Beruflich Dokumente

Kultur Dokumente

CA189

Hochgeladen von

florenttayCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CA189

Hochgeladen von

florenttayCopyright:

Verfügbare Formate

Research of The Harmful Gas Detection and Control System In Dairy

Yang Shifeng

College of Electronic information and automation

Tianjin University of Science & Technology

Tianjin 300222, China

yangsf@tust.edu.cn

Liu Yajuan

College of Electronic information and automation

Tianjin University of Science & Technology

Tianjin 300222, China

liuyajuan@mail.tust.cn

AbstractThis design constructs the harmful gas detection and

automatic control system for NH3 and H2S in the dairy, which

based on the electronic nose and LabVIEW virtual instrument

technology development platform. This control system tests the

harmful gas concentration of NH3 and H2S through the

semiconductor gas sensor MQ-137 and MQ-136; The NH3 and

H2S concentration change into the corresponding signals

through the A/D conversion chip, for the signal acquisition and

processing; The system realize the functions of the harmful gas

concentration of real-time data acquisition, display, storage,

which used graphical programming language LabVIEW, and

control the harmful gas concentration intelligently and

automation. This control system has the advantages of high

sensitivity, reliable work and the good effect

Keywords- LabVI EW; Electronic nose; SCM; Gas detection

Animal husbandry is an important part of the

agricultural economy, and the breeding industry of milk

cows is an important part of animal husbandry, the dairy not

only provide in a large number of high-quality milk

products but also provide the community with a large

number of employment opportunities, improving the living

quality, promoting the social economic development. It has

played an important role for social progress. [1]

With the development of economy and the improvement

of people's living standard, the demand of dairy products

increasing promote the rapid development of the dairies. In

recent years, the development of dairy industry is rapid, and

the number of cows and milk products is total in the world,

and industry development direction change into the scale,

intensive and professional barn feeding level.

But it also appeared some problems. As is known to all,

the modern animal husbandry production of four elements is

variety, feed nutrition, environment management and

disease prevention, the importance of livestock environment

also gradually cause the attention of the authorities. These

are two reasons, one is that the environment pollution by the

cows excrement is more serious, becoming a new pollution

source. If these excrement is not managed properly, it will

affect the sustainable development of the breeding industry

of milk cows, even threat to the humans health; The other

is that a lot of peculiar smell harmful gas is produced by

these waste, such as NH3,H2S. These will hazard the cow

health.

Dairy environment control is the key measures which

should be meet the cow the best growth needs and improve

the production level. Good control of the dairy is the

guarantee to improve the environment dairy production

capacity, get higher economic benefits and environmental

benefits. Therefore, the harmful gas concentration is

controlled effectively of the dairy, it is important

significance for the growth of cows and milk production,

give full play to its production potential and achieve high

yield, high efficiency. [2]

This paper used electronic nose, LabVIEW and single-

chip microcomputer technology, it design the dairy harmful

gas effective control system, realized the dairy real-time data

acquisition and automatic control, improve the work

efficiency and reliability.

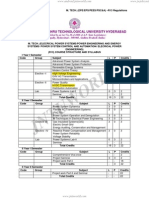

I. THE SYSTEM STRUCTURE AND WORKING PRINCIPLE

The LabVIEW virtual software platform developed upper

computer control system, the system communicates through

the RS-232 serial port and the next bit machine Atmega64

single-chip microcontroller, and the acquisition and

conversion of data processing to Atmega64

microcontroller.[3]

Lower machine through the A/D conversion chip

acquisition harmful gas gas concentration information, and

transfer to PC; PC according to the acquisition of the current

data and setting value judgement, down a machine a control

information; Lower machine according to the PC control

information, through the spraying facilities on milk field

spray, and harmful gas, reducing harmful gas concentration,

Make milk shop gas concentration less than set concentration,

so as to achieve the purpose of control NiuChang gas

concentration. System structure diagram 1 shows.

