Beruflich Dokumente

Kultur Dokumente

POWERGRID Experience On Life Assessment of EHV Current Transformers

Hochgeladen von

Om Bhaskar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

70 Ansichten7 SeitenThis paper investigates the effective diagnostic techniques

for assessing the condition of insulation in aged Current

Transformers.

Originaltitel

POWERGRID Experience on Life Assessment of EHV Current Transformers

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis paper investigates the effective diagnostic techniques

for assessing the condition of insulation in aged Current

Transformers.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

70 Ansichten7 SeitenPOWERGRID Experience On Life Assessment of EHV Current Transformers

Hochgeladen von

Om BhaskarThis paper investigates the effective diagnostic techniques

for assessing the condition of insulation in aged Current

Transformers.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

*R.K.

Tyagi, Manager(OS), Power Grid India Corporation of India Limited, India

Email:tyagir@powergridindia.com

POWERGRID Experience on Life Assessment of

EHV Current Transformers

R.K.Tyagi N.S.Sodha R.D.Kakkar

Manager(OS) Dy.Geneal Manager(OS) Executive Director(OS)

POWER GRID Corporation of India Limited, New Delhi

(India)

Synopsis

POWERGRID as Central Transmission Utility (CTU) in

India is operating about 40,000 ckt. kms of EHV

Transmission Lines and handling nearly 40% of Indias

total Power requirement which is being controlled

through 68 number EHV Substations spread throughout

the country. Presently about 3000 nos. EHV Current

Transformers of various makes & designs are under

operation. Current Transformers (CTs) are generally

considered a reliable piece of equipment and failure rate

is generally lower compared to other switchyard

equipments. Condition Monitoring checks on Current

Transformers, as followed in POWERGRID, include

measurement of Capacitance and Dissipation Factor,

Insulation Resistance, Thermovision Scanning and very

recently Dissolved Gas Analysis of insulating oil has also

been introduced.

This paper investigates the effective diagnostic techniques

for assessing the condition of insulation in aged Current

Transformers. A detailed Case Study on Life Assessment

tests carried out on CTs of three makes is presented in this

paper. Condition Monitoring tests adopted have revealed

the actual condition of CT insulation. CTs are now being

monitored properly for Oil/N2 gas leakages/pressures. In

few CTs where N2 gas had leaked, degradation of

Insulation was indicated by tests. Details of these tests

conducted with adopted diagnostic techniques and

benefits derived by POWERGRID are also discussed in

the paper.

INTRODUCTION

The age profile of EHV class CT in POWERGRID

network is in the range of 12-18 years. During last six

years, few CT failures attributable to primary insulation

failures were encountered. In all the cases, CT failures

occurred without any advance distress signal/alarm. All

CT failures were analyzed in detail and as a preventive

measure, a need was felt to adopt new techniques for

condition monitoring of CTs in service as preventive/

corrective measures.

Paper impregnated with oil is widely used for CT

windings. The oil/paper insulation degrades with time,

and this process depends on thermal, electrical and other

complex chemical reactions within the Equipment. The

ageing process of oil/paper insulating systems is very

complex and poses problems in their true and timely

identification. Due to ageing of insulation, dielectric

losses increase which are reflected as change in

dissipation factor (Tan delta). Other factors like

Capacitance value, moisture content (paper and oil) also

indicate the extent of ageing of the insulation. Sometimes

due to cavities/ voids in primary insulation, localized

21, rue d'Artois, F-75008 Paris

http://www.cigre.org

Session 2002

CIGR

23-304

Partial discharges cause carbonization, which may also

lead to pre-mature CT failures. The rate of Insulation

Ageing is directly proportional to the moisture content in

the paper/oil and presence of the oxygen markedly

increases this process by 2.5 to 10 times the normal

ageing rate.

LIFE ASSESMENT TECHNIQUES

A variety of electrical and chemical techniques are

available for testing insulation of CTs. Some of these are

applicable for assessing the condition of the insulation.

