Beruflich Dokumente

Kultur Dokumente

Cwa 46603

Hochgeladen von

SreenivasCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cwa 46603

Hochgeladen von

SreenivasCopyright:

Verfügbare Formate

Mechanical Training System

Courseware Sample

36737-F0

A

MECHANICAL TRAINING SYSTEM

COURSEWARE SAMPLE

by

the Staff

of

Lab-Volt Ltd.

Copyright 2006 Lab-Volt Ltd.

All rights reserved. No part of this publication may be reproduced,

in any form or by any means, without the prior written permission

of Lab-Volt Ltd.

Printed in Canada

January 2007

III

Table of Contents

Courseware Outline

Introduction to Mechanical Drive Systems Job Sheets . . . . . . . . . . . . . . . V

Introduction to Mechanical Drive Systems Work Orders . . . . . . . . . . . . . VI

Sample Job Sheet Extracted from Introduction to Mechanical Drive Systems

Job Sheet 8 Shaft Alignment and Rigid Couplings . . . . . . . . . . . . . . . . . . 3

Sample Work Order Extracted from Introduction to Mechanical Drive Systems

Work Order 8 Shaft Alignment and Rigid Couplings . . . . . . . . . . . . . . . . . 13

Other Sample Extracted from Introduction to Mechanical Drive Systems

Post-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

IV

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS JOB SHEETS

Courseware Outline

V

Job Sheet 1 Introduction to the Mechanical Training System

Job Sheet 2 Safety Procedures

Job Sheet 3 Key and Setscrew Fasteners

Job Sheet 4 Speed and Torque Measurements

Job Sheet 5 Efficiency

Job Sheet 6 Shafts and Pillow Block Bearings

Job Sheet 7 Shaft Alignment and Flexible Couplings

Job Sheet 8 Shaft Alignment and Rigid Couplings

Job Sheet 9 Motor Soft Foot Detection and Correction

Appendix A Unit Conversion Table

Appendix B Post-Test

We Value Your Opinion!

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS WORK ORDERS

Courseware Outline

VI

Work Order 1 Introduction to the Mechanical Training System

Work Order 2 Safety Procedures

Work Order 3 Key and Setscrew Fasteners

Work Order 4 Speed and Torque Measurements

Work Order 5 Efficiency

Work Order 6 Shafts and Pillow Block Bearings

Work Order 7 Shaft Alignment and Flexible Couplings

Work Order 8 Shaft Alignment and Rigid Couplings

Work Order 9 Motor Soft Foot Detection and Correction

Appendices A Equipment Utilization Chart

B Components of the Universal Base Assembly

C Components of the Motor Package

D Components of the Test and Measurement Package

E Components of the Tool Box Component Package

F Components of the Couplings Shafts Panel

G Components of the Pillow Block Bearings Panel

H Unit Conversion Table

I Safety Procedures

J Lockout/Tagout Procedure

K Start-up Procedure for the Constant Speed Motor

We Value Your Opinion!

Sample Job Sheet

Extracted from

Introduction to

Mechanical Drive Systems

8

SHAFT ALIGNMENT AND RIGID COUPLINGS

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS 3

Rigid shaft couplings are used to join lengths of shaft of equal or different diameter.

The main use is to extend the length of a shaft. It is rarely used to connect a prime

mover directly to a load. A rigid sleeve coupling is shown in Figure 8-1.

Figure 8-1. Rigid coupling.

Unlike flexible shaft couplings, rigid shaft couplings do not allow errors in alignment,

which may cause premature failure of bearings or shafts.

Rigid shaft couplings are installed after the shafts have been aligned. A straightedge

and feeler gauge are used to measure and adjust parallel and vertical alignment.

4 INTRODUCTION TO MECHANICAL DRIVE SYSTEMS

8

SHAFT ALIGNMENT AND RIGID COUPLINGS

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS 5

OBJECTIVES

In this job, you will perform a shaft alignment and install a rigid coupling.

EQUIPMENT REQUIRED

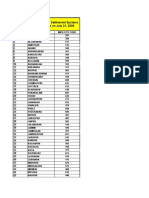

C Universal Base Assembly, model 46603

C Motor Package, model 46609

C Couplings Shafts Panel, model 46610

C Pillow Block Bearings Panel, model 46611

C Test/Measurement Package, model 46630

C Tool Box Component Package, model 46631

SAFETY PROCEDURES

Before proceeding with this job, complete the following check list.

