Beruflich Dokumente

Kultur Dokumente

Jsa

Hochgeladen von

Tanzeel Liaqat0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten10 SeitenTDS Rheomix 121

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTDS Rheomix 121

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten10 SeitenJsa

Hochgeladen von

Tanzeel LiaqatTDS Rheomix 121

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

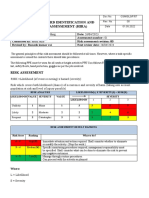

Job Hazard Analysis and Mitigation page 1 of 10

Ti t l e of Task or Empl oyee: ED& M Rout i ne Non-r out i ne Date_1/20/2006__

Complete instructions and supporting information is available at https://www-internal.slac.stanford.edu/esh/SLACsafety/jham/

Enter information into boxes which will expand to accommodate whatever length of text is entered. Once this J HA is complete, all participants

should sign in the Acknowledgement section.

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Work at computer work station, desk,

phone

Strains, eye, neck, muscle, back

problems, Repetitive Motion Injuries

(RMI) from improper use or bad

workstation ergonomics

Inadequate ventilation

Overloaded electrical circuits, fire

As needed: Ergonomic evaluation of workstation

Work station fixes as recommended by evaluation

Use of proper keyboarding techniques as recommended

by evaluation

Take breaks and use office exercise techniques

Make sure ventilation systems are functioning properly.

Have them checked if there are any questions.

Perform periodic work area self-assessment (e.g., look

for daisy chained extension cords or other safety

hazards in the work area)

Lifting, moving

Sprains, strains - back or other strain

injury from overexertion

Always use proper lifting techniques (Avoid twisting

while lifting, use your knees etc.)

Dont lift more than comfort level

Get help or use lifting tools for items exceeding 50#

Evaluate in field as needed

Use hand truck or similar for moving heavy / bulky

boxes, equipment

Work on or with metal parts in SPEAR,

on equipment racks, chassis, or

elsewhere.

Cuts from sharp edges and burrs. Review work process

Wear leather gloves

Deburr

Cover or protect edge

Hold metal with tools (e.g. vise-grips)

Job Hazard Analysis page 2 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Awkward reaching/contortion, reaching

heavy items on high shelves or racks

Muscle strain

Head bump

Cuts/lacerations

Injury from fall (see below)

Injury from dropped objects

Avoid awkward or poorly positioned reaches or lifts

reposition.

Wear gloves

Wear bump caps

Field repair/warning signs of jagged edges

Locate heavy items lower where practical, use ladder

and/or equipment when necessary. Do not overextend.

Work at height/use of ladders

Injury from fall, or from dropped objects Receive Harness training and adhere to content. Wear

fall protective harness where falls of 4 or more feet are

possible

Receive ladder training and adhere to content. Use

ladders only according to manufacturers instructions.

Stay out of ladder footprint while ladder is in use by

another.

Spotter system for power supplies and racks

Operating Circuit Breakers and

Disconnect Switches

Flash Hazard SLAC Training Course #239, General Electrical Safety

Follow the minimum PPE requirements

Category 0

Long sleeve shirt and long pants made from

natural fiber

Safety glasses/goggles

Category 1

Fire Retardant Coveralls

Hard Hat

Leather gloves

Leather shoes

Safety glasses/goggles

Follow the SSRL Circuit Breaker Reset and Disconnect

Switch Operation Procedure

Job Hazard Analysis page 3 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Walking around SSRL: shops, beam

enclosures, and other industrial areas

(i.e. work on RF power supplies in B140

[areas with limited egress, head bump

& tripping hazards])

Injury from slips, trips, falls on oily,

messy, uneven, or loose surfaces.

Injury from striking protruding objects

No running

Clean up spills on surfaces

Use good housekeeping/cleanup

Keep eyes on path

Use flashlights in dark areas (such as powers supplies &

racks)

Avoid unstable surfaces: stacked items, piles of debris,

etc.

