Beruflich Dokumente

Kultur Dokumente

Heat Transfer Through Vertical Cylinder

Hochgeladen von

milan44Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Transfer Through Vertical Cylinder

Hochgeladen von

milan44Copyright:

Verfügbare Formate

HEAT TRANSFER THROUGH VERTICAL CYLINDER IN STATIONARY FLUID

Natural convection heat transfer has been experimentally investigated for high Raleigh number by placing the cylindrical

heating element in stationary water. The uniform heat flux has been applied to large L/D ratio in this experiment. The

thermal behavior of this heating element has been found in good agreement with the existing information. The

temperature distribution along the surface of heating element with respect to the time was recorded. The experimental

result showed that the surface temperature of the water in narrow annular space heat sink increases more than that in

wide annular space heat sink with respect to time. The heat transfer coefficient, Nusselt number and Raleigh number

have been presented for experimental data and the corresponding relation is developed.

Keywords: Natural convection, Temp. distribution, Heat transfer coefficient, Nusselt number, Raleigh number

1. Introduction

Heat Transfer is the major operation in

industries. The natural convection is observed as a

result of motion of the fluid due to density changes

by heating or cooling process. Natural convection

heat transfer from vertical cylinders is relevant to

engineering applications such as vertical tubes of

HVAC system, launch pad of space shuttle, in

restrictive heating of electronic components, heat

loss from process piping, steam heated coils and

electric immersion heater in process vessels, heat

removal from spent nuclear fuel bundles and

cooling of nuclear reactor core after loss of coolant

accident and wasted nuclear rods stores in

repositories etc.

Literature data concerning natural convective

heat transfer from vertical cylinders are

widespread [1]. Several factors can affect

significantly as the experimental conditions usually

are different and not always precisely documented.

Also there is an inaccuracy in experimental data as

the disturbances of temperature and velocity can

be affected by bulk fluid movement or by fluid

circulation in undesired position. The heated fluid

is very sensitive to slight movement in bulk fluid.

The deflection in verticality also increases the

convective heat transfer from the upper part of hot

cylinder.

The natural convection heat transfer through

vertical cylinders in various configurations has

been studied [2] studied steady state natural

convection in vertical annulus enclosed from both

ends while Chughtai and Inayat studied the

annulus open from both ends. For large values of

L/D the curvature effects can not be ignored [1].

The natural convection heat transfer from vertical

slender cylinder was investigated numerically and

experimentally by many researchers. The

correlations suggested by them do not comprise

the dimensionless height of cylinder L/D showing

that these equations are used in narrow range of

curvature parameters. The steady state natural

convection from a single cylinder with constant

heat flux was studied numerically [3-5] in which

limited experiments were performed. The

computational investigations for natural convection

over vertical cylinders was done [6] with COSINAC

code using single channel mode to achieve the

goal of assembly of cylinders for which axial

temperature distribution was experimentally

required yet. In the present study, steady state

natural convection is studied experimentally with

L/D ratio of 44.88 with outer dia of 0.5 in SS tube.

In this natural convection problem, a cylindrical

electrical heating source of constant heat flux is

placed in stationary water tank. In order to

measure the surface temperatures, thermocouples

are installed at different axial locations on cylinder.

The experiments performed at different power

levels. Thermocouples reading are recorded on

personnel computer by means of Data Acquisition

Heat transfer through vertical cylinder in stationary fluid 177

The Nucleus, 46 (3) 2009

System. For uniform heat flux, experiments are

carried out to measure the surface temperature

variation with the flow of fluid due to density

difference. The surface to ambient fluid

temperature difference obtained and dimensional

correlations will be developed. Natural convection

phenomenon is characterized by a dimensionless

combination of internal, buoyancy & viscous

forces, known as Grashof number. Raleigh

number is another dimensionless group which is

studied with variation of Nusselt number to

characterize natural convection.

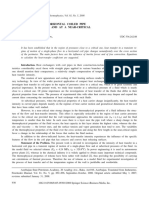

Figure 1. Schematic diagram of experimental setup.

