonderingthere must be a way.

Remember, like many of the doctors we build for, we are real-

ly all just practicing log builders.

My source for slings: East Shore Wire Rope and Rigging Supply,

Inc. 203-469-5204

5 Our usual riggingfrom the top:

spreader cables, spreader bar,

and slings of various length.

6 Daisy-chain of ve logs.

5

6

Number 57 LogBuildingNews 13

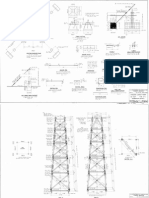

TechTalk

TRACTOR MOUNTED CRANE : : BANDMI LL ROOF

T

E

C

H

T

A

L

K

T

E

A

R

O

U

T

F

O

R

Y

O

U

R

J

I

G

B

O

O

K

A Boys Big Book of Jigs

A Log Builders Reference to Jigs, Tools and Techniques

An informative book on jigs and work methods specic to our trade.

Sections include:

Scribing and Layout Stairs and Railings

Cutting and Drilling Stairs and Railings

Holding Mills and Machines

Lifting Work Methods

Accessing Heights Resources

Cool Tools New Stuff

Available to ILBA members only

Convenient binder format allows additional information to be inserted

into appropriate sections, such as the TechTalk information at the centre

of this LBN. This will allow for unlimited expansion, creating a personal-

ized work handbook.

Send in your TechTalk ideas for future LBNs as other members have

done for you.

Price $95.00 CAN plus shipping

Ive always liked the idea of having my bandmill

under a roof but the complications of feeding

logs with a crane and the expense have preclud-

ed that idea. Ernie suggested a small roof on the

mill carriage. Great idea! It is cheap to build and

does good job of protecting the mill and opera-

tor. It also gives the mill carriage a bit of extra

protection from out of control crane operators!

John Boys

Higgs Murphy using his tractor-mounted, unfolding, crane at the Chris

and Wil Dancey's log timber-frame project. Higgs may be bringing this

crane to Montebello for pre-conference hands-on workshop.

To order, contact the ILBA office at 1-800-532-2900 or

250-547-8776 or email info@logassociation.org

JIG BOOK JIG BOOK

- - - -

On sale NOW!

14 LogBuildingNews SeptemberDecember 2005

Laser Meets French Scribe

by Pat Clark

This past spring at the Timber Framers conference we had the pleasure of

teaching round joinery to the square wood guys. My business partner

Paul and I have been developing a

technique that we call French

Scribe meets the Laser Beam.

Originally we applied it to the

mitered truss building technique,

but quickly discovered that the laser

beam opened up a whole range of

new layout possibilities . We have

used the laser for a multitude of lay-

out situations such as window and

door layout and cutout, post and beam joinery, loft (joist) log layout, cen-

tering of purlins and posts, mortise and tenon joinery, and the list goes on.

The beauty in the method is that all the joinery can be drawn and seen

before it is cut. We are nding that we are shaving lots of time off our lay-

out procedures, and thus potentially putting some extra coin in our pock-

ets and having fun at the same time.

This spring we intend to use this

technique in our pre-conference

gazebo workshop so there will be

ample opportunity for all to experi-

ment with this 21st century log

building technique. Well see you at

MontebelloBe there or be square!

Telling Our Story & Building Our Future

Le Chateau Montebello

33rd Annual Conference and AGM - April 6-9, 2006

Montebello 2006 is the place to expand your craft, your business

and your prots.

We have had some excellent conferences over the years, my

friendsfrom Yellowstone to Coeur d'Alene its pretty hard to

match those venues. So we decided not to try to match them,

instead, we decided to take a new attitude and simply make this

one Our Best Ever: Best Workshops, Best Seminars,

Best Entertainment, Best Food, Best Trade Show, Best Auction

and the Best opportunities for suppliers to showcase their servic-

es and products to the best gathering of big-wood builders ever.

And did we mention to Best Fun youve ever had and been

able to write off!

