Beruflich Dokumente

Kultur Dokumente

UNITEN ICCBT 08 Preliminary Design Chart of Cement Columns For Deep Soil

Hochgeladen von

Laura RossOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

UNITEN ICCBT 08 Preliminary Design Chart of Cement Columns For Deep Soil

Hochgeladen von

Laura RossCopyright:

Verfügbare Formate

ICCBT 2008 - E - (40) pp495-510

ICCBT2008

Preliminary Design Chart of Cement Columns for Deep Soil

Mixing Method in Tropical Peat

Y. Duraisamy*, University Malaysia Pahang, MALAYSIA

ABSTRACT

This paper presents the preliminary design chart of cement columns used for deep soil mixing

method. Initially, the effects of the cement column diameter on the compressibility have been

investigated in this study. The results indicated that compressibility index C

c

and C

decreased with increasing diameter of the cement column. Various dimensions of cement

columns were used to form cement columns in order to study the influence. Specimens with 15

mm, 30 mm, 45 mm, 50 mm, 60 mm, 80 mm and 100 mm diameter of cement columns were

cured for 7, 14 and 28 days, after which they were subjected to Rowe Cell consolidation test.

Results are also presented from test conducted on groups of cement columns using four, six,

nine and twelve columns of 15 mm diameter each to investigate the influence of number of

cement columns on compressibility of peat. Based on the results obtained, preliminary design

charts for cement columns were established as a guideline to engineers and academicians.

Keywords: Cement columns, compressibility, deep soil mixing, design chart, fibrous peat

soil, organic soil, Rowe Cell consolidation.

*Correspondence Author: Youventharan Duraisamy, University Malaysia Pahang, Malaysia. Tel:

+6095492284, Fax: +6095492299. E-mail: youventharan@ump.edu.my

Preliminary Design Chart of Cement Columns for Deep Soil Mixing Method in Tropical Peat

ICCBT 2008 - E - (40) pp495-510 496

1. INTRODUCTION

Peat represents the extreme form of soft soil. It is an organic soil which consists more than

70% of organic matters. Peat deposits are found where conditions are favorable for their

formation. In Malaysia, some 3 million hectares of land is covered with peat. While in

Indonesia, peat covers about 26 million hectares of the country land area. Two third of the

world coverage of tropical peat are in South East Asia. Since the coverage of peat soil is quite

extensive, utilization of these marginal soil are required in the recent years. Hence, suitable

geotechnical design parameters and construction techniques needed for this type of ground

condition. Peat poses serious problems in construction due to its long-term consolidation

settlements even when subjected to a moderate load [1]. Hence, peat is considered unsuitable

for supporting foundations in its natural state. Various construction techniques have been

carried out to support embankments over peat deposits without risking bearing failures but

settlement of these embankments remains excessively large and continues for many years.

Besides settlement, stability problems during construction such as localized bearing failures

and slip failures need to be considered. Deep Soil mixing (DSM) also referred to as Lime

Cement Column Method or just Cement Columns, invented by Kjeld Paus 30 years ago. It is a

form of soil improvement involving the mechanical mixing of in-situ soft and weak soils with

a cementatious compound such as lime, cement or a combination of both in different

proportions. Dry DSM method has been used in Sweden and Finland since 1967 for

improvement in soft clays and organic soils to increase the stability and to reduce the

settlements of embankments. This method seems to work well for soft silty clay though its

application for peat is yet to be proven. Thus the author initiated this laboratory based study

involving cement columns in peat soils prior to full scale test in order to evaluate the

performance.

2. EXPERIMENTAL DESIGN AND LABORATORY WORK

The main objective of this research was to find out the effects of cement column on

compressibility when installed in tropical peat soil. Apart from that researcher was also

interested to examine the peculiar engineering behavior of tropical peat with respect to their

compressibility characteristics due to variation in fiber content and organic content.

Meanwhile the index properties such as natural water content, organic content, liquid limit,

specific gravity and density of fibrous peat soils were obtained to establish suitable

correlation. Understanding the engineering properties and compressibility characteristics of

fibrous peat will be handy for engineers in determining suitable ground improvement method.

Thus, proper construction and foundation design guide for fibrous peat soils could be outlined

for future developments in peat ground.