2. Experimental

The experimental setup consists of a S.S.

cylinder, variable voltage power supply (variac),

data acquisition system and instrumentations for

temperature, voltage and current. A schematic

view of the setup is illustrated in Figure 1. The

cylinder is S.S. tube of 12.7mm outer diameter, 24

BWG, the active heated length is 570mm of total

length of 609mm. The both ends of the cylinder are

brass coupled to ensured sealing of power and

thermocouple wires against water. Twelve T-type

(copper constantan 1.5mm outer diameter)

thermocouples are embedded into the cylinder

internally at six axial positions with two

thermocouples at diametrically opposite position to

remove the perturbations in reading[7]. The

thermocouples are fiber glass insulated to resist

the temperature effects. A tubular heater of same

length of cylinder is installed at the center of S.S.

cylinder. The gap between the heater and the

cylinder wall is filled with Magnesium Oxide (MgO).

All the thermocouples are calibrated in ice and at

different temperatures using constant temperature

bath.

The cylinder was immersed vertically in 800

liter stationary demineralized water tank of 4ft

height and 2.5ft diameter. The cylinder was

internally heated by passing current through heater

by adjusting voltage. The vertical cylinder

surrounding by a quiescent bulk fluid (water) at

constant temperature T

b

is heated such that the

unit surface heat flux is constant. The experiments

to determine the heat transfer characteristics of

cylinder were conducted using demineralized

water to avoid scaling on the surface of the

cylinder. Constant power was supplied to the

cylindrical heater by adjusting voltage at same

level by variable voltage regulator (variac). The

temperature changes at the surface of the cylinder

measured by thermocouples were recorded after

each second on PC by data acquisition system.

The bulk water temperature at different depths was

found constant throughout the experiment due to

the large volume of water. The surface

temperatures were seemed to be at steady state

after 10-15 minutes but the data was recorded for

more than two hour. The verticality of the cylinder

was set very precisely. Due to high thermal

conductivity of MgO the electric power supplied to

the heater was almost obtained thermal power at

the surface of cylinder. The experiments were

performed at different power levels and

corresponding data of surface & bulk temperatures

with above procedure were recorded.

The major independent parameter of the

experiments is Grashof number. The experiment

was performed for more than two hour to reach

steady state. When the steady state was

established, the average readings of

thermocouples, input power was recorded to study

the steady state natural convection heat transfer

subjected to constant heat flux boundary

conditions were analyzed.

All the water properties are calculated at mean

film temperature (average of surface and bulk

temperature), by Yunus [8].

2

s b

f

T T

T

+

=

178

The Nucleus, 46 (3) 2009

The local Nusselt number

x

L

h L

Nu

k

=

Where

x

s x

Q

h

A T

=

The average values of Nusselt number can be

calculated as

L

L

h L

Nu

k

=

Where

0

1

x L

L x

x

h h

L

=

=

=

dx

The average values of surface temperature, bulk

temperature and mean film temperature can be

evaluated as:

0

0

1

1

2

x L

S S

x

x L

b b

x

S b

f

T T

L

T T

L

T T

T

=

=

=

=

=

=

+

=

dx

dx

The Grashof and the Raleigh numbers can be

calculated as

3

2

( )

.Pr

S b

L

L L

g L T T

Gr

Ra Gr

=

=

All the physical properties (C

p

,,, and k) of water

were evaluated at average film temperature.

3. Results and Discussion

The heating cylinder was vertically immersed in

demineralized water tank. The water tank diameter

was too large (about 750 dia of S.S. cylinder), so

the bulk temperature at different locations was

constant throughout the experiment. The condition,

constant temperature of the fluid at large

distances from heating source was satisfied.

Thermal power applied to the heater, installed at

the center of the cylinder is calculated same at the

surface of the cylinder. So the uniform heat flux is

observed at the surface of the cylinder. The

temperature was recorded by thermocouples by

taking the average value of two diametrically

installed T-type thermocouples which leads to

minimize the error caused by perturbation of the

temperature distribution around the thermocouples

measuring junction. The experiments were

performed for seven different uniform heat fluxes

ranges from 835 watt per meter square to 4422

watt per meter square with L/D of 44.88.

30.00

35.00

40.00

45.00

50.00

55.00

0 100 200 300 400 500 600

X (mm)

T

s

(

o

C

)

4422 w/m2

3474 w/m2

2770 w/m2

2216 w/m2

1693 w/m2

1240 w/m2

835 w/m2

Figure 2. Surface temperature distribution along axial distance

at different uniform heat fluxes.

