Beruflich Dokumente

Kultur Dokumente

Similarities N Different Deming Juran N Crosby

Hochgeladen von

Runaway ShujiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Similarities N Different Deming Juran N Crosby

Hochgeladen von

Runaway ShujiCopyright:

Verfügbare Formate

1

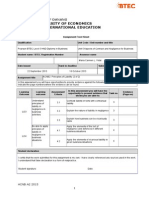

SIMILARITIES AND DIFFERENT BETWEEN WILLIAM EDWARD DEMING, JOSEPH M. JURAN AND PHILIPS P.

CROSBY

Similarities Wiliam Edward

Deming

Joseph M. Juran Philips P.Crosby

Importance of

customer

requirements as

standard

In Demings view, the

consumer is by

necessity the most

important part of the

production system:

without a consumer,

there is no reason to

produce.

Like Deming, Juran also

sees quality as a

concept which can only

be usefully defined by

the consumer. Strictly

put, Juran defines

quality as "fitness for

use."

Mr. Crosby defined

quality as a conformity

to certain specifications

set forth by

management and not

some vague concept of

"goodness." These

specifications are not

arbitrary either; they

must be set according

to customer needs and

wants.

The Responsible for

quality-management

Quality is made in the

board room.

Dr.Deming's ideas of

hard work, sincerity,

decency, and personal

responsibility, forever

changed the world of

management. "It is not

enough to just do your

best or work hard. You

must know what to

work on."

The process of

developing ideas was a

gradual one for Dr.

Juran. Top management

involvement, the Pareto

principle, the need for

widespread training in

quality, the definition of

quality as fitness for

use. Majority of Quality

problems are the fault

of poor management

rather than poor

workmanship.

Quality improvement

starts from the top.To

create a manufacturing

process that has zero

defects management

must set the tone and

atmosphere for

employees to follow. If

management does not

create a system by

which zero defects,not

thats close enough.

Goal of quality

Meet/exceed customer

needs; continuous

improvement.

continuous

improvement.

Continuous

improvement by setting

zero defects

production.

2

Different Wiliam Edward

Deming

Joseph M. Juran Philips P.Crosby

Basic orientation

toward quality

Technical- To Deming,

the only meaningful

definition of quality is

that which the

consumer specifies. A

product could meet

every possible technical

specification and be

offered at an

appropriate price, but if

it is the wrong product,

it is worthless to the

consumer.

Process-Juran's work

focuses on the idea of

process that

organizational quality

problems are largely

the result of insufficient

and ineffective planning

for quality. In addition,

Juran fleshed out many

of the implementation

issues involved with

quality through his

trilogy.

Motivational- Crosby

made two key points in

his arguments about

the responsibility of the

quality

department.First, he

argued that quality, as a

managed process, could

be a source of profit for

an organization.

Second, Crosby adopted

a "zero defects"

approach to

quality management,

and emphasized the

behavioral and

motivational

aspects of quality

improvement rather

than statistical

approaches.

What is quality?

Nonfaulty systems

Deming addressed the

entire process and

focused primarily the

assertion

that poor quality is not

the fault of the worker,

but is the fault of the

system. Deming also

strongly opposed the

creation of quality

inspection

departments.

Fitness for use.

freedom from

trouble

Juran defines quality as

"fitness for use, the

quality as a concept

which can only be

usefully defined by

the consumer.

Juran's work focuses on

the idea that

organizational quality

freedom from trouble

to achive result of

sufficient and effective

planning for

setting the goal of

quality.

Conformance to

requirements

Mr. Crosby defined

quality as a conformity

to certain specifications

set forth by

management and not

some vague concept of

"goodness." These

specifications are not

arbitrary either; they

must be set according

to customer needs and

wants.

3

Chief elements of

implementation

14-point program

Dr. Deming's famous 14

Points, originally

presented in Out of the

Crisis, serve as

management

guidelines. The points

cultivate a fertile soil in

which a more efficient

workplace, higher

profits, and increased

productivity may grow.