Techniques such as measurement of Insulation

Resistance, Dielectric Dissipation factor/ loss factor (Tan

Delta) and Capacitance Measurement are generally used

by Power Utilities since many years. After failure of few

CTs, tests like Dissolved Gas Analysis of oil,

Thermovision scanning etc. were also introduced in

POWERGRID which proved quite effective in identifying

developing faults at initial stages. Such Current

Transformers were removed from service thus

catastrophic failures could be avoided.

Analysis of degradation process of paper/ oil insulation is

generally based on the following criterion:

1. Increase of Tan delta with respect to original

value. An increase of 0.1% per year in the tan

delta value is considered normal.

2. Results of DGA are analyzed and rising trend of

key gases is monitored. Sudden increase in any

key gas indicates fault inside CT. Evaluation of

different gases in CTs is based on IEC-60599.

3. Monitoring of moisture content in oil and paper.

Presence of higher moisture content in paper

may accelerate Insulation ageing.

4. Increase of Capacitance indicates shorting of

insulation layers due to low intensity discharges,

presence of moisture due to sealing/ gasket

failure and ageing of insulation. Increase of

capacitance value more than 1% per year is

considered high and should be a matter of

concern.

Capacitance and Tan Delta Values

The effective implementation of tests like Capacitance

and Tan Delta measurement at site requires

compensations for the following factors:

(a) Effect of Temperature

(b) Effect of Ambient Humidity

(c) Effect of Electrostatic Interference

(d) Effect of System Frequency

Normally for new CTs, Tan Delta values are in the range

of 0.2% to 0.3%. Ageing of CT under normal operating

conditions will cause gradual increase in Tan delta value.

Tan Delta values upto 0.7% are generally considered

within permissible limits during service. However beyond

0.7% value of Tan, CTs need to be kept under close

monitoring.

The major hurdles in effective implementation of above

guidelines have been carrying out testing/ measurements

at site under induced voltage conditions. Use of proper

testing Equipments which measure correctly under site

conditions within specified accuracy limits with

repeatability is essential as variations/ changes in the

range of 0.1% are to be monitored to observe proper

trends.

Interpretation of Tan Delta Test Results

An increase of Dissipation Factor (Tan Delta)

accompanied by a marked increase in Capacitance

indicates excessive moisture in the insulation. Increase of

dissipation factor alone may be caused by thermal

deterioration or contamination other than water.

On CTs provided with power factor or Capacitance Test

Tap, the effect of leakage current over the surface of

porcelain bushings may be eliminated from the

measurement by testing in UST (Ungrounded Specimen

Test) mode.

Rise in dissipation factor with temperature:

Deterioration of insulation (due to moisture content/

aging) causes exponential rise in Tan Delta with increase

in temperature and is governed by the following equation:

Tan

T =

Tan

T0 e

(T-T0)

Where,

To= Standard Temperature

T = any temperature other than standard temperature To

(normally 20C)

= Temperature Coefficient

Tan

T0

= Tan Delta at Standard Temperature

Tan

T

= Tan Delta at any temperature T

0.01< < 0.015. If value i.e. Tan Delta temperature

coefficient is between 0.015 to 0.03, it shall be

recognized as characteristics of defective or questionable

condition. And value of more than 0.03 is a sign of

dangerous or alarming condition.

Insulation Resistance Measurement

(i) Dielectric Absorption Current

On application of direct Voltage on any insulation,

not only charging current alone flows but an

additional current known as dielectric absorption

current also flows. This current is due to the presence

of polar molecules in the insulation system.

(ii) Conduction Current

The steady state value of the current is known as the

conduction current. If one waits until the dielectric

absorption current has decayed to zero. In solid

insulating materials, which have absorbed moisture,

for increase in voltage stress there will be a non-

linear large increase of the conduction current.

The ratio of Insulation Resistance Values taken after 60

seconds and 15 seconds is termed as Polarisation Index.