The temperature variations along the vertical

cylinder at different axial distances from lower side

are shown in Figure 2. The surface temperature

distributions or different uniform heat fluxes are

illustrated. The rise in the temperature can be

observed along the axial distances as uniform heat

flux has been applied. Due to the high local heat

transfer coefficients at the lower side the surface

temperature rapidly raises in this portion and then

gradually after that as the local heat transfer

coefficient decreases as shown in Figure 3.

Generally heat flux is the main variable which may

effect the variation in surface temperature along

the cylinder. Figure 2 shows that the value of the

surface temperature gradually increases with

Heat transfer through vertical cylinder in stationary fluid 179

The Nucleus, 46 (3) 2009

length until a limit beyond which it begins to

decrease. At the lower part of the cylinder, the

boundary layer thickness is zero at the start of

heated length along the cylinder. Then the

boundary layer gradually increases which results

in heat transfer decreases locally and the surface

temperature begin to rise along the axial length of

cylinder. It should be straight after that due to

uniform heat flux but it can never approach due to

the following reason due to which the temperature

decreases. The water temperature rises as it is

heated along the cylinder and its physical

properties gradually changes with rise in

temperature. The increase in thermal conductivity

provide less resistance to the heat flow and the

decrease in viscosity gives less resistance to water

flow which causes the radial flow of hot water to

the bulk. So the local heat transfer begins to

increase. For the uniform heat flux in this portion

the temperature decrease is observed. The TsX

curve shows the variation of the surface

temperature along the cylinder for different heat

fluxes. Figure 2 reveals that the surface

temperature increase to reach the maximum value

then it decreases which can be attributed to the

development of thermal boundary layer faster due

to buoyancy effects.

0

50

100

150

200

250

300

350

400

450

500

0 100 200 300 400 500 600

X (mm)

h

x

(

w

/

m

2

o

C

)

4422 w/m2

3474 w/m2

2770 w/m2

2216 w/m2

1693 w/m2

1240 w/m2

835 w/m2

Figure 3. Local Heat Transfer Coefficient along axial distance

at different uniform heat fluxes.

The natural convection from uniformly heated

cylinder surface of length (L) exposed directly to

the water. The surface temperature variation is

used to calculate the local heat transfer coefficient

at different axial length of cylinder. The physical

properties of the water were calculated at average

film temperature. The local dimensionless

constants (Nusselt, Grashof and Raleigh number)

are calculated to find out the correlation for natural

convection heat transfer. The local Nusselt number

at different heat fluxes is plotted with the

dimensionless length of the vertical cylinder in

Figure 4. The figure shows the gradual increase in

Nusselt number along the length.

0

50

100

150

200

250

300

0 10 20 30 40 50

x/D

N

u

x

4422 w/m2

3474 w/m2

2770 w/m2

2216 w/m2

1693 w/m2

1240 w/m2

835 w/m2

Figure 4. Local Nusselt number along dimensionless length

x/D at different uniform heat fluxes.

NuL= 0.04(RaL D/L)

0.22

0.00

50.00

100.00

150.00

200.00

250.00

300.00

0 1E+12 2E+12 3E+12 4E+12 5E+12 6E+12 7E+12

RaL D/L

N

u

L

Figure 5. Correlation between average Nusselt number and

Raleigh number with geometric configuration.

The general correlation obtained by

dimensional analysis for convection heat transfer

in literature is empirically correlated in this study. In

this case of heat transfer from the surface of

180

The Nucleus, 46 (3) 2009

vertical cylinder one can expect that there are

combine effects of length and diameter. For

similarity with the flat surfaces of infinite diameter,

the characteristic linear dimensions in Nusselt and

Grashof numbers may be taken as cylinder length

(L). The Nusselt and Raleigh numbers are based

on length.

Nu

L

= f(Gr

L

Pr)

n

Figure 5 shows the average correlation

obtained from the present study for Ra

L

range

6.6x10

13

to 2.88x10

14

.

