Beruflich Dokumente

Kultur Dokumente

OUTERSHIELD 71 ELITE FCAW Acero Al Carbono PDF

Hochgeladen von

mtbecerrapOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

OUTERSHIELD 71 ELITE FCAW Acero Al Carbono PDF

Hochgeladen von

mtbecerrapCopyright:

Verfügbare Formate

128 T H E L I N C O L N E L E C T R I C C O M P A N Y WE L D I N G C O N S U M A B L E S C A T A L O G 129

Outershield

71 Elite

Welding Positions

Typical Applications All

Shipbuilding, barges

and offshore

platforms

Heavy equipment

Structural

fabrication

General fabrication

Smooth arc transfer and low spatter

Designed for welding with either 100% CO

2

or 75-82% Argon/balance CO

2

shielding gases

Good bead appearance

Fast freezing slag for out-of-position welding

Meets AWS D1.8 seismic lot waiver requirements

Conformances

Shielding Gas

100% CO

2

75 - 82% Argon / Balance CO

2

Flow Rate: 40 - 50 CFH

Mild Steel, All Position AWS E71T-1C-H8, E71T-9C-H8, E71T-1M-H8, E71T-9M-H8

Key Features

AWS A5.20/A5.20M: 2005

ASME SFA-A5.20:

FEMA 353

AWS D1.8

E71T-1C-H8, E71T-9C-H8,

E71T-1M-H8, E71T-9M-H8

E71T-1C-H8, E71T-9C-H8,

E71T-1M-H8, E71T-9M-H8

DIAMETERS / PACKAGING

Diameter 15 lb (6.8 kg) Plastic Spool

60 lb (27.2 kg) Master Carton

33 lb (15 kg)

Steel Spool

60 lb (27.2 kg)

Coil

600 lb (272 kg)

Accu-Trak

Drum in (mm)

0.045

0.052

1/16

(1.1)

(1.3)

(1.6)

ED029418

ED029419

ED029201

ED029204

ED029206

ED029202

ED029205

ED029207 ED029387

FLUX-CORED GAS-SHIELDED (FCAW-G) WIRE Structural Welding Code

Seismic Supplement

128 T H E L I N C O L N E L E C T R I C C O M P A N Y WE L D I N G C O N S U M A B L E S C A T A L O G 129

Outershield

71 Elite

(AWS E71T-1C-H8, E71T-9C-H8, E71T-1M-H8, E71T-9M-H8)

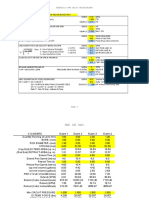

DEPOSIT COMPOSITION

(1)

As Required per AWS A5.20/A5.20M: 2005

%C %Mn %Si %S %P

Requirements

AWS E71T-1C-H8, E71T-9C-H8

AWS E71T-1M-H8, E71T-9M-H8

0.12

max.

1.75

max.

0.90

max.

0.03

max.

0.03

max.

Typical Results

(3)

As-Welded with 100% CO

2

As-Welded with 75% Ar/25% CO

2

0.01-0.04

0.02-0.04

1.41-1.50

1.55-1.65

0.44-0.60

0.56-0.75

0.01

0.01

0.01

0.01

(1)

Typical all weld metal.

(2)

Measured with 0.2% offset.

(3)

See test results disclaimer on pg. 12.

(4)

When welding under CO

2

, increase voltage by 1 Volt.

(5)

To estimate ESO, subtract 1/4 in (6.0 mm) from CTWD.

TYPICAL OPERATING PROCEDURES

Diameter, Polarity

Shielding Gas

(4)

CTWD

(5)

mm (in)

Wire Feed Speed Voltage

(volts)

Approx. Current

(amps)

Melt-Off Rate Deposition Rate Efciency

(%) m/min (in/min) kg/hr (lb/hr) kg/hr (lb/hr)

0.045 in (1.1 mm), DC+

75% Ar / 25% CO

2

19 (3/4)

4.5

6.4

7.6

8.9

10.2

12.8

15.3

(175)

(250)

(300)

(350)

(400)

(500)

(600)