G You are wearing safety glasses.

G You are wearing safety shoes.

G You are not wearing anything that might get caught such as a tie, jewelry, or

loose clothes.

G If your hair is long, tie it out of the way.

G The working area is clean and free of oil.

G The floor is not wet.

G Your sleeves are rolled up.

PROCEDURE

Lockout/Tagout Procedure

G 1. Set the disconnecting switch to OFF.

G 2. Write your name on a tag, and install it in the lockout device.

SHAFT ALIGNMENT AND RIGID COUPLINGS

6 INTRODUCTION TO MECHANICAL DRIVE SYSTEMS

G 3. Lock the disconnecting switch with the lockout device.

G 4. Lock the lockout device with your padlock.

G 5. Ask the instructor and each teammate to install their own padlocks in the

lockout device.

Note: The universal base should be set up from Job Sheet 7.

Repeat Job Sheet 7 if necessary.

Universal Base Setup

G 6. Loosen the pillow block bearing setscrews and slide the shaft away from the

motor.

G 7. Remove the flexible jaw coupling halves, insert, and keys from the two

shafts. Keep the rest of the setup intact.

G 8. Slide the sleeve coupling on the shaft supported by the pillow block

bearings.

Vertical Angular Alignment

G 9. Adjust the gap between the ends of the shafts to approximately 0.125 in.

G 10. Line up the shaft keyseats and position them at the 9-o'clock position.

G 11. Lay a straightedge on the top of the shafts and measure the gap at two

points using a feeler gauge as shown in Figure 8-2. Mark the position of the

two points with a soapstone marker.

SHAFT ALIGNMENT AND RIGID COUPLINGS

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS 7

Figure 8-2. Vertical angular alignment.

Gap at point 1:

Gap at point 2:

G 12. Calculate the vertical angular misalignment by subtracting the smaller gap

from the larger. Note the position at which the larger gap was measured.

Vertical angular misalignment:

Position of the larger gap:

G 13. Record the distance between the measurement points (soapstone marks)

along the shaft.

Distance between measurement points:

G 14. Calculate the shim ratio using the following formula:

where S

r

is the shim ratio;

L

1

is the distance between the slots of the motor base, in inches;

L

2

is the distance between the measurements points in inches.

Shim ratio:

SHAFT ALIGNMENT AND RIGID COUPLINGS

8 INTRODUCTION TO MECHANICAL DRIVE SYSTEMS

G 15. Calculate the required shim thickness using the following formula:

where S

t

is the shim thickness in inches;

S

r

is the shim ratio;

V

am

is the vertical angular misalignment in inches.

Shim thickness:

G 16. Determine if the front or the rear of the motor must be shimmed.

Side to be shimmed:

G 17. Loosen the screws on the determined motor base side and install the shims.

Note: An equal thickness of shims must be installed under the

two front or rear motor screws to raise it evenly.

G 18. Measure the gaps at point 1 and 2, and calculate the vertical angular

misalignment.

Gap at point 1:

Gap at point 2:

Vertical angular misalignment:

Vertical Parallel Alignment

G 19. Measure the gap at one point between the shafts, using a straightedge and

a feeler gauge.

G 20. Add shims with a total thickness equivalent to the gap under the four screws

of the motor plate.

Horizontal Alignment

G 21. Line up the shaft keyseats and position them at the 12-o'clock position.

G 22. Lay a straightedge on the side of the shafts at the 3-o'clock position.

SHAFT ALIGNMENT AND RIGID COUPLINGS

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS 9

G 23. Loosen the four motor screws, and adjust the motor position until there is no

gap between the straightedge and the shafts.

G 24. Tighten the motor screws.

Sleeve Coupling Installation

G 25. Install a key on both shafts. Make sure they are in line with the end of each

shaft.

G 26. Slide the sleeve coupling along both shafts and make sure there is no

interference at any point.

G 27. Tighten the coupling setscrews on the keys.

G 28. Ask the instructor to check your work.

G 29. Disassemble the setup and return the components to the storage location.

Name: Date:

Instructor's approval:

Sample Work Order

Extracted from

Introduction to

Mechanical Drive Systems

8

SHAFT ALIGNMENT AND RIGID COUPLINGS

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS 13

Task: To align two shafts. To install a rigid sleeve coupling.