The value of Polarisation Index is also one of the

important factors in indicating the health of the Insulation

of the Current Transformers.

FAILURES OF CURRENT TRANSFORMERS IN

POWERGRID

As brought out earlier, about 26 nos. EHV class CTs have

failed in last 6 years in POWERGRID network. Even

newly commissioned CTs have failed. A team of Experts

from POWERGRID involving Manufacturers also,

critically analyzed all failures. However their sudden

failures caused alarm and detailed failure analysis was

carried out at manufacturers works in few cases. Based on

failure analysis test results, following reasons of failures

were identified:

1. Primary insulation puncture/failure (Exhibit-1 and 2).

2. Non-uniform Electrical Stress on primary insulation

mainly in case of Live Tank design CTs.

3. Wrong Testing Procedure for Dissipation factor

Measurement at manufacturers works that could not

identify defects at works during pre-dispatch testing.

4. Improper primary insulation paper wrapping during

manufacturing process.

5. N2 gas leakage from sealing gaskets and N2 filling

point leading to moisture entry inside CT.*

Exhibit-1

Failure of Primary Insulation of Live Tank Type CT

Exhibit-2

Failure of Primary Insulation of Dead Tank Type

CT.

*- All the CT failures were analyzed in detail involving

respective manufacturers. The reasons were identified and

following preventive and corrective measures were taken

to reduce the failure rates:

1. Change in the Technical Specifications like

Testing of CTs as per IEC-60044 (1) specially

Partial Discharge Measurement.

2. Monitoring of change of Capacitance and Tan

Delta values from 0.1 p.u. to 1.1p.u. of the rated

Voltage.

3. Monitoring of change of Capacitance and tan

Delta before and after 1 minute HV Test.

4. Monitoring N2 gas pressure for all CTs having

N2 Cushion at the top for taking care oil

expansion/contraction.

With implementation of above measures, failures rate has

come down tremendously and even some CT defects were

detected at Manufacturers works during testing and same

were rectified/re-processed. For CTs of other makes in

which failure rate was almost zero, a pilot project was

taken up which is discussed as Case Study as given below

to assess the condition of such make of CTs so that

preventive actions may taken well in advance.

CASE STUDY

Majority of EHV class CTs in POWERGRID network are

approaching the age profile of 12-18 years. As mentioned

above, there have been number of CT failures attributable

to primary insulation failure. In view of sudden failures of

CTs in recent past without any alarm, it was considered

necessary to assess the condition of CTs, which are in

service for a very long time so as to prepare for any

eventuality in future. Out of the operating healthy

population, 15 CTs of three makes were identified for

detailed diagnostic checks.

Brief Technical Particulars of selected CTs considered

for Condition Assessment:

All CTs are 420kV class, rated current as 2000 Amperes,

BIL level of 1425kV and Switching Impulse Level of

1050kV. CTs selected were of two types:

(1) Dead tank type with N2 cushion at the top to

take care oil expansion and contraction due to

temperature variations. Paper with Paraffinic oil

is used as insulating medium.

(2) Live tank design fitted with Teflon bellow at the

top. Paper with Nepathenic oil is used as

insulating medium.

Diagnosis Methodology:

Following tests were conducted on these CTs under

shutdown:

1. Capacitance and Tan Delta Measurement

2. Dissolved Gas Analysis (DGA) of CT Oil as per IEC-

60599.

3. Oil Parameters Testing as per IS-1866 (IEC-60422).

4. Insulation Resistance Measurement (Polarization

Index Test)

For oil sampling, special adopters were developed and to

have uniformity, all Oil samples were tested only at

POWERGRIDs Centralized Insulating Oil Testing

Laboratory (CIOTL). For Measurement of Capacitance

and Tan Delta, CTs were removed from service (under

shutdown) and Tests were carried out after thoroughly

cleaning the Porcelain surfaces. Both side conductors i.e.

jumpers were removed from CT and Test Readings were

taken in UST(Ungrounded Specimen Test Mode) for most

of the CTs.