Place foam or warning colors on head-or body bump

hazards

Use appropriate PPE and abide by specific local PPE

rules

Work in high-noise RF cavity areas Hearing loss Avoid high-noise areas when practical

Abide by warning signs

Wear PPE (ear protection) as needed

Participate in Hearing Protection Program as needed

Work on electrical equipment with high-

V or other stored energy (cables, trays,

electrical outlets, breakers)

Electric shock

Arc flash

Flying objects

High-temperatures/fires

Hazardous vapors/fumes

Get Low/High-V training (Courses 251, 274)

Use GFCI where possible

Use good housekeeping/cleanup

Use equipment only according to manufacturers

requirements

Receive Lock/Tag (Course157) training and adhere to

Lock/Tag requirements

Adhere to SSRL equipment-specific installation &

maintenance procedures

Avoid energized electrical work when possible

Get and adhere to hot work permit when working on

energized electrical equipment or systems

Use sufficient lighting during work

Attend PPE training. Use safety screen/ gloves/ mats/

goggles, protective clothing, and/or glasses accordingly

Job Hazard Analysis page 4 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Control chassis removal Struck by falling chassis Use care when removing chassis. Look for loose items,

short power cords, or impeding items. Get help or use

tool for heavy or awkward chassis.

Walking around site and into shops and

other industrial areas of site

Slips, trips, falls, sprains from uneven

walkways, pavement, obstacles

Struck by vehicle

Inadequate or missing signage, safety

features (handrails, cautions, etc.)

No running

Use good housekeeping/cleanup

Walk only on improved surfaces when possible

Keep eyes on path

Look both ways before entering blind turns

Wear safety vest for prolonged activities in high vehicle

traffic areas

Look for and adhere to signage and warning tapes, etc.

Look for hazards that may be marked. Go slowly in

unfamiliar areas.

Identify safety concerns and suggest appropriate

improvements in safety signage, equipment, etc.

Job Hazard Analysis page 5 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Use of government cars, carts,

scooters, and bicycles. Use of personal

cars on site.

Injury by collision or spill/wreck

Injury to others, struck by vehicle

Burns/fire from gasoline

Maintain California Drivers License

Slow down in rain

Drive and ride defensively

Dont tailgate or follow others closely

Keep hands free to drive/ride

Wear protective headgear on scooters

Adhere to SLAC site traffic requirements and California

auto and bike regulations and Rules of the Road

Fill tanks only at station

Take care not to spill

Do not fill vehicles from jerry can

Keep ignition sources away while filling (cell phones,

smoking, car ignition, static from car entry during filling)

Keep truck beds free from debris that could fall out

Report violations to management and use your

defensive driving dont try to correct others errors if it

could make matters worse.

Use goodhouse keeping and cleanup

Work around heavy objects. (e.g.,

power supply lifting w/genie lifts & pallet

jacks)

Foot crushing

Receive PPE training and adhere to content.

Wear safety footwear where objects >50# could crush

feet

Avoid placing feet under any possibly-crushing load

Job Hazard Analysis page 6 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Use of chemicals (solder & flux, alcohol,

epoxies, solvents, cleaning fluids,

paints, coatings, etc.)

Burn

Poisoning

Difficulty breathing

Environmental contamination

Substitute non-hazardous materials when possible

No eating at workbenches

Wash your hands after use

Perform work outdoors where possible.

Use ventilated areas when indoors. Make sure

ventilation systems are functioning properly. Have them

checked if there are any questions.

Work away from ignition sources

Use less-toxic or flammable materials where possible.

Observe and use manufacturer precautions and

instructions

Obtain and use Material Safety Data Sheets (MSDS)

(see Industrial Hygiene (x4105)) when working with new

chemicals.

Receive PPE Training and adhere to content

Dispose of waste properly

Receive training on Handling Hazardous Material

Soldering Burns

Lead poisoning

Wear protective eyewear

Receive Lead Safety Training (#240)and adhere to

content (optional)

Use ventilation at workbenches

Proper disposal of solder residue

Job Hazard Analysis page 7 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Work in places (ring, etc.) potentially

occupied by wild animals

Infection/poisoning from contact with

wild animals

(raccoons/skunks/possums/feral

cats/ground squirrels, bees & wasps,

mosquitoes, foxes, mountain lions,

rattlesnakes, poisonous spiders)

Injury from car collision w/deer

Use insect repellent and tuck pants into shoes when

working in brush or tall grass. Perform tick self-

inspections regularly.

Take care in dark places: clear cobwebs with broom or

other item rather than with body.

Look carefully under outdoor items before moving them

Look carefully under items/racks in the Klystron Gallery

before placing a hand or foot under or into them.

Avoid other wild animals.

Wave and scare mountain lions & hope they are not

hungry

Use of paper cutters, staplers, punches,

other office equipment

Cuts, puncture wounds, strains, etc. Use office equipment only in accordance with

manufacturers instructions.

Use guards to protect fingers, etc.