Nu

L

= 0.04(Ra

L

D/L)

0.22

4. Conclusion

The steady state natural convection heat

transfer of uniformly heated vertical cylinder has

been investigated for high Grashof numbers. The

local and average parameters are presented. The

empirical correlation for average Nusselt number

and the product of average Raleigh number & D/L

is obtained. The experimental results shows an

addition to the previous work as most of the results

are reported for Ra

L

below the range of 10

13

.

Nomenclature

L overall heated length of cylinder, m

x local length of cylinder, m

D diameter of cylinder, m

Q rate of heat transfer, watt

q heat flux, w/m

2

g gravitational acceleration, m/sec

2

Ts surface temperature,

o

C

Tb bulk temperature of water,

o

C

k thermal conductivity, w/m

o

C

Cp specific heat capacity of water, J/kg

o

C

thermal expansion coefficient, 1/

o

K

density of water, kg/m

3

dynamic viscosity of water, kg/m-s

kinematic viscosity of water, m

2

/s

h local heat transfer coefficient, w/m

2 o

C

Nu Nusselt number

Pr Prandtle number

Gr Grashof number

Ra Raleigh number

x

in suffix shows the local value

L

in suffix shows the average value

References

C.O. Popiel, Heat Transfer Engineering 29,

No. 6 (2008) 521.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

M. Keyhani, F.A. Kulacki and R.N.

Christensen, Journal of Heat Transfer-

Transactions of the ASME 105, No. 3 (1983)

454.

H.R. Nagendra, M.A. Tirunarayanan and A.

Ramachandran, Chemical Engineering

Science, 25, No. 4 (1970) 605.

J.J. Heckel, T.S. Chen and B.F. Armaly, Heat

Transfer Transaction of ASME series C111,

No. 4 (1989) 1108.

H.R. Nagendra, M.A. Tirunarayanan and A.

Ramachandran, Chem. Engg. Sci. 24, No. 9,

(1969) 1491.

M.A. Basit et al., Applied Thermal

Engineering, 27, No. 1 (2007) 194.

S. Jarall and A. Campo, Experimental Heat

Transfer, 18, No. 3 (2005) 127.

C. Yunus, Heat Transfer a practical

approach. 3rd Ed. (2004): Mc-Graw Hill

Company.

Heat transfer through vertical cylinder in stationary fluid 181

Das könnte Ihnen auch gefallen

- Experimental Transient Natural Convection Heat Transfer From A Vertical Cylindrical TankDokument8 SeitenExperimental Transient Natural Convection Heat Transfer From A Vertical Cylindrical TankGeorge MaliarisNoch keine Bewertungen

- Ts-3 Thermal Performance and Pressure Drop of The Helical-Coil Heat Ex Changers With and Without Helically Crimped FinsDokument10 SeitenTs-3 Thermal Performance and Pressure Drop of The Helical-Coil Heat Ex Changers With and Without Helically Crimped FinsSoham PatilNoch keine Bewertungen

- Research Inventy: International Journal of Engineering and ScienceDokument5 SeitenResearch Inventy: International Journal of Engineering and ScienceinventyNoch keine Bewertungen

- Ijri Te 01 001 PDFDokument10 SeitenIjri Te 01 001 PDFijripublishersNoch keine Bewertungen

- D.G. Prabhanjian, G.S.V. Raghavan, T.J. Rennie, Comparison of Heat Transfer Rates Between A Straight Tube HE and A Helically Coiled HE - 2002Dokument7 SeitenD.G. Prabhanjian, G.S.V. Raghavan, T.J. Rennie, Comparison of Heat Transfer Rates Between A Straight Tube HE and A Helically Coiled HE - 2002fromgod83Noch keine Bewertungen

- 4 7 1 SM PDFDokument5 Seiten4 7 1 SM PDFTechnico TechnocratsNoch keine Bewertungen

- Parametric Study Concentric048Dokument6 SeitenParametric Study Concentric048Narayana Swamy GNoch keine Bewertungen

- Natural Convection Heat Transfer From A Long Heated Vertical Cylinder To An Adjacent Air Gap of Concentric and Eccentric ConditionsDokument6 SeitenNatural Convection Heat Transfer From A Long Heated Vertical Cylinder To An Adjacent Air Gap of Concentric and Eccentric ConditionskarthikeyanNoch keine Bewertungen

