Beruflich Dokumente

Kultur Dokumente

04chapter 1WISE Edited

Hochgeladen von

dvarsastry0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten17 Seitenansys

Originaltitel

04Chapter 1WISE Edited

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenansys

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten17 Seiten04chapter 1WISE Edited

Hochgeladen von

dvarsastryansys

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 17

Chapter 1.

Getting Started with ANSYS

1.1. Performing a Typical ANSYS Analysis

The ANSYS program has many finite element analysis capabilities, ranging from a simple,

linear, static analysis to a complex, nonlinear, transient dynamic analysis. The analysis guide

manuals in the ANSYS documentation set describe specific procedures for performing analyses for

different engineering disciplines. The next few sections of this chapter cover general steps that are

common to most analyses.

A typical ANSYS analysis has three distinct steps:

uild the model.

Apply loads and obtain the solution.

!eview the results.

1.2 Bilding a !odel

uilding a finite element model re"uires more of your time than any other part of the analysis.

#irst, you specify a $obname and analysis title. Then, you use the preprocessor to define the element

types, element real constants, material properties, and the model geometry.

1.2.1. Specifying a "o#name and Analysis Title

This tas% is not re"uired for an analysis, but is recommended.

1.2.1.1. $efining the "o#name

The jobname is a name that identifies the ANSYS $ob. &hen you define a $obname for an

analysis, the $obname becomes the first part of the name of all files the analysis creates. 'The

extension or suffix for these files( names is a file identifier such as .).* y using a $obname for each

analysis, you insure that no files are overwritten.

+f you do not specify a $obname, all files receive the name %&'( or file, depending on the operating

system. You can change the default $obname as follows:

y using the initial $obname entry option when you enter the ANSYS program, either via the

launcher or on the ANSYS execution command. #or details, see the ANSYS Operations

Guide.

#rom within the ANSYS program, you can use either of the following:

)tility !en*%ile*Change "o#name

1.2.1.2. $efining an Analysis Title

The ,tility -enu.#ile./hange Title, defines a title for the analysis. ANSYS includes the title

on all graphics displays and on the solution output.

1.2.1.+. $efining )nits

The ANSYS program does not assume a system of units for your analysis. 0xcept in

magnetic field analyses, you can use any system of units so long as you ma%e sure that you use that

system for all the data you enter. ',nits must be consistent for all input data.*

1.2.2. $efining (lement Types

The ANSYS element library contains more than 123 different element types. 0ach element

type has a uni"ue number and a prefix that identifies the element category: 0A-4, 56AN077,

S86+)9:, etc. The following element categories are available:

0A-

/8-+Nation

/8NTA/t

#6,+)

;Y50!elastic

+N#+Nite

6+N<

-ASS

-AT!+=

5+50

56AN0

S;066

S86+)

S8,!/e

S,!#ace

TA!>0t

,S0!

+NT0!face

?+S/8elastic 'or viscoplastic*

The element type determines, among other things:

The degree@of@freedom set 'which in turn implies the discipline@@structural, thermal, magnetic,

electric, "uadrilateral, bric%, etc.*

&hether the element lies in two@dimensional or three@dimensional space.

0A-4, for example, has six structural degrees of freedom ',=, ,Y, ,A, !8T=, !8TY, !8TA*, is a

line element, and can be modeled in B@) space. 56AN077 has a thermal degree of freedom 'T0-5*,

is an eight@node "uadrilateral element, and can be modeled only in C@) space.

You must be in the general preprocessor, to define element types.

You define the element type by name and give the element a type reference number.

This table of type reference number versus element name is called the element type table.

&hile defining the actual elements, you point to the appropriate type reference number using

'!ain !en*Preprocessor*Create*(lements*(lem Attri#tes*.

-any element types have additional options, %nown as <0Y85Ts, and are referred to as

<0Y85T'1*, <0Y85T'C*, etc. #or example, <0Y85T'9* for 0A-4 allows you to choose results to

be calculated at intermediate locations on each element, and <0Y85T'B* for S;066:B allows you to

suppress extra displacement shapes. You can specify <0Y85Ts using

'!ain !en*Preprocessor*(lement Type*Add,(dit,$elete*.

1.2.+. $efining (lement -eal Constants

0lement real constants are properties that depend on the element type, such as cross@sectional

properties of a beam element. #or example, real constants for 0A-B, the C@) beam element, are

area 'A!0A*, moment of inertia '+AA*, height ';0+>;T*, shear deflection constant 'S;0A!A*, initial

strain '+ST!N*, and added mass per unit length 'A))-AS*. Not all element types re"uire real

constants, and different elements of the same type may have different real constant values.

You can specify real constants using menu pathsD see the ANSYS Commands Reference for further

information. As with element types, each set of real constants has a reference number, and the table

of reference number versus real constant set is called the real constant table. &hile defining the

elements, you point to the appropriate real constant reference number using

'!ain !en*Preprocessor*Create*(lements*(lem Attri#tes*.

&hile defining real constants, %eep these rules and guidelines in mind:

#or models using multiple element types, use a separate real constant set 'that is, a different

reference number* for each element type. The ANSYS program issues a warning message if

multiple element types reference the same real constant set. ;owever, a single element type

may reference several real constant sets.

To verify your real constant input, use

)tility !en*'ist*(lements*Attri#tes . -ealConst

)tility !en*'ist*(lements*Attri#tes /nly

)tility !en*'ist*(lements*Nodes . Attri#tes

)tility !en*'ist*(lements*Nodes . Attri#tes . -ealConst

)tility !en*'ist*Properties*All -eal Constants

)tility !en*'ist*Properties*Specified -eal Const

#or line and area elements that re"uire geometry data 'cross@sectional area, thic%ness,

diameter, etc.* to be specified as real constants, you can verify the input graphically by using

the following procedure in the order shown:

)tility !en*PlotCtrls*Style*Si0e and Shape

)tility !en*Plot*(lements

ANSYS displays the elements as solid elements, using a rectangular cross@section for lin% and shell

elements and a circular cross@section for pipe elements. The cross@section proportions are

determined from the real constant values.

