Beruflich Dokumente

Kultur Dokumente

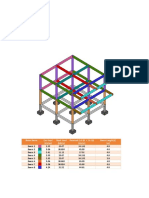

Beam Design - at Design Office

Hochgeladen von

Shamen AmarasekaraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Beam Design - at Design Office

Hochgeladen von

Shamen AmarasekaraCopyright:

Verfügbare Formate

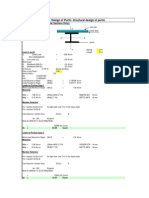

Design of Beam

Reference

b

f

h

f

b

w

h

f

= Heigth of slab (mm)= 125

Span = 16 (input) (Continous, flange beam)

Effe. Depth

Effe. Depth = Span / 16 Span ( mm) 4000

(d) = 250 mm

say d = 275 Input

Cover to r/f

As Durability

8110-1 Exposure Condition = Mild

Concrete Grade = C25

8110-1

Table 3.3 Cover = 25 mm

As fire resistance

8110-1 Fire Duration (Hr) = 1.5 Input

Table-3.4 Beam = Continouse

Cover = 20 mm

Cover Provided = 25 mm

Overall Height of beam = d + Cover + Dia/2 (bottom r/f ) + Dia (link)

Overall Height of beam = 318 mm

h = 325 mm Input

As fire resistance

Fire Duration (Hr) = 1.5

"T" Beam

Height of Beam (h)

8110-I

Table-3.9

Bredth of Beam (b

w

)

8110-1 b

w

> 200 mm

Figure 3.3

Say b

w

= 225 mm Input

8110-1

3.4.1.5

b

f

= Web width + l

z

/5

= 737.4 mm

Self weight = b

w

x ( h-h

f

) x L x 24 kN

= 4.169 kN

= 1.042 kN/m

Load from Slab

Slab Weight (Dead) =

= 29.28 kN

= 7.32 kN/m

Impose load =

= 36.60 kN

= 9.15 kN/m

Wall weight = Factor x Wall thickness x Height x Length

= 29.524 kN

= 7.381 kN/m

Total dead load = 15.743 kN/m

Total impose load = 9.150 kN/m

DL = 15.743 kN/m DL = 15.743

LL = 9.15 kN/m LL = 9.15

Effective width of flange beamBeam (b

f

)

a. for " T " beam

Load Analysis - Both "T" Beams or "L" Beam

Computation of self weight and Other dead loads

Dead load of slab x ( Area of Slab or slabs /2 ) x Factor x

No. of panal

live load x ( Area of Slab or slabs /2 ) x Factor x No. of

panal

A B C

4.000 4.000

Moments

Case -1 Maximum loading for both beam

design load = 1.4 DL + 1.6 LL

36.68

A B

L = 4.0 L =

For A - B , X

M

x

M

B

R

A WL

2

/8

R

B

Moments 73.3604

Differents 0

0

Corre. Moments 73.3604

M

B = 73.360 kNm

Then , Moment at B

R

A

= (WL*L/2-M

B

)/L

55.020 kN

Then ,0 <= x <= L

M

X

= W

AB

X

2

/2-R

A

X

M

x

= 0 , At X = 3.000 m

M

x

= 0 , At X = 0 and m

= 3.000 m

Moment @ X

M

X

= WX

2

/2-R

A

X

d M

X

= WX-R

A

dx

Then,

M Max @ dM

x

/dx=0

0 = WX-R

A

X = R

A

/W

= 1.500 m

Then, M max

M max = -41.265225 kNm

For B- C , X

M

x

M

B

R

A WL

2

/8

R

B

M

B = 73.360 kNm

Then , Moment at B

0 = W

BC

L

BC

2

/2+R

A

L

AB

-W

AB

L

AB

2

/2-R

C

L

BC

R

c

= 55.02 kN

Then ,0 <= x <= L

M

X

= W

BC

(L

AB

+L

BC

-X)

2

/2-R

c

(L

AB

+L

BC

-X)

=

=

=

M

x

= 0 , At X = 8 and m Input

= 5.000 m Input

Moment @ X

M

X

= W(L

AB

+L

BC

-X)

