Beruflich Dokumente

Kultur Dokumente

PDC Lab Report

Hochgeladen von

arslan_uetanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PDC Lab Report

Hochgeladen von

arslan_uetanCopyright:

Verfügbare Formate

LAB REPORT PROCESS AND

DYNAMIC CONTROL

SUBMITTED TO: SIR HASEEB JATOI

SUBMITTED BY:

ARSLAN ALI (2011-CH-63)

UNIVERSITY OF ENGINEERING & TECHNOLOGY

LAHORE

LAB#01 1

TH

SEPTEMBER, 2014 LAB LAYOUT

LAB#02 8

TH

SEPTEMBER, 2014 DEAD WEIGHT CALIBRATOR

OBJECTIVE

Calibration of Pressure Gauge using Dead Weight Calibrator

EQUIPMENT

1. The Dead Weight Calibrator

2. Standard Weights

3. Precision Gauge (if possible)

PROCEDURE

1. We closed the Needle Valves #2, #3, #4 while keeping the valve #1 open, so that the oil

can be added to the system

2. We checked the level of hydraulic oil in the Oil Cup; it was fill up to the mark. (in case

oil is less, add more oil to fill the cup unless the hydraulics may not develop).

3. Rotate the piston handle outwards completely to suck the oil in it.

4. We closed Needle Valve #1 now and opened Valve #2 (Pan for Weights) and Valve #3

(Pressure Gauge) after mounting the gauge to be tested on the nipple provided above

Needle Valve #3. (In case a precision gauge is also mounted, then open the valve #4 as

well, we didnt had any such gauge) Hence Oil flows to these points now and hydraulics

developed.

5. After this, we in ascending order put the standard weights on the Pan

6. Turn the handle of the cylinder piston to transmit the pressure toward the weight and

pressure gauge/s

7. When the fluid pressure is equal to the pan, it is lifted as well as the gauge indicates the

corresponding pressure. Note that the weight should be lifted to red line only. Beyond

white line it would be in effective.

8. We noted the reading and increased the weights in ascending order and then noted the

readings in descending order as well.

PRECAUTIONS

1. The relevant valves should be promptly closed and opened as mentioned in the

procedure; otherwise the hydraulic oil might spill outside or on the face of the users.

2. The standard weights should be placed, with care.

3. The hand wheel should be turned back before removing any heavy weights.

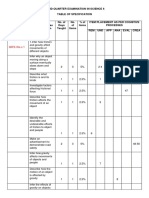

Weight Pressure (Kg/cm

2

) Inverse

0 0.7 0.5

1 1.0 1.0

2 1.1 1.8

3 2.0 2.2

4 3.5 4

5 4.2 4.2

6 5.0 5.8

11 10.0 10.3

16 16.0 16

21 22.0 22

26 26.0 26.3

36 38.0 36.2

46 46 46

56 55.5 56

62 62.0 62

0

10

20

30

40

50

60

70

0 10 20 30 40 50 60 70

Weight v/s Rev.Pressure

`

0

10

20

30

40

50

60

70

0 10 20 30 40 50 60 70

Weight v/s Pressur

LAB#03 15

TH

SEPTEMBER, 2014 THERMOCOUPLE

OBJECTIVE

To determine the time constant of a typical Iron-Constantan Thermocouple

EQUIPMENT

1. Thermocouple (J Type: Iron Constantan)

2. Heater

3. Digital Voltmeter

4. Stopwatch

5. Hookup Wires

PROCEDURE

Note the readings on the digital voltmeter. Switch on heater. As thermocouple receives heat,

digital voltmeter reading changes, record the reading every minute. After some time the

measured voltage shall settle on a particular time constant from the plot.

Draw graph of EMF V/S Time. Establish the time constant from the plot.

Establish the temperature at all measured EMF using the thermocouple table for

appropriate metals.

OBSERVATIONS

EMF VS TIME

Graph:

TIME CONSTANT CALCULATIONS

Max Reading on digital voltmeter = 9.4

63.2% of Max = 5.9408 mV

Time Constant = 12.85 min

0.1

0.3

0.6

1

1.5

2.1

2.7

3.3

3.9

4.5

5.1

5.6

6.2

6.6

7

7.4

7.7

8

8.3

8.5

8.7

8.9

9

9.1

9.3

9.4 9.4 9.4

0

1

2

3

4

5

6

7

8

9

10

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

E

M

F

TIME

EMF(MV) VS TIME (MIN)

TEMP VS TIME

Graph:

TIME CONSTANT CALCULATIONS

Max Reading of Temperature = 175.14

o

C

63.2% of Max = 110.6885

o

C

Time Constant = 12.2 min

QUESTIONS/ANSWERS FOR BETTER UNDERSTANDING

I. What are different types of thermocouple and which type of thermocouple used here?

Thermocouples are identified by a single letter type and grouped according to their

temperature range

0

15

30

45

60

75

90

105

120

135

150

165

180

195

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

T

e

m

p

(

D

e

g

C

)

Time (min)

Temp( Deg C) Vs Time (min)

1. Base Metals up to 1000 C Type J, Type E, Type T, Type K

2. Noble Metals up to 2000 C Type R, Type S, Type B

3. Refractory Metals up to 2600 C Type C, Type D, Type G

J-Type thermocouple was used in this experiment.

II. What do you know about SeeBeck Effect?

In 1821, Thomas Seebeck discovered if metals of two different materials were joined at both

ends and one end was at a different temperature than the other, a current was created. This

phenomenon is known as the Seebeck effect and is the basis for all thermocouples.

III. Why Thermocouples are preferred?

Thermocouples can be used to temperatures as high as 3100F, generally cost less than

RTDs and they can be made smaller in size (down to approximately .020 dia) to allow for

faster response to temperature. Thermocouples are also more durable than RTDs and can

therefore be used in high vibration and shock applications. Thermocouples are generally less

expensive than RTDs.

IV. Why results are not reliable?

Time of Response of thermocouple is very slow.

V. Show Thermocouple measuring circuit?

VI. Can Thermocouple measure gas, liquid and solid temperature?

Yes, it can measure gas, liquid and solid surface temperature.

VII. Why is thermocouple inclined above the heater?

There is no such restriction of inclination angle, but it is done only as a precaution. Has the

Thermocouple been placed straightly above the heater, it would have heated up the wires

connected to its other end, which we dont want.

VIII. Which characteristics of thermocouple can be determined?

1. Response Time:

It is defined as the time required to reach 63.2% of an instantaneous temperature change.

2. Speed of Response:

The speed of response of a sensor mainly depends on his mass and thermocouples can be

very thin so fast response

3. Sensitivity:

Sensitivity of thermocouple refers to how much sensitive thermocouple is to any

change.

IX. What is Hot Junction and Cold Junction?

A thermocouple is a type of temperature sensor, which is made by joining two dissimilar

metals at one end. The joined end is referred to as the HOT JUNCTION. The other end of

these dissimilar metals is referred to as the COLD END or COLD JUNCTION.

X. What is Cold Junction Compensation?

Simulate the potential effects that would result for a thermocouple wire pair between the

terminals, at their measured temperature, and another junction at a reference temperature of 0

degrees. Measure the potential across the thermocouple wire pair in series with the simulated

potential. Apply the linearizing curve to the sum, thus obtaining an estimated absolute

temperature directly. This is known as cold junction compensation. Usually, the simulation is

done electronically with specialized integrated circuit devices.

Electronic cold junction compensation

XI. Write on Thermocouple Installation?

Vertical installation is preferred in very high temperatures to avoid protection tube or

element sagging. Install thermocouples away from AC power lines to prevent electrical

noise. Do not run thermocouple wires in the same conduit with electrical wires.

Do not run a single thermocouple to two different instruments. This will result in instrument

imbalance.

A dual thermocouple should be used instead.

Electrical: Connect the positive thermocouple extension wire to the positive thermocouple

wire and the negative extension wire to the negative thermocouple wire.

TYPE J - The positive element is magnetic. It has a lower resistance in ohms per foot than

the negative element in the same wire gauge.

TYPE K - The negative element is slightly magnetic. It has a lower resistance in ohms per

foot than the positive element in the same wire gauge.

TYPE E - The negative element has a lower resistance in ohms per foot than the positive

element for the same wire gauge.

TYPE T -The positive element is copper in appearance. It has a lower resistance per foot in

ohms than the negative element of the same wire gauge.

TYPE R or S -The negative element is softer. The positive element has a lower resistance in

ohms per foot than the negative element of the same wire gauge.

TYPE N -The positive element has a higher resistance in ohms per foot than the negative

element of the same wire gauge.

OPERATION:

The temperature of the connection head should be kept at ambient temperature if possible to

avoid errors due to temperature gradient. The maximum recommended temperature at the

terminal block is 400F.