Breakthrough projects;

quality council; quality

teams.

14-step program; cost

of quality; quality

management "maturity

grid".

Inspection / defect

control

Cease dependence on

inspection to achieve

quality. Eliminate the

need for mass

inspection by building

quality into the product

in the first place.

Operator errors can be

reduced by :

foolproofing , keeping

people

attentive,training ,

changing technology ,

improving

communication ,

establishing

accountabilty ,

removing the error-

prone person and

motivation.

Two factors cause

defects or mistakes : -

Lack of knowledge and

lack of attention.

Improvement basis

Repeated use of PDSA

cycle.

Put everyone in the

company to work to

accomplish the

transformation. The

transformation is every

body's job.

Quality improvement

raises quality

performance to

imprecedented or break

through levels.

Quality improvement is

built on getting

everyone to do it right

the first time (DIRFT).

Quality improvement is

a process ,not a

program , and it takes a

long time for it to

become a normal part

of the scene.

Cost of quality

- Companies should

look at the total cost of

product or service

provided by others ,

and not just the

purchase price.

Accepting the lowest

bid does not guarantee

the lowest total cost.

- Cost Of Poor Quality

(COPQ) is the sum of all

costs that would

disappear if there were

no quality problems.

- Quality improvement

does not come free.

- Measurement of

quality is the price of

non conformance , not

indexes.

- Price of non

conformance is by

counting every thing

that is spent if every

thing was not done

right the first time.

4

Das könnte Ihnen auch gefallen

- Comparisons of Deming, Juran and CrosbyDokument4 SeitenComparisons of Deming, Juran and CrosbyluckiestmermaidNoch keine Bewertungen

- Philip Crosby Ques 2 Part ADokument7 SeitenPhilip Crosby Ques 2 Part AAnand MosumNoch keine Bewertungen

- Deming, Juran, and Crosby - Pioneers of Project ManagementDokument16 SeitenDeming, Juran, and Crosby - Pioneers of Project Managementalex josephNoch keine Bewertungen

- Crosby's Concept of Cost of QualityDokument7 SeitenCrosby's Concept of Cost of QualityRana Muhammad Arif KhanNoch keine Bewertungen

- Finals - Module-3Dokument6 SeitenFinals - Module-3Fatima Mae NadangaNoch keine Bewertungen

- Quality Gurus and Their ContributionDokument17 SeitenQuality Gurus and Their ContributionFayis FYSNoch keine Bewertungen

- Wa0012.Dokument14 SeitenWa0012.Syed QaiserNoch keine Bewertungen

- Wa0012.Dokument17 SeitenWa0012.Syed QaiserNoch keine Bewertungen

- Cbme 1 - Module 2Dokument4 SeitenCbme 1 - Module 2Neyka YinNoch keine Bewertungen

- The Quality Gurus Works and ContributionsDokument2 SeitenThe Quality Gurus Works and ContributionsKyla DaphneNoch keine Bewertungen

- Deming Juran and Crosby Pioneers of Project ManagementDokument17 SeitenDeming Juran and Crosby Pioneers of Project Managementbikram prasadNoch keine Bewertungen

- Major Contributors To TQMDokument4 SeitenMajor Contributors To TQMRuchika AgarwalNoch keine Bewertungen

- Chapter 2 TQMDokument9 SeitenChapter 2 TQMJustine Marie BalderasNoch keine Bewertungen

- Assighment by Anurag KumarDokument6 SeitenAssighment by Anurag Kumarkapil gargNoch keine Bewertungen

- List of Prominent Person of Total Quality ManagementDokument3 SeitenList of Prominent Person of Total Quality ManagementKim CasianoNoch keine Bewertungen

- Similarities Wiliam Edward Deming Philips P.CrosbyDokument1 SeiteSimilarities Wiliam Edward Deming Philips P.CrosbyGopalakrishnan KuppuswamyNoch keine Bewertungen