Proceedings of the 2nd International Symposium on Computer, Communication, Control and Automation (ISCCCA-13)

Published by Atlantis Press, Paris, France.

the authors, 2013

0171

II. HARDWARE DESIGN

Hardware design includes: main controller, gas sensor,

A/D conversion chip, serial communication, such as chip

selection and interface circuit design.

A. The main controller and interface circuit

The main controller is using AVR series MCU

ATmega64. ATmega64 one high performance and low

power consumption of the eight microprocessors, working

voltage of 4.5~5.5 V, 64 KB in the system of programmable

Flash, 2 KB of EEPROM, 4 KB on chip SRAM, 64 KB

optional external storage space, can through the SPI interface

in the system of the programming. The main controller

interface circuit as shown in figure 3 shows.(NH3

concentration is not more than 20 ppm,H2S concentration is

not more than 8 ppm)

PEN

1

PE0 RXD0/(PDI)

2

PE1 (TXD0/PDO)

3

PE2 (XCK0/AIN0)

4

PE3 (OC3A/AIN1)

5

PE4 (OC3B/INT4)

6

PE5 (OC3C/INT5)

7

PE6 (T3/INT6)

8

PE7 (IC3/INT7)

9

PB0 (SS)

10

PB1 (SCK)

11

PB2 (MOSI)

12

PB3 (MISO)

13

PB4 (OC0)

14

PB5 (OC1A)

15

PB6 (OC1B)

16

PB7 (OC2/OC1C)

17

PG3/TOSC2

18

PG4/TOSC1

19

RESET

20

VCC

21

GND

22

XTAL2

23

XTAL1

24

PD0 (SCL/INT0)

25

PD1 (SDA/INT1)

26

PD2 (RXD1/INT2)

27

PD3 (TXD1/INT3)

28

PD4 (IC1)

29

PD5 (XCK1)

30

PD6 (T1)

31

PD7 (T2)

32

PG0 (WR)

33

PG1 (RD)

34

PC0 (A8)

35

PC1 (A9)

36

PC2 (A10

37

PC3 (A11)

38

PC4 (A12)

39

PC5 (A13)

40

PC6 (A14)

41

PC7 (A15)

42

PG2 (ALE)

43

PA7 (AD7)

44

PA6 (AD6)

45

PA5 (AD5)

46

PA4 (AD4)

47

PA3 (AD3)

48

PA2 (AD2)

49

PA1 (AD1)

50

PA0 (AD0)

51

VCC

52

GND

53

PF7 (ADC7/TDI)

54

PF6 (ADC6/TDO)

55

PF5 (ADC5/TMS)

56

PF4 (ADC4/TCK)

57

PF3 (ADC3)

58

PF2 (ADC2)

59

PF1 (ADC1)

60

PF0 (ADC0)

61

AREF

62

GND

63

AVCC

64

U12

ATmega64-16AC

5.1k

5.1k

VCC

RST

11.0592M

22pF 22pF

GND

0.1F

VCC

GND

5.1k

VCC

PC_RXD_PE0

PC_TXD_PE1

RATE2_250_PD5

AD_SCK_PB1

AD_MOSI_PB2

AD_MISO_PB3

AD_SS_PB0

AD_DRDY_PB4

MATA-UP-PB5

MATA-DW-PB6

MATA-RUN-PB7

AC_PE2

5.1k SENSOR-PIN-PG0

VCC

0

DS18B20 PC0

DS18B20 PC1

DS18B20 PC2

DS18B20 PC3

DS18B20 PC4

DS18B20 PC5

Figure 6. Schematic circuit diagram of host controller interface

B. Gas sensitive sensor and A/D conversion module

System measuring ammonia and hydrogen sulfide of

harmful gas concentration respectively with MQ-137 and

MQ-136 semiconductor gas sensor. MQ-137 detection range

for 10-300 PPM ammonia, MQ-136 detection range of 1-100

PPM hydrogen sulfide, which conform to the control system

of concentration change requirements.