2.1 Sample Preparation

Undisturbed samples of fibrous peat soils were taken from three different locations in Banting

(located on the West coast of Peninsular Malaysia) by using a sampling tube. A suitable auger

was designed and fabricated to collect undisturbed fibrous peat samples as shown in Figure 1.

The handle was formed of a 60 cm cross bar and the stem of 100 cm height. The cylindrical

tube is 150 mm (internal) in diameter. The upper part of the cylindrical hollow body is fitted

with a cover plate. Meanwhile the lower part of the cylindrical tube was sharpened to cut

roots as the auger is slowly rotated into the peat ground during sampling. The thin tube was

Y. Duraisamy

ICCBT 2008 - E - (40) pp495-510 497

fitted with a valve, which is left open during sampling to release both air and water pressure.

The valve is then closed prior to withdrawal of the tube with the peat sample enclosed, thus

providing a vacuum effect to help the sample in place. Soon after the sampler is withdrawn,

the cylindrical tube was sealed with paraffin wax. Once in the laboratory, the top cover on the

cylindrical tube was opened to extract the sample into the Rowe Cell. This sampler is suitable

for sampling peat soil up to depth of about 1 m only. The auger enables the extraction of peat

core sample of 150 mm diameter by 230 mm length. The top and bottom of the specimen was

trimmed. Fibrous soil such as peat is easily disturbed therefore the trimming process was

carried out carefully. Furthermore, the trimming process was carried out quickly to minimize

changes in the water content of the soil sample.

Sample was then tested using Rowe Cell consolidation to overcome most of the disadvantages

of the conventional oedometer apparatus when performing consolidation tests on low

permeability soils, including non-uniform deposits. The most important features are the ability

to control drainage and to measure pore water pressure during the course of consolidation

tests. Figure 2 shows the experimental set up of using Rowe Cell. This system is based on

Rowe Cell consolidation cell and GDS pressure/volume controllers. Size of the cell used in

this research was 150 mm in diameter and 50 mm in height. The hydraulic pressure system

and vertical load can be applied to the sample surface either via a flexible diaphragm to give a

uniformly distributed pressure (free strain) or via a rigid plate to give uniform settlement

(equal strain). Rigid plate was used in the research as shown in Figure 3. Back pressure of 200

kN/m

2

was applied to the top drain of the cell so that the field hydraulic gradients can be

modeled. The bottom drain was provided with a tapping to a pressure transducer.

Figure 1. In-house peat sampler.

Preliminary Design Chart of Cement Columns for Deep Soil Mixing Method in Tropical Peat

ICCBT 2008 - E - (40) pp495-510 498

Figure 2. The experimental set up of Rowe Cell consolidation

Figure 3. Rigid plate to give equal strain.

To investigate the influence of diameter of columns, a single cement column was placed at the

center of the cell containing peat sample. A portion of the peat soil was taken out from the cell

using a PVC tube and replaced with dry cement powder to form the cement column as shown

in Figure 4. The diameters of the cement column were 15 mm, 30 mm, 45 mm, 50 mm, 60

mm and 80 mm. The samples were cured for 7, 14 and 28 days in a soaking basin as shown in

Figure 5. After the curing days, Rowe Cell consolidation test was carried out on the samples

consecutively. Meanwhile group cement columns of four, six, nine and twelve columns were

formed using 15 mm diameter PVC tube at the spacing of 2d (2 times the value of column

diameter) to investigate the influence of group cement columns in reducing compressibility of

peat soil. Based on past researchers recommendations and historical data, the author chose

typical dosage rate commonly used for peat soil 100 kg/m

3

, which corresponds to nine percent

by weight of dry soil to form cement columns.

Displacement

Transducer

Computer

Data Logger

Rowe Cell

GDS Back Pressure

Controller

Y. Duraisamy

ICCBT 2008 - E - (40) pp495-510 499

Figure 4. Method used to form cement column

Figure 5. Method used to cure peat-cement column sample.

Load increment was applied at 20, 40, 80, 160, and 320kN/m

2

. Additional load was placed on

the soil specimen to determine the soil behavior at higher pressure. Each load increment was

maintained for 24 hours. The test started with a vertical load of 20 kN/m

2

and deformation

transducer readings with corresponding time observations were recorded using data logger,

which was connected to computer. The load was maintained for 24 hours. After 24 hours, the

same procedure was repeated with different applied load. Time-deformation graphs were

plotted and settlements were determined using GDSLAB control and acquisition software.

