Beruflich Dokumente

Kultur Dokumente

v43 165

Hochgeladen von

Krishnaveni Subramani S0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten5 Seitenkl

Originaltitel

v43-165

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenkl

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten5 Seitenv43 165

Hochgeladen von

Krishnaveni Subramani Skl

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

AbstractMultiphasing of dc-dc converters has been known to

give technical and economical benefits to low voltage high power

buck regulator modules. A major advantage of multiphasing dc-dc

converters is the improvement of input and output performances in

the buck converter. From this aspect, a potential use would be in

renewable energy where power quality plays an important factor.

This paper presents the design of a 2-phase 200W boost converter for

battery charging application. Analysis of results from hardware

measurement of the boost converter demonstrates the benefits of

using multiphase. Results from the hardware prototype of the 2-phase

boost converter further show the potential extension of multiphase

beyond its commonly used low voltage high current domains.

KeywordsMultiphase, boost converter, power electronics.

I. INTRODUCTION

HE prediction that Gordon L. Moore made in a 1965

paper, or known today as Moore`s Law, that the number

of transistor on a chip will double every 18 months is one that

has continued to agree with the historical data [1]. Since it is

not a physical law, it does not have to continue on this trend

forever. One possible deviation from the historical trend of the

number of transistor per-chip is the ever so difficult task of

powering these microprocessors [1]. For example, the average

power per transistor for a Pentium chip today is approximately

1.3W. This small amount of power becomes a relatively

large problem because the number of transistor on a chip has

already surpassed 1 billion. The current power requirements

are around 200 watts for a single microprocessor for past and

future power requirements of microprocessors [2]. The

increasing power requirements, however, do not tell the whole

story. In order to understand the real challenge we have to

look at the current and voltage requirements as well. In order

to reduce power consumption of transistors, a lower voltage is

needed. The voltage is currently on the order of 1V. Taking

into account the increasing power requirements for future

microprocessors with the reduction in voltage (Vcc), the

Taufik is with the Electrical Engineering Department, California

Polytechnic State University, San Luis Obispo, CA 93407, USA (Phone: 805-

756-2318; fax: 805-756-2318; e-mail: taufik@calpoly.edu).

Tadeus Gunawan is with the Electrical Engineering Department, California

Polytechnic State University, San Luis Obispo, CA 93407, USA (e-mail:

rprasety@calpoly.edu)

Dale Dolan is with the Electrical Engineering Department, California

Polytechnic State University, San Luis Obispo, CA 93407, USA (e-mail:

dsdolan@calpoly.edu)

Makbul Anwari is with the Department of Electrical Engineering, Makkah,

Saudi Arabia (e-mail: makbul@ieee.org).

current must therefore increase. For high performance CPUs,

currents are presently upwards of 230A increasing into the

range of 270A in 2010 [2].

The solution to this problem is solved by a creative use of

buck converters that are placed in parallel with their control

signals offset by a phase angle, or commonly known today as

a multiphase Voltage Regulator Module (VRM). A voltage

regulator module (VRM) is a dc-dc converter that provides the

necessary power into a microprocessor. Design specifications

of VRMs are typically determined by microprocessor`s

manufacturers. For example, Intel has established design

guidelines for VRM called Intel VRM11.0 [3]. Today`s VRMs

are based on a topology called the multiphase synchronous

buck converter as shown in Figure 1 [4,5,6,7,8].

Fig. 1 Multiphase synchronous buck topology.

Despite the extensive use of multiphase in buck topology,

the advantages that multiphase have to offer have been

investigated to include other topologies such as reported in

[9,10]. One major benefit of multiphase is the improvement of

input and output characteristics due to frequency

multiplication produced by the multiphasing of input and

output current. This in turn produces smaller input and output

filtering requirements as well as faster transient performance

compared to the non-multiphase counterpart per given output

power. One application that would greatly benefit from these

benefits is dc-dc converters used in renewable energy. In

particular, those converters used to charge batteries from a dc

source. In some cases, the converter is required to step up the

voltage from the source to the battery voltage; hence the need

to use a Boost converter. In this paper, the design of a 2-phase

200W boost converter will be presented to exhibit the benefits

VDC

Q1

L1

C

R

Q2

Q3

Q4

L2

PHASE 1

PHASE 2

Design and Analysis of Two-Phase Boost

DC-DC Converter

Taufik Taufik, Tadeus Gunawan, Dale Dolan and Makbul Anwari

T

World Academy of Science, Engineering and Technology 43 2010

912

and hence the potential use of multiphase scheme beyond the

buck topology.

