Beruflich Dokumente

Kultur Dokumente

FL6003 PDF

Hochgeladen von

Mauricio Barrios CastellanosOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FL6003 PDF

Hochgeladen von

Mauricio Barrios CastellanosCopyright:

Verfügbare Formate

Elastomeric Couplings

Baldor offers the following BaldorMaska

Flexible Couplings for a wide variety of

applications that require elastomeric materials due to shaft misalignment.

Jaw Type Gear Type Tire Type

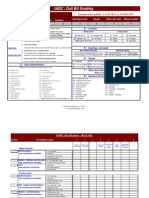

GENERAL CHARACTERISTICS

Starflex 4-Flex Maskaflex

Torque (in.-lbs) 3.5 - 6,228 60 - 47,268 900 - 82,500

Max. HP/100 RPM 9.9 18 130.9

Torsional wind-up (deg.) - 7

o

- 15

o

3

o

- 7

o

Angular misalignment (deg.) 1/2

o

- 1

o

1/4

o

- 1

o

4

o

Parallel misalignment (inch.) 0.010 - 0.015 0.010 - 0.040 0.047 - 0.203

Axial permissiveness - limited compressibility 0.063" - 0.266"

Sizes available 35 - 225 3 - 13 50 - 200

Elements available

Nitrile Rubber (NBR)

EPDM

Natural Rubber (NR)

Urethane

Hytrel

Hytrel

Bronze

Interchangeable by Part # and Size with Corresponding Elements

Variety of Insert Elements for different Applications

On-line Drive Selection Program and CAD Drawings for StarFlex & MaskaFlex types

Made from High Strength Cast Iron

Coupling Selection Process, Service Factors and Ratings in BaldorMaska

catalog

Important Reminder:

Selecting the proper type and

size of coupling & element

material, based on the

application, service factor,

temperature and environment,

will result in effcient, long-lasting

operations.

Elastomeric Couplings

StarFlex Jaw Type Drive Selection Program & CAD Drawings are available via website.

Inches and Metric Bores; Special bores in stock

Commonly used coupling for a wide variety of light-duty and medium applications.

All parts completely machined in cast iron

Simple design results in easy installation, removal & inspection

Four types of insert elements

Coupling Hub and Elements

Hub

No.

Type

Outside

Diameter

A

Hub

Diameter

HD

Overall

Length

B

Distance

between

flanges

C

Length

thru bore

D

Bore

Assy Wt.

Lbs. (Avg)

Approx.

WR2

lbs-in

2

Min. Max.

L035 * 1 5/8 - 13/16 9/32 17/64 1/8 (4mm) 3/8 (8mm) 0.10 0.003

L050 * 1 1 1/16 - 1 23/32 15/32 5/8 3/16 (5mm) 5/8 (16mm) 0.25 0.054

L070 1 1 3/8 - 2 1/2 3/4 3/16 (7mm) 3/4 (19mm) 0.50 0.115

L075 1 1 3/4 - 2 1/8 1/2 13/16 3/16 (9mm) 7/8 (22mm) 0.90 0.388

L090 1 2 1/8 - 2 9/64 33/64 13/16 3/16 (8mm) 1 (25mm) 1.35 0.772

L095 1 2 1/8 - 2 33/64 33/64 1 7/16 (11mm) 1 1/8 (28mm) 1.55 0.890

L099 1 2 17/32 - 2 27/32 23/32 1 1/16 7/16 (14mm) 1 3/16 (30mm) 2.25 2.048

L100 1 2 17/32 - 3 15/32 23/32 1 3/8 7/16 (12mm) 1 3/8 (35mm) 2.80 2.783

L110 1 3 5/16 - 4 1/4 7/8 1 11/16 5/8 (16mm) 1 5/8 (42mm) 5.95 8.993

L150 1 3 3/4 - 4 1/2 1 1 3/4 5/8 (16mm) 1 7/8 (48mm) 7.90 11.477

L190 2 4 1/2 4 5 1 2 3/4 (19mm) 2 1/8 (55mm) 13.80 39.256

L225 2 5 4 1/4 5 3/8 1 2 3/16 3/4 (30mm) 2 5/8 (65mm) 17.30 65.000

Dimensions

*Important: NOT SOLD INDIVIDUALLY. These parts are packaged 4 to a box.

TYPE 1

C

D

B

A

TYPE 2

C

A

D

B

HD

Element Characteristics

Properties

Temperature

Range

Misalignment

Shore

Hardness

Dampening

Capacity

Chemical

Resistance

Color Angular

Degree

Parallel

Inch

NBR (Rubber) Nitrile Butadiene

Rubber is an elastomeric element that

is oil resistant with the resilience and

elasticity of natural rubber.

