Beruflich Dokumente

Kultur Dokumente

Fractionation Column Calc

Hochgeladen von

zamijakaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fractionation Column Calc

Hochgeladen von

zamijakaCopyright:

Verfügbare Formate

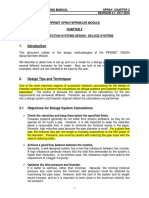

SUMMARY :

MM INCH MM FT

[1] BASED ON C-FACTOR METHOD - GPSA SECT. 19 3100 122 20288 67

[2] BASED ON NOMOGRAPH METHOD - GPSA SECT. 19 1700 67 21398 70

COLUMN DIAMETER COLUMN HEIGHT (T/T)

CALCULATION METHOD

[3] BASED ON DETAILED METHOD - GPSA SECT. 19 1850 73 21098 69

[4] BASED ON COULSON RICHARDSON METHOD 1850 73 21098 69

[5] PACKED COLUMN - GPSA SECT. 19 1450 57 28503 94

Vapour

[m

3

/h]

Bulk Liquid

[m

3

/h]

Temp.

[C]

Surface

Ten

[dyne/cm]

Mole

Weight

(Vap)

Density

(Vap) [lb/ft

3

]

Viscosity

(Vap) [cP]

Therm Cond

(Vap) [Btu/hr-ft-

F]

Heat Cap

(Vap)

[Btu/lb-F]

Mole

Weight

(Lt Liq)

Density

(Lt Liq)

[lb/ft

3

]

Viscosit

y (Lt

Liq) [cP]

Therm Cond

(Lt Liq)

[Btu/hr-ft-F]

Heat Cap

(Lt Liq)

[Btu/lb-F]

Vapour

[lb/hr]

Bulk

Liquid

[lb/hr]

Ethane Propane i-Butane n-Butane

TOP Condenser 0.00 59.25 50.14 3.90 42.56 2.64 0.01 0.01 0.55 43.52 27.68 0.07576 0.05 0.82 0.00 57914.63 2.18 0.94 0.51 0.41

1__Main TS 854.71 60.61 53.21 3.74 43.52 2.70 0.01 0.01 0.56 44.09 27.60 0.07552 0.05 0.83 81395.98 59065.69 2.23 0.98 0.54 0.44

2__Main TS 859.26 61.03 54.65 3.68 43.92 2.72 0.01 0.01 0.56 44.42 27.58 0.07562 0.04 0.83 82547.05 59440.02 2.26 1.00 0.55 0.45

3__Main TS 859.58 61.06 55.66 3.66 44.16 2.73 0.01 0.01 0.56 44.73 27.60 0.07595 0.04 0.83 82921.38 59513.28 2.28 1.01 0.56 0.46

4__Main TS 857.96 60.93 56.69 3.65 44.38 2.74 0.01 0.01 0.56 45.08 27.64 0.07644 0.04 0.83 82994.64 59467.96 2.30 1.03 0.57 0.46

5__Main TS 855.36 60.71 57.92 3.64 44.63 2.75 0.01 0.01 0.56 45.51 27.69 0.07700 0.04 0.83 82949.32 59367.45 2.32 1.04 0.58 0.47

6__Main TS 852.11 60.44 59.42 3.64 44.92 2.75 0.01 0.01 0.56 46.02 27.75 0.07766 0.04 0.83 82848.81 59239.03 2.35 1.06 0.60 0.48

7__Main TS 848.35 60.15 61.20 3.64 45.28 2.76 0.01 0.01 0.56 46.62 27.82 0.07837 0.04 0.82 82720.39 59100.38 2.39 1.09 0.61 0.50

8__Main TS 844.23 59.85 63.26 3.64 45.70 2.77 0.01 0.01 0.56 47.29 27.90 0.07907 0.04 0.82 82581.74 58960.99 2.43 1.11 0.63 0.52

9__Main TS 839.93 59.52 65.53 3.64 46.15 2.78 0.01 0.01 0.56 48.01 27.98 0.07974 0.04 0.82 82442.34 58808.22 2.48 1.15 0.65 0.53

10__Main TS 835.57 59.12 67.97 3.64 46.63 2.79 0.01 0.01 0.56 48.76 28.06 0.08035 0.04 0.81 82289.58 58577.23 2.54 1.18 0.67 0.55

11__Main TS 830.99 58.40 70.63 3.65 47.14 2.80 0.01 0.01 0.56 49.60 28.16 0.08097 0.04 0.81 82058.59 58081.58 2.60 1.22 0.70 0.58

12__Main TS 825.44 56.83 73.77 3.68 47.68 2.80 0.01 0.01 0.57 50.67 28.33 0.08185 0.04 0.80 81562.94 56849.24 2.67 1.26 0.73 0.60

FEED 13__Main TS 816.69 110.63 78.32 3.77 48.35 2.79 0.01 0.01 0.57 52.45 28.66 0.08358 0.04 0.79 80330.60 111975.53 2.79 1.33 0.78 0.64

14__Main TS 791.61 111.90 80.02 3.71 48.86 2.81 0.01 0.01 0.57 52.83 28.61 0.08330 0.04 0.79 78627.52 113070.59 2.82 1.36 0.80 0.66

15__Main TS 795.75 113.05 81.84 3.66 49.36 2.84 0.01 0.01 0.57 53.27 28.58 0.08315 0.04 0.79 79722.58 114100.84 2.85 1.38 0.82 0.68

16__Main TS 798.61 114.35 83.98 3.61 49.95 2.86 0.01 0.01 0.57 53.80 28.55 0.08303 0.04 0.80 80752.83 115284.25 2.88 1.41 0.84 0.70

17__Main TS 801.48 115.98 86.53 3.56 50.66 2.89 0.01 0.01 0.58 54.44 28.51 0.08287 0.04 0.80 81936.24 116765.57 2.92 1.45 0.87 0.73

18__Main TS 805.25 118.06 89.50 3.50 51.51 2.93 0.01 0.01 0.58 55.17 28.45 0.08259 0.04 0.80 83417.56 118626.67 2.97 1.49 0.90 0.76

19__Main TS 810.57 120.61 92.78 3.44 52.48 2.98 0.01 0.01 0.58 55.95 28.38 0.08212 0.04 0.81 85278.66 120871.80 3.02 1.54 0.94 0.79

20__Main TS 817.77 123.53 96.20 3.37 53.53 3.03 0.01 0.02 0.59 56.73 28.29 0.08117 0.04 0.82 87523.79 123416.22 3.07 1.59 0.98 0.83