XII. Explain Measuring sensor mechanism of thermocouple?

One particular advantage of thermocouples is that the sensing elements themselves are very

small, allowing thermocouples to be inserted into very small spaces and to respond to rapidly

changing temperatures. The electrical nature of the process means that the circuitry for

reading the thermocouple output can be remote from the sensor itself. Note that

thermocouple effects will be encountered wherever one metallic conductor meets another, so

that temperature differences along circuit boards can also give rise to voltages which are

comparable with the output from thermocouples. The resistance to the flow of electricity in

metallic materials varies with temperature. This can be used to good effect in platinum

resistance detectors. Platinum is particularly stable both electrically and mechanically and is

also stable with respect to time, producing a relatively linear change in resistance versus

temperature.

Because the output resistance change to temperature is relatively small, it follows that lead

lengths and resistances are therefore important features. In general when lead lengths are

short, or can be considered as an acceptable additive content, two wire configuration is

sufficient.

Three wire is the most commonly used and unless otherwise specified is supplied as

standard, the third wire is the compensator for lead length and providing that all three wire

have equal resistance, compensates for any ZERO or SPAN errors. (Not true for all bridges).

Four wire provides for high precision and is recommended for use with Zener Barriers.

XIII. What are the precautions while using thermocouple?

If operating at high temperatures, check the specifications of the probe insulation.

It takes up to 5 s for the outputs to turn ON after the power supply is turned ON. Take this

time into consideration.

Connection: Many measurement errors are caused by unintentional junctions. Remember that

any junction of two different metals will cause a junction. If you need to increase the length

of the leads from your thermocouple, you must use the correct type of thermocouple

extension wire.

To minimize thermal loading and improve response times, thermocouples are often made of

thin wire. It is always a good precaution to measure the resistance of your thermocouple

before use.

Das könnte Ihnen auch gefallen

- RTD and Thermocouple SensorsDokument4 SeitenRTD and Thermocouple SensorsCss GaneshNoch keine Bewertungen

- Experiment: - 1: AIM: To Calibrate and Measure Temperature Using Thermocouple. 1. ThermocoupleDokument59 SeitenExperiment: - 1: AIM: To Calibrate and Measure Temperature Using Thermocouple. 1. Thermocouplejasmin rachhadiyaNoch keine Bewertungen

- PC Lab ReportDokument16 SeitenPC Lab ReportHuma Saulat SaulatNoch keine Bewertungen

- Information Desk Ajay SysconDokument8 SeitenInformation Desk Ajay SysconSohel BangiNoch keine Bewertungen

- ME 320 Lab 1Dokument18 SeitenME 320 Lab 1Abhinav GuptaNoch keine Bewertungen

- Assignment 3 TransducerDokument12 SeitenAssignment 3 TransducerFirzan HaraziNoch keine Bewertungen

- Exp 6 Process Measurements TemperatureDokument17 SeitenExp 6 Process Measurements TemperatureHardik AgravattNoch keine Bewertungen

- Thermo Exp 2Dokument9 SeitenThermo Exp 2basim gohdarNoch keine Bewertungen

- Chapter 2 TemperatureDokument22 SeitenChapter 2 Temperaturetanzil10Noch keine Bewertungen

- Discuss The Procedure of Measurement of Temperature Using Thermocouple, State The Name of The Apparatus For The Experiment With A Neat SketchDokument4 SeitenDiscuss The Procedure of Measurement of Temperature Using Thermocouple, State The Name of The Apparatus For The Experiment With A Neat SketchDiptesh SojitraNoch keine Bewertungen

- Exp5 ThermocoupleDokument9 SeitenExp5 ThermocoupleMuhammad EsleemNoch keine Bewertungen

- Experiment 04Dokument14 SeitenExperiment 04Somnath BiswalNoch keine Bewertungen

- Temperature MeasurementDokument42 SeitenTemperature MeasurementjimsistiNoch keine Bewertungen

- LVDT RTDDokument7 SeitenLVDT RTDAjit PatraNoch keine Bewertungen

- RDT TEMPERATURE TRAINER ManualDokument7 SeitenRDT TEMPERATURE TRAINER ManualSHANKARNoch keine Bewertungen

- Experiment-01: Aim: Measurement of Temperature Using Suitable Sensor. Competency / SkillsDokument26 SeitenExperiment-01: Aim: Measurement of Temperature Using Suitable Sensor. Competency / SkillsAnsari TahoorNoch keine Bewertungen

- ThermocoupleDokument27 SeitenThermocoupleLester MarquezNoch keine Bewertungen

- Working Principle of Thermocouple.Dokument9 SeitenWorking Principle of Thermocouple.Akshat ChitnisNoch keine Bewertungen

- Temperature MeasurementsDokument10 SeitenTemperature MeasurementsAhmed KamelNoch keine Bewertungen

- Lab Report ThermocoupleDokument8 SeitenLab Report ThermocoupleKhalidIqbal100% (2)