PROCEDURE

G 1. Perform the Safety Procedures listed in Appendix I.

G 2. Perform the Lockout/Tagout Procedure described in Appendix J.

G 3. What is the main function of a rigid coupling such as the one shown in

Figure 8-1.

Figure 8-1. Rigid coupling.

G 4. Which of rigid or flexible couplings can accomodate the higher degree of

misalignment?

SHAFT ALIGNMENT AND RIGID COUPLINGS

14 INTRODUCTION TO MECHANICAL DRIVE SYSTEMS

G 5. Assemble the setup shown in Figure 4-3.

G 6. Install the flexible coupling on the driven shaft and use a feeler gauge and

a straightedge to measure the parameters required for the alignment as

shown in Figure 8-2.

Figure 8-2. Measurement of a parameter.

Vertical Angular Alignment

G 7. Record the following parameters:

Gap at point 1:

Gap at point 2:

Vertical angular misalignment:

Position of the larger gap:

Distance between measurement points:

Shim ratio:

Shim thickness:

Side to be shimmed:

SHAFT ALIGNMENT AND RIGID COUPLINGS

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS 15

G 8. Instal the shims.

Vertical Parallel Alignment

G 9. Measure the gap between the hubs and record it.

Gap:

G 10. Install the shims.

Horizontal Alignment

G 11. Adjust the motor position.

G 12. Complete the sleeve coupling installation.

G 13. Ask the instructor to check your work.

G 14. Disassemble the setup and return the components to the storage location.

Name: Date:

Instructor's approval:

Other Sample Extracted

from

Introduction to

Mechanical Drive Systems

INTRODUCTION TO MECHANICAL DRIVE SYSTEMS 19

Post-Test

1. What does the meter indicate on the control panel?

a. The voltage at the built-in AC outlet on the side of the control panel

b. The voltage at the built-in AC outlet on the universal base

c. The current delivered at the built-in AC outlet on the universal base

d. The current delivered at the built-in AC outlet on the side of the control panel

2. To which position should the Output Voltage selector be set when using the

constant speed motor on the universal base?

a. Fixed

b. Variable

c. Any position is correct

d. It depends on the use of the motor.

3. What is the use of the emergency button on the Start/Stop push-button station?

a. Controls the motors mounted on the universal base

b. Produces an emergency noise

c. De-energizes the built-in AC outlet on the universal base

d. De-energizes the built-in AC outlet on the side of the control panel

4. Who must install a padlock on the lockout device?

a. Each person involved in the job

b. Only one of the person involved in the job

c. The instructor only

d. It is never mandatory to install a padlock.

5. When should the safety panels be installed?

a. When there is an obvious risk of injury

b. When the constant speed motor is used

c. When asked by the instructor

d. Before any setup is powered

6. What does a photo-reflective tachometer measure?

a. The amount of light reflected by an object

b. The current in a component

c. The voltage in a component

d. The angular velocity of a rotating component

Post-Test (cont'd)

20 INTRODUCTION TO MECHANICAL DRIVE SYSTEMS

7. What is a prony brake used for?

a. Measure the input power of a prime mover

b. Provide a means for applying an adjustable load torque to the output shaft

of a prime mover

c. Brake a motor until it stops completely

d. Measure the current consumed by a motor when it stops

8. Where should a setscrew be tightened on a shaft?

a. Only on a key

b. On the flat surface of the shaft or on a key

c. Directly on the shaft keyseat

d. Preferably on the round portion of the shaft

9. What type(s) of coupling(s) can compensate for slight errors in shaft alignment?

a. Flexible couplings only

b. Rigid and flexible couplings

c. Rigid couplings only

d. Any existing type

10. What are the two basic types of shaft misalignment?

a. Horizontal angular and parallel

b. Angular and linear

c. Parallel and angular

d. Vertical angular and horizontal angular

Das könnte Ihnen auch gefallen

- Chevy Differentials: How to Rebuild the 10- and 12-BoltVon EverandChevy Differentials: How to Rebuild the 10- and 12-BoltBewertung: 5 von 5 Sternen5/5 (8)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- Https 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print PageDokument9 SeitenHttps 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Pagep.motortechNoch keine Bewertungen