21__Main TS 826.71 126.65 99.59 3.31 54.59 3.09 0.01 0.02 0.60 57.48 28.19 0.08063 0.04 0.82 90068.21 126097.93 3.11 1.63 1.01 0.86

22__Main TS 836.80 129.71 102.78 3.25 55.60 3.14 0.01 0.02 0.60 58.17 28.10 0.08056 0.03 0.83 92749.91 128713.24 3.15 1.67 1.05 0.89

23__Main TS 847.02 132.46 105.73 3.17 56.52 3.19 0.01 0.02 0.61 58.80 28.02 0.08042 0.03 0.84 95365.23 131052.37 3.18 1.71 1.08 0.93

24__Main TS 856.17 134.61 108.55 3.09 57.36 3.23 0.01 0.02 0.61 59.42 27.96 0.08024 0.03 0.84 97704.36 132893.37 3.21 1.75 1.11 0.96

25__Main TS 862.70 135.77 111.58 3.03 58.18 3.27 0.01 0.02 0.61 60.16 27.93 0.08008 0.03 0.85 99545.36 133914.25 3.25 1.79 1.15 0.99

26__Main TS 864.06 135.25 115.61 2.98 59.14 3.30 0.01 0.02 0.62 61.31 27.97 0.08004 0.03 0.85 100566.24 133581.31 3.32 1.85 1.20 1.03

BOTTOM Reboiler 856.24 33.60 122.35 2.96 60.62 3.31 0.01 0.02 0.62 63.47 28.11 0.08040 0.03 0.84 100233.29 33348.01 3.45 1.95 1.28 1.11

K Value

STRIPPING

SECTION

ENRICHING/

RECTIFYING

SECTION

SIZING COLUMN DISTILATION (C'' FACTOR METHOD)

Process Requirement

2.7 lb/ft

3

82994.6 lb/hr Max Value is Selected

30203.9 ft

3

/hr

268.8 GPM

61.1 m

3

/hr Max Value is Selected

27.8 lb/ft

3

3.7 dyne/cm

24.0 inch

0.6 m

Diameter Column Calculation, with C Factor Method

430.0 Fig 19-13 GPSA

1299.1 ft/hr Eq. 19-11 GPSA

9.0 ft

2749.0 mm

2750.0 mm

9.0 ft

Height of Column Required

12.0 ea Ideal Stage

11.0 ea

60.8 C

141.4 F

1.1

0.6

1.8

0.102 cP

0.102 mNs/m

2

0.181

81.0 % Fig 19-18 GPSA

81.0 % Fig 11.13 Coulson Richardson

13.6 ea

14.0 ea

3.3 ft Distance between top tray to gas outlet nozzle

1.0 m

9.5 m

Vapour Density

Rectifying/Enriching Section :

Tray Spacing

C Factor

Mass Flow Rate HC Gas

Flow Rate HC Gas

Liquid Density

Liquid Surface Tension

Liquid Rate

Stage/Tray

Feed viscosity@average temperature (m)

Average Light Key Relative Volatility@average temperature

Average Heavy Key Relative Volatility@average temperature

Average Light Key Relative Volatility to Heavy Key@average temperature

a.m

Plate Efficiency

VMAX

Diameter Column Required, DT

Average Column Temperature

Diameter Column Proposed

Space Inter Stage

Real stage

Proposed Number of Stage

Height of Column

Space

Process Requirement

3.0 lb/ft

3

100566.2 lb/hr Max Value is Selected

33038.9 ft

3

/hr

597.8 GPM

135.8 m

3

/hr Max Value is Selected

28.3 lb/ft

3

3.4 dyne/cm

24.0 inch

0.6 m

Diameter Column Calculation, with C Factor Method

430.0 Fig 19-13 GPSA

1238.3 ft/hr Eq. 19-11 GPSA

10.2 ft

3099.4 mm

3100.0 mm

10.2 ft

7.5 m

2

33.6 m

3

/hr

5.0 minutes Low to High Level

2.8 m

3

0.4 m

1.0 m Include low low to high high level

3.3 ft

Height of Column Required

14.0 ea

13.0 ea

97.0 C

206.6 F

1.4

0.8

1.7

0.069 cP

0.0694 mNs/m

2

0.1161

81.0 % Fig 19-18 GPSA

81.0 % Fig 11.13 Coulson Richardson

16.0 ea

16.0 ea

10.8 m

Selected Column Dimension

3100.0 mm

3.1 m

122.0 inch

10.2 ft

20288.0 mm

20.3 m

798.7 inch

66.6 ft

Summary :

3.1 m 122.0 inch

20.3 m 66.6 ft

Bottom Flow Rate

Liquid Hold Up/Residence Time

Volume of Liquid Hold Up

Column Height (T/T)

Height of Column

Vmax

Diameter Column Required, DT

Diameter Column Propose

Space Inter Stage

Stage/Tray

Column Diameter

Liquid Density

Liquid Surface tension,

C Factor

Stripping Section :

Tray Spacing

Vapour Density

Liquid Rate

Mass Flow Rate HC Gas

Flow Rate HC Gas, Vmax

Average Light Key Relative Volatility@average temperature

Average Heavy Key Relative Volatility@average temperature

Average Light Key Relative Volatility to Heavy Key@average temperature

Column Area

Height of Liquid Hold Up

Height of Bottom Side

Average Column Temperature

Feed viscosity@average temperature (m)

Real stage

Proposed Number of Stage

Selected Column Height

a.m

Plate Efficiency

Selected Column Diameter

SIZING COLUMN DISTILATION (NOMOGRAPH METHOD)

Process Requirement

2.7 lb/ft

3

82994.6 lb/hr Max Value is Selected

30203.9 ft

3

/hr

268.8 GPM

61.1 m

3

/hr Max Value is Selected

1.70E-02 m

3

/sec

27.8 lb/ft

3

3.68 dyne/cm

24.0 inch

0.6 m

Diameter Column Calculation, with Nomograph Method

8.4 ft

3

/s

2.8 ft

3

/s Eq 19-13 GPSA

4.0 ft For single pass tray - Fig 19-14 GPSA

1219.2 mm

Oke

0.0 ft For two pass tray - Fig 19-14 GPSA

0.0 mm

Not Oke

1250.0 mm

1.25 m

4.1 ft

Single (Cross Flow) Pass Fig 11.28. Coulson Ricardson

Single (Cross Flow) Pass

Height of Column Required

12.0 ea Ideal Stage

11.0 ea

60.8 C

141.4 F

1.1

0.6

1.8

0.102 cP

0.102 mNs/m

2

0.181

81.0 % Fig 19-18 GPSA

81.0 % Fig 11.13 Coulson Richardson

13.6 ea

14.0 ea

3.3 ft Distance between top tray to gas outlet nozzle

1.0 m

9.5 m

Diameter Column Required, DT

Remark for Single Pass Tray

VLOAD

Diameter Column Proposed

Remark for Two Pass Tray

Proposed Tray Lay Out

Average Column Temperature

Liquid Surface Tension

Flow Rate HC Gas

Liquid Rate

Vapour Density

Rectifying/Enriching Section :