1.2.+.1. Creating Cross Sections

+f you are building a model using 0A-44, 0A-1EE, or 0A-1E9, you can use the section

commands >,+ path e"uivalents to define and use cross sections in your models. See Beam

Analysis and Cross Sections in the ANSYS Structural Analysis Guide for information on how to use

the eamTool to create cross sections.

1.2.1. $efining !aterial Properties

-ost element types re"uire material properties. )epending on the application, material

properties may be:

6inear or nonlinear

+sotropic, orthotropic, or anisotropic

/onstant temperature or temperature@dependent.

As with element types and real constants, each set of material properties has a material

reference number. The table of material reference numbers versus material property sets is

called the material table. &ithin one analysis, you may have multiple material property sets

'to correspond with multiple materials used in the model*. ANSYS identifies each set with a

uni"ue reference number.

&hile defining the elements, you point to the appropriate material reference number using the

following:

!ain !en*Preprocessor*2Attri#tes2*$efine*$efalt Attri#s

1.2.3. Creating the !odel Geometry

8nce you have defined material properties, the next step in an analysis is generating a finite element

model@@nodes and elements@@that ade"uately describes the model geometry. The graphic below

shows some sample finite element models:

%igre 12+. Some sample finite element models

There are two methods to create the finite element model: solid modeling and direct generation. &ith

solid modeling, you describe the geometric shape of your model, then instruct the ANSYS program to

automatically mesh the geometry with nodes and elements. You can control the siFe and shape in the

elements that the program creates. &ith direct generation, you GmanuallyG define the location of each

node and the connectivity of each element. Several convenience operations, such as copying

patterns of existing nodes and elements, symmetry reflection, etc. are available.

)etails of the two methods and many other aspects related to model generation@@coordinate systems,

wor%ing planes, coupling, constraint e"uations, etc.@@are described in the ANSYS Modeling and

Meshing Guide.

1.2.3.1 !odel Generation

The ultimate purpose of a finite element analysis is to re@create mathematically the behavior of an

actual engineering system. +n other words, the analysis must be an accurate mathematical model of a

physical prototype. +n the broadest sense, this model comprises all the nodes, elements, material

properties, real constants, boundary conditions, and other features that are used to represent the

physical system.

+n ANSYS terminology, the term model generation usually ta%es on the narrower meaning of

generating the nodes and elements that represent the spatial volume and connectivity of the actual

system. Thus, model generation in this discussion will mean the process of defining the geometric

configuration of the models nodes and elements! The ANSYS program offers you the following

approaches to model generation:

Creating a solid model within ANSYS.

Using direct generation.

Importing a model created in a computer-aided design (CAD) system.

1.2.3.2 Typical Steps &n4ol4ed in !odel Generation within ANSYS

A common modeling session might ollow this general outline

(detailed inormation on italici!ed su"#ects can "e ound elsewhere

in this guide)$

egin by planning your approach. )etermine your ob$ectives, decide what basic form your

model will ta%e, choose appropriate element types, and consider how you will establish an

appropriate mesh density. You will typically do this general planning before you initiate your

ANSYS session.

0nter the preprocessor to initiate your model@building session. -ost often, you will build your

model using solid modeling procedures.

0stablish a "or#ing plane.

>enerate basic geometric features using geometric primiti$es and Boolean operators.

Activate the appropriate coordinate system.

>enerate other solid model features from the bottom up. That is, create #eypoints, and then

define lines, areas, and $olumes as needed.

,se more Boolean operators or number controls to $oin separate solid model regions

together as appropriate.

/reate tables of element attributes 'element types, real constants, material properties, and

element coordinate systems*.

Set elements attribute pointers.

Set meshing controls to establish your desired mesh density if desired. This step is not

always re"uired because default element siFes exist when you enter the program. '+f you

want the program to refine the mesh automatically, exit the preprocessor at this point, and

activate adapti$e meshing.*

/reate nodes and elements by meshing your solid model.

After you have generated nodes and elements, add features such as surface%to%surface

contact elements, coupled degrees of freedom, and constraint e&uations.

Save your model data to 'obname!).

0xit the preprocessor.

1.2.3.2.1 Comparing Solid !odeling and $irect Generation

You can use two different methods to generate your model: solid modeling and direct generation. &ith

solid modeling, you describe the geometric boundaries of your model, establish controls over the siFe

and desired shape of your elements, and then instruct the ANSYS program to generate all the nodes

and elements automatically. y contrast, with the direct generation method, you determine the location

of every node and the siFe, shape, and connectivity of every element prior to defining these entities in

your ANSYS model.

Although some automatic data generation is possible, the direct generation method is essentially a

hands@on, GmanualG method that re"uires you to %eep trac% of all your node numbers as you develop

your finite element mesh. This detailed boo%%eeping can become tedious for large models,

contributing to the potential for modeling errors. Solid modeling is usually more powerful and versatile

than direct generation, and is commonly the preferred method for generating your model.

+n spite of the many advantages of solid modeling, you might occasionally encounter circumstances

where direct generation will be more useful. You can easily switch bac% and forth between direct

generation and solid modeling, using the different techni"ues as appropriate to define different parts of

your model.

%o help you #udge which method might "e more suita"le or a gi&en situation'

the relati&e ad&antages and disad&antages o the two approaches are

summari!ed here.

1.2.3.2.1.1 Solid !odeling

8n the plus side, solid modeling

+s generally more appropriate for large or complex models, especially B@) models of solid

volumes.

Allows you to wor% with a relatively small number of data items.

Allows geometric operations 'such as dragging and rotations* that cannot be done with nodes

and elements.

Supports the use of GprimitiveG areas and volumes 'such as polygonal areas and cylindrical

volumes* and oolean operations 'intersections, subtractions, etc.* for Gtop downG

construction of your model.

#acilitates your use of the ANSYS program(s design optimiFation features.

+s re&uired for adaptive meshing.

+s re"uired in order to do area mesh refinement after loads have been applied 'solid model

loads are also re"uired*.

!eadily allows modifications to geometry.

#acilitates changes to element distributionD you are not bound to one analysis model.

;owever, solid modeling

/an sometimes re"uire large amounts of /5, time.

/an 'for small, simple models* sometimes be more cumbersome, re"uiring more data entries

than direct generation.