2.2 Testing programs

Index properties of peat soil used in the classification system of peat namely the water

content, organic content, specific gravity, fiber content, degree of humification and Atterberg

limits were determined based on test procedures according to the British Standard BS1377:

1990, Methods of test for soils for civil engineering purposes. Apart from the classifying

tests, compressibility behavior of the peat soil was determined by Rowe Cell consolidation

test for both the natural (untreated) and cement column installed peat samples. Due to the

large number of specimens, the testing procedures were separated into phases and sample

identification system was developed to assign each specimen with identifying labels. Table 1

illustrates the sample identification system used, type of column, dimensions of cement

column interface area and the area ratio.

Preliminary Design Chart of Cement Columns for Deep Soil Mixing Method in Tropical Peat

ICCBT 2008 - E - (40) pp495-510 500

Table 1. Sample identification system

Column Type Diameter

(mm)

Length

(mm)

Area (m

2

) l/d ratio Area

Ratio

SC1 Single 30 50 0.0061 1.67 0.04

SC2 Single 45 50 0.0102 1.11 0.09

SC3 Single 50 50 0.0118 1.00 0.11

SC4 Single 60 50 0.0122 0.83 0.16

SC5 Single 80 50 0.0226 0.62 0.28

GC1 Group (2 x 2) 15 50 0.0108 3.33 0.04

GC2 Group (2 x 3) 15 50 0.0162 3.33 0.06

GC3 Group (3 x 3) 15 50 0.0244 3.33 0.09

GC2 Group (3 x 4) 15 50 0.0325 3.33 0.12

3. RESULTS AND DISCUSSIONS

One of the objectives of this study was to find the relationship between the basic geotechnical

properties of fibrous peat soil with index parameters such as natural water content, organic

content and liquid limit. It must also be appreciated that compared with soils of mineral

origin, the peat soils, in particular those of the tropical genesis, have only recently been given

attention. As such even determination methods of some of the basic properties are still being

researched. In some cases no consensus has been reached, either with respects to the

methods, nor details of any given methods. However, for ease of comparison, the most

commonly used methods of determination of soil basic properties were used in this study.

3.1 Soil Description

Fibrous peat sample was obtained from marine and continental deposits on the West Coast of

Peninsular Malaysia. It consists primarily of low plasticity fines; some fine to medium sands

and it is dark brown in color. Characterization tests were performed according to the USDA

classification system and Von Post Scale. Soil classification tests were carried out on each soil

sample in accordance with accepted BS 1377: 1990 and ASTM ranges. The results of the

characterization tests are in Table 2. The Atterberg limits were determined on the soil

particles passing the 475 m sieve.

As seen in Table 2, a fairly significant increase in liquid limit with the increase in natural

water content. Huat [2] stated that the natural water content of peat in West Malaysia ranges

from 200 % to 700 % and with organic content in the range of 50 % to 95 %. The recorded

values in Table 2 fulfill this statement. Further more the liquid limit was in the range of 200 %

to 500 % as reported by Huat [2]. Engineering properties such as specific gravity and bulk

density of the samples were within the range as reported by Huat [2].

Y. Duraisamy

ICCBT 2008 - E - (40) pp495-510 501

3.2 Correlations of Index Properties

As mentioned before, one of the objectives of this paper was to study the relationship of the

basic geotechnical properties of tropical peat soils with some of the easily determined

parameters such as natural water content, organic content or liquid limit. Comparison was

made with the published correlations of the more established organic soils of the temperate

genesis.

Figure 6 shows the empirical relationships between organic content (OC) and liquid limit (LL)

which has been proposed by Skempton and Petley [3] for temperate peat. However equation

(1) does not seem to fit well in the case of tropical peat. For the case of tropical peat studied in

Malaysia, the best fit line of the samples is given in equation (2) (LL and OC in percent).

Liquid limit of the tropical peat soils found to range from 150 - 400%. In general, the liquid

limit of peat increases with increase in organic content. Using statistical analysis the

correlation between liquid limit and organic content of Banting peat was 0.6178.

0.5 5.0 LL OC = + (1)

0.3 3.0 LL OC = + (2)

0

100

200

300

400

500

600

0 20 40 60 80 100 120

Organic Content, %

L

i

q

u

i

d

L

i

m

i

t

,

%

Skempton & Petley (1970) Present Study

Figure 6. Liquid limit versus organic content.