Tray Spacing

Space Inter Stage

Stage/Tray

Mass Flow Rate HC Gas

Flow Rate HC Gas

Liquid Density

Real stage

Proposed Number of Stage

Average Light Key Relative Volatility@average temperature

Height of Column

Space

Average Heavy Key Relative Volatility@average temperature

Average Light Key Relative Volatility to Heavy Key@average temperature

Feed viscosity@average temperature (m)

a.m

Plate Efficiency

Process Requirement

3.0 lb/ft

3

100566.2 Lb/hr Max Value is Selected

33038.9 ft

3

/hr

597.8 GPM

135.8 m

3

/hr Max Value is Selected

3.77E-02 m

3

/sec

28.3 lb/ft

3

3.4 dyne/cm

24.0 inch

0.6 m

Diameter Column Calculation, with Nomograph Method

9.2 ft

3

/sec

3.2 ft

3

/sec Eq 19-13 GPSA

5.5 ft For single pass tray - Fig 19-14 GPSA

1676.4 mm

Oke

0.0 ft For two pass tray - Fig 19-14 GPSA

0.0 mm

Not Oke

1700.0 mm

1.70 m

5.6 ft

Double (Two) Pass Fig 11.28. Coulson Ricardson

Double (Two) Pass

2.3 m

2

33.6 m

3

/hr

5.0 minutes Low to High Level

2.8 m

3

1.2 m

1.5 m Include low low to high high level

4.9 ft

Height of Column Required

14.0 ea Ideal Stage

13.0 ea

97.0 C

206.6 F

1.4

0.8

1.7

0.069 cP

0.069 mNs/m

2

0.116

80.0 % Fig 19-18 GPSA

80.0 % Fig 11.13 Coulson Richardson

16.3 ea

17.0 ea

11.9 m

Selected Column Dimension

1700.0 mm

1.7 m

66.9 inch

5.6 ft

21397.6 mm

21.4 m

842.4 inch

70.2 ft

Summary :

1.7 m 66.9 inch

21.4 m 70.2 ft

Remark for Single Pass Tray

Tray Spacing

Diameter Column Required, DT

Liquid Rate

Stripping Section :

Vapour Density

VLOAD

Liquid Density

Liquid Surface Tension

Flow Rate HC Gas

Mass Flow Rate HC Gas

Flow Rate HC Gas

Proposed Tray Lay Out

Column Area

Diameter Column Required, DT

Remark for Two Pass Tray

Diameter Column Proposed

Space Inter Stage

Average Column Temperature

Average Light Key Relative Volatility@average temperature

Bottom Flow Rate

Liquid Hold Up/Residence Time

Volume of Liquid Hold Up

Height of Liquid Hold Up

Column Height (T/T)

a.m

Plate Efficiency

Real stage

Proposed Number of Stage

Height of Bottom Side

Selected Column Diameter

Selected Column Height

Column Diameter

Height of Column

Stage/Tray

Average Heavy Key Relative Volatility@average temperature

Average Light Key Relative Volatility to Heavy Key@average temperature

Feed viscosity@average temperature (m)

SIZING COLUMN DISTILATION (DETAILED METHOD)

Process Requirement

30203.94 ft

3

/hr Max Value is Selected

2.78 ft

3

/s Based on 80% flood with valve tray type

2.75 lb/ft

3

268.8 GPM

61.06 m

3

/hr Max Value is Selected

1.70E-02 m

3

/sec

27.83 lb/ft

3

3.68 dyne/cm

24.00 inch

0.61 m

Diameter Column Calculation, with Detailed Method

25.08 lb/ft

3

Fig 19-16 GPSA

186.00 Fig 19-16 GPSA

0.85 Fig 19-15 GPSA

0.88 Fig 19-15 GPSA

0.85 Lower value is selected

158.10 gpm/ft

2

Eq 19-14 GPSA

0.42 ft/sec Fig 19-17 GPSA

0.36 ft/sec Eq 19-15 GPSA

4.0 ft For single pass tray - Fig 19-14 GPSA

1219.2 mm

Oke

0.0 ft For two pass tray - Fig 19-14 GPSA

0.0 mm

Not Oke

1250.0 mm

1.25 m

4.1 ft

Single (Cross Flow) Pass Fig 11.28. Coulson Ricardson

Single (Cross Flow) Pass

1.00 Fig 19-14 GPSA

36.91 ft Eq 19-16 GPSA

0.82

12.09 ft

2

Eq 19-17 GPSA

2.07 ft

2

Eq 19-18 GPSA

1.33 ft

2

4.15 ft

2

2.07 ft

2

16.24 ft

2

Eq 19-19 GPSA

12.16 ft

2

Eq 19-20 GPSA

16.24 ft

2

Eq 19-20 GPSA

4.55 ft Eq 19-21 GPSA

1.39 m

1386.03 mm

1400.00 mm

1.40 m

4.59 ft

Selected ADM

Note :

If ADM is less than 11% AAM then use 11%

AAM or double ADM, whichever is smaller

ATM [Tower Cross Sectional Area] recommendation (1)

Diameter Column Proposed

Proposed Tray Lay Out

Diameter Column Required, DT

Remark for Single Pass Tray

Diameter Column Required, DT

ATM [Tower Cross Sectional Area] recommendation (2)

NP [Tray Lay Out]

FPL [Flow Patch Length]

FF [Flooding Factor]

AAM [Active Area]

CAFo [Vapor Capacity Factor]

CAF [Vapor Capacity Factor] related to System Factor]

ADM [Downcomer Area]

ADM recommendation (1)

ADM recommendation (2)

ATM [Tower Cross Sectional Area]

Remark for Two Pass Tray

Tray Spacing

L - V

Selected Foaming System Factor

Liquid Rate

Vapour Density

Rectifying/Enriching Section :

Flow Rate HC Gas

VLOAD

DT (Column Diameter]

Diameter Column Proposed

Selected ATM

Liquid Density

Liquid Surface Tension

VD*dsg [Downcomer Velocity]