/an sometimes GfailG 'the program will not be able to generate the finite element mesh* under

certain circumstances.

1.2.3.2.1.2 $irect Generation

(n the plus side' direct generation

Is con&enient or small or simple models.

)ro&ides you with complete control o&er the geometry and num"ering o

e&ery node and e&ery element.

*owe&er' direct generation

Is usually too time consuming or all "ut the simplest models+ the &olume

o data you must wor, with can "ecome o&erwhelming.

Cannot "e used with adapti&e meshing.

-a,es design optimi!ation less con&enient.

-a,es it di.cult to modiy the mesh (tools such as area mesh re/nement'

SmartSi!ing' etc. cannot "e used).

Can "ecome tedious' re0uiring you to pay more attention to e&ery detail

o your mesh+ tedium can sometimes cause you to "ecome more prone to

committing errors.

1.2.3.+ &mporting Solid !odels Created in CA$ systems

As an alternati&e to creating your solid models within ANSYS' you can create

them in your a&orite CAD system and then import them into ANSYS or analysis.

%his has the ollowing ad&antages$

You can a&oid a duplication o e1ort "y using e2isting CAD models to

generate solid models or analysis.

3ngineers can use amiliar tools to create their models.

*owe&er' models imported rom CAD systems may re0uire e2tensi&e repair i

they are not o suita"le 0uality or meshing.

1.2.5. Apply 'oads and /#tain the Soltion

+n this step, you use the S86,T+8N processor to define the analysis type and analysis options, apply

loads, specify load step options, and initiate the finite element solution. You also can apply loads

using the 5!057 preprocessor.

1.2.5.1. $efining the Analysis Type and Analysis /ptions

You choose the analysis type based on the loading conditions and the response you wish to

calculate. #or example, if natural fre"uencies and mode shapes are to be calculated, you would

choose a modal analysis. You can perform the following analysis types in the ANSYS program: static

'or steady@state*, transient, harmonic, modal, spectrum, buc%ling, and substructuring.

Not all analysis types are valid for all disciplines. -odal analysis, for example, is not valid for a

thermal model. The analysis guide manuals in the ANSYS documentation set describe the analysis

types available for each discipline and the procedures to do those analyses.

Analysis options allow you to customiFe the analysis type. Typical analysis options are the method of

solution, stress stiffening on or off, and Newton@!aphson options.

To define the analysis type and analysis options, use !ain !en*Preprocessor*'oads*New

Analysis or !ain !en* Preprocessor*'oads*-estart and the appropriate analysis option

commands

+f you are performing a static or full transient analysis, you can ta%e advantage of the Solution

/ontrols dialog box to define many options for the analysis. #or details about the Solution /ontrols

dialog box, see Solution.

You can specify either a new analysis or a restart, but a new analysis is the choice in most cases. A

single frame restart that allows you to resume a $ob at its end point or abort point is available for static

'steady@state*, harmonic 'C@) magnetic only*, and transient analyses. A multiframe restart that allows

you to restart an analysis at any point is available for static or full transient structural analyses. See

Restarting an Analysis for complete information on performing restarts. The various analysis guides

discuss additional details necessary for restarts. You cannot change the analysis type and analysis

options after the first solution.

8nce you have defined the analysis type and analysis options, the next step is to apply loads. Some

structural analysis types re"uire other items to be defined first, such as master degrees of freedom

and gap conditions. The ANSYS Structural Analysis Guide describes these items where necessary.

1.2.5.2. Applying 'oads

The word loads as used in ANSYS documentation includes boundary conditions 'constraints,

supports, or boundary field specifications* as well as other externally and internally applied loads.

6oads in the ANSYS program are divided into six categories:

)8# /onstraints

#orces

Surface 6oads

ody 6oads

+nertia 6oads

/oupled@field 6oads

You can apply most of these loads either on the solid model '%eypoints, lines, and areas* or the finite

element model 'nodes and elements*. #or details about the load categories and how they can be

applied on your model, see (oading in this manual.

Two important load@related terms you need to %now are load step and substep. A load step is simply a

configuration of loads for which you obtain a solution. +n a structural analysis, for example, you may

apply wind loads in one load step and gravity in a second load step. 6oad steps are also useful in

dividing a transient load history curve into several segments.

Substeps are incremental steps ta%en within a load step. You use them mainly for accuracy and

convergence purposes in transient and nonlinear analyses. Substeps are also %nown as time steps@@

steps ta%en over a period of time.

Note@@The ANSYS program uses the concept of time in transient analyses as well as

static 'or steady@state* analyses. +n a transient analysis, time represents actual time, in

seconds, minutes, or hours. +n a static or steady@state analysis, time simply acts as a

counter to identify load steps and substeps.

1.2.5.+. Specifying 'oad Step /ptions

6oad step options are options that you can change from load step to load step, such as number of

substeps, time at the end of a load step, and output controls. )epending on the type of analysis you

are doing, load step options may or may not be re"uired. The analysis procedures in the analysis

guide manuals describe the appropriate load step options as necessary. See (oading for a general

description of load step options.

1.2.5.1. &nitiating the Soltion

To initiate solution calculations, use either of the following:

!ain !en*Soltion*Crrent 'S

!ain !en*Soltion*soltion6method

&hen you issue this command, the ANSYS program ta%es model and loading information from the

database and calculates the results. !esults are written to the results file 'Jobname.RST,

Jobname.RTH, Jobname.RMG, or Jobname.RFL* and also to the database. The only difference is

that only one set of results can reside in the database at one time, while you can write all sets of

results 'for all substeps* to the results file.

You can solve multiple load steps in a convenient manner:

!ain !en*Soltion*%rom 'S %iles

Solution discusses this and other solution@related topics.

1.2.7. -e4iew the -eslts

8nce the solution has been calculated, you can use the ANSYS postprocessors to review the results.

Two postprocessors are available: General Postproc and Time8ist Postpro.

You use the general postprocessor, to review results at one substep 'time step* over the entire model

or selected portion of the model. The command '!ain !en*General Postproc*, valid only at the

egin level. You can obtain contour displays, deformed shapes, and tabular listings to review and

interpret the results of the analysis. This postprocessor offers many other capabilities, including error

estimation, load case combinations, calculations among results data, and path operations.