Most economical and widely-used

element.

-40 to +212 F

-40 to +100 C

1 .015 80A HIGH GOOD

BLACK

Urethane -- Urethane has 1.5 more

torque capability than NBR, provides

less dampening effect and has good

resistance to oil and chemicals.

Not recommended for cyclic or

start-stop applications.

-30 to +160 F

-34 to +71 C

1 .015

55D

L050-L110

90-95A

L150-L225

LOW VERY GOOD

ORANGE

Hytrel -- Hytrel is a pliant elastomer

suited to high torque / temperature

operations. Notable resistance to oil

and chemicals.

Not recommended for cyclic or

start-stop applications.

-60 to +250 F

-51 to 121 C

1/2 .015 55D LOW EXCELLENT

BEIGE

Bronze -- Bronze is a metal insert

designed exclusively for slow speed

operations that require high torque.

(Maximum 250 RPM)

Resistant to extreme environments

(temperature, water, oil, dirt).

-40 to +450 F

-40 to +232 C

1/2 .010 -- NIL EXCELLENT

GOLD

Important Reminder:

Selecting the proper insert

material is just as important

as selecting the correct type

and size of jaw coupling

because of the role it plays

in the performance and

maintenance of the product.

4-Flex Gear Type

Fixed Bore (J & S) & QD Bushing (B) Flanges;

SC Spacer Series

Flexible and versatile coupling with a 4-way fexing action that absorbs all types of

shock and vibration and accommodates axial, angular and parallel misalignment.

Precise concentrical product to avoid run-out and unbalance

EPDM & Hytrel sleeve elements; 1-2 piece and split formats

J & S fanges have 2 set screws

Flange Sizes

Fixed Bore QD Style SC Spacer Series Ratings

J* Flanges S Flanges B* Flanges SC Flanges Max. RPM

3J 9200

4J 7600

5J 5S 5SC 7600

6J 6S Types 1, 2 & 3 6B 6SC 6000

7S 7B 7SC 5250

8S Types 1 & 2 8B 8SC 4500

9S Types 1 & 2 9B 9SC 3750

10S Types 1 & 2 10B 10SC 3600

11S 11B 11SC 3600

12S 12B 12SC 2800

13S 13B 13SC 2400

14SC 2200

* Do not use with hytrel sleeves

Element Characteristics

JE

HS H

JES

E E (exploded)

SHAPES AVAILABLE EPDM HYTREL

1 pc, unsplit JE H

1 pc, split JES -

2 pieces E HS

TYPICAL USE General Purpose General Purpose

REL. RATING 1X 4X

WIND-UP ANGULAR 15 7

MISALIGNMENT 1 1/4

TEMPERATURE

maximum +275 F. +250 F.

minimum 30 F. 65 F.

Sleeve Types

Baldor Electric Company

P.O. Box 2400 Fort Smith, AR 72902-2400 U.S.A.

Phone (479) 646-4711 Fax (479) 648-5792 International Fax (479) 648-5895

www.baldor.com www.maskapulleys.com

Baldor Electric Company

FL6003

Printed in U.S.A.

9/10 TCP 5000

MaskaFlex Tire Type

QD Bushing Style

Coupling most suitable for applications with shock loads; QD style makes for easier

installation & dismounting and greater versatility than the fxed bore style without damaging

the shaft.

Revolutionary reinforced X-Tork tire element

Complete line available from 50 to 200

I mport ant Remi nder:

Applications that exceed 5000 ft/min may require more accurate balancing.

Shaft ends can project beyond the bushing; if the case, allow space between shaft ends for endfoat and misalignment.

Coupling Ratings & Misalignment

Coupling

No.

Bush.

Size

Max.

Bore

Max

RPM

HP per 100 RPM Service factors

Torque*

@ 1.0 S.F.

(LB in)

Average static

torsional stiffness

coefficient (H)

Approx.

WR2

(LB-FT2)

1.0 1.5 2.0 2.5 3.0

LB-lN/

DEG.

LB-IN/

RAD.