VDdsg [Downcomer Velocity related to System Factor]

Foaming System Factor

Height of Column Required

12.0 ea Ideal Stage

11.0 ea

60.8 C

141.4 F

1.1

0.6

1.8

0.102 cP

0.102 mNs/m

2

0.181

81.0 % Fig 19-18 GPSA

81.0 % Fig 11.13 Coulson Richardson

13.6 ea

14.0 ea

3.3 ft Distance between top tray to gas outlet nozzle

1.0 m

9.5 m

Process Requirement

33038.95 ft

3

/hr

3.19 ft

3

/sec Eq 19-13 GPSA

3.04 lb/ft

3

597.76 GPM

135.77 m

3

/hr Max Value is Selected

3.77E-02 m

3

/sec

28.29 lb/ft

3

3.36 dyne/cm

24.00 inch

0.61 m

Diameter Column Calculation, with Detailed Method

25.10 lb/ft

3

Fig 19-16 GPSA

186.00 Fig 19-16 GPSA

0.850 Fig 19-15 GPSA

0.847

0.847 Lower value is selected

157.62 gpm/ft

2

Eq 19-14 GPSA

0.41 ft/sec Fig 19-17 GPSA

0.35 ft/sec Eq 19-15 GPSA

5.5 ft For single pass tray - Fig 19-14 GPSA

1676.4 mm

Oke

0.0 ft For two pass tray - Fig 19-14 GPSA

0.0 mm

Not Oke

1700.0 mm

1.70 m

5.6 ft

Double (Two) Pass Fig 11.28. Coulson Ricardson

Double (Two) Pass

1.00 Fig 19-14 GPSA

50.20 ft Eq 19-16 GPSA

0.82

NP [Tray Lay Out]

FPL [Flow Patch Length]

FF [Flooding Factor]

Height of Column

L - V

Liquid Surface Tension

VD*dsg [Downcomer Velocity]

Foaming System Factor

Real stage

Proposed Number of Stage

Space

Selected Foaming System Factor

VDdsg [Downcomer Velocity related to System Factor]

CAFo [Vapor Capacity Factor]

CAF [Vapor Capacity Factor] related to System Factor]

Diameter Column Proposed

Proposed Tray Lay Out

Diameter Column Required, DT

Remark for Single Pass Tray

Vapour Density

Average Light Key Relative Volatility@average temperature

Average Heavy Key Relative Volatility@average temperature

Average Light Key Relative Volatility to Heavy Key@average temperature

Stripping Section :

Tray Spacing

a.m

Plate Efficiency

Stage/Tray

Space Inter Stage

Average Column Temperature

Flow Rate HC Gas

VLOAD

Liquid Density

Liquid Rate

Feed viscosity@average temperature (m)

Diameter Column Required, DT

Remark for Two Pass Tray

19.29 ft

2

Eq 19-17 GPSA

4.63 ft

2

Eq 19-18 GPSA

2.12 ft

2

9.25 ft

2

4.63 ft

2

28.54 ft

2

Eq 19-19 GPSA

14.34 ft

2

Eq 19-20 GPSA

28.54 ft

2

Eq 19-20 GPSA

6.03 ft Eq 19-21 GPSA

1.84 m

1837.30 mm

1850.00 mm

1.85 m

6.07 ft

2.7 m

2

33.6 m

3

/hr

5.0 minutes Low to High Level

2.8 m

3

1.0 m

1.2 m Include low low to high high level

3.9 ft

Height of Column Required

14.0 ea Ideal Stage

13.0 ea

97.0 C

206.6 F

1.4

0.8

1.7

0.069 cP

0.069 mNs/m

2

0.116

80.0 % Fig 19-18 GPSA

80.0 % Fig 11.13 Coulson Richardson

16.3 ea

17.0 ea

11.6 m

Selected Column Dimension

1850.0 mm

1.85 m

72.83 inch

6.07 ft

21097.6 mm

21.1 m

830.6 inch

69.2 ft

Summary :

1.9 m 72.8 inch

21.1 m 69.2 ft

Stage/Tray

Space Inter Stage

Column Area

Bottom Flow Rate

Liquid Hold Up/Residence Time

Volume of Liquid Hold Up

Height of Liquid Hold Up

Height of Bottom Side

ATM [Tower Cross Sectional Area] recommendation (2)

Selected ATM

DT (Column Diameter]

Diameter Column Proposed

ATM [Tower Cross Sectional Area] recommendation (1)

Note :

If ADM is less than 11% AAM then use 11%

AAM or double ADM, whichever is smaller

ATM [Tower Cross Sectional Area] recommendation (2)

Selected ATM

ATM [Tower Cross Sectional Area]

ATM [Tower Cross Sectional Area] recommendation (1)

AAM [Active Area]

ADM [Downcomer Area]

a.m

Average Column Temperature

Average Light Key Relative Volatility@average temperature

Average Heavy Key Relative Volatility@average temperature

Feed viscosity@average temperature (m)

Proposed Number of Stage

Plate Efficiency

Average Light Key Relative Volatility to Heavy Key@average temperature

Selected Column Diameter

Height of Column

Real stage

Column Diameter

Column Height (T/T)

Selected Column Height

SIZING COLUMN DISTILATION (COULSON RICHARDSON METHOD)

Process Requirement

82994.64 lb/hr Max Value is Selected

10.46 kg/sec

59513.28 lb/hr Max Value is Selected

7.50 kg/sec

2.75 lb/ft

3

44.02 kg/m

3

27.83 lb/ft

3

445.79 kg/m

3

3.68 dyne/cm

0.0037 N/m

0.610 m Range 0.15~1 m

24.00 inch 0.3~0.6 m for column diameter above 1 m

0.16 m/sec Eq 11-79 Coulson Richardson

1.36 m Eq 11-80 Coulson Richardson

0.23 Eq 11-82 Coulson Richardson

0.082 Fig 11-27 Coulson Richardson

0.06

0.18 m/sec

85 % normally 70~90% flooding velocity

0.15 m/sec higher vapour velocity give higher plate efficiency

higher vapour velocity give higher risk of flooding

0.15 m/sec

0.24 m

3

/sec

1.58 m

2

12 %

1.80 m

2

1.51 m

1513.88 mm

59.60 inch

1500.00 mm

1.50 m

59.06 inch

1.77 m

2

1.68E-02 m

3

/sec

Cross Flow (single pass) Fig 11-28 Coulson Richardson

Provisional Plate Design

1.50 m

1.77 m

2

0.21 m

2

1.55 m

2

1.34 m

2

7.5 %

0.10 m

2

0.85 normally 0.6~0.85 Fig 11-31 Coulson Richardson

1.28 m

40.00 mm liquid normally 40~90 mm for > atmosferic

normally 6~12 mm for vacuum application

higher weir height give better efficiency

higher weir height give higher pressure drop

4.00 mm normally 2.5~5 mm

larger hole size for fouling duty

5.00 mm 5 mm for CS and 3 mm for SS

Rectifying/Enriching Section :