You use the time history postprocessor, to review results at specific points in the model over all time

steps. The command '!ain !en*Time8ist Postpro*, valid only at the egin level. You can obtain

graph plots of results data versus time 'or fre"uency* and tabular listings. 8ther capabilities include

arithmetic calculations and complex algebra..

Chapter 2. 'oading

2.1. Loading Overview

The main goal of a finite element analysis is to examine how a structure or component responds to

certain loading conditions. Specifying the proper loading conditions is, therefore, a %ey step in the

analysis. You can apply loads on the model in a variety of ways in the ANSYS program. Also, with the

help of load step options, you can control how the loads are actually used during solution.

2.2. 9hat Are 'oads:

The word loads in ANSYS terminology includes boundary conditions and externally or internally

applied forcing functions, as illustrated in (oads. 0xamples of loads in different disciplines are:

Structural) displacements, forces, pressures, temperatures 'for thermal strain*, gravity

*hermal) temperatures, heat flow rates, convections, internal heat generation, infinite surface

Magnetic) magnetic potentials, magnetic flux, magnetic current segments, source current density,

infinite surface

+lectric) electric potentials 'voltage*, electric current, electric charges, charge densities, infinite

surface

,luid) velocities, pressures

%igre 221. 'oads inclde #ondary conditions as well as other types of loading

6oads are divided into six categories: )8# constraints, forces 'concentrated loads*, surface loads,

body loads, inertia loads, and coupled@field loads.

A -O, constraint fixes a degree of freedom ')8#* to a %nown value. 0xamples of constraints

are specified displacements and symmetry boundary conditions in a structural analysis,

prescribed temperatures in a thermal analysis, and flux@parallel boundary conditions.

A force is a concentrated load applied at a node in the model. 0xamples are forces and

moments in a structural analysis, heat flow rates in a thermal analysis, and current segments

in a magnetic field analysis.

A surface load is a distributed load applied over a surface. 0xamples are pressures in a

structural analysis and convections and heat fluxes in a thermal analysis.

A body load is a volumetric or field load. 0xamples are temperatures and fluences in a

structural analysis, heat generation rates in a thermal analysis, and current densities in a

magnetic field analysis.

.nertia loads are those attributable to the inertia 'mass matrix* of a body, such as gravitational

acceleration, angular velocity, and angular acceleration. You use them mainly in a structural

analysis.

Coupled%field loads are simply a special case of one of the above loads, where results from

one analysis are used as loads in another analysis. #or example, you can apply magnetic

forces calculated in a magnetic field analysis as force loads in a structural analysis.

2.5. 8ow to Apply 'oads

You can apply most loads either on the solid model 'on %eypoints, lines, and areas* or on the finite

element model 'on nodes and elements*. #or example, you can specify forces at a %eypoint or a

node. Similarly, you can specify convections 'and other surface loads* on lines and areas or on nodes

and element faces. No matter how you specify the loads, the solver expects all loads to be in terms of

the finite element model. Therefore, if you specify loads on the solid model, the program automatically

transfers them to the nodes and elements at the beginning of solution.

2.5.1. Solid2!odel 'oads; Ad4antages and $isad4antages

Ad4antages

Solid@model loads are independent of the finite element mesh. That is, you can change the

element mesh without affecting the applied loads. This allows you to ma%e mesh

modifications and conduct mesh sensitivity studies without having to reapply loads each time.

The solid model usually involves fewer entities than the finite element model. Therefore,

selecting solid model entities and applying loads on them is much easier, especially with

graphical pic%ing.

$isad4antages

0lements generated by ANSYS meshing commands are in the currently active element

coordinate system. Nodes generated by meshing commands use the global /artesian

coordinate system. Therefore, the solid model and the finite element model may have

different coordinate systems and loading directions.

Solid@model loads are not very convenient in reduced analyses, where loads are applied at

master degrees of freedom. 'You can define master )8# only at nodes, not at %eypoints.*

Applying %eypoint constraints can be tric%y, especially when the constraint expansion option

is used. 'The expansion option allows you to expand a constraint specification to all nodes

between two %eypoints that are connected by a line.*

You cannot display all solid@model loads.

Notes a#ot Solid2!odel 'oads

As mentioned earlier, solid@model loads are automatically transferred to the finite element

model at the beginning of solution. The ANSYS program overwrites any loads that already

exist on corresponding finite element entities.

)eleting solid@model loads also deletes all corresponding finite@element loads.

2.5.2. %inite2(lement 'oads: Advantages and )isadvantages

Ad4antages

!educed analyses present no problems, because you can apply loads directly at master

nodes.

There is no need to worry about constraint expansion. You can simply select all desired

nodes and specify the appropriate constraints.

$isad4antages

Any modification of the finite element mesh invalidates the loads, re"uiring you to delete the

previous loads and re@apply them on the new mesh.

Applying loads by graphical pic%ing is inconvenient, unless only a few nodes or elements are

involved.

The next few subsections discuss how to apply each category of loads@@constraints, forces,

surface loads, body loads, inertia loads, and coupled@field loads@@and then explain how to

specify load step options.

2.6.3. DOF Constraints

DOF constraints shows the degrees o reedom that can "e constrained in each

discipline and the corresponding ANSYS la"els. Any directions implied "y the

la"els (such as U4' 5(%6' AY' etc.) are in the nodal coordinate system. 7or a

description o di1erent coordinate systems' see the ANSYS Modeling and

Meshing Guide.

Commands for -O, constraints shows the commands to apply, list, and delete )8# constraints.

Notice that you can apply constraints on nodes, %eypoints, lines, and areas.

Ta#le 221. $/% constraints a4aila#le in each discipline

$iscipline $egree of %reedom ANSYS 'a#el

Structural

Translations

!otations

,=, ,Y, ,A

!8T=, !8TY, !8TA

Thermal Temperature T0-5

-agnetic

?ector 5otentials

Scalar 5otential

A=, AY, AA

-A>

0lectric ?oltage ?86T

#luid

?elocities

5ressure

Turbulent <inetic 0nergy

Turbulent )issipation !ate

?=, ?Y, ?A

5!0S

0N<0

0N)S

elow are examples of some of the >,+ paths you can use to apply )8# constraints:

!ain !en*Preprocessor*2'oads2*Apply*load type*/n Nodes

)tility !en*'ist*'oads*$/% Constraints*/n <eypoints

!ain !en*Soltion*Apply*load type*/n 'ines

See the ANSYS Commands Reference for additional >,+ path information and for descriptions of the

commands listed in Commands for -O, constraints.