2

/2-R

c

(L

AB

+L

BC

-X)

d M

X

= W(L

AB

+L

BC

-X)-R

c

dx

Then,

M Max @ dM

x

/dx=0

0 = W

BC

(L

AB

+L

BC

-X)-R

c

0 = W

BC

L

AB

+W

BC

L

BC

-W

BC

X-R

c

X = (W

BC

L

AB

+W

BC

L

BC

-R

c

)/W

BC

= 6.500 m

Then, M max

M max = -41.265 kNm

X = 0.000 1.500

Moments = 0.00 -41.27

Moments =

80

Case -II AB - Maximum

BC - Minimum

design load = 1.4 DL + 1.6 LL

36.68

A B

L = 4.000 L =

For A - B , X

M

x

M

B

R

A WL

2

/8

R

B

Moments 73.3604

Differents -41.8744

-20.9372

Corre. Moments 52.4232

M

B = 52.423 kNm

Then , Moment at B

R

A

= (WL*L/2-M

B

)/L

60.255 kN

Then ,0 <= x <= L

M

X

= WX

2

/2-R

A

X

M

x

= 0 , At X = 0.000 and m

= 3.285 m

Moment @ X

M

X

= WX

2

/2-R

A

X

d M

X

= WX-R

A

dx

Then,

M Max @ dM

x

/dx=0

0 = WX-R

A

-60

-40

-20

0

20

40

60

80

0

.

0

0

0

1

.

0

0

0

2

.

0

0

0

3

.

0

0

0

4

.

0

0

0

5

.

0

0

0

6

.

0

0

0

7

.

0

0

0

8

.

0

0

0

9

.

0

0

0 M

o

m

e

n

t

s

Length of Beam

X = R

A

/W

= 1.643 m

Then, M max

M max = -49.4901448 kNm

For B- C , X

M

x

M

B

R

A WL

2

/8

R

B

M

B = 52.423 kNm

Then , Moment at B

0 = W

BC

L

BC

2

/2+R

A

L

AB

-W

AB

L

AB

2

/2-R

C

L

BC

R

c

= 18.38 kN

Then ,0 <= x <= L

M

X

= W

BC

(L

AB

+L

BC

-X)

2

/2-R

c

(L

AB

+L

BC

-X)

=

M

x

= 0 , At X = 8.000 and m Input

= 5.665 m Input

Moment @ X

M

X

= W(L

AB

+L

BC

-X)

2

/2-R

c

(L

AB

+L

BC

-X)

d M

X

= W(L

AB

+L

BC

-X)-R

c

dx

Then,

M Max @ dM

x

/dx=0

0 = W(L

AB

+L

BC

-X)-R

c

0 = WL

AB

+WL

BC

-WX-R

c

X = (WL

AB

+WL

BC

-R

c

)/W

= 6.832 m

Then, M max

M max = -10.730 kNm

X = 0.000 1.643

Moments = 0.00 -49.49

Moments =

60

Case -III AB - Minimum

BC - Maximum

design load = 1.4 DL + 1.6 LL

15.74

A B

L = 4.000 L =

For A - B , X

M

x

M

B

R

A WL

2

/8

R

B

Moments 31.486

Differents 41.8744

20.9372

Corre. Moments 52.4232

M

B = 52.423 kNm

Then , Moment at B

R

A

= (WL*L/2-M

B

)/L

18.380 kN

Then ,0 <= x <= L

M

X

= WX

2

/2-R

A

X

M

x

= 0 , At X = 0 and m

= 2.335 m

Moment @ X

M

X

= WX

2

/2-R

A

X

d M

X

= WX-R

A

dx

Then,

-60

-40

-20

0

20

40

60

0

.

0

0

0

1

.

0

0

0

2

.

0

0

0

3

.

0

0

0

4

.

0

0

0

5

.

0

0

0

6

.

0

0

0

7

.

0

0

0

M

o

m

e

n

t

s

Length of Beam

M Max @ dM

x

/dx=0

0 = WX-R

A

X = R

A

/W

= 1.168 m

Then, M max

M max = -10.7295862 kNm

For B- C , X

M

x

M

B

R

A WL

2

/8

R

B

M

B = 52.423 kNm

Then , Moment at B

0 = W

BC

L

BC

2

/2+R

A

L

AB

-W

AB

L

AB

2

/2-R

C

L

BC

R

c

= 60.25 kN

Then ,0 <= x <= L

M

X

= W

BC

(L

AB

+L

BC

-X)

2

/2-R

c

(L

AB

+L

BC

-X)

=

M

x

= 0 , At X = 8.000 and m Input

= 4.710 m Input

Moment @ X

M

X

= W(L

AB

+L

BC

-X)

2

/2-R

c

(L

AB

+L

BC

-X)

d M

X

= W(L

AB

+L

BC

-X)-R

c

dx

Then,

M Max @ dM

x

/dx=0

0 = W(L

AB

+L

BC

-X)-R

c

0 = WL

AB

+WL

BC

-WX-R

c

X = (WL

AB

+WL

BC

-R

c

)/W

= 6.357 m

Then, M max

M max = -49.490 kNm

X = 0.000 1.168

Moments = 0.00 -10.73

Moments =

Hogging @ B

M max,Hog = 73.36 kNm

Saging A-B Mmax,sag = -49.49 kNm

Saging B-C Mmax,sag = -49.49 kNm

-60

-40

-20

0

20

40

60

0

.