II. TWO-PHASE BOOST CONVERTER

Figure 2 shows the basic 2-phase boost converter. One

advantage that is evident from the figure is that the multiphase

configuration allows the combination of output capacitor from

each individual boost into just a single capacitor C

O

. Due to

the frequency multiplication property of the multiphase, the

output voltage will actually have ripple component twice the

operating switching frequency of each individual boost

converter. This may further reduce the output filtering

requirement. The frequency multiplication effect also occurs

at the input side of the boost and hence reducing the input

filtering requirement as well as improving the quality of the

input current. In turns, both input and output sides of the

multiphase boost will emit less dv/dt and di/dt noises back to

the system connected to them.

Figure 3 illustrates the timing signals for the two phases

(switches Q1 and Q2). The frequency multiplication effect is

clearly shown on the combined Iin waveform as having its

period half that of individual inductor current. One advantage

that is not apparent from the Figure is the amount of peak to

peak ripple on the input current which should be half that of

each individual inductor current. This is called the ripple

cancellation effect in multiphase scheme.

Fig .2 Multiphase boost topology

Fig. 3 Timing signals for switches Q1 and Q2, the resulting inductor

current and input current, and switch currents

III. SIMULATION RESULTS

The Two-Phase Boost Converter was designed to meet

certain design parameters as listed in Table I. Since many

boost converters are being used in renewable energy

applications to step up battery output voltage, the converter

will be designed to have input and output voltages at the level

that would be achievable or usable by battery. The 200W

output power was chosen to match with available power rating

of PV panels. To ensure reliable and good quality output, the

proposed two-phase converter should have output voltage

peak-to-peak ripple and load regulation of less than 1%. In

addition, to account for variation at the input voltage, the

proposed converter should be able to maintain line regulation

within 1%. Table I summarizes the design requirements for

the 2-phase boost converter.

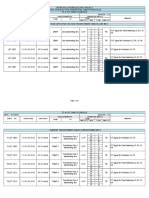

TABLE I. DESIGN REQUIREMENTS FOR THE CONVERTER

Based on these design requirements, each component in the

proposed was selected. A multiphase controller LT3782 from

Linear Technology was chosen to provide the control signals

for the two main switches in the 2-phase boost converter.

Before a hardware prototype was built, the 2-phase boost was

first simulated to ensure its operation. The software used for

the simulation is Linear`s LTSpice. The schematic of the 2-

phase boost is depicted in Figure 4 showing all the selected

components.

Table II summarizes the results from the computer

simulation. As shown the efficiency at full load is slightly

above 97%. From the table the line and load regulations are

calculated to be 0.0167% and 0.044% respectively. The peak

to peak inductor current ripple each was measured to be

0.85A. This relatively small ripple will be advantageous

mainly in suppressing rms loss at main components such as

the inductors themselves and the switches (MOSFETs). Figure

5 illustrates the final circuit board of the 2-phase boost

converter showing the top layer and bottom layer.

TABLE II. SIMULATION RESULTS

Vdc

L1

Q1

D1

L2

Q2

D2

Co

Ro

World Academy of Science, Engineering and Technology 43 2010

913

Fig. 4 LTSpiceIV schematic of the 2-phase boost converter

Figure 5 is a snapshot of the output voltage ripple during

steady state. It ripples between 48.001Volts and 47.994V with

an average value of 47.964V, approximately 99.9% of the

required value of 48V. Using the same values, the output

voltage ripple is calculated to be 0.007VP-P or 0.015% which

is well below the required 1% ripple. Secondly it is important

to check the output voltage frequency. The required operating

frequency of each phase is 500 kHz, thus creating an expected

output frequency of 1MHz due to frequency multiplication

effect of the Two-Phase topology. Looking at Figure 5, a full

period happens approximately between 19.242075ms and

19.24105ms.

This is the expected 1MHz output frequency.

Fig. 5 Output Voltage Ripple

The unfiltered output currents are recorded by measuring

the current through the schottky diodes individually. The

resulting plots have distinct characteristics, they are

discontinuous and trapezoid shaped as expected, see Figure 6.

