Beruflich Dokumente

Kultur Dokumente

ASTM (Kadar Air Agregat Halus)

Hochgeladen von

Efri Dwiyanto0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

250 Ansichten3 SeitenASTM (Kadar Air Agregat Halus)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenASTM (Kadar Air Agregat Halus)

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

250 Ansichten3 SeitenASTM (Kadar Air Agregat Halus)

Hochgeladen von

Efri DwiyantoASTM (Kadar Air Agregat Halus)

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Designation: C 70 94 (Reapproved 2001) An American National Standard

American Association State

Highway and Transportation Officials Standard

AASHTO No.: T142

Standard Test Method for

Surface Moisture in Fine Aggregate

1

This standard is issued under the xed designation C 70; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. Anumber in parentheses indicates the year of last reapproval. Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers eld determination of the

amount of surface moisture in ne aggregate by displacement

in water.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 128 Test Method for Specic Gravity and Absorption of

Fine Aggregate

2

C 566 Test Method for Total Moisture Content of Aggregate

by Drying

2

C 670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

2

3. Signicance and Use

3.1 This test method is not widely used. However, it is a

convenient procedure for eld or plant determination of

moisture content of ne aggregate if specic gravity values are

known and if drying facilities are not available. It can be used

to adjust aggregate weights for moisture content and to

determine surface moisture contribution to mixing water in

portland cement concrete.

3.2 The accuracy of the test method depends upon accurate

information on the bulk specic gravity of the material in a

saturated surface-dry condition.

4. Apparatus

4.1 Balance, having a capacity of 2 kg or more and sensitive

to 0.5 g or less.

4.2 FlaskA suitable container or ask, preferably of glass

or noncorrosive metal. The container may be a pycnometer, a

volumetric ask, a graduated volumetric ask, or other suitable

measuring device. The volume of the container shall be from

two to three times the loose volume of the sample. The

container shall be so designed that it can be lled to the mark,

or the volume of its contents read, within 0.5 mL or less.

5. Sample

5.1 Select a representative sample of the ne aggregate to be

tested for surface moisture content. It shall weigh not less than

200 g. Larger samples will yield more accurate results.

6. Procedure

6.1 The surface water content may be determined either by

weight or volume. In each case the test shall be made at a

temperature range of 65 to 85F (18 to 29C).

6.2 Determination by WeightDetermine the weight of the

container, in grams, lled to the mark with only water. Before

placing the sample into the container, adjust the level of the

water so that it will be sufficient to cover the sample without

going over the original mark. Introduce the weighed sample of

ne aggregate into the container and remove the entrained air.

Fill the container to the original mark, and determine the

weight in grams. Calculate the amount of water displaced by

the sample, as follows:

W

d

5 W

c

1 W

s

2 W (1)

where:

W

d

= weight of water displaced by the sample, g,

W

c

= weight of container lled to the mark with water, g,

W

s

= weight of sample, g, and

W = weight of container and sample, lled to the mark

with water, g.

6.3 Determination by VolumeMeasure a volume of water,

in millilitres, sufficient to cover the sample and place in the

container. Introduce the weighed sample of ne aggregate into

the container and remove the entrained air. Determine the

combined volume of the sample and the water by direct reading

when a graduated ask is used. When a pycnometer or

volumetric ask of known volume is used, ll the container to

the known volume mark with an additional measured volume

of water. The ask or pycnometer volume is then equal to the

combined volume of sample and water. Calculate the amount

of water displaced by the sample, as follows:

V

s

5 V

2

2 V

1

(2)

1

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee

C09.20on Normal Weight Aggregates.

Current edition approved Sept. 15, 1994. Published November 1994. Originally

published as C 70 27 T. Last previous edition C 70 79 (1992).

2

Annual Book of ASTM Standards, Vol 04.02.

1

Copyright ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

where:

V

s

= volume of water displaced by the sample, mL,

V

2

= combined volume of sample and water, mL, and

V

1

= total volume of water in the ask or pycnometer

required to cover the sample and bring the level up to

the known volume mark, mL.

7. Calculation

7.1 Calculate the percentage of surface moisture in terms of

the saturated surface-dry ne aggregate (see Appendix X1), as

follows:

P 5 @~W

d

2 V

d

!/~W

s

2 W

d

!# 3 100 (3)

where:

P = surface moisture in terms of saturated surface-dry

ne aggregate, %,

V

d

= weight of the sample (W

s

in 6.2) divided by the bulk

specic gravity of the ne aggregate in a saturated

surface-dried condition, determined as prescribed in

Test Method C 128, and

W

d

= weight of water displaced, g, and

W

s

= weight of sample, g

7.2 Calculate the percentage of surface moisture in terms of

dry aggregate if the absorption of the aggregate is known as

follows:

P

d

5 P@1 1 ~P

a

/100!# (4)

where:

P

d

= surface moisture in terms of dry ne aggregate, %,

and

P

a

= absorption of the ne aggregate, %, determined in

accordance with Test Method C 128.