2.5.5. %orces =Concentrated 'oads)

,orces a$ailable in each discipline shows a list of forces available in each discipline and the

corresponding ANSYS labels. Any directions implied by the labels 'such as #=, -A, /S>Y, etc.* are

in the nodal coordinate system. 'See Coordinate Systems in the ANSYS Modeling and Meshing

Guide for a description of different coordinate systems.* Commands for applying force loads lists the

commands to apply, list, and delete forces. Notice that you can apply them at nodes as well as

%eypoints.

Ta#le 22+. >%orces> a4aila#le in each discipline

$iscipline %orce ANSYS 'a#el

Structural

#orces

-oments

#=, #Y, #A

-=, -Y, -A

Thermal ;eat #low !ate ;0AT

-agnetic

/urrent Segments

-agnetic #lux

0lectrical /harge

/S>=, /S>Y, /S>A

#6,=

/;!>

0lectric

/urrent

/harge

A-5S

/;!>

#luid #luid #low !ate #68&

elow are examples of some of the >,+ paths to use for applying force loads:

!ain !en*Preprocessor*2'oads2Apply*load type*/n Nodes

)tility !en*'ist*'oads*%orces*/n <eypoints

!ain !en*Soltion*2'oads2Apply*load type*/n 'ines

See the ANSYS Commands Reference for descriptions of the commands listed in Table C@4.

2.5.5.1. -epeating a %orce

y default, if you repeat a force at the same degree of freedom, the new specification replaces the

previous one. You can change this default to add 'for accumulation* or ignore by using one of the

following:

!ain !en*Preprocessor*2'oads2Settings*%orces

!ain !en*Soltion*2'oads2Settings*2-eplace 4s. Add2%orces

2.5.5.2. Scaling %orce ?ales

The following command allows you to scale existing force values:

!ain !en*Preprocessor*'oads*/perate*2Scale %( 'oads2%orces

!ain !en*Soltion*/perate*2Scale %( 'oads2%orces

2.5.5.+. Transferring %orces

To transfer forces that have been applied to the solid model to the corresponding finite element

model, use one of the following:

!ain !en*Preprocessor*'oads*/perate*2Transfer to %(2*%orces

!ain !en*Soltion*/perate*2Transfer to %(2*%orces

To transfer all solid model boundary conditions, use:

!ain !en*Preprocessor*'oads*/perate*2Transfer to %(2*All Solid 'ds

!ain !en*Soltion*/perate*2Transfer to %(2*All Solid 'ds

2.5.7. Srface 'oads

Surface Loads Available shows surace loads a&aila"le in each discipline and

their corresponding ANSYS la"els. %he commands to apply' list' and delete

surace loads are shown in Commands for appling surface loads. You can apply

them at nodes and elements' as well as at lines and areas.

Table 2-5. Surfae loads available in ea! disi"line

$iscipline Srface 'oad ANSYS 'a#el

Structural 5ressure 5!0S/

Thermal

/onvection

;eat #lux

+nfinite Surface

/8N?

;#6,=

+N#

-agnetic

-axwell Surface

+nfinite Surface

-=&#

+N#

0lectric

-axwell Surface

Surface /harge )ensity

+nfinite Surface

-=&#

/;!>S

+N#

#luid

#luid@Structure +nterface

+mpedance

#S+

+-5)

All Superelement 6oad ?ector S06?

1. )o not confuse this with the 5!0S degree of freedom

elow are examples of some of the >,+ paths to use for applying surface loads.

!ain !en*Preprocessor*2'oads2*Apply*load type*/n Nodes

)tility !en*'ist*'oads*Srface 'oads*/n (lements

!ain !en*Soltion*2'oads2*Apply*load type*/n 'ines

See the descriptions of the commands listed in Commands for applying surface loads in the ANSYS

Commands Reference for more information.

Note@@The ANSYS program stores surface loads specified on nodes

internally in terms of elements and element faces. Therefore, if you use

both nodal and element surface load commands for the same surface,

only the last specification will be used.

ANSYS applies pressures on axisymmetric shell elements or beam elements on their inner or outer

surfaces, as appropriate. +n@plane pressure load vectors for layered shells 'S;06691 and S;06699 *

are applied on the nodal plane. <0Y85T'11* determines the location of the nodal plane within the

shell. &hen you use flat elements to represent doubly curved surfaces, values which should be a

function of the active radius of the meridian will be inaccurate.

2.5.7.1. Applying Pressre 'oads on Beams

To apply pressure loads on the lateral faces and the two ends of beam elements, use one of the

following:

!ain !en*Preprocessor*'oads*Apply*2Strctral2*Pressre*/n Beams

!ain !en*Soltion*Apply*2Strctral2*Pressre*/n Beams

You can apply lateral pressures, which have units of force per unit length, both in the normal and

tangential directions. The pressures may vary linearly along the element length, and can be specified

on a portion of the element, as shown in the following figure. You can also reduce the pressure down

to a force 'point load* at any location on a beam element by setting the 'O,,S* field to @1. 0nd

pressures have units of force.

%igre 22@. (Aample /f Beam Srface 'oads

2.5.7.2. Specifying Node Nm#er ?erss Srface 'oad

The command '!ain !en*Preprocessor*'oads*Settings*2%or Srface 'd2*Node %nction, or

!ain !en*Soltion*Settings*2%or Srface 'd2*Node %nction* specifies a GfunctionG of node

number versus surface load to be used when you apply surface loads on nodes or elements. +t is

useful when you want to apply nodal surface loads calculated elsewhere 'by another software

pac%age, for instance*. You should first define the function in the form of an array parameter

containing the load values. The location of the value in the array parameter implies the node number.