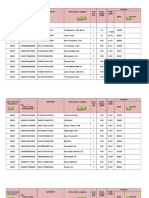

Results of 15 nos. tested CTs are given below in Table-1

Table-1

DGA Test Results CT

No.

Ma-

ke

Tan

Delta

Value at

10kV

(%)

Capa-

citan-

ce

(pF)

Insulation

Resistance

(M ) or

Polarization

Index

H2 CH4 C2H4 C2H6 C2H2 CO CO2

Remarks

1 A 0.13 963 1.7 2 45 4 1 3 518 787

2 A 0.2 921 1.0 2 42 4 2 6 458 890

3 A 0.3 926 2.1 3 38 5 2 0.9 415 852

4 B 0.5 300 1.1 30 5 2 10 0 26 1146

5 B 0.5 264 1.2 24 5 1 8 0 43 1157

6 B 0.5 283 1.5 3 6 1 21 0 17 1108

BDV, ppm

very poor

(<35kV

and

>25ppm)

7 C 0.29 878 1.6 7 11 2 3 0 122 415

8 C 0.28 876 1.2 3 5 0 2 0 36 167

9 C 0.31 883 1.2 4 5 0 1 0 36 247

10 C 0.28 932 2500M 4 187 2 10 0 93 822

11 C 0.22 922 2250M 4 8 1 5 0 45 570

DGA Test Results CT

No.

Ma-

ke

Tan

Delta

Value at

10kV

(%)

Capa-

citan-

ce

(pF)

Insulation

Resistance

(M ) or

Polarization

Index

H2 CH4 C2H4 C2H6 C2H2 CO CO2

Remarks

12 C 0.25 924 1800M 4 24 2 10 0 88 611

13 C 0.31 809 1.5 2 29 5 85 0 63 578

14 C 0.26 799 2.0 0 17 1 24 0 32 1199

15 C 0.26 808 1.33 0 14 1 17 0 43 414

Table-2

DGA Test Results CT

No.

Make Tan

Delta

Value

at

10kV

(%)

Cap

acita

nce

Insulation

Resistance

or

Polarizatio

n Index

H2 CH4 C2H4 C2H6 C2

H2

CO CO2

Remarks

1 A 0.33 959 1.16 0 7 11 2 0.5 525 688

2 A 0.2 955 1.37 0 5 4 1 0.5 444 1679

Analysis of the Test Results:

Brief summary of the test results is placed below:

1. DGA for most of the CTs were in order and

insulation degradation was due to normal ageing.

Except for CH4 value(187ppm) for CT(Sr.No.10)

and for C2H6 value(85ppm) for CT(Sr.No.13).

2. Oil parameters like BDV, moisture contents etc. were

also within limits except for three nos. CTs (at Sr.

Nos. 4 to 6) which violated norms. Oil was replaced

for all the thrre CTs (Sr.No.4 to 6) after which DGA,

BDV, Capacitance and Tan Delta values were found

to be within limits and CTs were successfully taken

into service.

3. Capacitance and Tan delta values are also within

acceptable limits except for CTs at Sr.No.1 to2 and 4

to 6 in which Test were taken in GST mode without

removing the Jumpers. Tests were repeated as

mentioned above at point no.2. For CTs at Sr.No. 1

and 2, all Tests were repeated and Test Results are

given in Table-2

4. IR test results also indicate normal values.

Benefits derived by POWERGRID

Pilot project was undertaken for those designs/ makes of

CTs where no failures were reported. The outcome of the

pilot project revealed normal Ageing of CTs even after

15-18 years of service. It was decided to replace oil for

three nos. CTs indicating poor values of BDV and

moisture content. After oil replacement, tests were

repeated and results improved and these CTs are

operating successfully. Two CTs were found violating

norms in respect of CH4 and C2H6 and have been kept

under close monitoring/ watch.

Based on the outcome of the pilot project, following

emerged:

1. CTs operating under normal conditions and free

from oil/N2 gas leakage problems are mostly

healthy even after 18 years of service.