Use of machine tools (drill presses,

cutters)

Cuts, lacerations, or contusions from

contact with point of operation or flying

materials

Use tools only according to manufacturers instructions

Do not defeat guards on point of operation or other

moving parts

Wear protective eyewear

Do not wear loose clothing/jewelry while operating

Tie hair back out of operation area

Use ventilation on machine systems

Work with 2% Be in Cu Chronic Beryllium disease (CBD) from

Be exposure

Do not machine BeCu

Work wet w/burned up contacts

Use good housekeeping/cleanup

Consult IH (x4105) as needed, with questions

Dispose of waste properly

Use of compressed air Debris blown in eye

Injection resulting in blood clot

Wear eye protection while working with air systems

Use vented nozzles

Avoid launching heavy or large objects

Wear dust masks for cleaning work

Job Hazard Analysis page 8 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

Cable or other assembly operations

Repetitive motion injury

Eye strain/fatigue

Use ergonomic tools

Take breaks

Exercise

Contact Medical when starting long-term repetitive work

Work in High Radiation Areas Overexposure to ionizing radiation Receive Radiation Worker I training and adhere to

content

Use of hand tools (for example cable

cutters files, hammers, knives, pliers,

scissors, screwdrivers, etc.)

Cuts, lacerations, or contusions from

contact with point of operation or flying

materials

Use tools only according to manufacturers instructions

Use right tool for the job

Wear protective eyewear for any activities which could

cause flying materials (hammering, cutting, chiseling,

etc.)

Use of portable power tools (drills,

Sawzalls, Dremels, etc)

Cuts, lacerations, or contusions from

contact with point of operation or flying

materials

Use tools only according to manufacturers instructions

Do not defeat guards on point of operation or other

moving parts

Plug into GFCI outdoors or wet areas

Wear protective eyewear

Do not wear loose clothing/jewelry while operating

Tie hair back out of operation area

Modulator trouble

shooting/maintenance of ceramic items

in modulators

Cuts from broken ceramics Wear leather gloves

Day to day work with difficult or

impossible deadlines, excessive

overtime, chronic unresolved problems

Stress Clarify tasks and priorities - do what is practical, do the

highest priorities first

Identify and address self-induced stress (e.g.,

catastrophizing - making things worse than they are);

Avoid rushing to the point of errors, rework, and

omissions;

Discuss issues at safety meetings;

Talk to supervisor or peers for reality checks

Discuss stress at staff meetings

Job Hazard Analysis page 9 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

All day to day work Hazard Awareness & Response

Approach

Take personal responsibility for your safety.

o Maintain self awareness of your activities and

surroundings. Apply appropriate actions from

above for your activities

o Mentally assess tasks before proceeding.

o Get training and/or education on activities before

performing work in new or unfamiliar areas.

o If sick stay home and get better.

o Be aware of implications when someone or

environment gets hurt -- financially (worker's comp,

health costs) and professionally (time away from

work, workload impact on others

o Identify and address stress

All work - General hazards

Earthquake

Fires

Spills

Other emergencies

EMERGENCIES: Follow emergency

procedures/personnel; participate in fire and earthquake

drills

SAFETY COORDINATOR: Pay attention to local safety

coordinator announcements, advice

DEPARTMENT SAFETY MEETING: Actively participate

in stand downs; reviews; information sharing; lessons

learned; site issues and controls

EARTHQUAKE PROOFING: Ensure bookcases, files

cabinets, etc. secured to walls and floors; place Heavy

items on lower shelves

SPILL MANAGEMENT: Secure area; clean / report spill)

Job Hazard Analysis page 10 of 10

Basic Job Tasks or Steps Potential Hazards Controls & Recommended Actions

All work security issues

Unknown/unauthorized personnel in

area

Missing/damaged materials or

equipment

Offer to help unidentified people, report to supervisor

and/or security if response is inappropriate

Report disturbed work area to supervisor and/or security

All work general practices

All GET HELP: ask for help anytime, any reason, any

question; supervisor, safety coordinator; peers; ES&H

experts; get 2nd opinion

EDUCATION: Get appropriate knowledge through

training, sharing information; and open communication.