21-24

23-26

24-27

25-28

26-29

27-30

28-31

130

155

180

205

230

260

290

1.7

2.4

2.9

3.4

4.0

5.0

6.0

(3.8)

(5.4)

(6.4)

(7.6)

(8.7)

(10.9)

(13.1)

1.5

2.1

2.5

3.0

3.5

4.3

5.2

(3.3)

(4.7)

(5.6)

(6.6)

(7.6)

(9.5)

(11.4)

87

87

87

87

87

87

87

0.052 in (1.3 mm), DC+

75% Ar / 25% CO

2

19 (3/4)

3.8

5.1

6.4

7.6

10.2

12.8

(150)

(200)

(250)

(300)

(400)

(500)

21-24

22-25

23-26

24-27

26-28

28-31

150

180

210

240

315

335

2.1

2.8

3.4

4.8

6.2

6.9

(4.6)

(6.1)

(7.6)

(10.6)

(13.7)

(15.2)

1.8

2.4

3.0

4.1

5.4

6.0

(3.9)

(5.2)

(6.5)

(9.1)

(11.8)

(13.1)

86

86

86

86

86

86

1/16 (1.6 mm), DC+

75% Ar / 25% CO

2

19 (3/4)

3.2

3.8

5.1

6.4

7.6

10.2

(125)

(150)

(200)

(250)

(300)

(400)

21-24

22-25

22-26

23-27

24-28

27-31

190

205

240

290

325

400

2.4

2.8

3.8

4.7

5.6

7.5

(5.2)

(6.2)

(8.3)

(10.3)

(12.4)

(16.5)

2.0

2.4

3.2

4.0

4.8

6.4

(4.4)

(5.3)

(7.0)

(8.8)

(10.5)

(14.0)

85

85

85

85

85

85

FLUX-CORED GAS-SHIELDED (FCAW-G) WIRE

MECHANICAL PROPERTIES

(1)

As Required per AWS A5.20/A5.20M: 2005

Yield Strength

(2)

Tensile Strength Elongation

Charpy V-Notch

J (ftlbf)

MPa (ksi) MPa (ksi) % @ -18C (0F) @ -29C (-20F)

Requirements

AWS E71T-1C-H8, E71T-9C-H8

AWS E71T-1M-H8, E71T-9M-H8

400 (58) min.

485-655 (70-95)

22 min.

27 (20) min.

27 (20) min.

Typical Results

(3)

As-Welded with 100% CO

2

As-Welded with 75% Ar/25% CO

2

545-565 (79-82)

585-595 (85-87)

585-615 (85-90)

625-630 (91-92)

28

25-28

74-83 (55-61)

92-99 (68-73)

58-64 (43-47)

70-83 (52-61)

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Avenue Cleveland, OH 44117-1199 U.S.A.

Phone: +1.216.481.8100 www.lincolnelectric.com

Lincoln Global, Inc. All Rights Reserved.

Issue Date 01/12

CUSTOMER ASSI STANCE POLI CY

The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our

customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond

to inquiries to the best of their ability based on information provided to them by the customers and the knowledge they may have concerning the application. Our employees,

however, are not in a position to verify the information provided or to evaluate the engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not

warrant or guarantee or assume any liability with respect to such information or advice. Moreover, the provision of such information or advice does not create, expand, or alter

any warranty on our products. Any express or implied warranty that might arise from the information or advice, including any implied warranty of merchantability or any warranty

of ftness for any customers particular purpose is specifcally disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specifc products sold by Lincoln Electric is solely within the control of, and remains the sole

responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service

requirements.

Subject to Change This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

TEST RESULTS

Test results for mechanical properties, deposit or electrode composition and diffusible hydrogen levels were obtained from a weld produced and tested according to

prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors,

including, but not limited to, weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confrm by qualifcation

testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended application.