- Emi Lab Sem V (Ece) Experiment No.: 1Dokument19 SeitenEmi Lab Sem V (Ece) Experiment No.: 1neha sharmaNoch keine Bewertungen

- Thermocouple TheoryDokument6 SeitenThermocouple TheorySamuël VaillancourtNoch keine Bewertungen

- Engineering Physics Minor ProjectDokument9 SeitenEngineering Physics Minor ProjectSaketh ChintamaneniNoch keine Bewertungen

- Above 500 Degrees C A PyrometerDokument6 SeitenAbove 500 Degrees C A PyrometerCharlie Licup100% (2)

- Exp 4 ThermocoupleDokument6 SeitenExp 4 ThermocoupleGnanaVelNoch keine Bewertungen

- CLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementDokument9 SeitenCLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementSiti Hajar MohamedNoch keine Bewertungen

- Thermocouple NotesDokument5 SeitenThermocouple NotesJane Marek100% (1)

- Exp 4 Thermocouple PDFDokument6 SeitenExp 4 Thermocouple PDFbd9051Noch keine Bewertungen

- Itc 90Dokument24 SeitenItc 90saravananNoch keine Bewertungen

- ME6504 - Metrology & Measurements Unit 5 - Measurement of Power, Flow & TemperatureDokument40 SeitenME6504 - Metrology & Measurements Unit 5 - Measurement of Power, Flow & TemperaturearunpdcNoch keine Bewertungen

- Thermistor LED Lamp - Class 12 Physics Investigatory Project Report - Free PDF DownloadDokument20 SeitenThermistor LED Lamp - Class 12 Physics Investigatory Project Report - Free PDF Downloado díasNoch keine Bewertungen

- Assignment2 For Che 352 Class-AsuDokument16 SeitenAssignment2 For Che 352 Class-AsuManu Kumar0% (1)

- ThermometersDokument7 SeitenThermometersChinthaka WeerasingheNoch keine Bewertungen

- Industrial VariablesDokument59 SeitenIndustrial VariablesMuhamad RidzwanNoch keine Bewertungen

- Wollo University Kombolcha Institute of Technology Chemical Engineering DepartmentDokument39 SeitenWollo University Kombolcha Institute of Technology Chemical Engineering Departmentየነበር ነበር በነበርNoch keine Bewertungen

- Lec One Sensors-1Dokument26 SeitenLec One Sensors-1Basma EltanekhyNoch keine Bewertungen

- Instrumentation Basics - 04 - Temperature MeasurementDokument43 SeitenInstrumentation Basics - 04 - Temperature MeasurementAhmad HamoudaNoch keine Bewertungen

- Experiment-15 Aim: - Study and Use Various Temperature Sensing Elements. Apparatus UsedDokument4 SeitenExperiment-15 Aim: - Study and Use Various Temperature Sensing Elements. Apparatus UsedHem DaveNoch keine Bewertungen

- Temperature MeasuremenntDokument25 SeitenTemperature MeasuremenntJan Edward L. SuarezNoch keine Bewertungen

- Instrumentation Training Tutorial Part2Dokument25 SeitenInstrumentation Training Tutorial Part2Gary8100% (1)

- This Work Is Prepared By:: Jasim Mohammed MehdiDokument12 SeitenThis Work Is Prepared By:: Jasim Mohammed MehdiJasim Al-rubayieNoch keine Bewertungen

- A Project Report On Temperature MeasurementDokument29 SeitenA Project Report On Temperature MeasurementPankaj0% (2)

- Resistance Temperature Detector: SensorsDokument10 SeitenResistance Temperature Detector: SensorsAlje GapazNoch keine Bewertungen

- RTD and ThermocouplesDokument12 SeitenRTD and Thermocouplesashutosh_katti5523100% (1)

- Temperature MeasurementDokument14 SeitenTemperature Measurementarkadjyothiprakash100% (1)

- 5 - Tempreture MEASURING DEVICESDokument35 Seiten5 - Tempreture MEASURING DEVICESAli MoustafaNoch keine Bewertungen

- Thermocouple PDFDokument5 SeitenThermocouple PDFjayesh maliNoch keine Bewertungen

- Measurement of TemperatureDokument24 SeitenMeasurement of Temperaturehadeed shaikhNoch keine Bewertungen

- Electrical Measurment and Instrumentation Mcqs CH 2Dokument16 SeitenElectrical Measurment and Instrumentation Mcqs CH 2kibrom atsbhaNoch keine Bewertungen

- Electric Bells and All About Them A Practical Book for Practical MenVon EverandElectric Bells and All About Them A Practical Book for Practical MenNoch keine Bewertungen