2.5.7.+. Specifying a Gradient Slope

You can use either of the following to specify that a gradient 'slope* is to be used for subse"uently

applied surface loads:

!ain !en*Preprocessor*'oads*Settings*2%or Srface 'd2Gradient

!ain !en*Soltion*Settings*2%or Srface 'd2Gradient

You can also use this command to apply a linearly varying surface load, such as hydrostatic pressure

2.5.7.5. )sing Srface (ffect (lements to Apply 'oads

Sometimes, you may need to apply a surface load that the element type you are using does not

accept. #or example, you may need to apply uniform tangential 'or any non@normal or directed*

pressures on structural solid elements, radiation specifications on thermal solid elements, etc. +n such

cases, you can overlay the surface where you want to apply the load with surface effect elements and

use them as a GconduitG to apply the desired loads. /urrently, the following surface effect elements

are available: S,!#121 and S,!#12B for C@) models and S,!#12C and S,!#124 for B@) models.

2.5.@. Body 'oads

Body loads a$ailable shows all body loads available in each discipline and their corresponding

ANSYS labels. The commands to apply, list, and delete body loads are shown in Commands for

applying body loads. You can apply them at nodes, elements, %eypoints, lines, areas, and volumes.

Ta#le 227. Body loads a4aila#le in each discipline

$iscipline Body 'oad ANSYS 'a#el

Structural

Temperature

#luence

T0-5

1

#6,0

Thermal ;eat >eneration !ate ;>0N

-agnetic

Temperature

/urrent )ensity

?irtual )isplacement

?oltage )rop

T0-5

1

HS

-?)+

?6T>

0lectric

Temperature

?olume /harge )ensity

T0-5/

/;!>)

#luid

;eat >eneration !ate

#orce )ensity

;>0N

#8!/

1. )o not confuse this with the T0-5 degree of freedom.

elow are examples of some of the >,+ paths to use for applying body loads:

!ain !en*Preprocessor*'oads*2'oads2Apply*load type*/n Nodes

)tility !en*'ist*'oads*Body 'oads*/n PicBed (lems

!ain !en*Soltion*2'oads2Apply*load type*/n <eypoints

)tility !en*'ist*'oads*Body 'oads*/n PicBed 'ines

!ain !en*Soltion*2'oads2Apply*load type*/n ?olmes

See the ANSYS Commands Reference for descriptions of the commands listed in Commands for

applying body loads.

Note@@ody loads you specify on nodes are independent of those

specified on elements. #or a given element, ANSYS determines which

loads to use as follows:

+t chec%s to see if you specified elements for body loads.

+f not, it uses body loads specified for nodes.

+f no body loads exist for elements or nodes, the body loads specified in command ta%e

effect.

2.5.@.1. Specifying a )niform Body 'oad

The following command specifies a uniform body load at all nodes in the model. -ost often, you use

this command or path to specify a uniform temperature fieldD that is, a uniform temperature body load

in a structural analysis or a uniform starting temperature in a transient or nonlinear thermal analysis.

This is also the default temperature at which the ANSYS program evaluates temperature@dependent

material properties.

!ain !en*Preprocessor*'oads*Apply*Temperatre*)niform Temp

!ain !en*Preprocessor*'oads*Settings*)niform Temp

!ain !en*Soltion*Apply*Temperatre*)niform Temp

!ain !en*Soltion*Settings*)niform Temp

2.5.@.3. -epeating a Body 'oad Specification

y default, if you repeat a body load at the same node or same element, the new specification

replaces the previous one. You can change this default to ignore using one of the following:

!ain !en*Preprocessor*'oads*Settings*Nodal Body 'd

!ain !en*Preprocessor*'oads*Settings*(lem Body 'ds

!ain !en*Soltion*Settings*Nodal Body 'd

!ain !en*Soltion*Settings*(lem Body 'ds

The settings you specify with either command or its e"uivalent >,+ paths stay set until they are reuse

the command or path. To reset the default setting 'replacement*, simply issue the commands or

choose the paths without any arguments.

2.5.@.5. Transferring Body 'oads

To transfer body loads that have been applied to the solid model to the corresponding finite element

model, use one of the following:

!ain !en*Preprocessor*'oads*/perate*Body 'oads

!ain !en*Soltion*/perate*Body 'oads

2.5.C. &nertia 'oads

The set of commands for inertia loads are listed below:

Ta#le 22C. &nertia loads commands

G)& !en Paths

!ain !en*Preprocessor*%'/T-AN Set )p*%low (n4ironment*Gra4ity

!ain !en*Preprocessor*'oads*Apply*Gra4ity

!ain !en*Preprocessor*'oads*$elete*Gra4ity

!ain !en*Soltion*%'/T-AN Set )p*%low (n4ironment*Gra4ity

!ain !en*Soltion*Apply*Gra4ity

!ain !en*Soltion*$elete*Gra4ity

!ain !en*Preprocessor*%'/T-AN Set )p*%low (n4ironment*-otating Coords

!ain !en*Preprocessor*'oads*Apply*/ther*Coriolis (ffects

!ain !en*Preprocessor*'oads*$elete*/ther*Coriolis (ffects

!ain !en*Soltion*%'/T-AN Set )p*%low (n4ironment*-otating Coords

!ain !en*Soltion*Apply*/ther*Coriolis (ffects

!ain !en*Soltion*$elete*/ther*Coriolis (ffects

!ain !en*Preprocessor*%'/T-AN Set )p*%low (n4ironment*-otating Coords

!ain !en*Preprocessor*'oads*Apply*/ther*Coriolis (ffects

!ain !en*Preprocessor*'oads*$elete*/ther*Coriolis (ffects

!ain !en*Soltion*%'/T-AN Set )p*%low (n4ironment*-otating Coords

!ain !en*Soltion*Apply*/ther*Coriolis (ffects

!ain !en*Soltion*$elete*/ther*Coriolis (ffects

!ain !en*Preprocessor*'oads*Apply*/ther*Coriolis (ffects

!ain !en*Preprocessor*'oads*$elete*/ther*Coriolis (ffects

!ain !en*Soltion*Apply*/ther*Coriolis (ffects

!ain !en*Soltion*$elete*/ther*Coriolis (ffects

!ain !en*Preprocessor*'oads*Apply*/ther*Anglar Accel

!ain !en*Preprocessor*'oads*$elete*/ther*Anglar Accel

!ain !en*Soltion*Apply*/ther*Anglar Accel

!ain !en*Soltion*$elete*/ther*Anglar Accel

!ain !en*Preprocessor*'oads*/ther*&nertia -elief

!ain !en*Preprocessor*'oads*/tpt Ctrls*&ncl !ass Smmry

!ain !en*Soltion*/ther *&nertia -elief

!ain !en*Soltion*)na#ridged !en*/tpt Ctrls*&ncl !ass Smmry

!ain !en*Preprocessor*'oads*Apply*/ther*Anglar ?elocity

!ain !en*Preprocessor*'oads*$elete*/ther*Anglar ?elocity

!ain !en*Soltion*Apply*/ther*Anglar ?elocity

!ain !en*Soltion*$elete*/ther*Anglar ?elocity

+nertia loads are effective only if your model has some mass, which is usually supplied by a density