- Experimental Study of Natural Convection Heat Transfer From An EnclosedDokument8 SeitenExperimental Study of Natural Convection Heat Transfer From An EnclosedAnonymous vVsidh3nNoch keine Bewertungen

- Heat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersDokument5 SeitenHeat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersShalehAhmad100% (1)

- Transient Analysis of Thermal Stratification in Chilled Water Storage TanksDokument8 SeitenTransient Analysis of Thermal Stratification in Chilled Water Storage TanksSamik MukherjeeNoch keine Bewertungen

- Natural Convection Heat Transfer in Vertical Internally Finned TubeDokument10 SeitenNatural Convection Heat Transfer in Vertical Internally Finned TubeAdarsh Kumar AngNoch keine Bewertungen

- Experimental and Theoretical Investigations of SpeDokument5 SeitenExperimental and Theoretical Investigations of Spefaiz firdausiNoch keine Bewertungen

- Investigation of A New Helical Flow Distributor Design To Extract Thermal Energy From Hot Water Storage TanksDokument14 SeitenInvestigation of A New Helical Flow Distributor Design To Extract Thermal Energy From Hot Water Storage TanksELECTRO MECHNoch keine Bewertungen

- Faculty of Engineering and Technology Department of Chemical EngineeringDokument10 SeitenFaculty of Engineering and Technology Department of Chemical Engineeringmasedi malatjiNoch keine Bewertungen

- Review B InggrisDokument10 SeitenReview B InggrisWillyam PrizkiabiNoch keine Bewertungen

- PergamonDokument6 SeitenPergamonArchana SomanNoch keine Bewertungen

- PressurenDrop in Double Pipe Heat ExchangersDokument5 SeitenPressurenDrop in Double Pipe Heat ExchangersdikimNoch keine Bewertungen

- Heat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidDokument5 SeitenHeat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidM. SukarmanNoch keine Bewertungen

- COMPARISON of Helical Coil Versus Straight Tube HXdocumentDokument7 SeitenCOMPARISON of Helical Coil Versus Straight Tube HXdocumentlram70Noch keine Bewertungen

- Simulation of Natural Convection in Concentric Annuli Between An Outer Inclined Square Enclosure and An Inner Horizontal CylinderDokument9 SeitenSimulation of Natural Convection in Concentric Annuli Between An Outer Inclined Square Enclosure and An Inner Horizontal CylinderIsraa YheaaNoch keine Bewertungen

- Fabrication and Design of Spiral Tube Heat Exchanger: Dr.B.jayachandriah, M. Uday Kumar, R.Jagaesh 3T.M Vamsi KrishaDokument5 SeitenFabrication and Design of Spiral Tube Heat Exchanger: Dr.B.jayachandriah, M. Uday Kumar, R.Jagaesh 3T.M Vamsi KrishadhavaleshNoch keine Bewertungen

- Applied Energy: C. Garnier, J. Currie, T. MuneerDokument5 SeitenApplied Energy: C. Garnier, J. Currie, T. MuneerResearcherzNoch keine Bewertungen

- HTC SingleFin in Water 031506Dokument5 SeitenHTC SingleFin in Water 031506Anya CooperNoch keine Bewertungen

- Zheng Yang 2016Dokument14 SeitenZheng Yang 2016Fábio A. BodnarNoch keine Bewertungen

- Revised-HT lab-Record-AUGUST-2023Dokument59 SeitenRevised-HT lab-Record-AUGUST-2023Satwik SahuNoch keine Bewertungen

- Experimental Investigation of Inclination Angle On Heat Transfer Characteristics of Wickless Solar Heat PipeDokument6 SeitenExperimental Investigation of Inclination Angle On Heat Transfer Characteristics of Wickless Solar Heat Pipeyellow_heart1837Noch keine Bewertungen

- Thermodynamics Lab ManualDokument9 SeitenThermodynamics Lab ManualEr Shankar Singh Dhami100% (2)

- Heat Transfer Lab ManualDokument43 SeitenHeat Transfer Lab ManualA SESHADRINoch keine Bewertungen

- Transferencia de Calor en Un Votator VerticalDokument21 SeitenTransferencia de Calor en Un Votator VerticalSebastian PinzonNoch keine Bewertungen