0

0

0

1

.

0

0

0

2

.

0

0

0

3

.

0

0

0

4

.

0

0

0

5

.

0

0

0

6

.

0

0

0

7

.

0

0

0

M

o

m

e

n

t

s

Length of Beam

=

h

(input)

(Continous, flange beam)

Input)

Dia. Bottom r/f (mm) = 16 Input

Dia of links (mm) = 10 Input

l

z

= 0.7 x L Input

L

s

= 3660 Input (length of Slab)

L

b

= 4000 Input (length of Beam)

Dead load

of slab

= 4 Input (From salb design)

Factor = 1 Input (From salb design)

No.of Panal = 1 Input (From salb design)

live load of

slab

= 5 Input (From salb design)

Factor = 1

No.of Panal = 1

thickness = 200 Input

height = 3355 Input

length = 4000 Input

Factor = 11 Input

kN/m Input

kN/m Input

Load Analysis - Both "T" Beams or "L" Beam

Dead load of slab x ( Area of Slab or slabs /2 ) x Factor x

No. of panal

live load x ( Area of Slab or slabs /2 ) x Factor x No. of

panal

36.6802

C

4.00 Input

WL

2

/8

R

C

73.3604

0

73.3604

X

WL

2

/8

R

C

W

AB

= 36.68 KN/m

W

BC

= 36.68 KN/m

L

AB

= 4.0 m

L

BC

= 4.0 m

3.000 4.000 5.000 6.500 8.000

0.00 73.36

73.36 0.00 -41.27 0.00

15.743

C

4.000 Input

WL

2

/8

R

C

31.486

20.9372

52.4232

9

.

0

0

0

1

0

.

0

0

0

WL

2

/8

R

C

356.736 45.32

107.564 13.665

7.8715 45.32

3.285 4.000 5.665 6.832 8.000

0.00 52.42

52.42 0.00 -10.7 0.00

36.6802

C

4.000 Input

WL

2

/8

R

C

73.3604

-20.9372

52.4232

7

.

0

0

0

8

.

0

0

0

9

.

0

0

0

1

0

.

0

0

0

X

WL

2

/8

R

C

233.19 12.7

691.76 37.7

37.68

2.335 4.000 4.710 6.357 8.000

0.00 52.42

52.42 0.00 -49.5 0.00

7

.

0

0

0

8

.

0

0

0

9

.

0

0

0

1

0

.

0

0

0

h

f

= 125

d = 275

Cover = 25

h = 325

Results

b

w

= 225

b

f

= 737.4

G

k

= 15.74

Q

k

= 9.15

Reference

b

f

h

f

b

w

h

f

= Heigth of slab (mm)= 125

Span = 20.8 (input) (Continous, flange beam)

Effe. Depth

Effe. Depth = Span / 20.8 Span ( mm) 4000

(d) = 192 mm

say d = 300 Input

Cover to r/f

As Durability

8110-1 Exposure Condition = Mild

Concrete Grade = 25

8110-1

Table 3.3 Cover = 25 mm

As fire resistance

8110-1 Fire Duration (Hr) = 1.5 Input

Table-3.4 Beam = Continouse

Cover = 20 mm

Cover Provided = 25 mm

Overall Height of beam = d + Cover + Dia/2 (bottom r/f ) + Dia (link)

Overall Height of beam = 343 mm

h = 350 mm Input

As fire resistance

Fire Duration (Hr) = 1.5

8110-1 b

w

> 200 mm

Figure 3.3 Say b

w

= 225 mm Input

Design of Beam

"L" Beam

Height of Beam (h)

8110-I

Table-3.9

Bredth of Beam (b

w

)

8110-1 a. for "t" beam

3.4.1.5 b

f

= Web width + l

z

/10

= 505 mm

Self weight = b

w

x ( h-h

f

) x L x 24 kN

= 4.238 kN

= 1.177 kN/m

Load from Slab

Slab Weight (Dead) =

= 28.80 kN

= 8.00 kN/m

Impose load =

= 25.20 kN

= 7.00 kN/m

Wall weight = Factor x Wall thickness x Height x Length

= 26.05554 kN

= 7.24 kN/m

Total dead load = 16.41 kN/m

Total impose load = 7.00 kN/m

Max Shear = 61.53 kN Support at both Ends

IstructE.Manual Required width of beam = 1000 v

1985 2d

3.7.3 = 159.97 mm

Provided > Required

Satisfied

Grade of Concrete C = 25

= 35.00 kNm

Consider full width of Beam,

Then, M/ bd

2

= 1.73 N/mm

2

8110-1

3.4.4.3 As = k' f

cu

bd

2

+ As'