Acknowledgements Print Name Signature or Initialed Date

Supervisor: M. Widmeyer Original signed 1/20/2006 1/20/2006

Participants: Tom Dao Original signed 1/20/2006 1/20/2006

Greg Johnson Original signed 1/20/2006 1/20/2006

Ramon Ortiz Original signed 1/20/2006 1/20/2006

Fernando Rafael Original signed 1/20/2006 1/20/2006

Critt Taylor Original signed 1/20/2006 1/20/2006

Ramona Theobald Original signed 1/20/2006 1/20/2006

John Wachter Original signed 1/20/2006 1/20/2006

Scott Wallters Original signed 1/20/2006 1/20/2006

Das könnte Ihnen auch gefallen

- 1910.147 Lockout-Tagout ProgramDokument13 Seiten1910.147 Lockout-Tagout Programquang06Noch keine Bewertungen

- L-M349 (L1b1a) Kenézy Ancestral JourneyDokument20 SeitenL-M349 (L1b1a) Kenézy Ancestral JourneyGábor Balogh100% (2)

- Case Study 2, LadderDokument2 SeitenCase Study 2, LadderYasmeen Khan0% (1)

- Dry Bulk Product Safety SOPDokument14 SeitenDry Bulk Product Safety SOPWan Sek ChoonNoch keine Bewertungen

- JHA Maintenance Tech HVACDokument2 SeitenJHA Maintenance Tech HVACMdavaNoch keine Bewertungen

- Fes TBT Housekeeping PDFDokument1 SeiteFes TBT Housekeeping PDFsalem enwaijiNoch keine Bewertungen

- HSE-201-PR - Form 1 - Toolbox Meeting FormDokument1 SeiteHSE-201-PR - Form 1 - Toolbox Meeting FormCobbinah MarkNoch keine Bewertungen

- Suspended Load SafetyDokument3 SeitenSuspended Load Safetymy_agautamNoch keine Bewertungen

- General Safety Orientation Guidelines (Replaced Irp 16)Dokument29 SeitenGeneral Safety Orientation Guidelines (Replaced Irp 16)dinuveraNoch keine Bewertungen

- Company ProfileDokument15 SeitenCompany ProfileMuhammad Syaqil NgNoch keine Bewertungen

- Safety & Health ProgramDokument2 SeitenSafety & Health ProgramD.k. PathakNoch keine Bewertungen

- JHA GasesDokument2 SeitenJHA GasesalokcNoch keine Bewertungen

- General Safety Inspection ChecklistDokument1 SeiteGeneral Safety Inspection ChecklistAyşe BalamirNoch keine Bewertungen

- Personal Protective EquipmentDokument1 SeitePersonal Protective EquipmentAgnes BNoch keine Bewertungen

- Safety OfficerDokument2 SeitenSafety OfficerAathithyaNoch keine Bewertungen

- 4.2 Unit GC2: Controlling Workplace Hazards: Learning OutcomesDokument18 Seiten4.2 Unit GC2: Controlling Workplace Hazards: Learning Outcomesnavin100% (2)

- Electrical Safety: Unsafe ConditionDokument38 SeitenElectrical Safety: Unsafe ConditionYvonne TohNoch keine Bewertungen

- Mobile Scaffold Inspection ChecklistDokument3 SeitenMobile Scaffold Inspection Checklistanthony murphyNoch keine Bewertungen

- Risk Assessment ActivityDokument5 SeitenRisk Assessment ActivityHarthwell CapistranoNoch keine Bewertungen

- Generic Risk Assessment - General Lathe Use v.1Dokument7 SeitenGeneric Risk Assessment - General Lathe Use v.1Darus YasunNoch keine Bewertungen

- Workplace Safety Climate Survey: Yes - No Yes - No Yes - NoDokument2 SeitenWorkplace Safety Climate Survey: Yes - No Yes - No Yes - NoBuddy KertunNoch keine Bewertungen

- Safety Training: Hot WorksDokument66 SeitenSafety Training: Hot WorksMuneeb Ur Rehman100% (1)

- Hira - 01Dokument3 SeitenHira - 01Angw BasumataryNoch keine Bewertungen

- Metal Chop Saw SopDokument2 SeitenMetal Chop Saw SopkylealamangoNoch keine Bewertungen

- Confined SpaceDokument19 SeitenConfined SpaceAamerNoch keine Bewertungen

- Effective Safety Management Systems: by George RobothamDokument33 SeitenEffective Safety Management Systems: by George RobothamLoganathan DharmarNoch keine Bewertungen

- Hazardous Substances TBTDokument16 SeitenHazardous Substances TBTissaNoch keine Bewertungen

- Hand and Powertool Safety PDFDokument8 SeitenHand and Powertool Safety PDFJamal Uddin100% (1)

- 8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseDokument14 Seiten8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseGeyko RuslanNoch keine Bewertungen

- Respirator Inspection ChecklistDokument1 SeiteRespirator Inspection ChecklistLalit TomarNoch keine Bewertungen