- Metal RodDokument65 SeitenMetal RodVidhya NairNoch keine Bewertungen

- Computational Simulation of Natural Convection in A Square Cavity Containing A Hot CylinderDokument10 SeitenComputational Simulation of Natural Convection in A Square Cavity Containing A Hot Cylinderlum_78Noch keine Bewertungen

- 21 Heat Transfer in Laminar Flow: ObjectiveDokument5 Seiten21 Heat Transfer in Laminar Flow: ObjectiveNadya HartasiwiNoch keine Bewertungen

- An Experimental Study of Thermal Performance of Shell-And-coil Heat ExchangersDokument7 SeitenAn Experimental Study of Thermal Performance of Shell-And-coil Heat ExchangersAbul Lais NalbandNoch keine Bewertungen

- Vertical Temperature Profiles and Borehole Resistance in A U-Tube Borehole Heat ExchangerDokument10 SeitenVertical Temperature Profiles and Borehole Resistance in A U-Tube Borehole Heat ExchangerwchavezbNoch keine Bewertungen

- Direq/CorDokument64 SeitenDireq/CorMohamed Ben MansourNoch keine Bewertungen

- Concentric Tube Heat ExchangerDokument19 SeitenConcentric Tube Heat ExchangerAnisAsyiqinNoch keine Bewertungen

- Zhou 2010Dokument6 SeitenZhou 2010unknown89meNoch keine Bewertungen

- Exp 3 AbsorptionDokument18 SeitenExp 3 Absorptionhasiqmal100% (1)

- Applied Thermal Engineering: C.J. Ho, L.C. Wei, Z.W. LiDokument8 SeitenApplied Thermal Engineering: C.J. Ho, L.C. Wei, Z.W. LireasercherNoch keine Bewertungen

- Vol 6 1 109 130 ASWATHADokument6 SeitenVol 6 1 109 130 ASWATHABvs RaghuvamsiNoch keine Bewertungen

- Helical Coil HeatDokument205 SeitenHelical Coil Heatemergingengineer100% (1)

- Air Temperature EffectDokument7 SeitenAir Temperature Effectvillaniea annisaNoch keine Bewertungen

- Thermal Modeling of Isothermal Cuboids and Rectangular Heat Sinks Cooled by Natural ConvectionDokument8 SeitenThermal Modeling of Isothermal Cuboids and Rectangular Heat Sinks Cooled by Natural ConvectionRam MurtyNoch keine Bewertungen

- Numerical Simulation of A Cylindrical Heat Pipe and Performance StudyDokument7 SeitenNumerical Simulation of A Cylindrical Heat Pipe and Performance StudypouriyaNoch keine Bewertungen

- Double Pipe Heat ExchangerDokument3 SeitenDouble Pipe Heat ExchangerSayyeda Neha FatimaNoch keine Bewertungen

- Experiment: 1 Parallel Flow Heat ExchangerDokument18 SeitenExperiment: 1 Parallel Flow Heat ExchangerAnonymous QM0NLqZONoch keine Bewertungen

- Dostal PDFDokument12 SeitenDostal PDFATUL SONAWANENoch keine Bewertungen

- Concentric TubeDokument34 SeitenConcentric TubeNajwa NaqibahNoch keine Bewertungen

- 4.ISCA RJEngS 2012 097Dokument5 Seiten4.ISCA RJEngS 2012 097andiNoch keine Bewertungen

- Solar Water Heater With Shell and Helical Coiled Tube Heat Exchanger As A Storage TankDokument11 SeitenSolar Water Heater With Shell and Helical Coiled Tube Heat Exchanger As A Storage TankKarimaNoch keine Bewertungen

- High Pressure Calorimetry Application To Phase Change Under PressureDokument8 SeitenHigh Pressure Calorimetry Application To Phase Change Under PressureAlfonso DominguezNoch keine Bewertungen

- Concentric Tube Heat Exchanger ReportDokument19 SeitenConcentric Tube Heat Exchanger Reportillyzl100% (1)

- Performance of Water Thermoelectric Cooler Connected in Series: An Experimental StudyDokument6 SeitenPerformance of Water Thermoelectric Cooler Connected in Series: An Experimental StudyInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Zhu2020 1Dokument8 SeitenZhu2020 1fabioNoch keine Bewertungen