Mass Flow Rate HC Gas

Mass Flow Rate HC Liquid

Liquid surface tension

Tray spacing

Vapour Density

Liquid Density

K1

Corrected K1

UF (flooding velocity]

Design flooding @maximum flow rate

UV [maximum vapor velocity causing excessive entrainment & pressure

drop]

DC [column diameter]

FLV [liquid - vapour flow factor]

Net area required

Down comer area

Column cross sectional area

Column diameter

Design UF

Selected design UF

Volumetric flow rate HC gas

Volumetric flow rate HC liquid

Tray Lay Out

Selected column cross sectional area

Selected column diameter

LW/DC

LW [weir length]

hW [weir height]

DC [column diameter]

AC [column area]

AD [downcomer area]

AN [net area]

AA [active area]

AH [hole area]

Hole size

Plate thickness

Check Weeping

7.50 kg/sec

80 % good design sieve tray give range turndown 50~120% capacity

6.00 kg/sec

41.87 mm liquid Eq 11-85 Coulson Richardson

36.09 mm liquid

Oke > 10 mm the height of liquid crest should be at least 10 mm @ lowest liquid rate

76.09 mm liquid

30.60 Fig 11-30 Coulson Richardson

1.71 m/sec Eq 11-84 Coulson Richardson

1.89 m/sec

Oke as weeping does not occur

Plate Pressure Drop

2.36 m/sec

1.25

7.5 %

0.875 Fig 11-34 Coulson Richardson

36.63 mm liquid Eq 11-88 Coulson Richardson

28.04 mm liquid Eq 11-89 Coulson Richardson

146.54 mm liquid Eq 11-90 Coulson Richardson

640.20 Pa

0.01 bar

0.09 psi

Oke as lower than 0.1 psi pressure drop maximum 0.1 psi

Downcomer Liquid Back Up

35.00 mm height is normally 5~10 mm below the outlet weir height

0.04 m

2

Eq 11-93 Coulson Richardson

0.04 m

2

23.59 mm liquid

252.00 mm liquid

324.80 mm liquid

Oke as flooding not occur and tray spacing is acceptable

Downcomer Residence Time

3.18 sec

Oke as > 3 sec Eq 11-95 Coulson Richardson

Process Requirement

100566.24 lb/hr Max Value is Selected

12.67 kg/sec

133914.25 lb/hr Max Value is Selected

16.87 kg/sec

3.04 lb/ft

3

48.76 kg/m

3

28.29 lb/ft

3

453.12 kg/m

3

3.36 dyne/cm

0.0034 N/m

0.700 m Range 0.15~1 m

27.56 inch 0.3~0.6 m for column diameter above 1 m

Minimum liquid rate

Maximum hOW

Minimum hOW

Remark

Maximum liquid rate

Turn down ratio

hW + hOW

K2 [weep point correlation]

UH-MIN [minimum design vapour velocity through the hole]

UH-Actual [minimum actual vapour velocity through hole]

UH-MAX [maximum design vapour velocity through the hole]

Ratio plate thickness to hole diameter

Ratio AH to AA

CO [orifice coefficient]

Remark

Dry plate drop

DPTOTAL

hD [pressure drop through the dry plate]

Residual head

hR [pressure drop as liquid surface tension, froth height and density]

Total pressure drop = hT = DPTOTAL

Remark

hAP [height of the bottom edge of the appron above the plate]

AAP [clearance area under downcomer]

Selected AM

hDC [head loss in the downcomer]

hB [back up in downcomer]

tR [downcomer residence time]

Remark

Stripping Section :

1/2 x (plate spacing + weir height)

Remark

Mass Flow Rate HC Gas

Mass Flow Rate HC Liquid

Vapour Density

Liquid Density

Liquid surface tension

Tray spacing

0.17 m/sec Eq 11-79 Coulson Richardson

1.41 m Eq 11-80 Coulson Richardson

0.44 Eq 11-82 Coulson Richardson

0.065 Fig 11-27 Coulson Richardson

0.05

0.13 m/sec

85 % normally 70~90% flooding velocity

0.11 m/sec higher vapour velocity give higher plate efficiency

higher vapour velocity give higher risk of flooding

0.11 m/sec

0.26 m

3

/sec

2.33 m

2

12 %

2.65 m

2

1.84 m

1837.90 mm

72.36 inch

1850.00 mm

1.85 m

72.83 inch

2.69 m

2

3.72E-02 m

3

/sec

Cross Flow (single pass) Fig 11-28 Coulson Richardson

Provisional Plate Design

1.85 m

2.69 m

2

0.32 m

2

2.36 m

2

2.04 m

2

5.4 %

0.11 m

2

0.85 normally 0.6~0.85 Fig 11-31 Coulson Richardson

1.57 m

40.00 mm liquid normally 40~90 mm for > atmosferic

normally 6~12 mm for vacuum application

higher weir height give better efficiency

higher weir height give higher pressure drop

4.00 mm normally 2.5~5 mm

larger hole size for fouling duty

5.00 mm 5 mm for CS and 3 mm for SS

Check Weeping

16.87 kg/sec

80 % good design sieve tray give range turndown 50~120% capacity

13.50 kg/sec

61.85 mm liquid Eq 11-85 Coulson Richardson

53.30 mm liquid

Oke > 10 mm the height of liquid crest should be at least 10 mm @ lowest liquid rate

93.30 mm liquid

30.80 Fig 11-30 Coulson Richardson

1.65 m/sec Eq 11-84 Coulson Richardson

1.89 m/sec

Weeping not occur

K2 [weep point correlation]

hW + hOW

Remark

Minimum hOW

Maximum hOW

Remark

UH-Actual [minimum actual vapour velocity through hole]

UH-MIN [minimum design vapour velocity through the hole]

DC [column diameter]

FLV [liquid - vapour flow factor]

K1

Corrected K1

UV [maximum vapor velocity causing excessive entrainment & pressure

drop]

UF (flooding velocity]

Design flooding @maximum flow rate

Design UF

Turn down ratio

Maximum liquid rate

Plate thickness

Minimum liquid rate

hW [weir height]

LW [weir length]