0.87f

y

z

Computation of reinforcement percentage of critical sections

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

For Hogging reinforcements at first interior support - Rectangular

live load x ( Area of Slab or slabs /2 ) x Factor x No. of

panal

Effective width of flange beamBeam (b

f

)

Computation of self weight and Other dead loads

Dead load of slab x ( Area of Slab or slabs /2 ) x Factor x

No. of panal

Check Bredth of Beam (b

w

) for Shear

k = M/bd

2

f

cu

= 0.069

k' = 0.156

Now, k < k'

No need Compression R/F

1. If Compression R/F is not Req.

k,

z = d 0.5 + (0.25-k/0.9) mm

= 274.85 mm But

0.95d =

Then ,z = 1.43

As = M/(0.87 f

y

z)

318.20 mm

2

25 0 0.00

20 0 0.00

16 0 0.00

12 2 226.29

10 1 78.57

304.86

2. If Compression R/F is Req.

k', z = d 0.5 + (0.25-k'/0.9) mm

= 233.07 mm But

0.95d =

Then ,z = 233.07

x = ( d - z ) /0.45 mm

148.74 mm

As' = (k-k') f

cu

bd

2

/(0.87 f

y

(d-d'))

-439.53 mm

2

As = k' f

cu

bd

2

+ As'

0.87 f

y

z

= 846.71 mm

2

25 0 0.00

20 0 0.00

16 4 804.57

12 2 226.29

10 0 0.00

1030.86

= -27.00 kNm

= 27.00 kNm

Consider full width of Beam,

S

a

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

S

a

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

For Sagging Movements at Mid spans

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

Use this Value

Dont Use

Then,

M/ bd

2

= 0.59 N/mm

2

k = M/bd

2

f

cu

0.024

k' = 0.156

Now, k < k'

No need Compression R/F

1. If Compression R/F is not Req.

K,

z = d 0.5 + (0.25-k/0.9) mm

= 291.86 mm But

0.95d =

Then ,z = 285.00

As = M/(0.87 f

y

z)

236.72 mm

2

25 0 0.00

20 0 0.00

16 0 0.00

12 2 226.29

10 1 78.57

304.86

2. If Compression R/F is Req.

K', z = d 0.5 + (0.25-k'/0.9) mm

= 233.07 mm But

0.95d =

Then ,z = 233.07

x = ( d - z ) /0.45 mm

-514.59 mm

As' = (k-k') f

cu

bd

2

/(0.95 f

y

(d-d'))

-1375.33 mm

2

As = k' f

cu

bd

2

+ As'

0.87 f

y

z

= 0.00 mm

2

25 0 0.00

20 0 0.00

16 0 0.00

12 0 0.00

10 0 0.00

0.00

for span

x = 148.74 mm

d = 1.5 mm

S

a

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

S

a

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

Use this Value

Dont Use

Provide Shear reinforcements

Assume:- Reinforcement have been provided as bent up bars.

Shear resistance

v

b

= A

sb

( 0.95 f

y

)( cos + sin cot ) (( d-d')/s

b

)

Let,

A

sb

= 8

2

mm

2

Input

= 45 Degree Input

= 60 Degree Input

s

b

= 200 mm Input

f

y

= 460 N/mm

2

Input

Then, v

b

= -135.74 kN

No.of bent bars = ((d-d')/Tan )/s

b

= 3.91

Provide No.of bent bars = 4

Then provide shear links with shear resistance greater than V

b

8110-1 100 As = 0.298

Table3.8 b

w

d

Table3.8 Vc = 0.45 N/mm

2

Input

and V

V = N/mm

2

Input

0.5 Vc = 0.225 N/mm

2

0.8 f

cu

= 4.00 N/mm

2

Check V < 0.8 f

cu

0 < 4.00

Check is Ok

Check

V < 0.5 Vc

0 > 0

Not Ok

8110-1

3.4.5.5 Spacing <= 0.75 d

1.125 mm

Say = 225 mm Input

8110-1 Maximum spacing f bars

3.12.11.2

3.12.11.2.3 Maximum spacing f bars = mm Input

Table 3.28 ( for =1)

8110-1 Minimum spacing of bars

3.12.11.1

Spacing >= h agg + 5mm

25 mm

Max. Span = 12.000

Effec.Depth

Table 3.9 Permisible Span = 26 Input

Effec.Depth

12.000 < 26

Check is Ok

Deflection check

Results

h

(input) h

f

=

(Continous, flange beam)