- 02 - Camshaft - Install PDFDokument11 Seiten02 - Camshaft - Install PDFNimNoch keine Bewertungen

- 6 SteeringDokument63 Seiten6 SteeringAdrian MotocNoch keine Bewertungen

- Smc-Man-Rack 3606Dokument6 SeitenSmc-Man-Rack 3606LUIZ GUSTAVONoch keine Bewertungen

- Single Bearing Generator Installation Procedures - LeTourneau, Inc.Dokument65 SeitenSingle Bearing Generator Installation Procedures - LeTourneau, Inc.pevare100% (3)

- 5330 New Carriage Drive Motor ReplacementDokument15 Seiten5330 New Carriage Drive Motor ReplacementBrenda ClayNoch keine Bewertungen

- Calibracion InyectoresDokument4 SeitenCalibracion InyectoresWladimir AmaguañaNoch keine Bewertungen

- Repair Instructions - On VehicleDokument112 SeitenRepair Instructions - On Vehiclelonuevo1Noch keine Bewertungen

- Swing Rack - InstallDokument7 SeitenSwing Rack - InstallGilney FreitasNoch keine Bewertungen

- Instalación Piñon PosteriorDokument9 SeitenInstalación Piñon PosteriorFredy QuistialNoch keine Bewertungen

- (OTO-HUI - Com) Rack and Pinion in The Freightliner CascadiasDokument13 Seiten(OTO-HUI - Com) Rack and Pinion in The Freightliner Cascadiaseng_ebrahim_2000Noch keine Bewertungen

- SpreadersDokument13 SeitenSpreadersEdgardo Alfonso Ilabaca Saez100% (1)

- Valve Lash G3408Dokument9 SeitenValve Lash G3408Djebali MouradNoch keine Bewertungen

- Alineacion CatDokument4 SeitenAlineacion CatAndrea Zalamea100% (1)

- 2 & 3 Wheeler Lab ManualDokument36 Seiten2 & 3 Wheeler Lab ManualKarthi100% (1)

- 18SP664 Cambio Actuador TurboDokument6 Seiten18SP664 Cambio Actuador TurboAngel DlsgNoch keine Bewertungen

- Calibre Valvulas MP8 s34-5116Dokument20 SeitenCalibre Valvulas MP8 s34-5116Jose AGNoch keine Bewertungen

- Disassembling The Governor ActuatorDokument8 SeitenDisassembling The Governor ActuatorЕвгений АбрамовNoch keine Bewertungen

- Installation Instructions For Vilter 25972Dokument8 SeitenInstallation Instructions For Vilter 25972jorge castilloNoch keine Bewertungen

- 2003 Nissan Altima 2.5 Serivce Manual PBDokument8 Seiten2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerNoch keine Bewertungen

- Caja Reductora de EngranajeDokument32 SeitenCaja Reductora de EngranajeJesùs AmèsquitaNoch keine Bewertungen

- GM 6t70 UpdatesDokument45 SeitenGM 6t70 UpdatesThePokeOne100% (9)

- Technical Note 3562A XG0NDokument120 SeitenTechnical Note 3562A XG0NEeepsNoch keine Bewertungen

- John Deere X Series H3 ConversionDokument36 SeitenJohn Deere X Series H3 ConversionKKNoch keine Bewertungen

- Crankshaft - InstallDokument7 SeitenCrankshaft - InstallLeonardo PerezNoch keine Bewertungen

- Speed Sensor - AdjustDokument6 SeitenSpeed Sensor - AdjustЕвгений АбрамовNoch keine Bewertungen

- Dezurik Mastergear Manual Actuators: Instruction August 2012Dokument9 SeitenDezurik Mastergear Manual Actuators: Instruction August 2012Charles MutetwaNoch keine Bewertungen

- SM - Volvo g976 Motor GraderDokument21 SeitenSM - Volvo g976 Motor GraderLuan Max100% (2)

- Cylinder Head - Install: Disassembly and AssemblyDokument8 SeitenCylinder Head - Install: Disassembly and Assemblyhocine gherbiNoch keine Bewertungen

- Camshaft TimingDokument8 SeitenCamshaft TimingHarol Ariel Sanchez MezaNoch keine Bewertungen

- Replace Governor ActuatorDokument8 SeitenReplace Governor ActuatorSteven ManuputtyNoch keine Bewertungen