Notice that the currents are phase shifted by 180

o

. This is

because the multiphasing forces the main MOSFETs to switch

alternately and evenly between the two phases, creating the

phase shift. The same effect also occurs for the input current

to each of the phases. This is represented by each individual

inductor current at the input stage of each phase. The overlay

waveforms of these inductor currents demonstrating the

multiphase shifting is shown in Figure 7.

Fig. 6 Output currents

Fig. 7 Overlay inductor currents

One of the main focuses in power electronics is efficiency.

Board layout, temperature and component tolerances all affect

World Academy of Science, Engineering and Technology 43 2010

914

the efficiency of a DC DC converter. In the simulation those

losses cannot be simulated. So it is apparent that the efficiency

calculations done based on the simulation result will not be

accurate, yet it gives a broad sense of the efficiency of the

design. Efficiency plot from the simulation results is given in

Figure 8 which shows efficiency above 90% above the 20%

load.

Fig. 8 Efficiency from simulation

IV. HARDWARE RESULTS

The hardware prototype was built on a pcb for reliability

using both the top and bottom layers, see Figure 9. The large

metal plate in the top layer is the ground trace for the

converter. It is made specifically so that the ground traces only

exist on the top of the board and close to the controller to

provide good grounding and thermal conductivity. On the

bottom layer there is only a few inches of ground trace to

connect the remaining parts that does not fit on the top layer.

The main focus of the PCB design is to separate the control

nodes and switching nodes as far away as possible to reduce

noise and ripple. On the top layer is where the pulse width

modulator can be found. All of the control nodes are also

found to the left and on the top layer of the board. To place the

switching nodes as far away as possible it is designed so they

are found to the right and on the bottom layer of the board.

The use of top and bottom layers also has the purpose of

getting better thermal flow and heat dissipation. As shown in

Figure 9, most components are surface mounts except for the

MOSFETs, inductors, and input capacitor.

Figure 10 shows the total input current and one of the

inductor currents, and as expected the input current has half

the peak to peak ripple as that of the individual inductor

current. The peak to peak output voltage ripple was observed

to be approximately 15mVpp which is significantly less than

the required 1%, see Figure 11. The small output voltage

ripple demonstrates one advantage of using multiphase since it

not only shows a better quality dc output but also the reduced

output filtering requirement. Load transient tests were also

performed to see how fast the proposed converter recovers

upon a step change in the load. Figure 12 shows both step up

and step down responses of the converter on its output voltage.

For the step down, the load was abruptly changed from 100%

to 10% load. The duration of the output voltage transient was

measured to be150ms. The positive overshoot of 6V was also

observed at the step change. As for the step up test, the load

was changed from 10% load to full load. At the step change

the output voltage exhibits about 7V negative overshoot which

corresponds to the large current being drawn suddenly by the

load. The transient time lasts for 125ms before settling into a

steady state. Also based on the hardware measurements, both

line and load regulations were measured at 2.11% and 8.67%.

These values exceed the targets of less than 1% for both line

and load regulations as listed in Table I.

Fig. 9 2-Phase Boost Converter circuit board showing its components

(a) top layer (b) bottom layer

Fig. 10 Inductor current and input current waveforms

Fig. 11 Output voltage peak to peak ripple

World Academy of Science, Engineering and Technology 43 2010

915

Fig. 12 Load transients: step down (top) and step up (bottom)

Lastly, the efficiency from the hardware measurements is

plotted as shown in Figure 13. The actual 2-phase boost

converter was found to be able to maintain its efficiency

consistently around 97% above 30% load as depicted in Figure

9. This is actually better than the expected values found from

the simulation and as listed in Table II where the 97% was

only achieved at 100% load. This proves yet a major

advantage of multiphasing specifically in reducing the

conduction losses due to reduced rms currents in each phase

compared to that if only one boost is used.

Fig. 13 Converter`s overal eIIiciency

V. CONCLUSION

In this paper, the benefits of using multiphase scheme for

boost converter have been demonstrated. When simulated, the

2-phase boost converter was able to achieve all desired goals.