Material Safety Data Sheets (MSDS) and Certifcates of Conformance are available on our website at www.lincolnelectric.com

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Manifest Your Desires with The Quantum CookbookDokument14 SeitenManifest Your Desires with The Quantum CookbookAgarta1111Noch keine Bewertungen

- Asme B31.8Dokument193 SeitenAsme B31.8mrivera100% (7)

- Basic ShapesDokument11 SeitenBasic Shapeschristopher templar100% (1)

- Copia de Hirsch-Hydraulic-CalculatorDokument1 SeiteCopia de Hirsch-Hydraulic-Calculatormtbecerrap0% (1)

- Copia de Hirsch-Hydraulic-CalculatorDokument1 SeiteCopia de Hirsch-Hydraulic-Calculatormtbecerrap0% (1)

- Copia de Hirsch-Hydraulic-CalculatorDokument1 SeiteCopia de Hirsch-Hydraulic-Calculatormtbecerrap0% (1)

- AWS D1-1 PQR-WPS Yes Pre QualifiedDokument2 SeitenAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerNoch keine Bewertungen

- Real Gas ThermodynamicsDokument112 SeitenReal Gas ThermodynamicsJohn AllenNoch keine Bewertungen

- Soil Nail Wall - Soil Nailing - Deep ExcavationDokument7 SeitenSoil Nail Wall - Soil Nailing - Deep ExcavationAlok Mehta0% (1)

- S P I C e J e T Q U e S T I o N SDokument43 SeitenS P I C e J e T Q U e S T I o N SDharavGosaliaNoch keine Bewertungen

- Best Book of Mathematics For All Copetitive ExamsDokument407 SeitenBest Book of Mathematics For All Copetitive ExamsMuhammad IshtiaqNoch keine Bewertungen

- Boston ReducersDokument356 SeitenBoston ReducersVicente Banda ZuñigaNoch keine Bewertungen

- Atos Industrial ValvesDokument22 SeitenAtos Industrial ValvesM S GokulNoch keine Bewertungen

- Conveyor Chain Design GuideDokument64 SeitenConveyor Chain Design GuideAtacomaNoch keine Bewertungen

- Mechanical FiberingDokument1 SeiteMechanical FiberingmtbecerrapNoch keine Bewertungen

- B PDFDokument69 SeitenB PDFAnonymous UoHUagNoch keine Bewertungen

- Piping Design InfoDokument279 SeitenPiping Design InfoPradeep SarodeNoch keine Bewertungen

- Catalogo PROPERCA ASTM A36-A283 GR C, A131 GR A, A285 GR C, A516 GR 70Dokument7 SeitenCatalogo PROPERCA ASTM A36-A283 GR C, A131 GR A, A285 GR C, A516 GR 70mtbecerrapNoch keine Bewertungen

- Control - Tuberia - 530 IVAN TUADokument58 SeitenControl - Tuberia - 530 IVAN TUAmtbecerrapNoch keine Bewertungen

- Structural ShapesDokument21 SeitenStructural ShapesjeefryNoch keine Bewertungen

- Copia de Cfp-Fluidpower-CalculatorDokument12 SeitenCopia de Cfp-Fluidpower-CalculatormtbecerrapNoch keine Bewertungen

- BPVCDokument1 SeiteBPVCmtbecerrapNoch keine Bewertungen

- Bonnie Forge Couple DimensionsDokument14 SeitenBonnie Forge Couple DimensionsTodd AlexanderNoch keine Bewertungen

- WeldBend Catalog PDFDokument186 SeitenWeldBend Catalog PDFDavid MahoneyNoch keine Bewertungen

- Factors Affecting Pipe Spool FabricationDokument7 SeitenFactors Affecting Pipe Spool FabricationtkarasonNoch keine Bewertungen

- Catalogo Leeson Electric Co PDFDokument534 SeitenCatalogo Leeson Electric Co PDFmtbecerrapNoch keine Bewertungen

- PSTL Bush 08Dokument7 SeitenPSTL Bush 08mtbecerrapNoch keine Bewertungen

- Pesos de Componentes SPG-SBRG-SPRGDokument3 SeitenPesos de Componentes SPG-SBRG-SPRGmtbecerrapNoch keine Bewertungen

- Renold Conveyor Section1&2 0508 PDFDokument51 SeitenRenold Conveyor Section1&2 0508 PDFmtbecerrapNoch keine Bewertungen