LW/DC

Hole size

AD [downcomer area]

AC [column area]

DC [column diameter]

Selected column diameter

AH [hole area]

AA [active area]

AN [net area]

Volumetric flow rate HC gas

Selected design UF

Column diameter

Column cross sectional area

Down comer area

Net area required

Tray Lay Out

Volumetric flow rate HC liquid

Selected column cross sectional area

Plate Pressure Drop

2.36 m/sec

1.25

5.4 %

0.850 Fig 11-34 Coulson Richardson

42.20 mm liquid Eq 11-88 Coulson Richardson

27.59 mm liquid Eq 11-89 Coulson Richardson

171.63 mm liquid Eq 11-90 Coulson Richardson

762.13 Pa

0.01 bar

0.111 psi

Not oke as higher than 0.1 psi pressure drop maximum 0.1 psi

Downcomer Liquid Back Up

35.00 mm height is normally 5~10 mm below the outlet weir height

0.06 m

2

Eq 11-93 Coulson Richardson

0.06 m

2

75.99 mm liquid

349.47 mm liquid

370.00 mm liquid

Oke as flooding not occur and tray spacing is acceptable

Downcomer Residence Time

3.03 sec

Oke as > 3 sec Eq 11-95 Coulson Richardson

Selected Column Dimension

1850.0 mm

1.85 m

72.83 inch

6.07 ft

Re-iterate enriching section with selected diameter

21097.60 mm

21.10 m

830.61 inch

69.22 ft

Summary :

1.9 m 72.8 inch

21.1 m 69.2 ft

Process Requirement

82994.64 lb/hr Max Value is Selected

10.46 kg/sec

59513.28 lb/hr Max Value is Selected

7.50 kg/sec

2.75 lb/ft

3

44.02 kg/m

3

27.83 lb/ft

3

445.79 kg/m

3

3.68 dyne/cm

0.0037 N/m

0.700 m Range 0.15~1 m

27.56 inch 0.3~0.6 m for column diameter above 1 m

UH-MAX [maximum design vapour velocity through the hole]

Dry plate drop

DPTOTAL

Total pressure drop = hT = DPTOTAL

hR [pressure drop as liquid surface tension, froth height and density]

Residual head

hD [pressure drop through the dry plate]

Remark

CO [orifice coefficient]

Ratio AH to AA

Ratio plate thickness to hole diameter

Remark

tR [downcomer residence time]

hDC [head loss in the downcomer]

Selected AM

Remark

1/2 x (plate spacing + weir height)

hB [back up in downcomer]

AAP [clearance area under downcomer]

hAP [height of the bottom edge of the appron above the plate]

Selected Column Diameter

Remark

Selected Column Height

Column Diameter

Column Height (T/T)

Mass Flow Rate HC Liquid

Vapour Density

Rectifying/Enriching Section : Re-iteration

Mass Flow Rate HC Gas

Tray spacing

Liquid Density

Liquid surface tension

0.18 m/sec Eq 11-79 Coulson Richardson

1.31 m Eq 11-80 Coulson Richardson

0.23 Eq 11-82 Coulson Richardson

0.082 Fig 11-27 Coulson Richardson

0.06

0.18 m/sec

85 % normally 70~90% flooding velocity

0.15 m/sec higher vapour velocity give higher plate efficiency

higher vapour velocity give higher risk of flooding

0.15 m/sec

0.24 m

3

/sec

1.58 m

2

12 %

1.80 m

2

1.51 m

1513.88 mm

59.60 inch

1850.00 mm

1.85 m

72.83 inch

2.69 m

2

1.68E-02 m

3

/sec

Cross Flow (single pass) Fig 11-28 Coulson Richardson

Provisional Plate Design

1.85 m

2.69 m

2

0.32 m

2

2.36 m

2

2.04 m

2

5.4 %

0.11 m

2

0.85 normally 0.6~0.85 Fig 11-31 Coulson Richardson

1.57 m

40.00 mm liquid normally 40~90 mm for > atmosferic

normally 6~12 mm for vacuum application

higher weir height give better efficiency

higher weir height give higher pressure drop

4.00 mm normally 2.5~5 mm

larger hole size for fouling duty

5.00 mm 5 mm for CS and 3 mm for SS

Check Weeping

7.50 kg/sec

80 % good design sieve tray give range turndown 50~120% capacity

6.00 kg/sec

36.41 mm liquid Eq 11-85 Coulson Richardson

31.38 mm liquid

Oke > 10 mm the height of liquid crest should be at least 10 mm @ lowest liquid rate

71.38 mm liquid

30.50 Fig 11-30 Coulson Richardson

1.69 m/sec Eq 11-84 Coulson Richardson

1.72 m/sec

Weeping not occur

UV [maximum vapor velocity causing excessive entrainment & pressure

drop]

DC [column diameter]

Design flooding @maximum flow rate

Design UF

Selected design UF

FLV [liquid - vapour flow factor]

K1

Corrected K1

UF (flooding velocity]

Column diameter

Selected column diameter

Volumetric flow rate HC gas

Net area required

Down comer area

Column cross sectional area

Tray Lay Out

DC [column diameter]

AC [column area]

Selected column cross sectional area

Volumetric flow rate HC liquid

LW/DC

LW [weir length]

hW [weir height]

AD [downcomer area]

AN [net area]

AA [active area]

AH [hole area]

Plate thickness

Maximum liquid rate

Hole size

Remark

hW + hOW

K2 [weep point correlation]

UH-MIN [minimum design vapour velocity through the hole]

Turn down ratio

Minimum liquid rate

Maximum hOW

Minimum hOW

UH-Actual [minimum actual vapour velocity through hole]

Remark

Plate Pressure Drop

2.15 m/sec

1.25

5.4 %

0.875 Fig 11-34 Coulson Richardson

30.54 mm liquid Eq 11-88 Coulson Richardson

28.04 mm liquid Eq 11-89 Coulson Richardson

134.99 mm liquid Eq 11-90 Coulson Richardson

589.72 Pa

0.01 bar

0.09 psi

Oke as lower than 0.1 psi pressure drop maximum 0.1 psi

Downcomer Liquid Back Up

35.00 mm height is normally 5~10 mm below the outlet weir height

0.06 m

2

Eq 11-93 Coulson Richardson

0.06 m

2

15.51 mm liquid

226.90 mm liquid

370.00 mm liquid

Oke as flooding not occur and tray spacing is acceptable

Downcomer Residence Time

4.35 sec

Oke as > 3 sec Eq 11-95 Coulson Richardson

UH-MAX [maximum design vapour velocity through the hole]