Figure 7 shows the relationship of dry density (

d

) and natural water content (w). For

temperate peat soils in the district of central Netherlands, the best fit line is given by equation

(3), proposed by Den Haan [4]. Data collected from the tropical peat sample was plotted on

the same figure and both the sample fit close to each other. However for identification of

tropical peat, a special equation was formed as equation (4). Using statistical analysis, the

correlation coefficient between dry density and natural water content of Banting peat was

0.7828.

Preliminary Design Chart of Cement Columns for Deep Soil Mixing Method in Tropical Peat

ICCBT 2008 - E - (40) pp495-510 502

0.856

35.075( )

d

w

= (3)

0.804

22.422( )

d

w

= (4)

0,000

0,200

0,400

0,600

0,800

1,000

1,200

1,400

1,600

0 100 200 300 400 500 600 700 800 900

Natural Water Content, %

D

r

y

D

e

n

s

i

t

y

,

M

g

/

m

3

Present Study Den Haan (1997)

Figure 7. Dry density versus natural water content

Specific gravity in peat soils are affected by the organic constituents, and cannot therefore

simply be set to somewhere near 2.65 2.75 as for in mineral soils. Den Haan [4] for

example quoted cellulose and lignin to have specific gravity of approximately 1.58 and 1.40

respectively. These low values would as expected reduces the compounded specific gravity

of organic soils. Figure 8 shows the variation of specific gravity with organic content using

correlation proposed by Kaniraj and Joseph [5], Huat [2], Skempton and Petley [3] and Den

Haan [4]. Experimental results plotted for specific gravity of tropical peat, fit closely with

equation 8 proposed by Den Haan [4]. Thus an equation was formed to establish the

identification process of tropical peat soil. Using statistical analysis, the correlation coefficient

between specific gravity and organic content of Banting peat was 0.9956.

1.6281 2.6859

s

G OC = + (5)

1.2 2.7

s

G OC = + (6)

1/ (0.358 0.357)

s

G OC = + (7)

1/ (0.362 0.371)

s

G OC = + (8)

Y. Duraisamy

ICCBT 2008 - E - (40) pp495-510 503

1

1,1

1,2

1,3

1,4

1,5

1,6

1,7

1,8

1,9

2

65 70 75 80 85 90 95 100

Organic Content, %

S

p

e

c

i

f

i

c

G

r

a

v

i

t

y

,

G

s

Eq.5 Eq.6 Eq.7 Eq.8 Present Study

Figure 8. Specific gravity versus organic content

3.3 Compression index, C

c

According to Li and Lee [6], compressibility parameters of soil are to some extent stress

dependent. Since developing peat ground often involves massive changes in the state of stress,

as well as pressure and saturation changes, it is important to understand the stress dependent

behavior of compressibility parameters and incorporate it in the peat soil stabilization plan.

Based on Figure 9, the compression index (C

c

) values from Rowe Cell consolidation test for

the natural fibrous peat were within the range of 1.878 to 3.627 for consolidation pressure of

40 kPa to 320 kPa. These values were from Rowe Cell consolidation test and measured higher

than the values from conventional oedometer test results. Results from conventional

oedometer test were far less reliable because back pressure was not induced and pore water

pressure was not measured during the course of the test. The compression index (C

c

) values

from oedometer test for fibrous peat was 1.453 to 3.211. However, these values were far

smaller than what has been reported for peat as 5 to 10 compared with that of clay of only 0.2

to 0.8 in the literature.

Table 2: Index properties of fibrous peat samples.

BH Water

Content

(%)

Liquid

Limit

(%)

Organic

Content

(%)

Von

Post

Scale

Fiber

Content

(%)

Specific

Gravity,

Gs

Void

ratio,

e

Bulk

Density,

(Mg/m

3

)

1 266 285 76 H5 65 1.52 7.541 0.922

2 330 350 84 H4 75 1.45 9.535 0.834

3 350 398 88 H4 77 1.42 10.48 0.811

4 181 250 73 H7 55 1.55 5.522 1.008

5 241 275 75 H6 58 1.53 6.536 0.856

6 140 240 70 H8 32 1.56 4.125 1.019

7 286 310 77 H5 68 1.51 7.895 0.956

8 300 330 80 H8 31 1.49 4.824 0.996

Preliminary Design Chart of Cement Columns for Deep Soil Mixing Method in Tropical Peat