Data obtained from hardware measurements indicated that the

converter met all of the goals except for the line and load

regulations. The line regulation may be improved by changing

the current sense resistor to make the converter more sensitive

to any change in the voltage. The load regulation on the other

hand may be improved by using higher quality output

capacitors to be able to hold the voltage better and cleaner

board layout to avoid crisscrossing of high frequency signals

on the circuit board. Nevertheless, results from hardware

measurements show the great potential of using multiphase for

boost converter especially to achieve excellent overall

converter`s eIIiciency, peak to peak output ripple, and load

transient response. It is also expected that the benefits may pay

off more for much higher output power levels such as those

used in renewable energy applications.

REFERENCES

[1]. Dodi Garinto. 'New Converter Architectures with Multi-interleaving

Technique Ior Future Microprocessors. IEEE INTELEC 2006: 28th

Annual International Telecommunications Energy Conference, 2006.

[2]. Tim Hegarty. 'BeneIits oI Multiphasing Buck Converters Part 2.

Power Management Design Line, 23 Nov. 2007.

[3]. Intel Corporation, Intel Technology Symposium, September 2001,

Seattle, WA.

[4]. X. Zhou, P. Xu, and F.C. Lee, 'A High Power Density, High Frequency

and Fast Transient Voltage Regulator Module with a Novel Current

Sharing and Current Sharing Technique, Proceedings of IEEE APEC,

1999.

[5]. X. Zhou, X. Zhang, J. Liu, P. Wong, J. Chen, H. Wu, L. Amoroso, F. C.

Lee, and D. Chen, 'Investigation oI Candidate VRM Topologies Ior

Future Microprocessors, IEEE Transactions on Power Electronics,

Volume 15, Issue 6, Nov 2000 pp. 1172 1182.

[6]. P. Xu, X. Zhou, P. Wong, K. Yao, and F.C. Lee, 'Design and

Performance Evaluation of Multi-Channel Interleaving Quasi-Square-

Wave Buck Y. Panov, M. Jovanovic, 'Design Considerations Ior 12-

V/1.5-V, 50-A Voltage Regulator Modules. IEEE Transaction on

Power Electronics, Volume 16, Issue 6, Nov. 2001, pp. 776 783.

[7]. R. MiItakhutdinov, 'Optimal Design oI Interleaved Synchronous Buck

Converter at High Slew-Rate Load Current Transients, Proceedings oI

Power Electronics Specialists Conference, 2001, Volume 3, June 2001,

pp.1714 1718.

[8]. Voltage regulator Module, Proceedings oI HFPC, 2000, pp. 82-88.

[9]. K. Agbossou, R. Simard, S. Kelouwani, A. Anouar, T. Bose,

'Multiphase control oI a boost converter Ior a renewable energy

system, Proceedings of Canadian Conference on Electrical

Engineering, May 2001, pp. 1029 1034.

[10]. J. Lee, J. Kim; C. Won; S. Jang; Y. Jung 'SoIt Switching Multi-phase

Boost Converter Ior Photovoltaic System, Proceedings oI Power

Electronics and Motion Control Conference, September 2008, pp. 1924

1928.

World Academy of Science, Engineering and Technology 43 2010

916

Das könnte Ihnen auch gefallen

- Lightning InjuriesDokument33 SeitenLightning InjuriesKrishnaveni Subramani SNoch keine Bewertungen

- Chapter - 15: Some Natural PhenomenaDokument28 SeitenChapter - 15: Some Natural PhenomenaKrishnaveni Subramani SNoch keine Bewertungen

- Engineering Study Material, Books And GuidanceDokument9 SeitenEngineering Study Material, Books And GuidancedhineshNoch keine Bewertungen

- Impedance Matching1Dokument5 SeitenImpedance Matching1Krishnaveni Subramani SNoch keine Bewertungen

- Journal of Electrostatics: Sadhana Talele, Paul Gaynor, Michael J. Cree, Jethro Van EkeranDokument14 SeitenJournal of Electrostatics: Sadhana Talele, Paul Gaynor, Michael J. Cree, Jethro Van EkeranKrishnaveni Subramani SNoch keine Bewertungen

- AC BridgesDokument10 SeitenAC BridgesKrishnaveni Subramani SNoch keine Bewertungen

- Solid-State Electronics: Lei Lin, Jian H. ZhaoDokument5 SeitenSolid-State Electronics: Lei Lin, Jian H. ZhaoKrishnaveni Subramani SNoch keine Bewertungen

- Chapter - 15: Some Natural PhenomenaDokument28 SeitenChapter - 15: Some Natural PhenomenaKrishnaveni Subramani SNoch keine Bewertungen