Input)

d =

Cover =

Dia. Bottom r/f (mm) = 16 Input

Dia of links (mm) = 10 Input

h =

b

w

=

Design of Beam

l

z

= 0.7 x L Input

L = 4000 Input (length of Slab) b

f

=

L = 3600 Input (length of Beam)

Dead load

of slab

= 4 Input (From salb design)

Factor = 1 Input (From salb design)

No.of Panal = 1 Input (From salb design)

live load of

slab

= 3.5 Input (From salb design)

Factor = 1

No.of Panal = 1

thickness = 175 Input

height = 3660 Input

length = 3600 Input

Factor = 11.3 Input

G

k

=

34.181 Q

k

=

Support at both Ends

Computation of reinforcement percentage of critical sections

For Hogging reinforcements at first interior support - Rectangular

live load x ( Area of Slab or slabs /2 ) x Factor x No. of

panal

Dead load of slab x ( Area of Slab or slabs /2 ) x Factor x

No. of panal

z < 0.95 d

1.425

z < 0.95 d

285

For Sagging Movements at Mid spans

Use this Value

Dont Use

z < 0.95 d

285

z < 0.95 d

285

Use this Value

Dont Use

Provide Shear reinforcements

125

300

25

350

225

505

16.41

7.00

Reference

b

f

b

w

h

f

= Heigth of slab (mm)=

Span = 16 (input) (Continous, flange beam)

Effe. Depth

Effe. Depth = Span / 16 Span ( mm)

(d) = 344 mm

say d = 411

Satisfied

Cover to r/f

As Durability

8110-1 Exposure Condition = Mild

Concrete Grade C = 25

8110-1

Table 3.3 Cover = 25 mm

As fire resistance

8110-1 Fire Duration (Hr) = 1.5 Input

Table-3.4 Beam = Continouse

Cover = 20 mm

Cover Provided = 25 mm

Overall Height of beam = d + Cover + Dia/2 (bottom r/f ) + Dia (link)

Overall Height of beam = 450 mm

h = 450 mm Input

As fire resistance

Fire Duration (Hr) = 1.5

8110-1 b

w

> 200 mm

Figure 3.3

Say b

w

= 225 mm Input

Design of Beam

"T" Beam

Height of Beam (h)

8110-I

Table-3.9

Bredth of Beam (b

w

)

8110-1

3.4.1.5 b

f

= Web width + l

z

/5

= 645 mm

Self weight = b

w

x ( h-h

f

) x L x 24 kN

= 8.910 kN

= 1.620 kN/m

Load from Slab

Slab Weight (Dead) =

= 75.900 kN

= 13.800 kN/m

Impose load =

= 49.500 kN

= 9.000 kN/m

Wall weight = Factor x Wall thickness x Height x Length

= 41.703 kN

= 7.582 kN/m

Then,

Total dead load = 23.002 kN/m

Total impose load = 9.000 kN/m

Max Shear = 90.00 kN

Max Shear = 128.16 kN

Max Shear = 128.16 kN

IstructE.Manual Required width of beam = 1000 v

1985 2d

3.7.3 = 155.91 mm

Provided > Required

Satisfied

Grade of Concrete C = 25

= 70.00 kNm

Consider full width of Beam,

Effective width of flange beamBeam (b

f

)

a. for " T " beam

Computation of self weight and Other dead loads

Dead load of slab x ( Area of Slab or slabs /2 ) x Factor x

No. of panal

live load x ( Area of Slab or slabs /2 ) x Factor x No. of

panal

Check Bredth of Beam (b

w

) for Shear

Computation of reinforcement percentage of critical sections

For Hogging reinforcements at first interior support - Rectangular

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

Then, M/ bd

2

= 1.84 N/mm

2

8110-1

3.4.4.3 As = k' f

cu

bd

2

+ As'

0.87 f

y

z

k = M/(bd

2

f

cu

)

= 0.074

k' = 0.156

Now, k < k'

No need Compression R/F

1. If Compression R/F is not Req.

k,

z = d 0.5 + (0.25-k/0.9) mm

= 374.03 mm

Then ,z = 374.03

As = M/(0.87 f

y

z)

467.64 mm

2

25 0

20 0

16 3

12 0

10 2

2. If Compression R/F is Req.

k', z = d 0.5 + (0.25-k'/0.9) mm

= 319.30 mm

Then ,z = 319.30

x = ( d - z ) /0.45 mm

203.78 mm

As' = (k-k') f

cu

bd

2

/(0.87 f

y

(d-d'))

-541.48 mm

2

As = k' f

cu

bd

2

+ As'

0.87 f

y

z

= 1159.99 mm

2

25 0

20 0

16 4

12 2

10 0

Use this Value

Dont Use

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

H

o

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

= -175.00 kNm

= 175.00 kNm

Consider full width of Beam,

Then,

M/ bd

2

= 1.61 N/mm

2

k = M/bd

2

f

cu

0.064

k' = 0.156

Now, k < k'