specification. 'You can also supply mass to the model by using mass elements, such as -ASSC1, but

density is more commonly used and is more convenient.* As with all other data, the ANSYS program

re"uires you to use consistent units for mass. +f you are accustomed to the ritish system of units,

you might sometimes wish to use "eight density 'lbIin

B

* instead of mass density 'lb@sec

C

IinIin

B

*, for

convenience.

,se weight density in place of mass density only under these conditions:

The model will only be used in a static analysis.

No angular velocity or angular acceleration is applied.

>ravitational acceleration is unity 'g J 1.3*.

A handy way to specify density so that you can use it readily in either a Gconvenient,G weight@density

form or Gconsistent,G mass@density form is to define a parameter for gravitational acceleration, g:

Ta#le 221D. 9ays of specifying density

Con4enient %orm Consistent %orm $escription

g J 1.3 g J BE:.3 5arameter definition

-5,)0NS,1,3.CEBIg -5,)0NS,1,3.CEBIg )ensity of steel

A/06,,g A/06,,g >ravity load

2.7.1. /tpt Controls

8utput controls, as their name indicates, control the amount and nature of output from an analysis.

There are two primary output controls:

Ta#le 2211. /tpt controls commands

G)& !en Paths Prpose

!ain !en*Preprocessor*'oads* /tpt Ctrls*$B,-eslts %ile

!ain !en*Soltion*Sol>n Control;Basic Ta#

!ain !en*Soltion*/tpt Ctrls*$B,-eslts %ile

!ain!en*Soltion*)na#ridged!en*/tptCtrls*$B,-eslts%ile

/ontrols what ANSYS writes

to the database and results

file and how often it is

written.

!ain !en*Preprocessor*'oads* /tpt Ctrls*Sol Printot

!ain !en*Soltion*/tpt Ctrls*Sol Printot

!ain !en*Soltion*)na#ridged !en*/tpt Ctrls*Sol

Printot

/ontrols what is printed

'written to the solution

output file, Jobname.OUT*

and how often it is written.

The following command allows you to delete load step files from within the ANSYS program.

!ain !en*Preprocessor*'oads*/perate*$elete 'S %iles

!ain !en*Soltion*/perate*$elete 'S %iles

Another useful load step related commands ,which allows you to delete all loads and reset all

load step options to their defaults. You can use it, for example, to Gclean upG the load step

data before reading in a load step file for modifications.

!ain !en*Preprocessor*'oads*$elete*All 'oad $ata*data type

!ain !en*Preprocessor*'oads*-eset /ptions

!ain !en*Preprocessor*'oads*Settings*-eset %actors

!ain !en*Soltion*-eset /ptions

!ain !en*Soltion*Settings*-eset %actors

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- MonorailDokument9 SeitenMonoraildvarsastryNoch keine Bewertungen

- Position Analysis QuestionsDokument3 SeitenPosition Analysis Questionsdvarsastry100% (1)

- Helical Torsion Springs: Stress, Deflection & Stiffness Explained in 40 CharactersDokument4 SeitenHelical Torsion Springs: Stress, Deflection & Stiffness Explained in 40 CharactersdvarsastryNoch keine Bewertungen

- MASS WeightDokument1 SeiteMASS WeightdvarsastryNoch keine Bewertungen

- Agricultural Research and Development: Green RevolutionDokument12 SeitenAgricultural Research and Development: Green RevolutiondvarsastryNoch keine Bewertungen

- Introduction To Engineering: The Wright Brothers, Orville and Wilbur Invented Aeroplane For The First Time I 1903Dokument3 SeitenIntroduction To Engineering: The Wright Brothers, Orville and Wilbur Invented Aeroplane For The First Time I 1903dvarsastryNoch keine Bewertungen

- Worksheet 4: Brittle Coulomb Mohr Theory: VQ IbDokument2 SeitenWorksheet 4: Brittle Coulomb Mohr Theory: VQ IbdvarsastryNoch keine Bewertungen

- Indian History TimelineDokument5 SeitenIndian History TimelineRohan PandhareNoch keine Bewertungen

- Different Vedanta SchoolsDokument3 SeitenDifferent Vedanta SchoolsdvarsastryNoch keine Bewertungen

- VR SyllabusDokument1 SeiteVR SyllabusdvarsastryNoch keine Bewertungen

- Week-1 Phases of DesignDokument9 SeitenWeek-1 Phases of DesigndvarsastryNoch keine Bewertungen

- Mechanical Engineering Interview Questions With AnswersDokument10 SeitenMechanical Engineering Interview Questions With AnswersdvarsastryNoch keine Bewertungen

- Aircraft Manufacturing DesignDokument2 SeitenAircraft Manufacturing DesigndvarsastryNoch keine Bewertungen

- Plummer BlockDokument1 SeitePlummer BlockdvarsastryNoch keine Bewertungen

- Submitted By:: S.Praveen Kumar (150070362) P.ABISHEK (150070302)Dokument7 SeitenSubmitted By:: S.Praveen Kumar (150070362) P.ABISHEK (150070302)dvarsastryNoch keine Bewertungen

- Engineering Design Process ExplainedDokument4 SeitenEngineering Design Process ExplaineddvarsastryNoch keine Bewertungen