Packaging good gas sensor has only 6 needle tube feet,

including four for signal out, 2 used to provide heating

current. This kind of gas sensor for sensitivity adjustment is

very important, so in order to ensure accurate measurement,

ought to consider the influence of temperature and humidity

field milk.

A/D chip as the core unit of data acquisition, data

acquisition circuit design must according to the actual

application carefully selection. In order to meet the accuracy

of data acquisition, speed and channel parameters

requirement, also in order to simplify the circuit design, we

adopt the MAXIM company MAX197 as A/D conversion

chip.[4]

MAX197 is one by using successive approximation way

of working, the internal integration of the input tracking/hold

circuit, Through the 8+4 parallel interface and SCM

connection, with two power down mode, through the

software programming choose eight input channel a modulus

conversion, Are widely used in industrial control system,

robot, data acquisition system, medical instruments and

telecommunication system. Used for gas concentration

acquisition of gas sensors and A/D conversion interface

circuit shown in figure 3.

3

2

1

U2

L

M

3

3

6

B

Z

2

.

5

10k

4148

4148

2.7k

0.1F

+2.5

VCC

AIN1-

AIN1+

0.1F

0.1F

0.1F

GND

0.1F

0.1F

0.1F

100

100

AD1+

AD1-

GND

REF+

9

REF-

10

AIN1+

7

AIN1-

8

AIN2+

6

AIN2-

11

DOUT

13

CS

4

DRDY

12

RST

5

GND

16

CLKOUT

3

DIN

14

SCLK

1

CLKIN

2

VDD

15

U1

AD7705B

2.4576M

15pF 15pF 0.1F

5.1k

VCC

VCC

AD_SS_PB0

AD_MOSI_PB2

AD_MISO_PB3

AD_SCK_PB1

AD_DRDY_PB4

AIN2-

AIN2+

0.1F

0.1F

0.1F

GND

0.1F

0.1F

0.1F

100

100

AD2+

AD2-

GND

+ 10uF +

47uF

Figure 7. Schematic circuit diagram of gas sensor and A/D conversion

C. Serial communication

MAX232AESE chip is the RS-232 communication

standard single power level conversion chip, the use of +5V

power supply. MAX232 interface circuit as shown in figure

4.[5]

RS232

MCUATmega64

PC

MAX197

MQ-136

MAX197

MQ-137

Spraying

medicine

H2S

concentration

NH3

concentration

dairy

Figure 1. Structure of system

Proceedings of the 2nd International Symposium on Computer, Communication, Control and Automation (ISCCCA-13)

Published by Atlantis Press, Paris, France.

the authors, 2013

0172

13

10

11

8

12

9

14

7

C1+

1

C2+

4

GND

15

C1-

3

VCC

16

R1

T1

T2

R2

C2-

5

V-

6

V+

2

U4

MAX232AESE

0.1F

0.1F

0.1F

0.1F VCC

0.1F

PC_RXD_PE0

PC_TXD_PE1 100

100

PC_COM2

PC_COM3

Figure 8. Schematic circuit diagram of interface of MAX232AESE

III. SOFTWARE DESIGN

A. MCU programming

The single chip microcomputer program written in C

language, and its main finish the concentration of harmful

gases, collection, storage and data sending work, and

according to the PC control signal, control drug head open.

B. PC program design

Overriding the NI company LabVIEW as the

development of information system software. LabVIEW

development environment object oriented, and network,

peripheral any integration, openness, high adaptability, short

development cycle, be helpful for data processing, sharing

and the deployment of simple, can reduce the development

cost and time, reduce the cost of the whole monitoring

system.

In the test and control system, the PC program design is

the key link, mainly responsible for accept gas sensors to

send data, through the writing of the corresponding program

to receive data processing, to the production process

monitoring, diagnosis and storage operation and related data

analysis. LabVIEW provide hundreds of instrument source

level driver, including DAQ, GPIB, VXI, RS a 232 and RS a

485, according to the need can in LabVIEW developed by

various hardware driver, also can through the dynamic link

library (DLL) using other language development drive

library, thus further expand its function.