ICCBT 2008 - E - (40) pp495-510 504

3.4 Coefficient of secondary compression, C

Based on Figure 10, the coefficient of secondary compression (C

) values from Rowe Cell

consolidation test for the natural (untreated) fibrous peat was within the range of 0.0608 to

0.0985 for consolidation pressure of 40 kPa to 320 kPa. These values were from Rowe Cell

consolidation test and measured higher than the values from conventional oedometer test

results. The coefficient of secondary compression (C

) value from oedometer test for fibrous

peat was 0.0374 to 0.0901. These values are considerably higher than the limiting values of

between 0.02 and 0.04 for highly organic soils as suggested by Hobbs [7].

According to Mesri [8], soil with C

values of more than 0.064 is categorized as soil with

extremely high secondary compressibility. The coefficient of secondary compression C

(=e/log t) was determined from the slope of the e-log t curves during the period of 4 to 24

hours after load increment, assuming that the secondary compression would have started 4

hours after loading. The variation of C

with applied consolidation pressure can be seen in

Figure 10. The C

increases as the consolidation pressure is increased. Similar trend was

observed with samples tested using oedometer. Thus, fibrous peat samples used in this

research will cause high secondary settlements with the increase in loading over the time. [8]

3.5 Law of compressibility

Mesri and Castro [9] reported that the value of C

/C

c

law for peat and muskeg lies in the range

of 0.05 to 0.07. Based on Table 4, value of C

/C

c

law for tropical peat determined from

conventional oedometer test was about 0.027. Whereas samples tested using Rowe Cell

consolidation was recorded 0.02. These values are generally not in agreement with the values

reported in literature. Since the value of C

/C

c

law for tropical peat is lower than the value of

C

/C

c

law reported in the literature, less creep settlement develops when the fibrous peat soil

is loaded. However, this need to be verified with further research works involving field study.

Again according to Mesri et al. [10], reliable data suggests that C

/C

c

for peat lies within the

range 0.06 0.01. However studies carried out by Paikowsky et al. [11] on Cranberry bog

peat, Massachusetts showed that C

/C

c

is not constant but varies.

0

0,5

1

1,5

2

2,5

3

3,5

4

0 50 100 150 200 250 300 350

Consolidation Pressure, (kPa)

C

o

m

p

r

e

s

s

i

o

n

I

n

d

e

x

,

C

c

Fibric Peat (Rowe Cell)

Hemic Peat (Rowe Cell)

Sapric Peat (Rowe Cell)

Fibric Peat (Oedometer)

Hemic Peat (Oedometer)

Sapric Peat (Oedometer)

Figure 9: Compression index versus consolidation pressure.

Y. Duraisamy

ICCBT 2008 - E - (40) pp495-510 505

0

0,01

0,02

0,03

0,04

0,05

0,06

0,07

0,08

0,09

0,1

0 50 100 150 200 250 300 350

Consolidation Pressure, (kPa)

C

o

e

f

f

i

c

i

e

n

t

o

f

S

e

c

o

n

d

a

r

y

C

o

m

p

r

e

s

s

i

o

n

,

C

Fibric Peat (Rowe Cell)

Hemic Peat (Rowe Cell)

Sapric Peat (Rowe Cell)

Fibric Peat (Oedometer)

Sapric Peat (Oedometer)

Hemic Peat (Oedometer)

Figure 10: Coefficient of secondary compression versus consolidation pressure

3.6 Effect of a single cement column

As for the main objective of this research, cement columns of two dimensions were prepared

and installed in peat soils. Cement column with (45 mm diameter x 50 mm length) and (60

mm x 50 mm length) were formed. They were cured for 7, 14 and 28 days to find out the

factors influencing the performance of cement columns. Just as expected the cement columns

cured for 28 days were proven more effective in reducing the compressibility parameters C

c

and C

when tested using Rowe Cell Consolidation test. A single cement column with 60 mm

diameter (area ratio = 0.16) recorded the smallest values of C

c

and C

a

compared to 45 mm

diameter (area ratio = 0.09) of cement column (see Figure 11).