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Induction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryVon EverandInduction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryBewertung: 5 von 5 Sternen5/5 (2)

- Handbook of Mechanical and Materials EngineeringVon EverandHandbook of Mechanical and Materials EngineeringBewertung: 5 von 5 Sternen5/5 (4)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaVon EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNoch keine Bewertungen

- Michelson Interferometer ArticleDokument3 SeitenMichelson Interferometer ArticleWILLIAM IMMANUEL MARTINNoch keine Bewertungen

- Simplified Feynman DiagramsDokument23 SeitenSimplified Feynman Diagramssid_senadheera50% (2)

- Control of STATCOM by Using Optimal Reactive Power Flow SolutionsDokument5 SeitenControl of STATCOM by Using Optimal Reactive Power Flow Solutionsshiks16Noch keine Bewertungen

- Kinematics of MachineDokument4 SeitenKinematics of MachineSumit KambleNoch keine Bewertungen

- Physical Science: Quarter 1 - Module 1 Week 1: Formation of Elements Week 2: Polarity of MoleculesDokument19 SeitenPhysical Science: Quarter 1 - Module 1 Week 1: Formation of Elements Week 2: Polarity of MoleculesMarie Grace Eguac Taghap100% (1)

- Three Phase Transformer TrainerDokument20 SeitenThree Phase Transformer TrainerHaroon AsadNoch keine Bewertungen

- Electromagnetic Waves: JEE-PhysicsDokument10 SeitenElectromagnetic Waves: JEE-PhysicsManas kumarNoch keine Bewertungen

- Solid StateDokument49 SeitenSolid Statekishangopi123Noch keine Bewertungen

- Worksheet On Atomic Structure, STD 8thDokument3 SeitenWorksheet On Atomic Structure, STD 8thArshad KhanNoch keine Bewertungen

- Module HEAT TRANSFER UCLDokument4 SeitenModule HEAT TRANSFER UCLIrene KoronakiNoch keine Bewertungen

- ACDCModuleUsersGuide PDFDokument366 SeitenACDCModuleUsersGuide PDFRahman EjazNoch keine Bewertungen

- Sensor Lect4Dokument23 SeitenSensor Lect4morton1472Noch keine Bewertungen

- Design of 765kv Transmission LineDokument10 SeitenDesign of 765kv Transmission LineNaveen SabbavarapuNoch keine Bewertungen

- Springs and The Balance WheelDokument2 SeitenSprings and The Balance WheelNiels Kjaer-PedersenNoch keine Bewertungen

- Diffraction and Interference in QEDDokument7 SeitenDiffraction and Interference in QEDYashNoch keine Bewertungen

- Lecture 23 Oblique Incidence and ReflectionDokument21 SeitenLecture 23 Oblique Incidence and Reflectionvaldesc_tolNoch keine Bewertungen

- The Anatomy of A WaveDokument4 SeitenThe Anatomy of A WaveDan BautistaNoch keine Bewertungen

- Gujarat Technological UniversityDokument2 SeitenGujarat Technological UniversitydharmeshNoch keine Bewertungen

- Combustion POTTERDokument52 SeitenCombustion POTTERmarzinus100% (2)

- Mock Test Paper NeetDokument28 SeitenMock Test Paper NeetmayankNoch keine Bewertungen

- Kittel4 4Dokument3 SeitenKittel4 4Gilberto PereiraNoch keine Bewertungen

- Tuned Mass Damper Report PDFDokument21 SeitenTuned Mass Damper Report PDFRitu t Raj100% (1)

- Grade 7 Daily Lesson Plan: I. ObjectivesDokument3 SeitenGrade 7 Daily Lesson Plan: I. ObjectivesJanecil A. BonzaNoch keine Bewertungen

- Introduction To MicrosDokument105 SeitenIntroduction To MicroschopkarNoch keine Bewertungen

- Henry Su2 HBXPTDokument34 SeitenHenry Su2 HBXPTHenry MongeNoch keine Bewertungen

- 02 Some Exercises With SolutionsDokument6 Seiten02 Some Exercises With SolutionsANGIE PAOLA RODELO PANZANoch keine Bewertungen

- 3rd PT Science 6Dokument14 Seiten3rd PT Science 6Dhines CBNoch keine Bewertungen

- Shaft Calculation BaseDokument40 SeitenShaft Calculation BaseObaciuIonel100% (1)

- Robert Caldwell - Dark Energy CosmologyDokument21 SeitenRobert Caldwell - Dark Energy CosmologyLopmazNoch keine Bewertungen