No need Compression R/F

1. If Compression R/F is not Req.

K,

z = d 0.5 + (0.25-k/0.9) mm

= 379.20 mm

Then ,z = 379.20

As = M/(0.87 f

y

z)

1153.17 mm

2

32 -

25 -

20 4

16 -

12 -

10 -

0

2. If Compression R/F is Req.

K', z = d 0.5 + (0.25-k'/0.9) mm

= 319.30 mm

Then ,z = 319.30

x = ( d - z ) /0.45 mm

203.78 mm

As' = (k-k') f

cu

bd

2

/(0.87 f

y

(d-d'))

-603.45 mm

2

As = k' f

cu

bd

2

+ As'

0.87 f

y

z

= 3,325.30 mm

2

25 0

20 0

16 0

12 0

10 0

Use this Value

Dont Use

S

a

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

S

a

g

g

i

n

g

s

e

c

t

i

o

n

D

e

s

i

g

n

For Sagging Movements at Mid spans

for span

x = 203.78 mm

d = 411 mm

Assume:- Reinforcement have been provided as bent up bars.

Shear resistance

v

b

= A

sb

( 0.95 f

y

)( cos + sin cot ) (( d-d')/s

b

)

Let,

A

sb

= 8

2

mm

2

= 45 Degree

= 60 Degree

s

b

= 200 mm

f

y

= 460 N/mm

2

Then, v

b

= 1010.36 kN

No.of bent bars = ((d-d')/Tan )/s

b

= 5.64

Provide No.of bent bars = 6

Then provide shear links with shear resistance greater than V

b

Then provide shear links with shear resistance greater than V

b

100 As = 1.359

b

w

d

Table3.8 Vc = (0.79/r

m

)(100A

s

/b

w

d)

1/3

(400/d)

1/4

(f

u

/25)

1/3

Provide Shear reinforcements

100A

s

= 1.359

8110-1 b

w

d

r

m

= 1.25

400/d = 0.97 but 400/d < 1

Hence = 0.97

f

u

/25 = 1.00

Then, Vc = 0.695 N/mm

2

Vc+0.4 = 1.095 N/mm

2

0.8 f

cu

= 4.000 N/mm

2

Max shear

V = 1.266 N/mm

2

0.5 Vc = #VALUE! N/mm

2

0.8 f

cu

= 4.00 N/mm

2

Check V < 0.8 f

cu

1.2657665 < 4.00

Check is Ok

Check

V < 0.5 Vc

1.2657665 > 0

Not Ok

8110-1

3.4.5.5 Spacing <= 0.75 d

308.25 mm

Say = 225 mm

8110-1 Maximum spacing f bars

3.12.11.2

3.12.11.2.3 Maximum spacing f bars = mm

Table 3.28 ( for =1)

8110-1 Minimum spacing of bars

3.12.11.1

Spacing >= h agg + 5mm

25 mm

Max. Span = 13.382

Effec.Depth

Deflection check

Table 3.9 Permisible Span = 26

Effec.Depth

13.382 < 26

Check is Ok

h

f

h

150 (input)

(Continous, flange beam)

5500 Input)

d + Cover + Dia/2 (bottom r/f ) + Dia (link) Dia. Bottom r/f (mm) = 16 Input

Dia of links (mm) = 6 Input

L

s1

L

s2

L

b

Design of Beam

"T" Beam

l

z

= 0.7 x L Input

L

s (average)

= 3000 Input (length of Slab)

L

b

= 5500 Input (length of Beam)

Slab Weight = 3.6 Input (From salb design)

Finishing = 1 Input (From salb design)

Dead load

of slab

= 4.6 Input (From salb design)

Factor = 1 Input (From salb design)

No.of Panal = 2 Input (From salb design)

live load of

slab

= 2 Input (From salb design)

Finishing = 1 Input (From salb design)

Total Live = 3 Input (From salb design)

Factor = 1 Input (From salb design)

No.of Panal = 2 Input (From salb design)

Factor x Wall thickness x Height x Length thickness = 200 Input

height = 3355 Input

length = 5500 Input

Factor = 11.3 Input

46.6032

Input

Support at both Ends

Dead load of slab x ( Area of Slab or slabs /2 ) x Factor x

No. of panal

live load x ( Area of Slab or slabs /2 ) x Factor x No. of

panal

Computation of reinforcement percentage of critical sections

For Hogging reinforcements at first interior support - Rectangular

But z < 0.95 d

0.95d = 390.45

0.00

0.00

603.43

0.00

157.14

760.57

But z < 0.95 d

0.95d = 390.45

0.00

0.00

804.57

226.29

0.00

1030.86

Use this Value

Dont Use

167.063

But z < 0.95 d

0.95d = 390.45

0.00

0.00

1257.14

0.00

0.00

0.00

1257.14

But z < 0.95 d

0.95d = 390.45

0.00

0.00

0.00

0.00

0.00

0.00

Use this Value

Dont Use

For Sagging Movements at Mid spans

A

sb

( 0.95 f

y

)( cos + sin cot ) (( d-d')/s

b

)