- ESDA2012 82599 (Version Final)Dokument6 SeitenESDA2012 82599 (Version Final)Juan Pablo Ramirez VazquezNoch keine Bewertungen

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManVon EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNoch keine Bewertungen

- Final Sukhoi 9Dokument1 SeiteFinal Sukhoi 9milan44Noch keine Bewertungen

- Sukhoi Climing UpDokument1 SeiteSukhoi Climing Upmilan44Noch keine Bewertungen

- Sukhoi IsoDokument1 SeiteSukhoi Isomilan44Noch keine Bewertungen

- Figther Aircraft SukhoiDokument1 SeiteFigther Aircraft Sukhoimilan44Noch keine Bewertungen

- SukhoiDokument1 SeiteSukhoimilan44Noch keine Bewertungen

- Sukhoi Front-Top ViewDokument1 SeiteSukhoi Front-Top Viewmilan44Noch keine Bewertungen

- MIG AircraftDokument1 SeiteMIG Aircraftmilan44Noch keine Bewertungen

- Sukhoi 4Dokument1 SeiteSukhoi 4milan44Noch keine Bewertungen

- Sukhoi 5Dokument1 SeiteSukhoi 5milan44Noch keine Bewertungen

- LSA PlaneDokument1 SeiteLSA Planemilan44Noch keine Bewertungen

- Sukhoi 1Dokument1 SeiteSukhoi 1milan44Noch keine Bewertungen

- Glossary of Material TermsDokument22 SeitenGlossary of Material Termsmilan44Noch keine Bewertungen

- Sukhoi 2Dokument1 SeiteSukhoi 2milan44Noch keine Bewertungen

- Mig 29Dokument1 SeiteMig 29milan44Noch keine Bewertungen

- Cyclic PlasticityDokument2 SeitenCyclic Plasticitymilan44Noch keine Bewertungen

- AirplaneDokument1 SeiteAirplanemilan44Noch keine Bewertungen

- Mig 29Dokument1 SeiteMig 29milan44Noch keine Bewertungen

- Failure Theories Von MisesDokument12 SeitenFailure Theories Von Misesrezajun2820Noch keine Bewertungen

- Failure Theories Von MisesDokument12 SeitenFailure Theories Von Misesrezajun2820Noch keine Bewertungen

- Joining StructuresDokument5 SeitenJoining Structuresmilan44Noch keine Bewertungen

- Equations of MotionDokument8 SeitenEquations of Motionmilan44Noch keine Bewertungen

- Vabrition DataDokument20 SeitenVabrition Datamilan44Noch keine Bewertungen

- Histeresis in FatigueDokument2 SeitenHisteresis in Fatiguemilan44Noch keine Bewertungen

- Composite Failure CriteriaDokument5 SeitenComposite Failure Criteriamilan44Noch keine Bewertungen

- 978 1 58503 432 1 2Dokument24 Seiten978 1 58503 432 1 2Xavi VergaraNoch keine Bewertungen

- Glossary of Material TermsDokument22 SeitenGlossary of Material Termsmilan44Noch keine Bewertungen

- Vabrition DataDokument7 SeitenVabrition Datamilan44Noch keine Bewertungen

- SS ProfileCatalogDokument92 SeitenSS ProfileCatalogmilan44Noch keine Bewertungen

- Therm Ow Ell InstallationDokument4 SeitenTherm Ow Ell Installationmilan44Noch keine Bewertungen

- 1918 - On The Mechanical Theory of The Vibrations'of Bowed - RamanDokument34 Seiten1918 - On The Mechanical Theory of The Vibrations'of Bowed - RamanMarcus Vinicius Da Silva EvangelistaNoch keine Bewertungen

- Effect of Yaw Angle Misalignment On BrakeDokument20 SeitenEffect of Yaw Angle Misalignment On BrakeakkkkNoch keine Bewertungen

- A Micro Project Report ON: Maharashtra State Board of Technical Education, MumbaiDokument18 SeitenA Micro Project Report ON: Maharashtra State Board of Technical Education, MumbaiPrashant PoteNoch keine Bewertungen