Total moisture content, on a dry aggregate basis, is the sum

of the surface moisture, P

d

, and the absorption, P

a

.

8. Report

8.1 Report surface moisture test results as determined by

this method to the nearest 0.1 %.

9. Precision and Bias

9.1 This procedure is estimated to be less precise than

properly conducted moisture content tests by drying (Test

Method C 566). Accurate specic gravity information is essen-

tial to the bias of this method. Test Method C 566 can be used

to verify the level of bias.

9.2 PrecisionThese estimates of precision are based on

results from the AASHTO Materials Reference Laboratory

(AMRL) Prociency Sample Program, of testing conducted on

Fine Aggregate Prociency Sample Numbers 99 and 100. The

precision limits are based on test results submitted by 144

laboratories that tested two ne aggregate test samples of

approximately 500 g mass with average surface moisture

contents of 2.323 % and 2.075 % respectively.

9.2.1 Single-Operator PrecisionThe single-operator stan-

dard deviation of a single test result has been found to be

0.50 %.

3

Therefore, results of two properly conducted tests by

the same operator should not differ by more than 1.39 %.

9.2.2 Multilaboratory PrecisionThe multilaboratory stan-

dard deviation of a single test result has been found to be

0.82 %.

3

Therefore, results of two properly conducted tests in

different laboratories on the same material should not differ by

more than 2.31 %.

3

9.3 BiasSince there is no accepted reference material

suitable for determining the bias of this test procedure, no

statement on bias (other than that in 9.1) is made.

10. Keywords

10.1 ne aggregate; ne aggregate moisture; surface mois-

ture

APPENDIX

(Nonmandatory Information)

X1. DEVELOPMENT OF EQUATIONS

X1.1 These equations are readily derived from basic

relationships. For convenience express P in terms of the ratio

r, that is, the ratio of the weight of surface moisture to the

weight of the saturated, surface-dry sample. It follows that:

r 5

W

s

2 @W

s

/~1 1 r!#

W

s

/~1 1 r!

(X1.1)

X1.1.1 If G is bulk specic gravity of the saturated, surface-

dry ne aggregate, then

W

d

5

W

s

G~1 1 r!

1 W

s

2

W

s

1 1 r

(X1.2)

where the rst term gives the water displaced by the

saturated surface-dry ne aggregate and the second that dis-

placed by the surface moisture.

X1.1.2 From Eq X1.2:

W

s

1 1 r

5

W

d

2 W

s

1

G

2 1

(X1.3)

By denition,

W

s

5 V

d

G (X1.4)

X1.1.3 Substituting for W

s

/(1 + r) and W

s

in Eq X1.1 and

simplifying,

r 5 ~W

d

2 V

d

!/~W

s

2 W

d

! (X1.5)

3

These numbers represent, respectively, the (1s) and d2s) limits as described in

Practice C 670.

C 70

2

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

C 70

3

Das könnte Ihnen auch gefallen

- SolutionMINI CASEThe Leveraged Buyout of Cheek ProductsDokument4 SeitenSolutionMINI CASEThe Leveraged Buyout of Cheek ProductsEfri Dwiyanto100% (2)

- MCI Capital Structure TheoryDokument13 SeitenMCI Capital Structure TheoryEfri DwiyantoNoch keine Bewertungen

- PDF Warf Computers Case Chapter 27 Answers DDDokument3 SeitenPDF Warf Computers Case Chapter 27 Answers DDEfri DwiyantoNoch keine Bewertungen

- PDF Case 43 Flinder Valves and Controls Inc DDDokument9 SeitenPDF Case 43 Flinder Valves and Controls Inc DDEfri DwiyantoNoch keine Bewertungen

- Goodweek Tires SolutionDokument4 SeitenGoodweek Tires SolutionEfri DwiyantoNoch keine Bewertungen

- Yeats Valves Controls Inc SolutionDokument6 SeitenYeats Valves Controls Inc SolutionEfri DwiyantoNoch keine Bewertungen

- Casa de Diseno Integrative Case 7Dokument7 SeitenCasa de Diseno Integrative Case 7Efri DwiyantoNoch keine Bewertungen

- ASTM (Berat Jenis Semen)Dokument2 SeitenASTM (Berat Jenis Semen)Efri Dwiyanto100% (1)

- ASTM C-29 Bulk Density (Unit Weight) and Voids in Aggregate PDFDokument4 SeitenASTM C-29 Bulk Density (Unit Weight) and Voids in Aggregate PDFNur Asriana -Noch keine Bewertungen