We know we have the Best Location, as no venue is more rep-

resentative of this conferences theme TELLING OUR STORY

BUILDING OUR FUTURE. We will be housed in North Americas

largest and most historic log structureto look back on the

craftbut this conference will be dedicated to our industry mov-

ing forward. The latest tools and jigs, the newest techniques, and

the state-of-the-art software and legal contracts are just some of

what youll experience at Montebello.

The Conference and AGM is the opportunity for like-minded

professionals to dene and establish the future of our craft and

The Poor-Mans

Round-Log Hundegger

Higgs Murphys Higgy Jigger is a setup that ts

on an ordinary bandmill track. It incorporates an

indexing head, a tail stock and a Makita chain

mortiser to make what I call the poor mans round-

log Hundegger!

This low-cost setup will be used to fabricate log

components at the pre-conference Montebello

gazebo workshop. Workshop participants will get

to use the Higgy Jigger and several other great

tools for boosting productivity. The Montebello

workshop will also feature production roof layout

and cutting techniques in both square timber and

round log. Opportunities like this are rare!

I LBA CONFERENCE 2 0 0 6

Number 57 LogBuildingNews 15

industry. We look forward to seeing new and old faces, and we

welcome your contributions and participation at Montebello

2006! Indications are that we will enjoy a record attendance.

Reinvest in your business by learning something new, getting

reinvigorated and growing and improving your bottom line.

Celebrate some of the greatest contributors to our industry

and association. Join us in recounting our 33-year history. One of

our own will receive our greatest expression of admiration. But

there may be some surprise awards too! Superb photos will com-

pete for recognition for the Picture Perfect Awardselect and

send us yours! And meet the designers and architects who awe

us with examples of their ne log homes.

We are a new, enthusiastic Conference Committee and we

pledge to create an experience that you will never forget.

Whether you follow the 1. Hands-on (Efficient Building Practices)

conference path or the 2. Business (Improving Your Bottom

Line) path, or a mix, we guarantee a rewarding experience.

Great pre-conference courses being planned:

Laser layout techniques with Pat Clark: trusses and more

Log grading certication

Computer design training

Construction details (a new book!)

Construction contracts that work

New ILBA job-costing software LogHelper, designed for log

building. CautionThis program can lead to greater prots!

We are building a structure that will stay on the Montebello

estate

Log Games A few twists to the tradition, and even more fun

to watch

1 Efficient Building Practices the Hands On

Conference Path:

Moisture Content How to get it down

Log Home Finishes corn husk blasting strippers applica-

tion preparation professional methods maintenance

Tech Talk John Boys will host this favorite with a few twists

Higgs Murphy demonstrates the Poor Mans Hundegger!

Due Diligence Health and Safety Program, WCB/OSHA

requirements fall protection systems

Tractor-mounted folding crane that really works

Window and door installation techniques, hands-on, in detail

Stair building for log homes

Complex joinery in timber and in the round the details from

an expert

Tool sharpening Presented by an expert and new sponsor

2 Improving Your Bottom Line the Business

Conference Path:

Marketing/sales seminar track lead by an acknowledged expert

Negotiations and closing the sale when to say nothing at all

A new job-costing software LogHelper, designed for log

building. CautionThis program can lead to greater prots!

Contracts to build that keep all parties on the same team

Insurance Errors and omissions Liability : learn what you

really need

Running a lean and protable manufacturing operation

Finding and keeping excellent employees Employee termina-

tion Nitty gritty advice for you

International Codes Council (ICC) A report on the proceed-

ings and discussion about the grading and construction manu-

al

Log Standards The Committee will propose a revamp that

moves us all forward

Marketing and Sales A panel of successful log and timber

builders will lead a group discussion for builders who plan their

businesses for greater stability: How did you do it?

Whats in the future of handcrafted log building will there

be a Hundegger for Log Homes?

This year well have group and individual photos that will

make it into your photo album. So show your face at Montebello

April 6 9, 2006!