MX 50 JA 1 1/4 4500 1.43 .95 .72 .57 .48 900 224 12,850 .08 3/64 1/16

MX 60 SH 1 5/8 4000 2.86 1.91 1.43 1.14 .95 1,800 414 23,700 .24 1/16 5/64

MX 70 SDS 1 15/16 3600 3.49 2.33 1.75 1.40 1.16 2,200 544 31,200 .45 5/64 3/32

MX 80 SK 2 1/2 3100 5.71 3.81 2.86 2.28 1.90 3,600 876 50,200 .88 5/64 7/64

MX 90 SK 2 1/2 2800 6.90 4.60 3.45 2.76 2.30 4,350 1,088 62,400 1.60 3/32 1/8

MX 100 SF 2 3/4 2600 8.33 5.55 4.17 3.33 2.78 5,250 1,530 87,700 2.90 7/64 1/8

MX 110 SF 2 3/4 2300 12.30 8.20 6.15 4.92 4.10 7,750 2,420 138,700 4.30 7/64 9/64

MX 120 E 3 7/16 2100 19.90 13.27 9.95 7.96 6.63 12,540 4,014 217,000 6.70 1/8 5/32

MX 140 F 3 15/16 1840 43.78 29.19 21.89 17.51 14.59 27,590 8,296 476,000 19.50 9/64 3/16

MX 160 J 4 1560 59.98 39.99 29.99 23.99 19.99 37,800 12,000 688,000 34.60 11/64 13/64

MX 200 J 4 1300 130.90 87.27 65.45 52.36 43.63 82,500 29,000 1,662,000 103.00 13/64 17/64

* To obtain the maximal torque, multiply by 2.5 the nominal torque. (X-Tork tire)

M

a

x

.

p

a

r

a

l

l

e

l

m

i

s

a

l

i

g

n

m

e

n

t

M

a

x

.

a

x

i

a

l

m

i

s

a

l

i

g

n

m

e

n

t

Tire Element Characteristics

Thermally stabilized natural rubber bonded together with double-woven textile cords

Multiple cables in toe reinforce stability and fange grip for greater torque capacity (see photo insert)

Ridged extremity and inner sidewalls designed for enhanced grip of the fanges

Mounting

Installation sheet and gages included with every part to properly install and obtain the correct space

between fanges.

Drive Selection Program & CAD Drawings are available via website.

Das könnte Ihnen auch gefallen

- Pulleys TechDokument8 SeitenPulleys TechashkansoheylNoch keine Bewertungen

- Acople Grilla Love JoyDokument1 SeiteAcople Grilla Love JoyClaudia C. DiazNoch keine Bewertungen

- FRAME RIVETS REPLACEMENT WITH BOLTS SERVICE TIPS - Article No. 97-4-7Dokument2 SeitenFRAME RIVETS REPLACEMENT WITH BOLTS SERVICE TIPS - Article No. 97-4-7FlogamagNoch keine Bewertungen

- TEREX Halco Hammers & BitsDokument35 SeitenTEREX Halco Hammers & BitsNelson F. Leon CarvajalNoch keine Bewertungen

- Drill StemDokument28 SeitenDrill Stemchonubobby100% (1)

- Okuma Simul Turn 400Dokument11 SeitenOkuma Simul Turn 400paulkupasNoch keine Bewertungen

- Roller Screw BrochureDokument8 SeitenRoller Screw BrochureRjgandhi65Noch keine Bewertungen

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDokument5 SeitenEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- Kumera Girth Gear Technical ManualDokument12 SeitenKumera Girth Gear Technical ManualBhaskar Reddy100% (1)

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyDokument4 SeitenTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69Noch keine Bewertungen

- Goulds AF: Axial Flow PumpsDokument11 SeitenGoulds AF: Axial Flow PumpsKarthick VenkateshNoch keine Bewertungen

- CAOIMPEX Drilling ToolsDokument42 SeitenCAOIMPEX Drilling ToolsDrilling TechNoch keine Bewertungen

- Hydraulic Cylinders CHDokument8 SeitenHydraulic Cylinders CHStoianovici CristianNoch keine Bewertungen

- Stud Bolt SpecificationDokument8 SeitenStud Bolt SpecificationsantoshblonkarNoch keine Bewertungen

- Accessories For Tools CNCDokument16 SeitenAccessories For Tools CNCIonutNoch keine Bewertungen

- Manual TongsDokument5 SeitenManual TongsAlas KHNoch keine Bewertungen

- Luz de Valvulas e Inyectores Serie 60Dokument6 SeitenLuz de Valvulas e Inyectores Serie 60Kelvin Ramirez100% (2)

- Alignment Coupling Operation Manual Tyre-FlexDokument37 SeitenAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelNoch keine Bewertungen

- Cilindros Hidráulicos Parker - 2H - 1110-UkDokument42 SeitenCilindros Hidráulicos Parker - 2H - 1110-UkPeterson MagroNoch keine Bewertungen

- Pump Installation and Maintenance: Learning OutcomeDokument6 SeitenPump Installation and Maintenance: Learning OutcomeMohammed Amin BenharkatNoch keine Bewertungen