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

1,8

2

0 5 10 15 20 25 30

Curing Time, days

C

o

m

p

r

e

s

s

i

o

n

I

n

d

e

x

,

C

c

SC2

SC1

SC4

SC3

Figure 11. Compression Index versus Curing Time for Fibrous Peat Using Single Column

Preliminary Design Chart of Cement Columns for Deep Soil Mixing Method in Tropical Peat

ICCBT 2008 - E - (40) pp495-510 506

3.7 Effect of a group of cement columns

A group of cement columns of diameter 15 mm each with a spacing of 2d were used. Based

on Figure 12 when nine cement columns in the form of a 3 x 3 group tested, compressibility

parameters were reduced more effectively than only four cement columns (2 x 2) used at the

same spacing. This means that compressibility parameters decreased with an increasing

number of cement columns in a group. Technically group of nine cement columns have larger

area ratio of 0.09 compared to group of four cement columns with area ratio of 0.04, which

influence the compressibility. Again the 28 days of curing time has significant impact on the

final compressibility parameters values recorded.

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

1,8

0 5 10 15 20 25 30

Curing Time, days

C

o

m

p

r

e

s

s

i

o

n

I

n

d

e

x

,

C

c

SC2

SC4

GC1

GC2

Figure 12. Compression Index versus Curing Time for Fibrous Peat Using Group Column

4. PARAMETRIC STUDY

A parametric study was conducted assuming a normally consolidated 5m-depth peat ground

with embankment (see Figure 13). Assumptions and data used in the calculation were

presented in Table 3. Using one dimensional consolidation theory and Anglo Saxon method,

ultimate consolidation settlements were obtained using equation (9) and (10).

o p

p

e

H

Cc S

o

p log

1

+

= (9)

Note:

S

p

= primary settlement of the soil layer (m), H = initial thickness of the soil layer (m), Cc, =

compression index, e

o

= initial void ratio, p = total pressure acting at the middle of soil layer

(kPa), p

o

= effective overburden pressure acting at the middle of soil layer (kPa)

p

s

s

t

t

H C S log = (10)

Y. Duraisamy

ICCBT 2008 - E - (40) pp495-510 507

Note:

S

s

= secondary settlement of the soil layer (m), H = initial thickness of the soil layer (m), C

=

coefficient of secondary compression, t

s

= duration of load (days), t

p

= duration of primary

consolidation (days)

Figure 13. Illustration of Case Study Used for Parametric Study

The following data in Table 3 are based on the data obtained from experimental work carried

out in the laboratory and mentioned earlier in this paper. However, the unit weight of fill

material was assumed.

Table 3. Typical parameters used in settlement calculations

Parameter Value

Specific Gravity, G

s

1.4

Initial Void Ratio, e

o

10

Natural Moisture Content, w

o

300%

Unit Weight Fill,

d

18 kN/m

3

5. DESIGN CHART DEVELOPMENT

With the establishment of geotechnical database on index properties of peat, primary and

secondary x-axis for the following chart in figure 14 was constructed for fibrous type of peat

soil. Data comprise of C

c

and C

values from fibrous peat sample with corresponding organic

content were then plotted in this chart. This chart is suitable as a design guide for engineers to

predict settlements using two compressibility parameters C

c

and C

while the organic content

or liquid limit of sample is determined from simple laboratory test. This chart is only

applicable for fibrous type of peat with organic content more than 70 % and fiber content

more than 66 %.

Preliminary Design Chart of Cement Columns for Deep Soil Mixing Method in Tropical Peat

ICCBT 2008 - E - (40) pp495-510 508

0

0,02

0,04

0,06

0,08

0,1

0,12

88 75 73

Organic Content, %

C

o

e

f

f

i

c

i

e

n

t

o

f

S

e

c

o

n

d

a

r

y

C

o

m

p

r

e

s

s

i

o

n

,

C

0

0,5

1

1,5

2

2,5

3

3,5

4

294 255 249

Liquid Limit, %

C

o

m

p

r

e

s

s

i

o

n

I

n

d

e

x

,

C

c

C Cc

Figure 14. Organic content (and liquid limit) versus compression index and coefficient of secondary

compression.