Please send additional suggestions for presenters or additional

seminar/workshop opportunities to Brian Lloyd at bg_lloyd@hot-

mail.com

Conference Organizer

The Montebello Conference Committee is looking for proposals

from people, perhaps an ILBA member, to be a paid Conference

Coordinator. Please contact Brian Lloyd for more information

250-549-3545 or bg_lloyd@hotmail.com

This will be the Best Gathering

of Big-Wood Builders Ever!

Brian Lloyd

ABOVE AND LEFT The Chateau Montebello

I LBA CONFERENCE 2 0 0 6

16 LogBuildingNews SeptemberDecember 2005

Mira Jean Steinbrecher

Mira Jean Steinbrecher, AIA, has worked

in the industry since 1990 when she was

hired as staff architect for a Canadian

handcrafted log building company. In

1991, she established Jean Steinbrecher

Architects, a rm specializing in the

design of log & timber buildings. A for-

mer ILBA officer and design columnist for

Log Home Living magazine, she continues

to serve to the industry through teaching

and the written word.

Chris Dancey

I used to spend time in my south west

Ontario woodlot wondering how to make

it a place to live. The red pines my par-

ents planted hinted at the possibility of

building a log home, but I had no idea

how to begin. When I learned about Allan

Mackies school, I knew I had to take a

course in building with round logs. That

was 1988 and my life has included log

building ever since.

Currently, Im the Manager of Commu-

nication for Dietrichs North America. We

sell and support 3D CAD/CAM software

for wood construction. With input from

the log building industry, Dietrichs pro-

grammers developed the capability of

designing with round tapered logs and

now many of our clients are designers,

architects and builders, who work with

round logs. Intimate knowledge of log

building is denitely an asset.

My use of the computer is for commu-

nication, which often includes creating

the Dietrichs ads, so my Honors Degree

in Fine Art and the year studying design

are helpful.

Following university, I began my rst

company and most of the past 30 years

Ive been self-employed. Even now, Im

also operating a certied organic farm

and promoting the use of natural building

materials, such as industrial hemp, straw,

wood chips and shavings, clay and lime.

Ive never wanted to be normal, so

hanging out with other creative risk-tak-

ers, like the members of the ILBA, is very

satisfying. Im happy to say that as a

woman, Ive never felt I dont belong.

Susan Witter

Off in the wild hin-

terland of northwest

Washington state,

Susan pulls Timber

Framers Guild stuff

together.

Publications like

Scantlings, the

conference pro-

ceedings, and the

second Joinery and

Design book, and

short pieces such as

the candidates

statements, all fall within her area.

It is quiet and isolated, but she nds it

fun to hear from new Guild members, all

excited about this new group theyve

found, and from those old hands running

things behind the scenes.

Women in the Industry

by Cathy Hansen

Yes, there are many of us in the industry. There are many companies

that are solely owned by a woman, and many husband and wife teams.

So we thought in this issue we would feature some of the women who

are actively involved in the log building industry.

Number 57 LogBuildingNews 17

Here are a few

reasons why we

have log building

standards

UPPER LEFT The result of lack of overhang,

the exposed logs rot away over time.

UPPER RIGHT Imagine cutting the bottom of

the truss out! This kind of poor building

practice still exists.

BOTTOM Second oor T & G oor boards

are exposed to the weather and more

deciencies. Unfortunately this was only

one of about ten structures in a row built

in this fashion at this site. Again we

stopped into assist these non-ILBA

members with a some log building

standards education.

18 LogBuildingNews SeptemberDecember 2005

can say were denitely used for a particu-

lar project (logs, hourly-wage labor, labor

paid by the foot or by the piece, sales

commissions, steel, transport); plus

2) All your indirect costs, also called

overhead, (insurance, tools, equipment,

fuels, office expenses, waste, repairs,

wages paid by salary, telephone, advertis-

ing, computers, a prot, and so on).

Cost is what you pay to build a log

shell for a customer; and Price is what

the customer pays you. This article is

about getting an accurate handle on your

costs. Pricing is a very important aspect of

getting jobs, but with limited space, Ill

stick to costing for now.

But, let me just emphasize the obvious:

the price a customer pays you must be

equal to, or greater than, your cost. And,

therefore, knowing your cost accurately is

essential to prevent you from selling too

low and losing money.