- 92510-7474 Ijet-IjensDokument7 Seiten92510-7474 Ijet-IjensKrishnaveni Subramani SNoch keine Bewertungen

- 2006 18 Spring Wiring Matters Power Factor Correction PFCDokument3 Seiten2006 18 Spring Wiring Matters Power Factor Correction PFCArsyad Harus SemangattNoch keine Bewertungen

- Reversed Switch-On Dynistor Switches of Gigawatt Power Microsecond PulsesDokument10 SeitenReversed Switch-On Dynistor Switches of Gigawatt Power Microsecond PulsesKrishnaveni Subramani SNoch keine Bewertungen

- Pulsed Electric Field Processing in Food Technology: Yashwant Kumar, Krishna Kumar Patel and Vivek KumarDokument12 SeitenPulsed Electric Field Processing in Food Technology: Yashwant Kumar, Krishna Kumar Patel and Vivek KumarKrishnaveni Subramani SNoch keine Bewertungen

- Basics of ElectricityDokument29 SeitenBasics of ElectricityKrishnaveni Subramani SNoch keine Bewertungen

- Real Time Pasteurization DataDokument3 SeitenReal Time Pasteurization DataKrishnaveni Subramani SNoch keine Bewertungen

- BB 1998Dokument14 SeitenBB 1998Krishnaveni Subramani SNoch keine Bewertungen

- Electrical Modeling of Medium Conductivity's Influence on ElectroporationDokument23 SeitenElectrical Modeling of Medium Conductivity's Influence on ElectroporationKrishnaveni Subramani SNoch keine Bewertungen

- Matlab Lect 3Dokument8 SeitenMatlab Lect 3Krishnaveni Subramani SNoch keine Bewertungen

- Enthan Uyir Kadhaliye PDFDokument65 SeitenEnthan Uyir Kadhaliye PDFAjay Sanmukanathan60% (5)

- Electric Field Calculations by NumericalmethodsDokument99 SeitenElectric Field Calculations by NumericalmethodsvignanarajNoch keine Bewertungen

- Impedance Matching Optimization Based On MATLABDokument112 SeitenImpedance Matching Optimization Based On MATLABKrishnaveni Subramani SNoch keine Bewertungen

- D0515032413Dokument4 SeitenD0515032413Krishnaveni Subramani SNoch keine Bewertungen

- Engineering20090100001 94428501Dokument9 SeitenEngineering20090100001 94428501Krishnaveni Subramani SNoch keine Bewertungen

- Kennedy BioPhys 08Dokument10 SeitenKennedy BioPhys 08Krishnaveni Subramani SNoch keine Bewertungen

- High-Frequency Soft-Switching DC-DC Converters For Voltage and Current DC Power SourcesDokument18 SeitenHigh-Frequency Soft-Switching DC-DC Converters For Voltage and Current DC Power SourcesFaraz AhmadNoch keine Bewertungen

- Conf 97Dokument4 SeitenConf 97Krishnaveni Subramani SNoch keine Bewertungen

- Effect of L and C On Q FactorDokument0 SeitenEffect of L and C On Q FactorTayyab NoumanNoch keine Bewertungen

- DT 31574579Dokument6 SeitenDT 31574579IJMERNoch keine Bewertungen

- Average Current Mode Control For LLC SeriesDokument8 SeitenAverage Current Mode Control For LLC SeriesKrishnaveni Subramani SNoch keine Bewertungen

- Electronics Lab 11Dokument19 SeitenElectronics Lab 11Krishnaveni Subramani SNoch keine Bewertungen

- Theory of Impedance Networks: The Two-Point Impedance and LC ResonancesDokument21 SeitenTheory of Impedance Networks: The Two-Point Impedance and LC ResonancesKrishnaveni Subramani SNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- A Simulation Research On Single Phase Bridge Full Control Resistive Load Rectifying Circuit Based On MATLABDokument6 SeitenA Simulation Research On Single Phase Bridge Full Control Resistive Load Rectifying Circuit Based On MATLABTú MinhNoch keine Bewertungen

- MIB Settings of 20 MVA Power TransformerDokument3 SeitenMIB Settings of 20 MVA Power TransformerRavi Shankar VNoch keine Bewertungen