- ASTM (Los Angeles Test)Dokument4 SeitenASTM (Los Angeles Test)Efri DwiyantoNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Weight Fixed Cone ValveDokument9 SeitenWeight Fixed Cone ValveJohn TLNoch keine Bewertungen

- Concrete Mix Proportioning Using EMMA SoftwareDokument12 SeitenConcrete Mix Proportioning Using EMMA SoftwareYuliusRiefAlkhalyNoch keine Bewertungen

- Cape Biology Unit 2 Lab PDF FreeDokument4 SeitenCape Biology Unit 2 Lab PDF FreeChanel clarksonNoch keine Bewertungen

- Supernova Simulation LabDokument3 SeitenSupernova Simulation LabAlli ANoch keine Bewertungen

- Batch: General InformationDokument5 SeitenBatch: General InformationNaik LarkaNoch keine Bewertungen

- Liquid Viscosity: 5.1. Trial ObjectivesDokument5 SeitenLiquid Viscosity: 5.1. Trial ObjectivesririnNoch keine Bewertungen

- Hysteretic Relative Permeability EffectsDokument8 SeitenHysteretic Relative Permeability Effectshfdshy12Noch keine Bewertungen

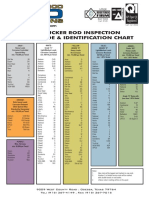

- Permian Rod Operations - Sucker Rod Identification Chart PDFDokument1 SeitePermian Rod Operations - Sucker Rod Identification Chart PDFMinimaxou78Noch keine Bewertungen

- Discussion Between Essar Power & FAG Bearings India LTDDokument2 SeitenDiscussion Between Essar Power & FAG Bearings India LTDJay Rameshbhai ParikhNoch keine Bewertungen

- N Giungas Presentation PDokument73 SeitenN Giungas Presentation PGustavo FuentesNoch keine Bewertungen

- Design of Syphon AqueductDokument118 SeitenDesign of Syphon AqueductGuru MurthyNoch keine Bewertungen

- Mole Balance: Reaction Engineering CKB 20104Dokument7 SeitenMole Balance: Reaction Engineering CKB 20104Syafiq Hashim SpikerNoch keine Bewertungen

- B31 - 3 Interpretation - Numerical Index (Volumes 1 To 25)Dokument7 SeitenB31 - 3 Interpretation - Numerical Index (Volumes 1 To 25)Jorge O Solano TorresNoch keine Bewertungen

- Chem 40.1 Msds Exer 6Dokument7 SeitenChem 40.1 Msds Exer 6Angela Sietereales RamosNoch keine Bewertungen

- Physics Form 5Dokument4 SeitenPhysics Form 5Kaiwen ChinNoch keine Bewertungen

- VSL Primary Gas StandardsDokument59 SeitenVSL Primary Gas Standards分析室信箱Noch keine Bewertungen

- Etp ManualDokument35 SeitenEtp ManualAtul Sharma100% (3)

- (1967) History of The Lenz-Ising ModelDokument13 Seiten(1967) History of The Lenz-Ising ModelJakler NicheleNoch keine Bewertungen

- BFC 3042 Chapter 4bDokument10 SeitenBFC 3042 Chapter 4bInahMisumiNoch keine Bewertungen

- Sampling Wood Preservatives Prior To Testing: Standard Test Methods ForDokument6 SeitenSampling Wood Preservatives Prior To Testing: Standard Test Methods ForNiken Bayu RNoch keine Bewertungen

- Requisitions IndexDokument13 SeitenRequisitions IndexKarnan ThirugnanamNoch keine Bewertungen

- Mock 2-Chem SPMDokument11 SeitenMock 2-Chem SPMLyna JingomNoch keine Bewertungen

- CIP13 Concrete BlistersDokument2 SeitenCIP13 Concrete Blisters7774R105Noch keine Bewertungen

- Diatomaceous Earth PDFDokument4 SeitenDiatomaceous Earth PDFYan YanNoch keine Bewertungen

- TmaDokument5 SeitenTmaShan Dela VegaNoch keine Bewertungen

- Chandan Matty Theory CompleteDokument199 SeitenChandan Matty Theory Completemir zainNoch keine Bewertungen

- Cremophor A GradesDokument8 SeitenCremophor A GradesMd.ali-bin-saifullah100% (4)

- Selective PrecipitationDokument6 SeitenSelective PrecipitationEdcademiaNoch keine Bewertungen

- Summer Holiday HomeworkDokument13 SeitenSummer Holiday Homeworkneerajbro2679Noch keine Bewertungen

- ABS Polar Ice Class Ship Structure DesignDokument48 SeitenABS Polar Ice Class Ship Structure Designronny-suNoch keine Bewertungen