- Avance Semana10.Piping2300Dokument60 SeitenAvance Semana10.Piping2300mtbecerrapNoch keine Bewertungen

- Principles For Welding Procedure Qualification Tests PDFDokument35 SeitenPrinciples For Welding Procedure Qualification Tests PDFmtbecerrapNoch keine Bewertungen

- Kitz 3 Way - 4 SeatedDokument6 SeitenKitz 3 Way - 4 SeatedmtbecerrapNoch keine Bewertungen

- Ev DG05Dokument14 SeitenEv DG05mtbecerrapNoch keine Bewertungen

- Tsubaki Backstop AntiretornoDokument12 SeitenTsubaki Backstop Antiretornomtbecerrap100% (1)

- OneSteel Valve Product CatalogueDokument40 SeitenOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- Forged Steel ValveDokument100 SeitenForged Steel ValveHan KokoNoch keine Bewertungen

- Irjet V5i5256 PDFDokument5 SeitenIrjet V5i5256 PDFMuhsinaNoch keine Bewertungen

- Acceleration (Inclined Plane)Dokument5 SeitenAcceleration (Inclined Plane)jambunaNoch keine Bewertungen

- EPA 1668 A, Ag-2003Dokument129 SeitenEPA 1668 A, Ag-2003Karina Rondon RivadeneyraNoch keine Bewertungen

- Purmelt QR 3317 BR 2Dokument2 SeitenPurmelt QR 3317 BR 2Mikel Pacheco IglesiasNoch keine Bewertungen

- Abdel Jawad 2005Dokument8 SeitenAbdel Jawad 2005Alberto Tupa OrtizNoch keine Bewertungen

- Schrodinger Equation DerivationDokument12 SeitenSchrodinger Equation DerivationAndrés López Martínez100% (1)

- Solving The Simandoux EquationDokument15 SeitenSolving The Simandoux Equationjose_rarmenta100% (1)

- About The Company: Machined and Forged ComponentsDokument18 SeitenAbout The Company: Machined and Forged ComponentsankitNoch keine Bewertungen

- Fluid MechanicsDokument29 SeitenFluid Mechanicsaminur3rahman-1Noch keine Bewertungen

- E1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes TérmicasDokument3 SeitenE1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes Térmicasfredy lopezNoch keine Bewertungen

- Cup Making MachineDokument3 SeitenCup Making MachineJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- ChemDokument2 SeitenChemBaliuag Guia100% (4)

- Chemistry Project: To Study The Quantity of Casein Present in Different Samples of MilkDokument14 SeitenChemistry Project: To Study The Quantity of Casein Present in Different Samples of Milkveenu68Noch keine Bewertungen

- Metrology AssignmentDokument31 SeitenMetrology AssignmentKailas Sree Chandran100% (1)

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Dokument9 SeitenCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Jesús Luis Arce GuillermoNoch keine Bewertungen

- Newton's Laws of Motion Worksheet.Dokument2 SeitenNewton's Laws of Motion Worksheet.Llama jennerNoch keine Bewertungen

- DMCR Detection Measurement Control RelayDokument5 SeitenDMCR Detection Measurement Control RelayMuhammad AbuzarNoch keine Bewertungen

- Quantum NumbersDokument10 SeitenQuantum Numbersaplattinum1633Noch keine Bewertungen

- Datasheet MPX5100DPDokument16 SeitenDatasheet MPX5100DPKemahyanto Exaudi SiahaanNoch keine Bewertungen

- P 211enDokument26 SeitenP 211enRadhakrishnan BalasubramanianNoch keine Bewertungen

- Marsh FunnelDokument2 SeitenMarsh Funnel123shripadNoch keine Bewertungen

- Optimum Penstocks For Low Head Microhydro Schemes - Alexander, Giddens - 2008Dokument13 SeitenOptimum Penstocks For Low Head Microhydro Schemes - Alexander, Giddens - 2008cbarajNoch keine Bewertungen

- Commercial Building Structural Design and AnalysisDokument19 SeitenCommercial Building Structural Design and AnalysisPatrikNoch keine Bewertungen