Ratio plate thickness to hole diameter

Ratio AH to AA

CO [orifice coefficient]

Dry plate drop

tR [downcomer residence time]

hD [pressure drop through the dry plate]

Residual head

hR [pressure drop as liquid surface tension, froth height and density]

Total pressure drop = hT = DPTOTAL

DPTOTAL

Remark

hAP [height of the bottom edge of the appron above the plate]

AAP [clearance area under downcomer]

Remark

Selected AM

hDC [head loss in the downcomer]

hB [back up in downcomer]

1/2 x (plate spacing + weir height)

Remark

SIZING COLUMN DISTILATION (C'' FACTOR METHOD)

Process Requirement

2.7 lb/ft

3

82994.6 lb/hr Max Value is Selected

30203.9 ft

3

/hr

268.8 GPM

61.1 m

3

/hr Max Value is Selected

27.8 lb/ft

3

3.7 dyne/cm

59513.3 lb/hr Max Value is Selected

0.1 cP

Diameter Column Calculation, with C Factor Method

0.7

0.3

0.225

0.5 inch water/ ft of packing normally 0.2~0.6 inch water/ft of packing

1.2E-03 bar/ft of packing

0.035 Fig 19-22 GPSA

Plastic pall ring 2 inch < 1 inch packing size for column diameter < 0.3 m

1~1.5 inch packing size for column diameter 0.3~0.9 m

2~3 inch packing size for column diameter > 0.9 m

26.0 Fig 19-23 GPSA

3.6

1.9 lb/ft

2

.sec

12.2 ft

2

3.9 ft

1.2 m

1203.1 mm

47.4 inch

1250.0 mm

1.3 m

49.2 inch

4.1 ft

Height of Column Required

12.0 ea Ideal Stage

11.0 ea

80.2 C

176.3 F

1.1

0.6

1.8

0.102 cP

0.102 mNs/m

2

0.181

81.0 % Fig 19-18 GPSA

81.0 % Fig 11.13 Coulson Richardson

13.6 ea

14.0 ea

2.8 ft Fig 19-24 GPSA

0.4~0.5 m for pall ring, sadle 1 inch

0.6~0.75 m for pall ring, sadle 1.5 inch

0.75~1 m for pall ring, sadle 2 inch

39.2 ft

3.3 ft Distance between top tray to gas outlet nozzle

1.0 m

42.5 ft

12.9 m

12948.2 mm

Space

a.m

Plate Efficiency

Mass Flow Rate HC Liquid

GP

2

x mL

0.1

x FP x (rW/rL)

0.1

32.17 x rV x (rL - rV)

A1 = Ratio Mass Flow Rate HC Liquid to Gas

A2 = (V/L)

1/2

A1 x A2

DP

FP [packing factor]

Gp

2

Gp

Real stage

Proposed Number of Stage

Height of Column

Packing/internal type

DT (column diameter]

Average Light Key Relative Volatility to Heavy Key@average temperature

Average Column Temperature

Diameter Column Proposed

Space Inter Stage

Liquid Rate

Stage/Tray

AC [column cross sectional area]

Feed viscosity@average temperature (m)

Average Light Key Relative Volatility@average temperature

Average Heavy Key Relative Volatility@average temperature

Vapour Density

Rectifying/Enriching Section :

Liquid Viscosity

Mass Flow Rate HC Gas

Flow Rate HC Gas

Liquid Density

Liquid Surface Tension

HETP

Height of Packing Bed

Process Requirement

3.0 lb/ft

3

100566.2 lb/hr Max Value is Selected

33038.9 ft

3

/hr

597.8 GPM

135.8 m

3

/hr Max Value is Selected

28.3 lb/ft

3

3.4 dyne/cm

133914.3 lb/hr Max Value is Selected

0.1 cP

Diameter Column Calculation, with C Factor Method

1.3

0.3

0.437

0.5 inch water/ ft of packing normally 0.2~0.6 inch water/ft of packing

1.2E-03 bar/ft of packing

0.022 Fig 19-22 GPSA

Plastic pall ring 2 inch < 1 inch packing size for column diameter < 0.3 m

1~1.5 inch packing size for column diameter 0.3~0.9 m

2~3 inch packing size for column diameter > 0.9 m

26.0 Fig 19-23 GPSA

2.5

1.6 lb/ft

2

.sec

17.7 ft

2

4.8 ft

1.4 m

1448.5 mm

57.0 inch

1450.0 mm

1.5 m

57.1 inch

4.8 ft

Height of Column Required

14.0 ea Ideal Stage

13.0 ea

97.0 C

206.6 F

1.4

0.8

1.7

0.069 cP

0.069 mNs/m

2

0.116

81.0 % Fig 19-18 GPSA

81.0 % Fig 11.13 Coulson Richardson

16.0 ea

16.0 ea

2.8 ft Fig 19-24 GPSA

0.4~0.5 m for pall ring, sadle 1 inch

0.6~0.75 m for pall ring, sadle 1.5 inch

0.75~1 m for pall ring, sadle 2 inch

44.8 ft

13.7 m

1.7 m

2

33.6 m

3

/hr

5.0 minutes Low to High Level

2.8 m

3

1.7 m

1.9 m Include low low to high high level

6.2 ft

15555 mm

15.6 m

51.0 ft

Flow Rate HC Gas

Real stage

Stage/Tray

Space Inter Stage

Average Column Temperature

Stripping Section :

Mass Flow Rate HC Liquid

Liquid Rate

Column Area

Height of Packing Bed

Liquid Viscosity

DT (column diameter]

a.m

Plate Efficiency

Packing/internal type

FP [packing factor]

Gp

2

Liquid Surface Tension

A1 = Ratio Mass Flow Rate HC Liquid to Gas

Liquid Density

A2 = (V/L)

1/2

Proposed Number of Stage

HETP

A1 x A2

DP

Average Light Key Relative Volatility@average temperature

GP

2

x mL

0.1

x FP x (rW/rL)

0.1

32.17 x rV x (rL - rV)

Mass Flow Rate HC Gas

Vapour Density

Average Light Key Relative Volatility to Heavy Key@average temperature

Feed viscosity@average temperature (m)

Gp

AC [column cross sectional area]

Diameter Column Proposed

Average Heavy Key Relative Volatility@average temperature

Height of Column

Bottom Flow Rate

Liquid Hold Up/Residence Time

Volume of Liquid Hold Up

Height of Liquid Hold Up

Height of Bottom Side

Selected Column Dimension

1450.0 mm

1.5 m

57.1 inch

4.8 ft

28503.2 mm

28.5 m

1122.2 inch

93.5 ft

Summary :