Input

Input

Input

Input

Input

Then provide shear links with shear resistance greater than V

b

As = #####

(0.79/r

m

)(100A

s

/b

w

d)

1/3

(400/d)

1/4

(f

u

/25)

1/3

Provide Shear reinforcements

Input

Input

Deflection check

Input

h

f

= 150

d = 411

Cover = 25

h = 450

b

w

= 225

Results

b

f

= 645

G

k

= 23.00

Q

k

= 9.00

Das könnte Ihnen auch gefallen

- Stair Case Design - at Design OfficeDokument14 SeitenStair Case Design - at Design OfficeShamen AmarasekaraNoch keine Bewertungen

- 6.2 Beam DesignDokument12 Seiten6.2 Beam DesignShamen Amarasekara100% (2)

- Slab Design-@ Design OfficeDokument40 SeitenSlab Design-@ Design OfficeShamen AmarasekaraNoch keine Bewertungen

- All Type of Footing DesignDokument23 SeitenAll Type of Footing DesignAyazAkram100% (6)

- Design BeamDokument50 SeitenDesign BeammonirithneangNoch keine Bewertungen

- Raft Slab DesignDokument5 SeitenRaft Slab DesignLekins Sefiu Yekini100% (2)

- RC Beam Design (Cantilever)Dokument7 SeitenRC Beam Design (Cantilever)api-1975359867% (3)

- Spread Footing DesignDokument3 SeitenSpread Footing Designjkem_fontanilla542580% (10)

- Concrete Design Excel SheetDokument16 SeitenConcrete Design Excel SheetCleth Hiren Santos25% (4)

- Monolithic Staircase DesignDokument5 SeitenMonolithic Staircase DesignAzraiAzizNoch keine Bewertungen

- Column Design Name of Work:-: PK - Nandwana@yahoo - Co.inDokument27 SeitenColumn Design Name of Work:-: PK - Nandwana@yahoo - Co.innsureshbabu0% (1)

- RC Footing Design FinalDokument39 SeitenRC Footing Design Finalmegget100% (10)

- Revised Pad Footing Rev.1 (10.7.2018)Dokument4 SeitenRevised Pad Footing Rev.1 (10.7.2018)Ally KhooNoch keine Bewertungen

- Roof SlabDokument2 SeitenRoof SlabnoneNoch keine Bewertungen

- Pile DesignDokument2 SeitenPile DesignOlanrewaju Okunola100% (1)

- Isolated Footing Design Example and Excel SheetDokument8 SeitenIsolated Footing Design Example and Excel Sheetosama prog100% (1)

- Lintel DesignDokument3 SeitenLintel DesignPrashant HuddarNoch keine Bewertungen

- Foundation DesignDokument15 SeitenFoundation Designlokesh.lucky.nit7228Noch keine Bewertungen

- Design of Slab (One Way)Dokument9 SeitenDesign of Slab (One Way)anumned100% (1)

- RCC13 Punching ShearDokument11 SeitenRCC13 Punching ShearMUTHUKKUMARAMNoch keine Bewertungen

- Slab Design ACI With Reinforcment (Sketch)Dokument7 SeitenSlab Design ACI With Reinforcment (Sketch)chemtahir100% (1)

- Column DesignDokument6 SeitenColumn DesignKenneth CajefeNoch keine Bewertungen

- Concrete Footing DesignDokument7 SeitenConcrete Footing DesignCarmel Buniel Sabado100% (3)

- Design of Isolated Rectangular FootingDokument3 SeitenDesign of Isolated Rectangular FootingdsanandaNoch keine Bewertungen

- Structural Design of PurlinDokument3 SeitenStructural Design of PurlinGeorge GeorgianNoch keine Bewertungen

- Cantilever CanopyDokument2 SeitenCantilever Canopyapi-19753598Noch keine Bewertungen

- Two Way Slab Design Excel SheetDokument13 SeitenTwo Way Slab Design Excel Sheetsalmantop186% (7)

- Design of PileDokument2 SeitenDesign of PileklynchelleNoch keine Bewertungen

- Calculation On Sizing of SlabDokument20 SeitenCalculation On Sizing of SlabazhimsyammelNoch keine Bewertungen