- MBE4000 EGR Connector Pipe InstallationDokument6 SeitenMBE4000 EGR Connector Pipe InstallationАндрейNoch keine Bewertungen

- Pa Dal MountingDokument2 SeitenPa Dal MountingStephen AmbNoch keine Bewertungen

- Arbol de Levas Como MedirloDokument9 SeitenArbol de Levas Como Medirloariel avalosNoch keine Bewertungen

- 3516B Generator Set Engine - Fuel Injector Adjustment - SIS - CATERPILLARDokument5 Seiten3516B Generator Set Engine - Fuel Injector Adjustment - SIS - CATERPILLARpevare78% (9)

- Repair Instructions - Off Vehicle PDFDokument37 SeitenRepair Instructions - Off Vehicle PDFFernando OrtizNoch keine Bewertungen

- Direccion Asistida Mazda PDFDokument56 SeitenDireccion Asistida Mazda PDFGabriel Balcazar100% (1)

- Testing and AdjustingDokument20 SeitenTesting and AdjustingAlexandra Yupanqui sarmiento100% (2)

- GORBEL Freestanding Motorized Jib Crane - ManualDokument18 SeitenGORBEL Freestanding Motorized Jib Crane - Manualaiyubi2Noch keine Bewertungen

- Clutch ManualDokument16 SeitenClutch ManualCO BDNoch keine Bewertungen

- Unit Injector Synchronization - Adjust: 3114, 3116 and 3126 Industrial, Marine and Generator Set EnginesDokument6 SeitenUnit Injector Synchronization - Adjust: 3114, 3116 and 3126 Industrial, Marine and Generator Set EnginesChristian Vinueza VillavicencioNoch keine Bewertungen

- Sturmey Archer Hub TechnicalDokument8 SeitenSturmey Archer Hub TechnicalbobnunleyNoch keine Bewertungen

- Subaru - Impreza - Workshop Manual - 1999 - 2002Dokument8.373 SeitenSubaru - Impreza - Workshop Manual - 1999 - 2002bart3omiej3boguszewiNoch keine Bewertungen

- Installation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)Dokument23 SeitenInstallation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)aliNoch keine Bewertungen

- Remove Transmission (Direct Drive)Dokument51 SeitenRemove Transmission (Direct Drive)Sayutie_Anak_A_2175100% (2)

- WEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishDokument2 SeitenWEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishadalcomjesusNoch keine Bewertungen

- Sheppard - SteeringDokument40 SeitenSheppard - SteeringTony MelendezNoch keine Bewertungen

- Steering Purge 14MDokument3 SeitenSteering Purge 14MvaroNoch keine Bewertungen

- Hyponic InstallationDokument7 SeitenHyponic InstallationDeMen NguyenNoch keine Bewertungen

- Clutch ManualDokument29 SeitenClutch ManualVarun KoriviNoch keine Bewertungen

- Alignment of TwoDokument15 SeitenAlignment of TwoquintanacalzadillasjaimeNoch keine Bewertungen

- SDS MK4i Swerve Modules Assembly GuideDokument16 SeitenSDS MK4i Swerve Modules Assembly GuideIbraheem HaSsanNoch keine Bewertungen

- Installation InstructionsDokument5 SeitenInstallation InstructionsLeonel PaseroNoch keine Bewertungen

- Ajuste Del EngramDokument6 SeitenAjuste Del EngramLuis OcampoNoch keine Bewertungen

- Tiras de Desgaste RielDokument6 SeitenTiras de Desgaste RielCristobal Gutierrez CarrascoNoch keine Bewertungen

- Special Features of The f5r 740 EngineDokument146 SeitenSpecial Features of The f5r 740 EngineBen Van Der MerweNoch keine Bewertungen

- Assembly Compression AirDokument3 SeitenAssembly Compression Airaqshal candraNoch keine Bewertungen

- Small Block Chevrolet: Stock and High-Performance RebuildsVon EverandSmall Block Chevrolet: Stock and High-Performance RebuildsBewertung: 4 von 5 Sternen4/5 (6)

- NLC Recruitment 2017Dokument8 SeitenNLC Recruitment 2017Kshitija100% (1)