In the test and control system, the PC through the

harmful gas concentration control main program from lower

machine gas concentration information processing, query

and display, and a machine to a control command, and then

control corresponding drug nozzle, complete dairy gas

detection automatic control system.As shown in figure 5.

Figure 9. Data real-time acquisition module block diagram

1) Gas concentration test procedures

According to the literature, Design gas concentration

measurement cycle program, a cyclic process is divided into

the basic process: Acquisition and judgment to sprinkle

medicine. The basic process is shown as shown in figure 6.

2) Man-machine interface

The man-machine interface including data display and

system control model, the user can through the interface

Settings gas concentration control parameters and inquires

the history data, realize human-machine interaction.

In the system is running, can display the drug nozzle

work and dairy air condition, etc. Under special

circumstances, can by clicking on the drug head model to

manual control spray drug shut, stop state.

IV. DESIGN RESULT

The basic functions of information systems, including

identification permissions, user management, recipe

management, equipment operation, status monitoring,

information recording and harmful gas concentration control.

V. CONCLUSIONS

This system use of the electronic nose technology and

LabVIEW technology, realize the dairy harmful gas

concentration of automatic control, with sensitivity and

safety associated with adjustable, reliable, simple structure,

long service life, low cost and easy to use. The results show

that, the application of this system can control the milk shop

harmful gas concentration, can be in small milk field use, can

effectively improve the cows in the growth period of milk

Figure 6. Basic flow chart

YES

Drug spraying

open

start

Acquisition

NH3,H2S

concentration

Is greater than

the set point?

NO

YES

End

setting time

NO

Proceedings of the 2nd International Symposium on Computer, Communication, Control and Automation (ISCCCA-13)

Published by Atlantis Press, Paris, France.

the authors, 2013

0173

field environment, and reduce the labor intensity of their

keepers.

REFERENCES

[1] Chen Xihui,Zhang Yinhong. 8.20 labview programming from entry to

the master [M]. Beijing: Tsinghua University Press,2007

[2] Li Yuhua. Virtual instrument development platform LabVIEW

software [J]. Computer Automated Measurement and Control,

1996(3)45-49

[3] Zhongbai Zhou, Baoshan He. Multi-sensor technique and solid-state

electrochemical sensor system for real-time and dynamic monitoring

of multi-component gases[J]. Sensors and Aetuators B,

108(2005)379-384.

[4] Peter A.Blume LabVIEW programming style [M]. Beijing:

Publishing House of Electronics Industry2009198

[5] Wang Shen, Liu Xuelan, Wang Yonghong. Research and

implementation of environmental control automation system based on

Chushi[J]. Computer Knowledge and Technology, 2008, (9): 1730

1732.

Proceedings of the 2nd International Symposium on Computer, Communication, Control and Automation (ISCCCA-13)

Published by Atlantis Press, Paris, France.

the authors, 2013

0174

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Kannur University B Tech s5 SyllubusDokument6 SeitenKannur University B Tech s5 SyllubusappurajkvNoch keine Bewertungen

- An Embedded System and GSM Based Autonomous Industrial Effluent Monitoring and Controlling SystemDokument12 SeitenAn Embedded System and GSM Based Autonomous Industrial Effluent Monitoring and Controlling SystemAnand PrabhuNoch keine Bewertungen

- Pest Controlling RobotDokument25 SeitenPest Controlling Robothamed razaNoch keine Bewertungen

- Temperature Based Speed Control of Fan Using Arduino: April 2019Dokument7 SeitenTemperature Based Speed Control of Fan Using Arduino: April 2019benjaCR TubeNoch keine Bewertungen

- AI-Thinker RHF-76-052 Hardware Design Guide v01 PDFDokument10 SeitenAI-Thinker RHF-76-052 Hardware Design Guide v01 PDFnavivoc270Noch keine Bewertungen