1.5 m 57.1 inch

28.5 m 93.5 ft

Selected Column Diameter

Column Diameter

Column Height (T/T)

Selected Column Height

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Aspen OLI Standard Getting Started 2006 PDFDokument93 SeitenAspen OLI Standard Getting Started 2006 PDFzamijakaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityDokument49 SeitenHemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityzamijakaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Spray Chapter2 PDFDokument45 SeitenSpray Chapter2 PDFzamijakaNoch keine Bewertungen

- AfterCooler Seperators Drains PDFDokument11 SeitenAfterCooler Seperators Drains PDFzamijakaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Design Aeration1Dokument64 SeitenDesign Aeration1zamijakaNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Activated Sludge: January 2016 7-1 Design Criteria Ch. 7Dokument17 SeitenActivated Sludge: January 2016 7-1 Design Criteria Ch. 7zamijakaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- MAE 4230/5230: Introduction To CFD: Rajesh BhaskaranDokument26 SeitenMAE 4230/5230: Introduction To CFD: Rajesh BhaskaranzamijakaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- HAC MAterialDokument123 SeitenHAC MAterialzamijaka100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- L.Y.M. Gicquel and O. VermorelDokument8 SeitenL.Y.M. Gicquel and O. VermorelzamijakaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- PSMDokument62 SeitenPSMzamijakaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Breather Valve CalcDokument12 SeitenBreather Valve CalczamijakaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Properties of Hazardous MixturesDokument63 SeitenProperties of Hazardous MixtureszamijakaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Oil Water Separator SizingDokument6 SeitenOil Water Separator Sizingzamijaka100% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- GeneratorDokument25 SeitenGeneratorzamijakaNoch keine Bewertungen

- Lubricant Properties CalculatorDokument14 SeitenLubricant Properties CalculatorzamijakaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Nptel: Mass Transfer II - Video CourseDokument3 SeitenNptel: Mass Transfer II - Video CourseShiva KumarNoch keine Bewertungen

- Effects of Liquefaction On StructuresDokument38 SeitenEffects of Liquefaction On Structurestusharghosh86% (14)

- CHM2 11 - 12 Q3 0702 FDDokument49 SeitenCHM2 11 - 12 Q3 0702 FDKim balugayNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Air Diffusion Performance Index (ADPI) of Diffusers For Heating ModeDokument21 SeitenAir Diffusion Performance Index (ADPI) of Diffusers For Heating ModeAlbert Aromin EngrNoch keine Bewertungen

- Modeling CO2 Capture With Aqueous MonoethanolamineDokument8 SeitenModeling CO2 Capture With Aqueous MonoethanolamineSuprio KamalNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Pressure VesselDokument40 SeitenPressure VesselPrt00789% (18)

- Steam Jet RefrigerationDokument14 SeitenSteam Jet RefrigerationSAATVIK JAINNoch keine Bewertungen

- LDD 30502 Ship Resistance and Ship Resistance and Propulsion TOPIC 1: Total Hull ResistanceDokument9 SeitenLDD 30502 Ship Resistance and Ship Resistance and Propulsion TOPIC 1: Total Hull ResistanceIkram NajihuddinNoch keine Bewertungen

- AfdhalDokument11 SeitenAfdhalRiky Mario YuluciNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Dryers in Word FileDokument5 SeitenDryers in Word FileHaroon RahimNoch keine Bewertungen

- Air Distribution For Large Spaces PDFDokument7 SeitenAir Distribution For Large Spaces PDFJojolasNoch keine Bewertungen

- 17chp06 Process Heat Transfer LabDokument50 Seiten17chp06 Process Heat Transfer LabpandianvijaybharathiNoch keine Bewertungen

- Internal Forces Internal StressesDokument6 SeitenInternal Forces Internal Stressespaulus polarindoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Operasi Teknik Kimia Iii Rizka Amalia, S.T., M.TDokument60 SeitenOperasi Teknik Kimia Iii Rizka Amalia, S.T., M.TEnricoNoch keine Bewertungen

- DMM 1 Assignment Questions FinalDokument2 SeitenDMM 1 Assignment Questions FinalSrimanthula SrikanthNoch keine Bewertungen

- W. F. Chen, Plasticity For Structural Engineers, 1988-384Dokument1 SeiteW. F. Chen, Plasticity For Structural Engineers, 1988-384ahmed shakerNoch keine Bewertungen

- First Semester Engineering Chemistry - I Question BankDokument7 SeitenFirst Semester Engineering Chemistry - I Question BankPRIYA RAJI0% (1)

- ACC-performance-enhancement H ReuterDokument48 SeitenACC-performance-enhancement H Reuterbaca88Noch keine Bewertungen

- Microsoft Word Water PumpsDokument2 SeitenMicrosoft Word Water PumpsJosh Vincent Ranque0% (1)

- Archemids PrincipleDokument10 SeitenArchemids PrincipleMUHAMMAD AKRAMNoch keine Bewertungen

- Calculate Shelland Tube For PSV Fire CaseDokument5 SeitenCalculate Shelland Tube For PSV Fire CaseJohanRodriguezNoch keine Bewertungen

- Final Project DissertationDokument54 SeitenFinal Project DissertationDateme AbamNoch keine Bewertungen

- CAPE Physics 2016 U1 P2 PDFDokument22 SeitenCAPE Physics 2016 U1 P2 PDFAjani AndersonNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lecture 06 Biophysics Free EnergyDokument12 SeitenLecture 06 Biophysics Free EnergyBelaliaNoch keine Bewertungen

- Les Photos de Matérieles de ForagesDokument18 SeitenLes Photos de Matérieles de Foragesعبد العزيز مروى100% (1)

- Punching Shear - ACI CodeDokument5 SeitenPunching Shear - ACI CodePartha Pratim Roy100% (1)

- Flow in Rotating CavityDokument11 SeitenFlow in Rotating CavityAttique JavaidNoch keine Bewertungen

- Thermal Science and Engineering ProgressDokument10 SeitenThermal Science and Engineering ProgressAmirNoch keine Bewertungen

- 09 Worksheet 1Dokument1 Seite09 Worksheet 1Jr YansonNoch keine Bewertungen

- Solutions For 4.5 4.6 4.7 4.16 4.18 4.21 4.33 and 4.35Dokument5 SeitenSolutions For 4.5 4.6 4.7 4.16 4.18 4.21 4.33 and 4.35Anonymous 62sYgZ6Tp50% (2)