2. N2 gas monitoring is very important for all CTs

with N2 cushion at the top. N2 monitoring

procedure was standardized and implemented

throughout POWERGRID.

3. Suspected CTs having high values of dissolved

gases are kept under constant watch.

CONCLUSION:

Condition of 15 nos. EHV class CTs in service has been

assessed as discussed above. The CTs selected for Pilot

project were based on the age profile and the CTs which

are having almost zero failures. Condition assessment of

sample CTs has proved that CTs even after 12-18 years of

service are healthy and looked after properly. Introduction

of new condition assessment tests in POWERGRID have

brought down CT failures and better performance of CTs

is expected in future. Constant updation of diagnostic

testing techniques can reduce failures/ down time to

increase system availability & reliability.

ACKNOWLEDGEMENT

The authors are thankful to the POWERGRID

management for permitting them to present the papers in

CIGRE-2002. The views expressed in this paper are of the

authors and not necessarily that of the POWERGRID

organization.

REFERENCES:

[1] Mark F.Lachman, Doble engineering Company,

Application of Equivalent Circuit Parameters to

offline diagnostics of Power Transformer

(Preview).

[2] G.CSEPES, I.HAMOS, J. SCHMIDT, A.

BOGNAR, A DC Expert System (RVM) for

checking the re-furbishment efficiency of high

voltage oil paper insulating system using

polarization spectrum analysis in range of Long

time Constants, CIGRE August,94(12-206).

[3] Mark F. Lachman, Doble engineering Company,

Application of Equivalent Circuit Parameters to

offline diagnostics of Power Transformer

(Preview).

[4] Enhanced Diagnosis of Power Transformers

using On and off line methods: results,

examples and future trends.

By S.Tenbohlen, U.Sundermann, H.Borsi, P.Werle &

H.Matthes, Cigre 2000

Das könnte Ihnen auch gefallen

- Temperature Correction Factors - Power Grid IndiaDokument6 SeitenTemperature Correction Factors - Power Grid IndiaAMIT BISWASNoch keine Bewertungen

- Power Transformers: Overview Factors On Assessing Insulation LifeDokument8 SeitenPower Transformers: Overview Factors On Assessing Insulation LifeДенис ЛяпуновNoch keine Bewertungen

- Field Experience With Sweep Frequency Response Analysis For Power Transformer Diagnosis PDFDokument8 SeitenField Experience With Sweep Frequency Response Analysis For Power Transformer Diagnosis PDFThien Nguyen VanNoch keine Bewertungen

- Online Condition Monitoring Systems For High Voltage Circuit BreakersDokument51 SeitenOnline Condition Monitoring Systems For High Voltage Circuit Breakersdevarshi_shuklaNoch keine Bewertungen

- Upptcl Training (Ee)Dokument27 SeitenUpptcl Training (Ee)AakashNoch keine Bewertungen

- Online Drying Systems With MoistureDokument51 SeitenOnline Drying Systems With MoisturePrasanna MohandossNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument11 SeitenDisclosure To Promote The Right To InformationEMD VSTPSNoch keine Bewertungen

- PR6100SA-005-A HVPD Kronos Monitor Product Presentation 22.05.2015 PDFDokument65 SeitenPR6100SA-005-A HVPD Kronos Monitor Product Presentation 22.05.2015 PDFKhoilnNoch keine Bewertungen

- Interpretation of Transformer FRA Responses - Part II: Influence of Transformer StructureDokument8 SeitenInterpretation of Transformer FRA Responses - Part II: Influence of Transformer StructureErfan AhmedNoch keine Bewertungen

- IEEE Guide C5712200-2022Dokument84 SeitenIEEE Guide C5712200-2022Sontri ChiggumNoch keine Bewertungen

- LL SgdaDokument20 SeitenLL SgdapetarlNoch keine Bewertungen

- Chap 6 - High Voltage Testing of EquipmentDokument16 SeitenChap 6 - High Voltage Testing of Equipmenthadrien100% (1)