- Safty ProgramDokument27 SeitenSafty ProgramMohamed ReezaNoch keine Bewertungen

- Arkansas Kraft Division Contractor Safety OrientationDokument63 SeitenArkansas Kraft Division Contractor Safety Orientationdavid_stephens_29Noch keine Bewertungen

- SOP-34 Ladders SafetyDokument3 SeitenSOP-34 Ladders SafetyBoiler ScrubberNoch keine Bewertungen

- Msds of OxygenDokument7 SeitenMsds of OxygensahilchemNoch keine Bewertungen

- Office - Safety - Training-Trident Hydrojetting Philippines Inc.Dokument40 SeitenOffice - Safety - Training-Trident Hydrojetting Philippines Inc.Dlraje DlrajeNoch keine Bewertungen

- Project HSE Monthly Activity Plan: OH&S Management SystemDokument1 SeiteProject HSE Monthly Activity Plan: OH&S Management SystemBhagat Deepak100% (1)

- TSTI FormDokument2 SeitenTSTI FormJinu ThomasNoch keine Bewertungen

- Confined Space Training OutlineDokument28 SeitenConfined Space Training OutlineCarrigan BillNoch keine Bewertungen

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Dokument6 SeitenCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- Safety Induction TrainingDokument62 SeitenSafety Induction TrainingshoaibNoch keine Bewertungen

- Mod10 Work at Height QuizDokument11 SeitenMod10 Work at Height QuizMhanna AYNoch keine Bewertungen

- TBT Manual HandlingDokument1 SeiteTBT Manual HandlingNishadh NishNoch keine Bewertungen

- Confined Space AwarenessDokument49 SeitenConfined Space Awarenesstejas gajelli100% (1)

- Confined Space SapDokument2 SeitenConfined Space SapfairusNoch keine Bewertungen

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Dokument3 SeitenKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNoch keine Bewertungen

- Example JSADokument3 SeitenExample JSAnattwa2010Noch keine Bewertungen

- HIRAC - Work - at - Height - Template PDFDokument8 SeitenHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariNoch keine Bewertungen

- Confined Spaces Standard Operating Procedure and Permit CombinedDokument8 SeitenConfined Spaces Standard Operating Procedure and Permit CombinedRaza Muhammad SoomroNoch keine Bewertungen

- OSHA 511 Sub I PPEDokument33 SeitenOSHA 511 Sub I PPEAhmed Hassan SabryNoch keine Bewertungen

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDokument3 SeitenAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNoch keine Bewertungen

- Autoclaves - Generic Assessment - L Use of AutoclavesDokument1 SeiteAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiNoch keine Bewertungen

- IM-09-A2 Working at Height ChecklistDokument2 SeitenIM-09-A2 Working at Height ChecklistVishnu SNoch keine Bewertungen

- Confined Space New SOP 19-03-2023Dokument7 SeitenConfined Space New SOP 19-03-2023Meghanath LalemmaNoch keine Bewertungen

- Appendix A-Job Safety Analysis FormDokument3 SeitenAppendix A-Job Safety Analysis Formjiks_i4uNoch keine Bewertungen

- Incident Checklist: Other ActionsDokument1 SeiteIncident Checklist: Other Actionsloveson709Noch keine Bewertungen

- Safety ProgramDokument21 SeitenSafety ProgramSits RdddNoch keine Bewertungen

- Sop LotoDokument6 SeitenSop Lotohse bsjNoch keine Bewertungen

- SHE-ECP-09-011 Good Stacking & Storage Procedure Rev02Dokument7 SeitenSHE-ECP-09-011 Good Stacking & Storage Procedure Rev02grantNoch keine Bewertungen

- Lab Design Guide ChecklistDokument9 SeitenLab Design Guide ChecklistTanveer AzizNoch keine Bewertungen

- Qcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working ADokument9 SeitenQcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working Abryanpastor106Noch keine Bewertungen

- Jsa FormDokument4 SeitenJsa FormjihadspiritNoch keine Bewertungen

- Honda CityDokument8 SeitenHonda CityTanzeel LiaqatNoch keine Bewertungen

- Industry Research Production and Linkages With Academia: Evidence From Uk Science ParksDokument18 SeitenIndustry Research Production and Linkages With Academia: Evidence From Uk Science ParksTanzeel LiaqatNoch keine Bewertungen

- CERC (2014 Edition)Dokument462 SeitenCERC (2014 Edition)Jason Simpson100% (1)