Lineal Foot

At the heart of this costing method is that

the lineal foot of log shipped is our basic

unit for costing. (Of course, you can use

lineal meters instead of lineal feet.) The

lineal feet of logs shipped is equal to

the total of all the logs that you send on

trucks or in containers to build a particular

shell. Lay every log for a shell package

out, every post, wall log, purlin, truss part,

joist, rafter, ends touching ends, in a

straight linethats the lineal feet of log

shipped.

We have found that lineal feet (LF) of

log is a better measure of cost than either

weight (no matter whether you use

pounds, metric tonnes, or whatever) or

volume (whether you use cubic meters,

board feet, cubic feet, truckloads, or con-

tainer loads).

Lineal feet works whether the logs are

green or dry (costing by weight would

not work well here). And LF costing works

for us when the shell uses a mix of diame-

ters (small for pole rafters, large for walls,

and so on) costing by volume would

not be as accurate for that sort of job that

uses a mix of diameters.

Lineal foot costing, when you consider

it, just makes sense because it ts a lot of

what we do and what we pay for. After

all, when you are buying logs, you dont

call the logger to order 3400 square feet

of logs, you buy 65 logs 45-feet long for

a job. Or you know how many lineal feet

of log t on one truck and you order 3

truckloads in order to get what you really

want, which is 2925 lineal feet for this

job.

Your cost to peel logs is directly related

to how many feet of logs go under the

drawknife, not how big or small the house

oorplan is. Your cost to scribe logs, your

cost to notch and groove logs, your cost

to transport logs all these are closely

related to the lineal feet of logs that are

being processed by you from raw material

into ready-to-assemble log shell.

You know me, Im the guy who is into

the craft of handcrafting. I have spent a

couple decades working on tools, tech-

niques, and teaching others the craft. My

business plan was: seek out different and

challenging projects that made me learn

with every job.

We are craftsmen, but we are also pro-

ducers turning raw materials into n-

ished product each year. And it is worth

considering the productivity of even one-

man yards in terms of a quantity of raw

log turned into log home shell. We are

processing trees at a certain cost to create

a value-added product that has a price. I

guess Im just saying the obvious: we are

craftsmen and we are businessmen.

Most of our business costs are very

closely related to the quantity of logs we

process, and I really cant think of many

log building costs that are closely related

to the square feet of log shell size. And

yet, many of us have been using square

feet of oorplan to estimate our produc-

tion costs, and help determine our prices.

But, as I will soon show, there is a huge

difference between square-foot-costing a

1400 SF house and square-foot-costing a

4400 SF house. If you have one price per

square foot for the shells you sell, then

you may make a good prot on some

projects, but Ill bet you lose your shirt on

others.

(Lineal foot costing works best if you

usually use about the same diameter log

for your homes. If, however, for one job

you use 14-inch logs and for the next job

you use 23-inch logs, then you should

probably be costing your shells by the ton

(or the cubic meter), not the lineal foot.

Since many log home companies tend to

get comfortable using about the same size

log time and again, lineal foot costing

works well for them.)

Your Cost Per Lineal Foot

How can you know what something will

cost to build if youve never built it

before? Yet this confronts us with every

customer who calls inas an industry lots

of us rarely build the same house twice.

We give prices for things weve never

done, and thats risky. We must minimize

the risk of an error in costing.

You have to rely on your history, which

means you need to have some basic

records going back more than one job.

The better your records are, and the

longer your history, the more accurately

you will know your cost.

I am not talking here about reducing

your costs. That is certainly important, but

right now you must know what your actu-

al costs have been recently (no matter

whether you think they are too high or

just right!).

Use your nancial records from last year

to determine your total costs. You may be

able to use last years tax return to get the

numbers you need. If not, then start mak-

ing a list of all your direct and overhead

costs.

Next, look at your bottom line: were

you happy with last years prot? If not,

then how much extra income would

you have needed to have been happy?