Maximum reduction in C

c

value with the corresponding value of length to diameter ratio (l/d)

of each cement column is then plotted in Figure 15. Based on this figure it shows that small

l/d ratio of cement column is effective in decreasing compression ratio value. This chart could

be used as a design guide to select the effective dimension of cement column for deep soil

mixing method in tropical peat soil. Effective l/d ratio can be determined either by using the

chart or from the given formula. For example for fibrous soil with 75 % organic content,

based on Figure 14, C

c

value of 1.6 is predicted. Using 60 % of reduction in C

c

value will give

an improved value of 0.96 using cement column is predicted. Referring to Figure 15 for

desired C

c

of 0.96, the effective l/d ratio of 0.8 is needed.

Cc = 0.721Ln(l / d) + 1.1436

0

0,5

1

1,5

2

2,5

0 0,5 1 1,5 2 2,5 3 3,5

(l / d) ratio

C

o

m

p

r

e

s

s

i

o

n

I

n

d

e

x

,

C

c

Tropical Fibric Peat

Figure 15. Compression index versus l/d ratio.

Y. Duraisamy

ICCBT 2008 - E - (40) pp495-510 509

5. CONCLUSIONS

New and novel preliminary design chart has been established based on laboratory

experimental data on fibrous peat soil reinforced with cement columns and validated using

software. A significant reduction in compressibility was observed by increasing the diameter

of the cement columns, increasing the number of cement columns and increasing the amount

of cement in cement columns.

REFERENCES

[1]. Jarret, P. M. Geoguide 6, Site Investigation for Organics Soils and Peat. JKR Document 20709-

0341-95. Institut Kerja Raya Malaysia 1995.

[2]. Huat, B. K. Organic and Peat Soils Engineering. Universiti Putra Malaysia Press, Serdang 2004.

[3]. Skempton, A. W. and Petley, D.J. Ignition loss and other properties of peats and clays from

Avonmouth, Kings Lynn & Cranberry Moss. Geotechniques. 1970 Vol 20, no. 4, pp. 343-356.

[4]. De Haan, E. J. An overview of the mechanical behavior of peat and organic soils and some

appropriate construction techniques. In Proceedings of Conference on Recent Advances in Soft

Soil Engineering, Kuching , Sarawak, 1997 pp. 17-45.

[5]. Kaniraj, S. R. and Joseph, R. R. Geotechnical behavior of organic soils of North Sarawak. Paper

presented in 4

th

International Conference on Soft Soil Engineering, Voncouver Canada, October 4-

6, 2006.

[6]. Li, Q. and Lee, S. Stress Dependent Reservoir Properties. Paper presented in GEO Asia 2006

Petroleum Geology Conference. Kuala Lumpur Convention Center, Malaysia, June 4, 2006.

[7]. Hobbs, N.B. Morphology and the properties and behavior of some British and foreign peats.

Quaterly Journal of Engineering Geology 1986 19:7-80. London.

[8]. Mesri, G. Coefficient of secondary compression, J. Soil Mech. Found. Div, ASCE. 1973 Vol. 99,

no. SMI.

[9]. Mesri, G. and Castro, A. C

/C

c

concept and K

o

during secondary compression. Journal of

Geotechnical Engineering, 1987 Vol. 123. pp. 230-247.

[10].Mesri, G., Statark, T.D., Ajlouni, M.A. & Chen, C.S. Secondary compression of peat with or

without surcharging. Journal of Geotechnical & Geoenvironmental Engineering., 1997 123(5),

pp.441-421.

[11].Paikowsky, S., Elsayed, A & Kurup, P.U. Engineering properties of Cranberry bog peat. In

Proceedings of 2

nd

International Conference on Advances in Soft Soil Engineering and

Technology, Putrajaya, Malaysia. 2003 pp. 153-171.

Das könnte Ihnen auch gefallen

- Ppr12 056alrDokument14 SeitenPpr12 056alrLaura RossNoch keine Bewertungen

- Estimation of Undrained Shear Strength For Peat Using CPTDokument4 SeitenEstimation of Undrained Shear Strength For Peat Using CPTLaura RossNoch keine Bewertungen

- 3.2 ULS CyclicDokument5 Seiten3.2 ULS CyclicLaura RossNoch keine Bewertungen

- Culvert Design IhsDokument38 SeitenCulvert Design IhsLaura RossNoch keine Bewertungen

- Bond GE 2010 Part 1 Pile Design To EC7Dokument5 SeitenBond GE 2010 Part 1 Pile Design To EC7Laura RossNoch keine Bewertungen