- T-08 LTC Dga Guide AscheDokument7 SeitenT-08 LTC Dga Guide Aschebcqbao100% (1)

- Valence Training BrochureDokument12 SeitenValence Training Brochurerodruren100% (1)

- Case Studies of The Transformers Failure Analyses: July 5, 2015Dokument10 SeitenCase Studies of The Transformers Failure Analyses: July 5, 2015Rama SubrahmanyamNoch keine Bewertungen

- SR - No. Description Particulars: Shilchar Technologies Limited::::::::::::::::::::::::::::::::: Gauranteed & Other ParticularsDokument1 SeiteSR - No. Description Particulars: Shilchar Technologies Limited::::::::::::::::::::::::::::::::: Gauranteed & Other Particularsram krishnanNoch keine Bewertungen

- VIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFDokument8 SeitenVIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFgeorge_cpp2Noch keine Bewertungen

- 400 KB Circuit Breaker Installation Pro6Dokument24 Seiten400 KB Circuit Breaker Installation Pro6sanjayNoch keine Bewertungen

- Interpretation of Sweep Frequency Response AnalysiDokument8 SeitenInterpretation of Sweep Frequency Response AnalysiRyan JohnNoch keine Bewertungen

- 2 - 14 Experiences EuroDoble MeetingsDokument22 Seiten2 - 14 Experiences EuroDoble Meetingsbcqbao100% (1)

- Inter Trip RelayDokument10 SeitenInter Trip RelayNam Hoai Le100% (1)

- Difference Between AC and DC Hi PotDokument1 SeiteDifference Between AC and DC Hi Potunnikrish05Noch keine Bewertungen

- 1431928880session II CBDokument84 Seiten1431928880session II CBAnonymous i2u3XW8UJHNoch keine Bewertungen

- Bushing Power Factor Training PPTDokument44 SeitenBushing Power Factor Training PPTMiguel Zuñiga100% (1)

- Failure Analysis of A Power Transformer Using Dissolved Gas Analysis - A Case StudyDokument4 SeitenFailure Analysis of A Power Transformer Using Dissolved Gas Analysis - A Case StudyInternational Journal of Research in Engineering and Technology100% (1)

- RIP (Resin Impregnated Paper) Bushing For EHV Class Power TransformerDokument3 SeitenRIP (Resin Impregnated Paper) Bushing For EHV Class Power TransformerBaSant KohliNoch keine Bewertungen

- Prismatic Oil Level GaugeDokument2 SeitenPrismatic Oil Level GaugevipulpanchotiyaNoch keine Bewertungen

- Effect Residual Magnetism On The Magnetic Core of A TransformerDokument4 SeitenEffect Residual Magnetism On The Magnetic Core of A Transformerhendro suprianto nugrohoNoch keine Bewertungen

- Communication Technologies Augmenting Power TransmissionDokument54 SeitenCommunication Technologies Augmenting Power TransmissionChaitanyaVigNoch keine Bewertungen

- Invited Speaker - Vitor Sokolov PDFDokument21 SeitenInvited Speaker - Vitor Sokolov PDFAndar ApriadiNoch keine Bewertungen

- Commissioning Numerical RelaysDokument24 SeitenCommissioning Numerical RelaysVHMANOHARNoch keine Bewertungen

- Comment Insulation Resistance (IR) Values - Electrical Notes & ArticlesDokument41 SeitenComment Insulation Resistance (IR) Values - Electrical Notes & ArticlesMunazar HussainNoch keine Bewertungen

- CT Internal StructureDokument3 SeitenCT Internal StructureSudhakar KethireddyNoch keine Bewertungen

- Gas Insulated Transformer Full ReportDokument36 SeitenGas Insulated Transformer Full Reportsknayak690% (10)

- Omicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesDokument8 SeitenOmicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesNguyen Vu Nhat HaNoch keine Bewertungen