(Be realistic!) And, if you did not pay your-

self (or your spouse) a salary, then youll

need to decide what you were worth to

the business last year and add that on,

too. Add those three numbers together

total business costs plus prot correction

(if needed) plus unpaid salarywell call

this your annual corrected costs.

Now, gure out how many lineal feet of

log you processed during that same peri-

od of time. This is not the quantity of log

Costing Log Home Shells

from page 1

Number 57 LogBuildingNews 19

you purchased, it is the quantity you shipped out of your yard

processedanother way to think of it is it is the amount of log

you sold. Divide the annual corrected costs by lineal feet of

logwork sold, and you have your cost per lineal foot.

We use lineal feet of logwork shipped, or sold, rather than total

quantity of logs purchased for one simple reason: its a more use-

ful way to cost a house quickly and accurately for a customer.

Heres what I mean: a customer brings you a sketch of a house

they want. While he sits there, you do some measuring and nd

that his design has, say, 3560 lineal feet of logs in it. That is, you

are going to try to sell him a shell that will have 3560 lineal feet.

Multiply 3560 times your cost per lineal footnow, size him up to

guess how much above cost your price should bequickly you

can give him a good ballpark estimate of the price for his cocktail-

napkin sketch of his home.

Whats My Cost PLF?

I have not told you my cost per lineal foot, or even a range of

possible North American costs PLF because you do not need to

know them. You need to focus on your cost per lineal foot,

because you must run your business, and make your sales, using

sale prices that are not below your costs.

Sure, it would be nice to know the competitors costs! But if

your costs were legitimately higher (or lower) than mine (your

logs cost more, or labor cost more, or fuel cost more, or your yard

rental cost more, insurance rates are higher, or your transport

costs are higher, etc), and you ignored this, and just beat my

For more info: 1-866-202-2345 or www.accutechinnovations.com

Cut upto 70 angles. + or - 1/4 accuracy

Convert any size chainsaw into a

portable saw mill

Achieve a level of accuracy never

seen with a chainsaw

Transport or store all your chainsaw mills

PRECISION PORTABLE CHAINSAW MILLS

20 LogBuildingNews SeptemberDecember 2005

price, and won the job, then youd be in

big trouble. Congratulations, you got the

job and now youre going to lose

money! You must know your costs, not

mine, or anyone elses.

Obviously, knowing your costs is a great

rst step to reducing your costswhich

can sure help you be competitively priced

and boost your prots. Reducing costs is a

good subject for another article, but is not

the critter I am chasing here.

Size Counts

Log homes with smaller oor space cost

more to build per square foot than log

homes with larger oor space. Size

counts, when costing handcrafted log-

work.

Three examples are shown in Figure 1.

All example plans have 9-foot tall full-

scribe-t log walls, door and window

openings that suit the size building, one-

story only, and a log post-and-purlin roof

system adequate for support.

First, a 40 by 60 that has a total of

2400 square feet of living space. This log

shell kit would ship about 2360 lineal feet

of logs. Next, a mid-sized 30 by 38 with a

total of 1140 square feet. This log shell

would ship about 1670 lineal feet of log

package. Finally, a small cabin, 20 by 24

with a total of 480 SF living space that

would ship about 1000 lineal feet of log-

work (Column C shows lineal feet of log

shipped for each shell).

Lets say that I sell log shells for $45 PSF.

So, the larger shell Id sell for $108,000,

the medium shell Id sell for $51,300, and

the small shell Id sell for $21,600. These

prices are all just the square footage of

each shell times $45.

But how much am I getting paid by the

lineal foot of logs I have processed? In the

bigger shell I am being paid $46 PLF

(rounding to nearest dollar); the medium

shell is bringing me $31 PLF; and for the

smaller shell I get $22 PLF (see Column

D).

Umm, do you see the problem? The

small, medium and larger shells all sold for

$45 per square foot, thats my price! So

everything should be okay, right? But Im

being paid $46 for every lineal foot of log

I ship for the 2400 square foot shell, but I

only get $22 PLF for the 480 square foot

shell. Im being paid half as much for

every single foot of log that I nd, buy,

transport, peel, move around the yard,

lift, scribe, notch, insure, gasket, transport,

and assemble!