- Randolph M. Et Al. Challenges of Offshore Geotechnical Engineering.Dokument54 SeitenRandolph M. Et Al. Challenges of Offshore Geotechnical Engineering.Laura RossNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- En 1993 09Dokument160 SeitenEn 1993 09Vio ChiNoch keine Bewertungen

- GATE Chemical Engineering 2015Dokument18 SeitenGATE Chemical Engineering 2015Sabareesh Chandra ShekarNoch keine Bewertungen

- Be and Words From The List.: 6B Judging by Appearance Listening and ReadingDokument3 SeitenBe and Words From The List.: 6B Judging by Appearance Listening and ReadingVale MontoyaNoch keine Bewertungen

- Mba633 Road To Hell Case AnalysisDokument3 SeitenMba633 Road To Hell Case AnalysisAditi VarshneyNoch keine Bewertungen

- Caroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledDokument2 SeitenCaroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledCaroline BabinNoch keine Bewertungen

- CHASE SSE-EHD 1900-RLS LockedDokument2 SeitenCHASE SSE-EHD 1900-RLS LockedMarcos RochaNoch keine Bewertungen

- Sustainable Development Precautionary PR 2Dokument12 SeitenSustainable Development Precautionary PR 2PramodNoch keine Bewertungen

- WT Capability Statement PE 2020Dokument1 SeiteWT Capability Statement PE 2020Muhannad SuliemanNoch keine Bewertungen

- Dredge Yard Gate Valve BrochureDokument5 SeitenDredge Yard Gate Valve BrochureFederico BabichNoch keine Bewertungen

- Make Yeast StarterDokument2 SeitenMake Yeast StarterAlexandraNoch keine Bewertungen

- Angle ModulationDokument26 SeitenAngle ModulationAtish RanjanNoch keine Bewertungen

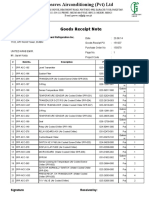

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDokument4 SeitenGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNoch keine Bewertungen

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDokument8 SeitenDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloNoch keine Bewertungen

- PCM 2.4l Turbo 5 de 5Dokument2 SeitenPCM 2.4l Turbo 5 de 5Felix VelasquezNoch keine Bewertungen

- Void Engineers (Convention: Mage The Ascension)Dokument6 SeitenVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- Capacity Analysis of Kashmir Highway IslamabadDokument71 SeitenCapacity Analysis of Kashmir Highway Islamabadm saadullah khanNoch keine Bewertungen

- CTRLX Automation BrochureDokument60 SeitenCTRLX Automation BrochureNinja do SofáNoch keine Bewertungen

- CE-23113-SP-902-R01-00 Asset SpecificationDokument14 SeitenCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберNoch keine Bewertungen

- A New Procedure For Generalized Star Modeling Using Iacm ApproachDokument15 SeitenA New Procedure For Generalized Star Modeling Using Iacm ApproachEdom LazarNoch keine Bewertungen

- GL Career Academy Data AnalyticsDokument7 SeitenGL Career Academy Data AnalyticsDeveloper GuideNoch keine Bewertungen

- Kat-A 4102 Rotovalve Edition3!12!02-2013 enDokument4 SeitenKat-A 4102 Rotovalve Edition3!12!02-2013 enWalter PiracocaNoch keine Bewertungen

- Zener Tester: by MedhatkoDokument6 SeitenZener Tester: by Medhatkosaran gulNoch keine Bewertungen

- 74 Series Logic ICsDokument6 Seiten74 Series Logic ICsanon-466841Noch keine Bewertungen

- EXPERIMENT 1 - Bendo Marjorie P.Dokument5 SeitenEXPERIMENT 1 - Bendo Marjorie P.Bendo Marjorie P.100% (1)

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDokument2 Seiten22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnNoch keine Bewertungen

- Electro TechniquesDokument2 SeitenElectro TechniquesPinkk DaisyfieldNoch keine Bewertungen

- Hume 100 ReviewerDokument7 SeitenHume 100 ReviewerShai GaviñoNoch keine Bewertungen

- Finding Targets PDFDokument9 SeitenFinding Targets PDFSteve TangNoch keine Bewertungen

- Aicte Internship Approval Pending 1Dokument7 SeitenAicte Internship Approval Pending 1Anisha KumariNoch keine Bewertungen

- Car Parking DesignDokument6 SeitenCar Parking Designcharler kinyuajNoch keine Bewertungen