- November2017 Physics Paper 2 HL MarkschemeDokument15 SeitenNovember2017 Physics Paper 2 HL MarkschemeAnanya AggarwalNoch keine Bewertungen

- Engineering Mechanics (10CIV23)Dokument3 SeitenEngineering Mechanics (10CIV23)RadhaAnanthalekshmiNoch keine Bewertungen

- Matlab Program For IS 1893: EARTHQUAKE RESISTANT DESIGN OF STRUCTURESDokument9 SeitenMatlab Program For IS 1893: EARTHQUAKE RESISTANT DESIGN OF STRUCTURESEr. Hisham Ajmal PC100% (2)

- Characteristics and Dynamics of Compressible Cavitating Flows With Special Emphasis On Compressibility EffectsDokument27 SeitenCharacteristics and Dynamics of Compressible Cavitating Flows With Special Emphasis On Compressibility EffectsQianZHNoch keine Bewertungen

- 00 Downhole Hydraulic KTC VersionDokument44 Seiten00 Downhole Hydraulic KTC VersionaungwinnaingNoch keine Bewertungen

- DGT Scalars and Vectors PDFDokument26 SeitenDGT Scalars and Vectors PDFJames DenisNoch keine Bewertungen

- Mechanical WavesDokument23 SeitenMechanical WavesAgus SetyawanNoch keine Bewertungen

- Yield Line TheoryDokument7 SeitenYield Line TheoryasdNoch keine Bewertungen

- 1-D, WB-2Dokument1 Seite1-D, WB-2Monal KumarNoch keine Bewertungen

- Second Day January 21 Structural 1Dokument9 SeitenSecond Day January 21 Structural 1BongA.SalinasNoch keine Bewertungen

- L2C1 MEC420 1D Kinematics of Particle FS2 PDFDokument30 SeitenL2C1 MEC420 1D Kinematics of Particle FS2 PDFMuhammad Danial Hakim Bin JohariNoch keine Bewertungen

- B.Tech. 2nd Year Chemical AICTE Model Curriculum 2019-20Dokument23 SeitenB.Tech. 2nd Year Chemical AICTE Model Curriculum 2019-20Anmol YadavNoch keine Bewertungen

- Chapter 15 (1oth Physics)Dokument2 SeitenChapter 15 (1oth Physics)Noor UlainNoch keine Bewertungen

- Chapter One-Soil Compression and Settlement AnalysisDokument92 SeitenChapter One-Soil Compression and Settlement AnalysisLencha BekeleNoch keine Bewertungen

- FrameCE ProposedDokument9 SeitenFrameCE ProposedMarvin Lester QuiatzonNoch keine Bewertungen

- 9 Dam Break PDFDokument13 Seiten9 Dam Break PDFBrandon ArmeroNoch keine Bewertungen

- Worked Example For Unbraced Frame Designed Colum Wind Moment MethodDokument22 SeitenWorked Example For Unbraced Frame Designed Colum Wind Moment MethodAce LowNoch keine Bewertungen

- Lab 3 Gas FulDokument20 SeitenLab 3 Gas FulMarouane AdamNoch keine Bewertungen

- Gearless Transmission Research PaperDokument10 SeitenGearless Transmission Research PaperresonancebansalNoch keine Bewertungen

- Machines Physics CXCDokument5 SeitenMachines Physics CXCdemetri lanezNoch keine Bewertungen

- Structural Mechanics PDFDokument2 SeitenStructural Mechanics PDFJOHN MAKOTONoch keine Bewertungen

- Energies 11 02687Dokument17 SeitenEnergies 11 02687Lucas ErburuNoch keine Bewertungen

- Experimental Studies On The Dynamic Compressive and Tensile Strength of Clay Brick Under High Strain RatesDokument12 SeitenExperimental Studies On The Dynamic Compressive and Tensile Strength of Clay Brick Under High Strain RatesalokaNoch keine Bewertungen

- Buckling and Ultimate Strength Assessment For Offshore Structures APRIL 2004Dokument5 SeitenBuckling and Ultimate Strength Assessment For Offshore Structures APRIL 2004Flávio RodriguesNoch keine Bewertungen

- Leg Calculation 02Dokument15 SeitenLeg Calculation 02rudi 01Noch keine Bewertungen