- Engineering Design Process & Masdar City Renewable Energy CaseDokument2 SeitenEngineering Design Process & Masdar City Renewable Energy CasedvarsastryNoch keine Bewertungen

- Submitted By:: S.Praveen Kumar (150070362) P.ABISHEK (150070302)Dokument7 SeitenSubmitted By:: S.Praveen Kumar (150070362) P.ABISHEK (150070302)dvarsastryNoch keine Bewertungen

- LectureDokument4 SeitenLecturedvarsastryNoch keine Bewertungen

- Lesson 8: Unit 1Dokument4 SeitenLesson 8: Unit 1dvarsastryNoch keine Bewertungen

- Modelling Hysteresis for an MR DamperDokument9 SeitenModelling Hysteresis for an MR DamperdvarsastryNoch keine Bewertungen

- Hydrodynamic Bearing TheoryDokument20 SeitenHydrodynamic Bearing TheoryPRASAD32675% (4)

- Cap 02Dokument0 SeitenCap 02Navneet RankNoch keine Bewertungen

- Machine Design Expanded Book ViewDokument8 SeitenMachine Design Expanded Book ViewdvarsastryNoch keine Bewertungen

- Cap 11Dokument16 SeitenCap 11Prangyadeepta ChoudhuryNoch keine Bewertungen

- Silicone OilDokument3 SeitenSilicone OilPrakash SharmaNoch keine Bewertungen

- HP Pavilion 15-au118TX Quickspecs Performance Video AudioDokument1 SeiteHP Pavilion 15-au118TX Quickspecs Performance Video AudiodvarsastryNoch keine Bewertungen

- Cap 01Dokument0 SeitenCap 01Daniel SantosNoch keine Bewertungen

- HWDay 1Dokument25 SeitenHWDay 1dvarsastryNoch keine Bewertungen

- Silicone FluidsDokument27 SeitenSilicone FluidsdvarsastryNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Documentation For: Bank - MasterDokument6 SeitenDocumentation For: Bank - MastervijucoolNoch keine Bewertungen

- 03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1Dokument352 Seiten03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1sadh94Noch keine Bewertungen

- Quality Management Project On Quality Tools of "Ford Motors"Dokument6 SeitenQuality Management Project On Quality Tools of "Ford Motors"Anuj SharmaNoch keine Bewertungen

- Performance of tuned mass dampers under wind loadsDokument13 SeitenPerformance of tuned mass dampers under wind loadsDhirendra Kumar PandeyNoch keine Bewertungen

- Sika PDS E SikaRep SDokument3 SeitenSika PDS E SikaRep Slwin_oo2435Noch keine Bewertungen

- Landscape - Cut & Fill StopingDokument24 SeitenLandscape - Cut & Fill StopingRAJIV VINOD CONJEEVARAM 1961714Noch keine Bewertungen

- Column and Wall Load Take Down Spreadsheet v1.0 - CLDokument28 SeitenColumn and Wall Load Take Down Spreadsheet v1.0 - CLBilal KhattabNoch keine Bewertungen

- DP TV Aver 15022 DriversDokument94 SeitenDP TV Aver 15022 DriversMohammed Tahver Farooqi QuadriNoch keine Bewertungen

- Partition WallDokument24 SeitenPartition WallSHRADDHA GHUGENoch keine Bewertungen

- Capitulos 10 y 11Dokument34 SeitenCapitulos 10 y 11mlpz188669Noch keine Bewertungen

- Wastewater Treatment Plant Operator Certification TrainingDokument69 SeitenWastewater Treatment Plant Operator Certification Trainingkokushkin02Noch keine Bewertungen

- Aerodrome Controller (ADC) ExamDokument5 SeitenAerodrome Controller (ADC) ExamaxnpicturesNoch keine Bewertungen

- Payables Open Interface Import in Oracle Apps R12Dokument11 SeitenPayables Open Interface Import in Oracle Apps R12sudharshan79Noch keine Bewertungen

- Cloud Radio Access Network Architecture Towards 5G NetworkDokument171 SeitenCloud Radio Access Network Architecture Towards 5G NetworkwobblegobbleNoch keine Bewertungen

- Lincoln FC ElectrodesDokument44 SeitenLincoln FC ElectrodeszmcgainNoch keine Bewertungen

- Magic Quadrant For Identity Governance and AdministrationDokument18 SeitenMagic Quadrant For Identity Governance and AdministrationmilosvblNoch keine Bewertungen

- VELUXDokument16 SeitenVELUXEko SalamunNoch keine Bewertungen

- Digital Transformation in The Age of The Customer POVDokument12 SeitenDigital Transformation in The Age of The Customer POVjasmineNoch keine Bewertungen

- 04 Metal and Glass-Wood PolicyDokument1 Seite04 Metal and Glass-Wood Policykitek100% (1)

- Article ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsDokument4 SeitenArticle ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsdombaraNoch keine Bewertungen

- ISa GRAFDokument18 SeitenISa GRAFEdwin MateusNoch keine Bewertungen

- Jolywood-JW-HD144N-545-570 Bifacial 2285x1134x30Dokument2 SeitenJolywood-JW-HD144N-545-570 Bifacial 2285x1134x30Agata GuzikNoch keine Bewertungen

- Physical Chem 1 (Combined)Dokument35 SeitenPhysical Chem 1 (Combined)Yit JuanNoch keine Bewertungen

- BPM Third Wave Smith Fingar Apr2003 PDFDokument10 SeitenBPM Third Wave Smith Fingar Apr2003 PDFNadeem AzadNoch keine Bewertungen

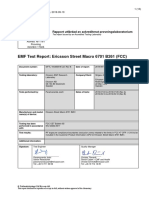

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDokument13 SeitenEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfNoch keine Bewertungen

- Sublimation of CaffeineDokument3 SeitenSublimation of CaffeineNabil ShaikhNoch keine Bewertungen

- SGP PDFDokument4 SeitenSGP PDFpadmajasivaNoch keine Bewertungen

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDokument49 SeitenKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07Noch keine Bewertungen

- Mousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeDokument1 SeiteMousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeMorteza AtaeiNoch keine Bewertungen

- MS Electrical Cable InstallationDokument11 SeitenMS Electrical Cable InstallationAhmed Rashed ANoch keine Bewertungen