I paid the same price for the logs for all

three projects, I paid the hourly staff the

same to scribe and cut, I paid the peelers

$2 per foot, I paid almost $3 per gallon

for fuel, my insurance is not lower when I

build small cabin shells than when I build

larger shells. It is difficult to nd savings

that could explain a drop in my cost of

52% (from $46 to $22 PLF). I might be

able to nd a cost savings of 5% or 10%

because of shorter logs being used for the

smaller shell, but a 52% savings? No way.

I may think I am selling all my homes at

the same price, $45 PSF. Actually, I am

selling smaller cabins at half-price, and I

dont even know Im doing it, and I am

losing money every time! Ive got to make

a change to my costing method before I

go broke.

If you sell your 2400 SF shells at $45

per square foot, and make a tidy prot

doing it, then your losses on smaller shells

are indicated by the numbers in Column

F. The small cabin, that I thought I

priced well at $21,600 ($45 PSF), actually

should have been priced closer to

$46,000 (and this is more than $90 per

square foot).

Why Does This Happen?

Big buildings get more usable square

footage of oorplan per amount of exteri-

or wall used. You cannot escape itit is a

fact of geometry.

Draw a small square and mark each

edge as 10 feet long. It has 100 square

feet and uses 40 lineal feet of wall.

Draw another square and mark each edge

as 100 feet long. It has 10,000 square feet

of area and uses 400 lineal feet of wall.

The large square encloses 25 square feet

for each lineal foot of wall, but the small

square encloses only 2.5 square feet for

each lineal foot of wall.

You get ten times the bang for the buck

in the big building. Oversimplied exam-

ple? Yes. But I hope it grabs your atten-

tion, because it is really important. Size

counts. No one builds a log home shell

that is 100 by 100 with no interior walls,

I can hear you say. True. But youd have

to add in 3,600 lineal feet of interior walls

(about 32,000 lineal feet of log!) to make

the larger shell have the same LFPSF as

the small shell. Try drawing in another

3,600 lineal feet of wall inside the 100 x

100 buildingit wont t!

Large buildings are cheaper to build PSF

than small buildingsask anyone in the

shed, pole barn, or warehouse construc-

tion business.

Roofers price by the square foot of roof

they cover, not by the square foot of the

buildings oorplan. Sheetrockers price by

the area they need to cover in sheetrock,

not the square footage of the buildings

oor. Stonemasons price their work by the

face foot which is the surface area of

Figure 1

Three log home shells priced by the Square Foot (SF), and then converted to nd the

price they would bring you per Lineal Foot (LF). If $46 PLF brings you a prot, then

Column F shows your loss on the other two jobs. Column G shows density of log

in the design, low numbers indicate the design is more efficient in log use.

Number 57 LogBuildingNews 21

WELCOME!

NEW COMPANY MEMBERS

BG Stadig Handcrafted Log Homes

Creative Log Homes

Kristalo Lodges

Log & Cottage Shows

Northern Spirit Log Homes

Pacic Lumber & Shipping LLC

Pennsylvania Drafting & Design

Ranch Creek, Ltd

RSM Drafting Services

RENEWI NG COMPANY MEMBERS

Angels Log Homes

Back Country Logcrafters

Chinook Log Homes

College of the Rockies

Doubletree Logging

Flynn Log Homes

Ingenius Web Design

Integrated Pole Ltd.

Interior Logging Association

Kenwest Enterprises Ltd.

Living Log and Timber Ltd.

Log Home Agency

NACHI

North Region Log Homes

Old Yale Log Homes Ltd

Pat Wolfe Log Building School

Perma-Chink Systems Inc

Stihl Ltd.

Suret Log Homes Ltd.