- The Contract Management Process Post AwardDokument11 SeitenThe Contract Management Process Post AwardTanzeel LiaqatNoch keine Bewertungen

- Introduction To Feasibility Studies 97Dokument32 SeitenIntroduction To Feasibility Studies 97Tanzeel LiaqatNoch keine Bewertungen

- GnatusDokument36 SeitenGnatusNacer Mezghiche100% (1)

- Police Forces and The Administration of Justice in Tanzania.Dokument6 SeitenPolice Forces and The Administration of Justice in Tanzania.Praygod Manase100% (2)

- Finance Budget - Ankur WarikooDokument28 SeitenFinance Budget - Ankur WarikooVivek Gupta100% (1)

- Campbell Smith - Harris032311Dokument2 SeitenCampbell Smith - Harris032311Heather X RhodesNoch keine Bewertungen

- Case Study of AmoebiasisDokument16 SeitenCase Study of AmoebiasisGlorielle ElvambuenaNoch keine Bewertungen

- Chapter 3 ContDokument12 SeitenChapter 3 ContVenus Frias-AntonioNoch keine Bewertungen

- Why Do Climates Change ?: Climate Changes Over The Last MillenniumDokument44 SeitenWhy Do Climates Change ?: Climate Changes Over The Last Millenniumshaira alliah de castroNoch keine Bewertungen

- IFRS Session 1 To 3Dokument40 SeitenIFRS Session 1 To 3techna8Noch keine Bewertungen

- Curriculum in MalaysiaDokument37 SeitenCurriculum in MalaysiaEmily Ling100% (1)

- Govt Considers Putting ShahbazDokument27 SeitenGovt Considers Putting ShahbazWanderer123Noch keine Bewertungen

- South WestDokument1 SeiteSouth WestDarren RadonsNoch keine Bewertungen

- Buchanan, KeohaneDokument34 SeitenBuchanan, KeohaneFlorina BortoșNoch keine Bewertungen

- SAGEM FAST 3202 (Livebox) ENGLISHDokument140 SeitenSAGEM FAST 3202 (Livebox) ENGLISHspam47spam47Noch keine Bewertungen

- Living GraceDokument227 SeitenLiving GraceÁdám NógrádiNoch keine Bewertungen

- 20 Heirs of Alfredo Bautista VS LindoDokument3 Seiten20 Heirs of Alfredo Bautista VS LindoJerome LeañoNoch keine Bewertungen

- How To Use KEATDokument5 SeitenHow To Use KEATAamir KhanNoch keine Bewertungen

- Agmt - Spa Schedule HDokument20 SeitenAgmt - Spa Schedule Hapi-340431954Noch keine Bewertungen

- Literature ReviewDokument7 SeitenLiterature Reviewapi-353923446Noch keine Bewertungen

- Onechanbara - Bikini Samurai Squad Game GuideDokument83 SeitenOnechanbara - Bikini Samurai Squad Game GuideStefan RoscaNoch keine Bewertungen

- Division of Genetics ICAR-Indian Agricultural Research Institute, New Delhi - 110012Dokument9 SeitenDivision of Genetics ICAR-Indian Agricultural Research Institute, New Delhi - 110012Shivam PateriyaNoch keine Bewertungen

- Convention Concerning The Protection of The WorldDokument41 SeitenConvention Concerning The Protection of The WorldMonica Ardeleanu100% (1)

- English ExercisesDokument2 SeitenEnglish ExercisesLiceth HuertasNoch keine Bewertungen

- J2 P IntroductionDokument9 SeitenJ2 P IntroductionnitinvnjNoch keine Bewertungen

- ACO S Range BrochureDokument20 SeitenACO S Range BrochureSyed RaziuddinNoch keine Bewertungen

- Program 2019 MTAPTL Annual Convention PDFDokument3 SeitenProgram 2019 MTAPTL Annual Convention PDFrichardlfigueroaNoch keine Bewertungen

- Determining The Value of The Acceleration Due To Gravity: President Ramon Magsaysay State UniversityDokument12 SeitenDetermining The Value of The Acceleration Due To Gravity: President Ramon Magsaysay State UniversityKristian Anthony BautistaNoch keine Bewertungen

- QAS M001 SLPS Quality Assurance ManualDokument49 SeitenQAS M001 SLPS Quality Assurance ManualMHDNoch keine Bewertungen

- My Kindergarten BookDokument48 SeitenMy Kindergarten BookfranciscoNoch keine Bewertungen