- IADC Dull Bit GradingDokument9 SeitenIADC Dull Bit Gradingzerocool2kNoch keine Bewertungen

- Butter Mueller 5bt520e0015wf00g1000Dokument2 SeitenButter Mueller 5bt520e0015wf00g1000Manusawin PinsongNoch keine Bewertungen

- RR11 Brochure PDFDokument4 SeitenRR11 Brochure PDFel.runitaNoch keine Bewertungen

- Caracteristicas Motores PDFDokument60 SeitenCaracteristicas Motores PDF0ZKRCITHONoch keine Bewertungen

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDokument6 SeitenElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNoch keine Bewertungen

- PEM Self Clinching Self Locking FastenersDokument4 SeitenPEM Self Clinching Self Locking FastenersAce Industrial SuppliesNoch keine Bewertungen

- PHD GuiaDokument14 SeitenPHD GuiaEd GarNoch keine Bewertungen

- Power Stream Couplings-Specn SheetsDokument6 SeitenPower Stream Couplings-Specn SheetsAmol PatkiNoch keine Bewertungen

- 01 Rockbreaker Systems 1 MRHDokument50 Seiten01 Rockbreaker Systems 1 MRHJuan Diego ArizabalNoch keine Bewertungen

- Rotator PipeDokument4 SeitenRotator PipetisnaNoch keine Bewertungen

- Goodwin BFRDokument2 SeitenGoodwin BFRHamdzan As'atNoch keine Bewertungen

- Suction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsDokument2 SeitenSuction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsZMCONTROLNoch keine Bewertungen

- Toyo Rubber CouplingDokument14 SeitenToyo Rubber CouplingGreg SanjayaNoch keine Bewertungen

- PHNCDokument6 SeitenPHNCAmit MangaonkarNoch keine Bewertungen

- Arvis Brochure Plain BearingsDokument28 SeitenArvis Brochure Plain BearingsJavierNoch keine Bewertungen

- Milling Equipment: Product DetailsDokument9 SeitenMilling Equipment: Product DetailsPepy PeachNoch keine Bewertungen

- Hibon - SN Ingersoll Rand BlowerDokument7 SeitenHibon - SN Ingersoll Rand BlowermarquezsiemNoch keine Bewertungen

- SD II PDF - OCRDokument18 SeitenSD II PDF - OCRSuraj KumarNoch keine Bewertungen

- Single Core & Multicore Flexible CablesDokument12 SeitenSingle Core & Multicore Flexible Cablesdh24992499Noch keine Bewertungen

- Lonas de Freios Industriaisi Fras-LeDokument2 SeitenLonas de Freios Industriaisi Fras-LeMarco ViniciusNoch keine Bewertungen

- Pernos Huck C50LDokument4 SeitenPernos Huck C50LAngelina Santiago JimenezNoch keine Bewertungen

- Perforadora Cop - Spec Rr14 EpirocDokument4 SeitenPerforadora Cop - Spec Rr14 EpirocNeilNoch keine Bewertungen

- 2642 Ni 71350002Dokument56 Seiten2642 Ni 71350002ToudNoch keine Bewertungen

- H1000e K FJDokument8 SeitenH1000e K FJSyarif HidayatullahNoch keine Bewertungen

- SKF Bearing Fitting Tool TMFT 33Dokument2 SeitenSKF Bearing Fitting Tool TMFT 33Nang Dapi100% (1)

- Unbrako Catalog FastenerDokument26 SeitenUnbrako Catalog Fastenerdesign_rajeev100% (1)

- CDA - Elecon Flexible CouplingDokument5 SeitenCDA - Elecon Flexible CouplingMohit GuptaNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsVon EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsBewertung: 5 von 5 Sternen5/5 (1)

- Drilling Fluids Processing HandbookVon EverandDrilling Fluids Processing HandbookBewertung: 4.5 von 5 Sternen4.5/5 (4)

- High-Performance GM LS-Series Cylinder Head GuideVon EverandHigh-Performance GM LS-Series Cylinder Head GuideBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallVon EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallBewertung: 4 von 5 Sternen4/5 (8)

- Carbon Emissions Don't Cause Global Warming: BackgroundDokument5 SeitenCarbon Emissions Don't Cause Global Warming: BackgroundLibertyAustraliaNoch keine Bewertungen

- JMO Solutions 2008Dokument4 SeitenJMO Solutions 2008ichkhuyNoch keine Bewertungen

- Sorsogon State College Engineering & ArchitectureDokument11 SeitenSorsogon State College Engineering & ArchitectureArianne Mae De Vera GallonNoch keine Bewertungen