The Finnish Handcrafters Association

Timber Frame Business Council

TJ's Wood Products

WARSS

Woody's Log Homes

NEW I NDI VI DUAL MEMBERS

Anderson, Andy

Farella, Geoffrey

Frigon, Guy

Goryk, Tim

Newell, Doug

Visser, Dan

Wood, Mike

RENEWI NG I NDI VI DUAL MEMBERS

Baker, Duane

Buehlmann, Ivo

Christman, Jed

Furtado, Tony

Hammers, Bill

Klose, Tim

Mickelson, Steve

Moore, Brian

Snow, Gordon

Sparshu, Audra

NEW EMPLOYEE MEMBERS

Corll, Marty North Region Log Homes

RENEWI NG EMPLOYEE MEMBERS

Cowles, Jerry Bromley Log Homes

Simms, Dale Bromley Log Homes

CAS H DONATI ONS TO I LBA

Ed Shure

Robert W. Chambers

John Boys

New and Renewing Members

Since Our Last Issue

wall (not oor) that they are covering

with stone.

Log railing producers often price their

product by the lineal footnot by the

square foot of deck they enclose. And log

builders who supply log railings with their

homes often switch from square-foot cost-

ing for the log home shell over to lineal-

foot costing for rails. Square foot of oor-

plan does a poor job of accurately indicat-

ing your real cost for all your projects. It

can work for your sweet spot of size,

but if you take on smaller projects, then

you are taking on big risks.

The Next Step

These have been simple examples to illus-

trate the problem of relying only on

square-foot costing. Your next step is to

look at least two past projects you built

(but the more you can look at, the bet-

ter). Choose one that was smallish, and

one that was largish in square footage.

For one of these you should feel or know

that it was protable.

22 LogBuildingNews SeptemberDecember 2005

Count up the total lineal feet of logs

shipped for each project, and make a

table like the one shown above that will

compute your cost per square foot and

cost per lineal foot for each project.

You already know what you should be

getting paid per lineal foot (you gured

that at the start of this articleits your

total business costs, corrected if needed,

divided by the total lineal feet of logwork

shipped during that same time period).

Now how do these two projects measure

up to that number? What can you learn

from this? Print a copy of the results and

tape it to your desk, use it for computing

your cost when estimating future projects.

Our Experience

Natural Log Homes has been using per-

lineal-foot costing for about 4 years. We

have not yet had a project that didnt

work better with PLF costing than with

PSF costing. In that time, our projects

have been as small as 120 square feet and

as large as 4,200 square feet.

We have been able to really study the

work process in our yard, man by man,

and step by step. We track each step of

processing a log from bark-on, to assem-

bled on the foundation. Some things we

stopped counting because we found they

were not helpful (one of those was the

number of pieces of logs that were being

handled for each job).

We track weekly progress on all jobs,

and we separately track each jobs prof-

itability, so we know which jobs we did

well (and which, not so well) on. We build

a wide variety of stylessimple and com-

plex plans, loads of trusses and only

purlins on 2x posts, complex oor systems

and 2x joists, and we have found that per-

lineal-foot costing is still our most accurate

measure of time and prot.

We still estimate each new job on a

spreadsheet that counts every hole to be

drilled, every notch scribed and cut, every

joist attened, every door and window

cut, and so on. But our cost per lineal foot

varies surprisingly little from job to job.

The tendency is always to say, oh, but

that Deer Pond house it was so complex,

it cant cost the same PLF as that simple

4-wall cabin for Mud Lake. Well, take a

good look at those jobs, and I think you

may be surprised. Logwork is logwork, no

matter how big or small, simple or com-

plex, and we now have great condence

in the per-lineal-foot method of costing

our shells.

Lineal Foot Per Square Foot

LSPSF

A good gauge of log home design and

cost efficiency we call lineal feet per

square foot. This is the number of lineal

feet of logs used in the house divided by

the total square footage of living space in

the plan. It is a measure of the density of

logwork in a design, and of log building

efficiency, it varies from about 0.6 (very

efficient) to over 3.0 (not very efficient).

(Figure 1, Column G shows Lineal Feet

Per Square Feet.)

A house that has 3.0 lineal feet per

square foot uses a lot of logs (for example,

6000 lineal-feet of logs shipped for a 2000