- PLC ModemDokument6 SeitenPLC ModemGopinath KudaravalliNoch keine Bewertungen

- Educating Global Engineers With EPS@ISEP: The "Pet Tracker" Project ExperienceDokument10 SeitenEducating Global Engineers With EPS@ISEP: The "Pet Tracker" Project ExperienceCicaj MicajNoch keine Bewertungen

- Innovative Protection of Valuable Trees Fromsmuggling Using RFID and SensorsDokument10 SeitenInnovative Protection of Valuable Trees Fromsmuggling Using RFID and SensorskrsugavanamNoch keine Bewertungen

- GD32F103xx Datasheet Rev 2.7Dokument76 SeitenGD32F103xx Datasheet Rev 2.7victor SanmiguelNoch keine Bewertungen

- BC-2800 Service Manual (1.0)Dokument111 SeitenBC-2800 Service Manual (1.0)Edgar Mendoza GarcíaNoch keine Bewertungen

- Teaching Plan: RGM College of Engineering & Technology, Nandyal-518 501Dokument6 SeitenTeaching Plan: RGM College of Engineering & Technology, Nandyal-518 501Tara GonzalesNoch keine Bewertungen

- Low Speed AVR OscilloscopeDokument9 SeitenLow Speed AVR OscilloscopeRodolfoPerezEscalonaNoch keine Bewertungen

- Chapter 1 IntroductionDokument4 SeitenChapter 1 IntroductionRajesh BnNoch keine Bewertungen

- CEO Letter Highlights Ajay Syscon WarrantyDokument28 SeitenCEO Letter Highlights Ajay Syscon WarrantyRenato Abalos100% (1)

- Cellenium 30Jr Service Manual Ver - 1.01Dokument63 SeitenCellenium 30Jr Service Manual Ver - 1.01Jackson NjarambaNoch keine Bewertungen

- Stmicroelectronics Pfe Book 2024Dokument34 SeitenStmicroelectronics Pfe Book 2024Haythem JameiNoch keine Bewertungen

- Higher Sem Univ Exam Slot Feb 2021Dokument26 SeitenHigher Sem Univ Exam Slot Feb 2021formyphdNoch keine Bewertungen

- Elecrical Power SystemsDokument23 SeitenElecrical Power SystemsVishwanathSrinivasNoch keine Bewertungen

- Architecture of 8086 MicrocontrollerDokument3 SeitenArchitecture of 8086 MicrocontrollerShubhan SinghNoch keine Bewertungen

- Microprocessor Book by B Ram CompressDokument2 SeitenMicroprocessor Book by B Ram CompressSanika LandeNoch keine Bewertungen

- Dish Antenna Positioning Control Through Android AppDokument46 SeitenDish Antenna Positioning Control Through Android AppEngrABaloch100% (1)

- Wall Following RobotDokument15 SeitenWall Following RobotShameer BabuNoch keine Bewertungen

- Automatic Railway Gate Control System Is A Simple But Very Useful ProjectDokument6 SeitenAutomatic Railway Gate Control System Is A Simple But Very Useful ProjectAditya WardhaNoch keine Bewertungen

- Ti Iwr6412Dokument84 SeitenTi Iwr6412alperusluNoch keine Bewertungen

- Arm 32Dokument20 SeitenArm 32Surbhi Pal0% (1)

- Efficient Solar Tracking SystemDokument23 SeitenEfficient Solar Tracking SystemGodfred NkansahNoch keine Bewertungen

- List of Common Microcontrollers: AlteraDokument28 SeitenList of Common Microcontrollers: AlteraFelix ArtNoch keine Bewertungen

- Analog Device Micro ConverterDokument20 SeitenAnalog Device Micro ConvertershaileshNoch keine Bewertungen

- Quiz Buzzer Using 8051 ReportDokument9 SeitenQuiz Buzzer Using 8051 ReportTes 2000100% (1)

- Embedded Systems: What They Are and How They WorkDokument6 SeitenEmbedded Systems: What They Are and How They WorkEng-ibrahim al-absiNoch keine Bewertungen