- SKKT 132, SKKH 132: Thyristor Bridge, SCR, BridgeDokument5 SeitenSKKT 132, SKKH 132: Thyristor Bridge, SCR, BridgeRahim AfghanNoch keine Bewertungen

- Battery Charger Circuit Using SCRDokument12 SeitenBattery Charger Circuit Using SCRKeerthana Kejal50% (2)

- Zhou 2019 IOP Conf. Ser. Earth Environ. Sci. 252 032144Dokument11 SeitenZhou 2019 IOP Conf. Ser. Earth Environ. Sci. 252 032144Dante FilhoNoch keine Bewertungen

- Dynamic Modelling of Power ConvertersDokument62 SeitenDynamic Modelling of Power ConvertersAlfred ThamNoch keine Bewertungen

- Introduction to Power Electronics ConceptsDokument8 SeitenIntroduction to Power Electronics ConceptsYamburger LoveNoch keine Bewertungen

- Afridi CV 2013Dokument13 SeitenAfridi CV 2013seyed mohsen SalehiNoch keine Bewertungen

- Electricalpower Engineering Exam Study GuideDokument35 SeitenElectricalpower Engineering Exam Study GuideCharaf BelNoch keine Bewertungen

- ANNEXURE-ADokument3 SeitenANNEXURE-Amuhammad ahsanNoch keine Bewertungen

- 4857-59 Cable Schedule Sending End Switchyard LRMP TRMP CT CVT MBDokument3 Seiten4857-59 Cable Schedule Sending End Switchyard LRMP TRMP CT CVT MBDev Dutt DwivediNoch keine Bewertungen

- 5 KVA UPS Docs HI REL PDFDokument53 Seiten5 KVA UPS Docs HI REL PDFAbdelwhab ElsaftyNoch keine Bewertungen

- Presentation Ebus eDokument24 SeitenPresentation Ebus echopinaNoch keine Bewertungen

- Buck-Boost Converter - WikipediaDokument8 SeitenBuck-Boost Converter - WikipediaSudip MondalNoch keine Bewertungen

- Gating Circuit Components and FunctionsDokument2 SeitenGating Circuit Components and FunctionsAmit ParchakeNoch keine Bewertungen

- Thyristor Controlled Voltage Regulators: Working Group B4.35Dokument70 SeitenThyristor Controlled Voltage Regulators: Working Group B4.35cryss_89Noch keine Bewertungen

- BuckDokument8 SeitenBuckWoldie KassieNoch keine Bewertungen

- Diode Applications: Rectifier CircuitsDokument7 SeitenDiode Applications: Rectifier Circuitseric labordoNoch keine Bewertungen

- Bpe MicroprojectDokument8 SeitenBpe MicroprojectIshwari JadhavNoch keine Bewertungen

- Cycloconverter ManualDokument6 SeitenCycloconverter ManualShankar ArunmozhiNoch keine Bewertungen

- Galvaphil - lf1S - Alert CompleteDokument1 SeiteGalvaphil - lf1S - Alert CompleteStephen GomezNoch keine Bewertungen

- Ferrite Transformer Turns Calculation For HighDokument67 SeitenFerrite Transformer Turns Calculation For HighJaiParkash100% (1)

- European Copper Institute - Ballasts For Fluorescent LightsDokument48 SeitenEuropean Copper Institute - Ballasts For Fluorescent LightsSreekanth RaveendranNoch keine Bewertungen

- 1.characteristics of SCRDokument6 Seiten1.characteristics of SCRVenkat Sai ChowdaryNoch keine Bewertungen

- MATLAB Simulation of A Variable Speed Controller For A Three Phase Induction MotorDokument4 SeitenMATLAB Simulation of A Variable Speed Controller For A Three Phase Induction MotorSanila Cm100% (2)

- Basic-Electronics (Rectifier) !Dokument30 SeitenBasic-Electronics (Rectifier) !Rahim AnsariNoch keine Bewertungen

- Pec - Exp 1 To 10Dokument49 SeitenPec - Exp 1 To 10Harshit SolankiNoch keine Bewertungen

- Pages From 0625 - s16 - QP - 42 - 08Dokument2 SeitenPages From 0625 - s16 - QP - 42 - 08lelon ongNoch keine Bewertungen

- Skee 2324Dokument26 SeitenSkee 2324lee chungNoch keine Bewertungen

- Camry PDFDokument102 SeitenCamry PDFmihai_1957Noch keine Bewertungen