- Gurus To QualityDokument8 SeitenGurus To QualityDarl YabutNoch keine Bewertungen

- BME OM Finals 3Dokument19 SeitenBME OM Finals 3Lorraine Noquilla TabaldoNoch keine Bewertungen

- Deming Juran CrosbyDokument9 SeitenDeming Juran CrosbyManoj AdhikariNoch keine Bewertungen

- LeadershipDokument6 SeitenLeadershipThea Danica BrazaNoch keine Bewertungen

- Quality Without TearsDokument34 SeitenQuality Without Tearsapi-377461489% (9)

- W.Edward Deming: Huchchappa .W Hareesh. DDokument15 SeitenW.Edward Deming: Huchchappa .W Hareesh. DHarish DesalliNoch keine Bewertungen

- Crosby's Philosophy For Quality ImprovementDokument7 SeitenCrosby's Philosophy For Quality ImprovementSz ZamanNoch keine Bewertungen

- TQM Chapter 1Dokument41 SeitenTQM Chapter 1Farah Al-MajaliNoch keine Bewertungen

- Lesson 2 - Gurus of Total Quality ManagementDokument48 SeitenLesson 2 - Gurus of Total Quality Managementckcastillo44Noch keine Bewertungen

- MNGT 13Dokument13 SeitenMNGT 13monicasheillaNoch keine Bewertungen

- Lendio, Anghel Gabriel. BIT-3B (AT) G2 Self Assessment QuestionsDokument9 SeitenLendio, Anghel Gabriel. BIT-3B (AT) G2 Self Assessment QuestionsTOLENTINO, Selwin Daniel A.Noch keine Bewertungen

- Philip CrosbyDokument3 SeitenPhilip CrosbyAnand MosumNoch keine Bewertungen

- Quality Management Experts: Deming, Juran and CrosbyDokument24 SeitenQuality Management Experts: Deming, Juran and CrosbyAdrien SicardNoch keine Bewertungen

- The Juran Quality Trilogy and its importance in quality managementDokument13 SeitenThe Juran Quality Trilogy and its importance in quality managementLunaNoch keine Bewertungen

- Juran Quality Trilogy ExplainedDokument11 SeitenJuran Quality Trilogy ExplainedLunaNoch keine Bewertungen

- Chapter 2 Foundations of Quality Management Lecture NotesDokument16 SeitenChapter 2 Foundations of Quality Management Lecture Notesmark sanad100% (1)

- Deming'S Contributions: The U.S. Department of Defense's Definition of Total QualityDokument5 SeitenDeming'S Contributions: The U.S. Department of Defense's Definition of Total Qualityrajit3910Noch keine Bewertungen

- Quality in Construction WorksDokument21 SeitenQuality in Construction WorksSabyasachi Naik (Zico)Noch keine Bewertungen

- TQM GurusDokument18 SeitenTQM GurusmbuyaivoneNoch keine Bewertungen

- TQMDokument11 SeitenTQMAbdulazeez AlamuNoch keine Bewertungen

- Quality Gurus: Their Philosophies, Principles & MethodsDokument54 SeitenQuality Gurus: Their Philosophies, Principles & MethodsazraNoch keine Bewertungen

- Quality Awards FrameworkDokument3 SeitenQuality Awards FrameworkkyramuiiNoch keine Bewertungen

- Philip Crosby's Contributions to Quality ManagementDokument2 SeitenPhilip Crosby's Contributions to Quality ManagementGelay BorrelNoch keine Bewertungen

- Understanding Key Philosophies of Total Quality ManagementDokument28 SeitenUnderstanding Key Philosophies of Total Quality Managementiam GiokerNoch keine Bewertungen