- Receipt For Payment of Bills/Demand Notes. This Receipt Is Generated From BSNL PortalDokument1 SeiteReceipt For Payment of Bills/Demand Notes. This Receipt Is Generated From BSNL PortalSreenivas100% (1)

- 26 3 PDFDokument1 Seite26 3 PDFPrasannaBhagavathNoch keine Bewertungen

- March 2015Dokument1 SeiteMarch 2015SreenivasNoch keine Bewertungen

- Nlcil Detailed Advt032017Dokument1 SeiteNlcil Detailed Advt032017SreenivasNoch keine Bewertungen

- BSNL Landline Bill - Oct'13Dokument1 SeiteBSNL Landline Bill - Oct'13jkfunmaityNoch keine Bewertungen

- Bank CodesDokument2.094 SeitenBank CodeskoinsuriNoch keine Bewertungen

- Instruction Candidates Mech PDFDokument2 SeitenInstruction Candidates Mech PDFSreenivasNoch keine Bewertungen

- Nlcil Detailed Advt032017Dokument7 SeitenNlcil Detailed Advt032017SreenivasNoch keine Bewertungen

- Fund Factsheet For NovDokument131 SeitenFund Factsheet For NovSreenivasNoch keine Bewertungen

- Telugu Brihat Parasara Hora Sastra BPHS Chapters 1 97 (1) 46702322Dokument160 SeitenTelugu Brihat Parasara Hora Sastra BPHS Chapters 1 97 (1) 46702322రఘు శర్మ రూపాకుల100% (1)

- 17th Exam ProspectusDokument21 Seiten17th Exam ProspectusNavin ShuklaNoch keine Bewertungen

- NLC Recruitment 2017Dokument8 SeitenNLC Recruitment 2017Kshitija100% (1)

- Ecs-Direct Debit Mandate FormDokument2 SeitenEcs-Direct Debit Mandate Formrndsoft100% (1)

- EA4ADokument3 SeitenEA4ASreenivasNoch keine Bewertungen

- PreheatingDokument1 SeitePreheatingSreenivasNoch keine Bewertungen

- Form 15GDokument2 SeitenForm 15GSrinivasa RaghavanNoch keine Bewertungen

- 3ADokument16 Seiten3ASreenivasNoch keine Bewertungen

- 4a KeyDokument10 Seiten4a KeySreenivasNoch keine Bewertungen

- Products - Alloys - Carbon SteelsDokument3 SeitenProducts - Alloys - Carbon SteelsSreenivasNoch keine Bewertungen

- 1.2 Basics of EnergyDokument7 Seiten1.2 Basics of Energyanilchaudhari2006Noch keine Bewertungen

- 1.2 Basics of EnergyDokument7 Seiten1.2 Basics of Energyanilchaudhari2006Noch keine Bewertungen

- Help FileDokument3 SeitenHelp FileSharma BharatNoch keine Bewertungen

- Alloying and Their PropertiesDokument6 SeitenAlloying and Their PropertiesWaqar MansoorNoch keine Bewertungen

- 2 ADokument11 Seiten2 ASreenivasNoch keine Bewertungen

- CH 14 CarbonandAlloySteelsDokument42 SeitenCH 14 CarbonandAlloySteelsdarwin_hua100% (1)

- Beeindia - in Energy Managers Auditors Documents Exam Advt.15thExamDokument1 SeiteBeeindia - in Energy Managers Auditors Documents Exam Advt.15thExamBrijraj PandeyNoch keine Bewertungen

- Coal Sieving ProcedureDokument3 SeitenCoal Sieving ProcedureMiguel PalominoNoch keine Bewertungen

- Re20375 2006-12Dokument4 SeitenRe20375 2006-12atifkhushnoodNoch keine Bewertungen

- Calculation of Pulverizer Minimum Primary Airflow and Proper Air To Fuel RelationshipDokument2 SeitenCalculation of Pulverizer Minimum Primary Airflow and Proper Air To Fuel Relationshipank_mehraNoch keine Bewertungen

- Maps and Damos ID For EDC16 VAG ECUDokument7 SeitenMaps and Damos ID For EDC16 VAG ECUGuler RahimNoch keine Bewertungen

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Dokument2 SeitenDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenNoch keine Bewertungen

- CM6 Combined 2013Dokument154 SeitenCM6 Combined 2013مسعد مرزوقىNoch keine Bewertungen