- Gutter DesignDokument6 SeitenGutter Designtawas200% (1)

- One Way Slab DesignDokument4 SeitenOne Way Slab DesignMario FeghaliNoch keine Bewertungen

- BEAM DesignDokument45 SeitenBEAM DesignJoseph Cloyd L. LamberteNoch keine Bewertungen

- Single Isolated Square Footing FPSDokument8 SeitenSingle Isolated Square Footing FPSengmohamad19880% (1)

- Slab DesignDokument6 SeitenSlab DesignJonasIrvinGallegoNoch keine Bewertungen

- Stirrup DesignDokument4 SeitenStirrup Designapmintu100% (1)

- Staircase DesignDokument45 SeitenStaircase DesignHenRy Ngu 旭67% (3)

- Squre Footing Design (WSD)Dokument3 SeitenSqure Footing Design (WSD)api-19753598Noch keine Bewertungen

- Retain Wall Counter FortDokument48 SeitenRetain Wall Counter FortSWADES RANJAN PAIRANoch keine Bewertungen

- Beam DesignDokument37 SeitenBeam DesignYinka Akinkunmi100% (1)

- Sample Beam DesignDokument12 SeitenSample Beam DesignmokalnganNoch keine Bewertungen

- A. Design of Flanged Beam SectionDokument7 SeitenA. Design of Flanged Beam SectionWilson PatyalNoch keine Bewertungen

- Design: Rigid Solutions - Final CoachingDokument11 SeitenDesign: Rigid Solutions - Final CoachingEugene Ralph TimoteoNoch keine Bewertungen

- Design of Stair Case With Central Stringer BeamDokument27 SeitenDesign of Stair Case With Central Stringer Beamsssmou73% (15)

- 33 KV E Pole DesignDokument40 Seiten33 KV E Pole DesignSri Gaja Govind BabuNoch keine Bewertungen

- Stair CaseDokument19 SeitenStair CaseVanu VamalaiNoch keine Bewertungen

- Curved+Beam+by+B C +punmiaDokument34 SeitenCurved+Beam+by+B C +punmiaHasanuzzaman PalashNoch keine Bewertungen

- Design of A Singly Reinforced T-BeamDokument2 SeitenDesign of A Singly Reinforced T-BeamVivek Thakur SujanianNoch keine Bewertungen

- Design of Stair Case With Central Stringer BeamDokument45 SeitenDesign of Stair Case With Central Stringer BeamCONSTHURAG2012Noch keine Bewertungen

- Design of MonorailDokument9 SeitenDesign of MonorailAnonymous Q8XIGqHyCNoch keine Bewertungen

- T Beam Roof SlabDokument22 SeitenT Beam Roof SlabRohit Khandelwal100% (1)

- Design For Reinforcement in Pier: Slenderness RatioDokument2 SeitenDesign For Reinforcement in Pier: Slenderness RatioPreetam SundarayNoch keine Bewertungen

- DesignDokument34 SeitenDesignAbhay SuwalNoch keine Bewertungen

- Design of Wall Footing Project #Dokument3 SeitenDesign of Wall Footing Project #Raghad F Al-Zu'biNoch keine Bewertungen

- BridgeT BeamDokument23 SeitenBridgeT BeamMochammad Syafi UddinNoch keine Bewertungen

- Unit 5Dokument31 SeitenUnit 5Nirina ArimananaNoch keine Bewertungen

- Technical Calculation of Segmental PC I Beam For Bridge SPAN (CTC) L I. DataDokument30 SeitenTechnical Calculation of Segmental PC I Beam For Bridge SPAN (CTC) L I. DataAnisha MayaNoch keine Bewertungen

- Group 3Dokument32 SeitenGroup 3Clarens CortezNoch keine Bewertungen

- 2 Design of Beam Ledges 23052014Dokument2 Seiten2 Design of Beam Ledges 23052014Ahmad Badsha QuadriNoch keine Bewertungen

- NOTES SeviceabilityDokument81 SeitenNOTES Seviceabilitydileep 443Noch keine Bewertungen

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationVon EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNoch keine Bewertungen

- Greater Colombo Water Rehabilitation Project Pipe: Measurement Sheet ForDokument1 SeiteGreater Colombo Water Rehabilitation Project Pipe: Measurement Sheet ForShamen AmarasekaraNoch keine Bewertungen

- Treatment Plant HeaderDokument3 SeitenTreatment Plant HeaderShamen AmarasekaraNoch keine Bewertungen

- Column DesignDokument11 SeitenColumn DesignShamen Amarasekara100% (2)

- Column Design - at Design OfficeDokument56 SeitenColumn Design - at Design OfficeShamen AmarasekaraNoch keine Bewertungen