- Quality Case 1Dokument24 SeitenQuality Case 1san_sant96Noch keine Bewertungen

- Deming's 14 Points for QualityDokument3 SeitenDeming's 14 Points for QualityJesel CatchoniteNoch keine Bewertungen

- TQMDokument8 SeitenTQMMeena SinghNoch keine Bewertungen

- TQM Leaders Who Changed Quality ManagementDokument21 SeitenTQM Leaders Who Changed Quality ManagementSandeep MohantyNoch keine Bewertungen

- Philip Bayard Crosby: A Presentation By: Abhishek Kumar and Vishakha ChopraDokument40 SeitenPhilip Bayard Crosby: A Presentation By: Abhishek Kumar and Vishakha ChopraVishakha Chopra100% (4)

- MieakarlaCalloway IT301 U5Dokument13 SeitenMieakarlaCalloway IT301 U5Mieakarla CallowayNoch keine Bewertungen

- Crosby's Philosophy: University of Experimental Technological Research YACHAY TECHDokument4 SeitenCrosby's Philosophy: University of Experimental Technological Research YACHAY TECHJonathhan RecaldeNoch keine Bewertungen

- Chapter 3 Gurus of Total Quality ManagementDokument9 SeitenChapter 3 Gurus of Total Quality ManagementCALIPDAN, Roselyn D. (Lyn)Noch keine Bewertungen

- Philip B. Crosby's Contributions to Quality Management PhilosophyDokument13 SeitenPhilip B. Crosby's Contributions to Quality Management Philosophyman319Noch keine Bewertungen

- Chapter 1Dokument55 SeitenChapter 1Rahaf JarrarNoch keine Bewertungen

- Quality PrinciplesDokument46 SeitenQuality PrinciplesSimran RajputNoch keine Bewertungen

- Lec 2 TQM Cont. of Quality GurusDokument63 SeitenLec 2 TQM Cont. of Quality Gurusshasan247Noch keine Bewertungen

- Quality Is Certain: How to Implement Crosby's 14 StepsDokument28 SeitenQuality Is Certain: How to Implement Crosby's 14 StepsShrikrishna BirajdarNoch keine Bewertungen

- MAN 416 - Chapter 2 Philosophers)Dokument39 SeitenMAN 416 - Chapter 2 Philosophers)Umar RanaNoch keine Bewertungen

- The Pioneers of TQM and Their PhilosophiesDokument52 SeitenThe Pioneers of TQM and Their PhilosophiesVineet Kohli100% (5)

- TQMDokument160 SeitenTQMEzekiel Eljay MacatangayNoch keine Bewertungen

- Philip CrosbyDokument4 SeitenPhilip CrosbySilviu BeletoiuNoch keine Bewertungen

- Cbme 11 - M4Dokument13 SeitenCbme 11 - M4jeninaNoch keine Bewertungen

- Becoming Lean: Practical Steps to Build CompetitivenessVon EverandBecoming Lean: Practical Steps to Build CompetitivenessBewertung: 5 von 5 Sternen5/5 (1)

- HR Assignment - Ha ThanhDokument19 SeitenHR Assignment - Ha ThanhRunaway ShujiNoch keine Bewertungen

- 1.1 Discuss Definitions of Quality in Terms of Business and Services ProvisionDokument10 Seiten1.1 Discuss Definitions of Quality in Terms of Business and Services ProvisionRunaway ShujiNoch keine Bewertungen

- Developing Global Management Competencies IDokument5 SeitenDeveloping Global Management Competencies IRunaway ShujiNoch keine Bewertungen

- Business Game ScheduleDokument2 SeitenBusiness Game ScheduleRunaway ShujiNoch keine Bewertungen

- PP 10Dokument27 SeitenPP 10Ahmed BdairNoch keine Bewertungen

- The Work Breakdown Structure TemplateDokument1 SeiteThe Work Breakdown Structure TemplateRunaway ShujiNoch keine Bewertungen