- RHS Columnuns Embedded in RC ResearchDokument29 SeitenRHS Columnuns Embedded in RC ResearchErnie Ernie100% (1)

- Gas Technology Institute PresentationDokument14 SeitenGas Technology Institute PresentationAris KancilNoch keine Bewertungen

- Annex 1 - Air Dryer Duct DRG List - 140717Dokument1 SeiteAnnex 1 - Air Dryer Duct DRG List - 140717vemanreddy29Noch keine Bewertungen

- Electrical ContactorDokument14 SeitenElectrical ContactorRaphael212219Noch keine Bewertungen

- SamplesDokument14 SeitenSamplesSanjayNoch keine Bewertungen

- AC DC AcDokument3 SeitenAC DC AcPhani KumarNoch keine Bewertungen

- Conveyor Belt: Heavy Duty RubberDokument5 SeitenConveyor Belt: Heavy Duty RubberHeidrahNoch keine Bewertungen

- Design and Development of Vibratory Cockles Grading MachineDokument23 SeitenDesign and Development of Vibratory Cockles Grading MachinehalizaNoch keine Bewertungen

- UNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmDokument2 SeitenUNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmArjun BhargavaNoch keine Bewertungen

- Transmission and DistributionDokument10 SeitenTransmission and Distributionprabhjot singh186% (21)

- 320d WiringDokument2 Seiten320d WiringMohamed Harb100% (5)

- Flapper Diverter Valve BrochureDokument4 SeitenFlapper Diverter Valve BrochureRicardo Ramírez ZapataNoch keine Bewertungen

- Catalogo. Aparatos de Maniobra y Proteccion - Sirius. Siemens PDFDokument52 SeitenCatalogo. Aparatos de Maniobra y Proteccion - Sirius. Siemens PDFPedro MalpicaNoch keine Bewertungen

- 802 OM 4-InspDokument12 Seiten802 OM 4-InspGabriel vieiraNoch keine Bewertungen

- GPU Programming in MATLABDokument6 SeitenGPU Programming in MATLABkhaardNoch keine Bewertungen

- Computational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)Dokument441 SeitenComputational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)EisernesHerzNoch keine Bewertungen

- FP CLOCK - csproj.FileListAbsoluteDokument14 SeitenFP CLOCK - csproj.FileListAbsolutePhi Huỳnh NgôNoch keine Bewertungen

- HTML Meta TagsDokument4 SeitenHTML Meta Tagsmamcapiral25Noch keine Bewertungen

- Appendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1Dokument3 SeitenAppendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1gonzalesNoch keine Bewertungen

- Databook Continental Agri 2006 PDFDokument0 SeitenDatabook Continental Agri 2006 PDFdanilo3073Noch keine Bewertungen

- Notificatio N (Rese Rvation) Gove Rnment: A Cu) UTDokument1 SeiteNotificatio N (Rese Rvation) Gove Rnment: A Cu) UT122-Ayush Kumar ParganihaNoch keine Bewertungen

- Ericsson Essentials Health & Safety Plan Sample: Good For Smaller Projects and Bid QualificationsDokument18 SeitenEricsson Essentials Health & Safety Plan Sample: Good For Smaller Projects and Bid QualificationsmohammedelrabeiNoch keine Bewertungen

- 2014 - Solved Problems in Facility PlanningDokument135 Seiten2014 - Solved Problems in Facility Planninghshshdhd86% (7)

- NPT Thread Dimensions PDFDokument1 SeiteNPT Thread Dimensions PDFRamnandan MahtoNoch keine Bewertungen

- Electrical Model of Thermal Power PlantDokument81 SeitenElectrical Model of Thermal Power PlantMahesh KumbharNoch keine Bewertungen

- The Effects of Dissolved Sodium Chloride (Nacl) On Well Injectivity During Co2 Storage Into Saline AquifersDokument20 SeitenThe Effects of Dissolved Sodium Chloride (Nacl) On Well Injectivity During Co2 Storage Into Saline AquifersMuhammad FatchurroziNoch keine Bewertungen

- Veritas™ Volume Manager Administrator's Guide Solaris - VXVM - Admin - 51sp1 - SolDokument614 SeitenVeritas™ Volume Manager Administrator's Guide Solaris - VXVM - Admin - 51sp1 - Solakkati123Noch keine Bewertungen