- Oc818 Manual v03-1Dokument5 SeitenOc818 Manual v03-1Luca PayetNoch keine Bewertungen

- Unit Test 7 (PDF)Dokument1 SeiteUnit Test 7 (PDF)emirelliucNoch keine Bewertungen

- Refrigerant Solutions: Refrigerant Retrofit For Existing R22 EquipmentDokument2 SeitenRefrigerant Solutions: Refrigerant Retrofit For Existing R22 EquipmentpriyoNoch keine Bewertungen

- AN-PFC-TDA 4863-3 Calculation-Tool For PFC-Preconverter Using TDA 4863Dokument9 SeitenAN-PFC-TDA 4863-3 Calculation-Tool For PFC-Preconverter Using TDA 4863NaciConSolNoch keine Bewertungen

- The 50 Most Inspiring Travel Quotes of All TimeDokument4 SeitenThe 50 Most Inspiring Travel Quotes of All Timeungku1Noch keine Bewertungen

- The Greek LettersDokument18 SeitenThe Greek LettersSupreet GuptaNoch keine Bewertungen

- Agricultural Machinery in PakistanDokument19 SeitenAgricultural Machinery in PakistanBadar NiaziNoch keine Bewertungen

- HP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessDokument4 SeitenHP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessPằngPằngChiuChiuNoch keine Bewertungen

- Blood Glucose Units Conversion Table: Endocrinology & Diabetes UnitDokument1 SeiteBlood Glucose Units Conversion Table: Endocrinology & Diabetes UnitDrFarah Emad AliNoch keine Bewertungen

- Travelsinvarious03clar BWDokument522 SeitenTravelsinvarious03clar BWSima Sorin MihailNoch keine Bewertungen

- Rockwell Allen BradleyDokument73 SeitenRockwell Allen BradleymaygomezNoch keine Bewertungen

- B2 - Effects of UV-C Treatment and Cold Storage On Ergosterol and Vitamin D2 Contents in Different Parts of White and Brown Mushroom (Agaricus Bisporus)Dokument6 SeitenB2 - Effects of UV-C Treatment and Cold Storage On Ergosterol and Vitamin D2 Contents in Different Parts of White and Brown Mushroom (Agaricus Bisporus)Nadya Mei LindaNoch keine Bewertungen

- ADT Cat D400EDokument2 SeitenADT Cat D400EEbran AndromedaNoch keine Bewertungen

- Nestle Internship ResumeDokument2 SeitenNestle Internship ResumeHasnain AshrafNoch keine Bewertungen

- Fractal Audio Footswitch Functions Guide PDFDokument22 SeitenFractal Audio Footswitch Functions Guide PDFerikNoch keine Bewertungen

- Https - Threejs - Org - Examples - Webgl - Fire - HTMLDokument9 SeitenHttps - Threejs - Org - Examples - Webgl - Fire - HTMLMara NdirNoch keine Bewertungen

- Service Manual: RP-6000 MK6 LTD RP-6000 MK6 BDokument44 SeitenService Manual: RP-6000 MK6 LTD RP-6000 MK6 BFivor EdwardsNoch keine Bewertungen

- Qualitest Canada BrochureDokument7 SeitenQualitest Canada BrochureBala SingamNoch keine Bewertungen

- SSMTT-27 E1 PDFDokument8 SeitenSSMTT-27 E1 PDFblackNoch keine Bewertungen

- PrionDokument22 SeitenPrionAnushkaNoch keine Bewertungen

- Sarason ComplexFunctionTheory PDFDokument177 SeitenSarason ComplexFunctionTheory PDFYanfan ChenNoch keine Bewertungen

- DHL Product Solutions Portfolio 2017Dokument1 SeiteDHL Product Solutions Portfolio 2017Hanzla TariqNoch keine Bewertungen

- LTE 3GPP Band13 Test Entrance CriteriaDokument130 SeitenLTE 3GPP Band13 Test Entrance CriteriaBuchi Reddy0% (1)

- Quiz Business MathDokument5 SeitenQuiz Business MathMA. JEMARIS SOLISNoch keine Bewertungen

- NTDCDokument8 SeitenNTDCjaved_hanifNoch keine Bewertungen

- Oplan Tumbler ProposalDokument3 SeitenOplan Tumbler ProposalKay Tuppil ManzanillaNoch keine Bewertungen

- Sensors & Transducers: (Code: EI 401)Dokument4 SeitenSensors & Transducers: (Code: EI 401)Mayukh BiswasNoch keine Bewertungen