- Assignment MAAR 1Dokument28 SeitenAssignment MAAR 1Runaway ShujiNoch keine Bewertungen

- Personal and Professional Development PlanDokument33 SeitenPersonal and Professional Development PlanRunaway Shuji33% (3)

- Assignment MAAR 2Dokument47 SeitenAssignment MAAR 2Runaway ShujiNoch keine Bewertungen

- PUMA Company Profile - Sports Brand HistoryDokument1 SeitePUMA Company Profile - Sports Brand HistoryRunaway ShujiNoch keine Bewertungen

- Financial Analysis For Boa CoffeeDokument2 SeitenFinancial Analysis For Boa CoffeeRunaway ShujiNoch keine Bewertungen

- The Main Barrier of Marketing Plan For Cie: Name: Tran Anh Dung (Jay) Lecturer: Mr. Frederick IgnacioDokument23 SeitenThe Main Barrier of Marketing Plan For Cie: Name: Tran Anh Dung (Jay) Lecturer: Mr. Frederick IgnacioRunaway ShujiNoch keine Bewertungen

- APC 309 ABC Mock Exam Solution A and BDokument3 SeitenAPC 309 ABC Mock Exam Solution A and BRunaway ShujiNoch keine Bewertungen

- Personal and Professional Development PlanDokument33 SeitenPersonal and Professional Development PlanRunaway Shuji33% (3)

- Assignment Guiide OBDokument5 SeitenAssignment Guiide OBRunaway ShujiNoch keine Bewertungen

- ACNB 2 of 2 2015 AugustDokument7 SeitenACNB 2 of 2 2015 AugustRunaway ShujiNoch keine Bewertungen

- The Relationship Between Educational Attainment and Professional Attainment in DanangDokument3 SeitenThe Relationship Between Educational Attainment and Professional Attainment in DanangRunaway ShujiNoch keine Bewertungen

- Sbe A2 Sud12Dokument8 SeitenSbe A2 Sud12Runaway ShujiNoch keine Bewertungen

- Assignment 1 Sbe GuideDokument1 SeiteAssignment 1 Sbe GuideRunaway ShujiNoch keine Bewertungen

- CIE BudgetDokument7 SeitenCIE BudgetRunaway ShujiNoch keine Bewertungen

- EthicsDokument23 SeitenEthicsRunaway ShujiNoch keine Bewertungen

- A1 - BDM - NancyDokument21 SeitenA1 - BDM - NancyRunaway ShujiNoch keine Bewertungen

- SBE 1 SampleDokument11 SeitenSBE 1 SampleRunaway ShujiNoch keine Bewertungen

- Event Date Lunch Set Menu 11 December 2014: Time Venue Number of Guest 10:00 Lemongrass Rest 43 Studen + 5 Staff MemberDokument3 SeitenEvent Date Lunch Set Menu 11 December 2014: Time Venue Number of Guest 10:00 Lemongrass Rest 43 Studen + 5 Staff MemberRunaway ShujiNoch keine Bewertungen

- Assignment 1 Sbe GuideDokument1 SeiteAssignment 1 Sbe GuideRunaway ShujiNoch keine Bewertungen

- Redo WLP 1Dokument8 SeitenRedo WLP 1Runaway ShujiNoch keine Bewertungen

- Ical-111 76 183 2 RVDokument4 SeitenIcal-111 76 183 2 RVhebishtNoch keine Bewertungen

- Grade - Sem 1Dokument4 SeitenGrade - Sem 1Runaway ShujiNoch keine Bewertungen

- Assignment TQM 1Dokument13 SeitenAssignment TQM 1Runaway ShujiNoch keine Bewertungen

- SEO-Optimized Title for II Internal Test Question Bank on UML ConceptsDokument2 SeitenSEO-Optimized Title for II Internal Test Question Bank on UML ConceptsRencli TellisNoch keine Bewertungen

- CH08 Location StrategyDokument45 SeitenCH08 Location StrategyfatinS100% (5)

- Basics of Innovation ManagementDokument29 SeitenBasics of Innovation ManagementChavez RamonNoch keine Bewertungen

- TMC PepsiCo 03Dokument3 SeitenTMC PepsiCo 03snafarooqiNoch keine Bewertungen

- Application of Lean Six Sigma in HealthcareDokument9 SeitenApplication of Lean Six Sigma in HealthcareAnonymous ibmeej9Noch keine Bewertungen

- Is 14489 1998Dokument19 SeitenIs 14489 1998Imran Bagwan100% (1)

- Employee Relations ResumeDokument6 SeitenEmployee Relations Resumegbfcseajd100% (2)

- PMP® Exam Simulation #1Dokument70 SeitenPMP® Exam Simulation #1keight_NNoch keine Bewertungen

- Guide To Internal AuditDokument86 SeitenGuide To Internal Auditradoniaina100% (1)

- Gather Evidence.: 10 PointsDokument11 SeitenGather Evidence.: 10 PointsmilahrztaNoch keine Bewertungen

- Inventory Control FinalDokument13 SeitenInventory Control Finalamrendrakr09243460% (5)

- RPA Awareness Training QDokument3 SeitenRPA Awareness Training QAshish Parakh100% (1)

- Cost AccountingDokument22 SeitenCost AccountingDani SoaveNoch keine Bewertungen

- Performance Management GuideDokument306 SeitenPerformance Management GuiderakeshrakeshNoch keine Bewertungen

- Assignment 2 DR ShantalDokument4 SeitenAssignment 2 DR ShantalBishoy EmileNoch keine Bewertungen

- Working Capital Management at BEMLDokument20 SeitenWorking Capital Management at BEMLadharav malikNoch keine Bewertungen

- CV Laurentiu ManglutescuDokument5 SeitenCV Laurentiu ManglutescuManglutescu LaurentiuNoch keine Bewertungen

- 1.0 HsemsDokument47 Seiten1.0 HsemsQizz92100% (4)

- Process costing methods and calculationsDokument10 SeitenProcess costing methods and calculationsTricia Mae Fernandez67% (3)

- Transportation Planning ProcessDokument29 SeitenTransportation Planning ProcessGraciele Sera-Revocal100% (2)

- Social Media Strategy TemplateDokument31 SeitenSocial Media Strategy TemplateVikash Prasad100% (2)

- Computer - Based Purchases Disbursements ApplicationsDokument18 SeitenComputer - Based Purchases Disbursements ApplicationsChristine Jane RamosNoch keine Bewertungen

- System Planning and Development On AccountingDokument26 SeitenSystem Planning and Development On Accountinghttp://www.HelpWithassignment.com/Noch keine Bewertungen

- Job Description - Senior Management ConsultantDokument2 SeitenJob Description - Senior Management Consultantnicole wanjaNoch keine Bewertungen

- 1 Create A Leadership Development Plan PDFDokument5 Seiten1 Create A Leadership Development Plan PDFnica gargarita100% (2)

- Chapter 10-Customer Relationship ManagementDokument19 SeitenChapter 10-Customer Relationship Managementdicky fatriasNoch keine Bewertungen

- Strategic Partnering Conceptual Framework - AcDokument4 SeitenStrategic Partnering Conceptual Framework - AcTin Flores AlvairaNoch keine Bewertungen

- Βιβλιαράκι Εκπαιδευτικής ΈκθεσηςDokument24 SeitenΒιβλιαράκι Εκπαιδευτικής ΈκθεσηςmalekosnNoch keine Bewertungen

- BI & Analytics Leader with 7+ Years Experience Driving GrowthDokument3 SeitenBI & Analytics Leader with 7+ Years Experience Driving GrowthAjit KumarNoch keine Bewertungen

- Project CharterDokument16 SeitenProject CharterlyndengeorgeNoch keine Bewertungen