- SFRA White PaperDokument4 SeitenSFRA White Paperykh92167Noch keine Bewertungen

- 3 PH Transformer and Generator ModelsDokument11 Seiten3 PH Transformer and Generator ModelsMansa ManuNoch keine Bewertungen

- DCRM WorkshopDokument32 SeitenDCRM WorkshoplrpatraNoch keine Bewertungen

- Transmission Line Tower Earthing Analysis Using SafeGrid PDFDokument5 SeitenTransmission Line Tower Earthing Analysis Using SafeGrid PDFBaskar ElNoch keine Bewertungen

- Atlanta Transformer ComponentsDokument74 SeitenAtlanta Transformer Componentsalex696Noch keine Bewertungen

- CB Testing SCOPE Compatibility ModeDokument58 SeitenCB Testing SCOPE Compatibility ModeVepty whoops100% (1)

- Bus Switching Scheme PDFDokument6 SeitenBus Switching Scheme PDFJAYKUMAR SINGHNoch keine Bewertungen

- Dirana Anp 10017 EnuDokument29 SeitenDirana Anp 10017 Enubcqbao100% (1)

- Analysis Using Various Approaches For Residual Life Estimation of Power TransformersDokument19 SeitenAnalysis Using Various Approaches For Residual Life Estimation of Power TransformersJicheng PiaoNoch keine Bewertungen

- Case Study of VLF / Tan Delta & Partial Discharge Acceptance Testing of New 23kV CablesDokument38 SeitenCase Study of VLF / Tan Delta & Partial Discharge Acceptance Testing of New 23kV CablesAshwin SevariaNoch keine Bewertungen

- Doble Lemke Power Transformer Advanced PD Monitoring UHF 2009Dokument21 SeitenDoble Lemke Power Transformer Advanced PD Monitoring UHF 2009taufiqishak09Noch keine Bewertungen

- Health Indexing of TransformerDokument35 SeitenHealth Indexing of TransformerSamanway BeraNoch keine Bewertungen

- Transformer Sweep Frequency Response Analyzer HYRZ-902 Technical ManualDokument18 SeitenTransformer Sweep Frequency Response Analyzer HYRZ-902 Technical ManualPaulRuedaNoch keine Bewertungen

- Sample Report Oltc Condition Assesment PDFDokument22 SeitenSample Report Oltc Condition Assesment PDFWaqas MahmoodNoch keine Bewertungen

- S1Agile EN RN I.1 PDFDokument10 SeitenS1Agile EN RN I.1 PDFCorey PorterNoch keine Bewertungen

- TSDOS Adv Diag Testing DW PDFDokument61 SeitenTSDOS Adv Diag Testing DW PDFDhammika Dharmadasa100% (1)

- CB Monitor: On Line Circuit Breaker Monitoring SystemDokument4 SeitenCB Monitor: On Line Circuit Breaker Monitoring Systemashu_2787Noch keine Bewertungen

- Knowledge is "Real Power": Introduction to Power QualityVon EverandKnowledge is "Real Power": Introduction to Power QualityNoch keine Bewertungen

- Detecting Distribution Transformer FaultsDokument19 SeitenDetecting Distribution Transformer Faultsbangovan0% (1)

- DCRM Workshop PGCI BhiwadiDokument75 SeitenDCRM Workshop PGCI Bhiwadigaurang1111Noch keine Bewertungen

- Product: Complete Diagnostic SolutionsDokument8 SeitenProduct: Complete Diagnostic SolutionsbhpNoch keine Bewertungen

- 3 Main Causes of False Differential Current in TransformerDokument14 Seiten3 Main Causes of False Differential Current in TransformerPandurang YadavNoch keine Bewertungen

- Protection Systems Based On Rogowski SensorsDokument6 SeitenProtection Systems Based On Rogowski SensorsjulianvillajosNoch keine Bewertungen

- Ethics Vs Morals - Difference and ComparisonDokument7 SeitenEthics Vs Morals - Difference and ComparisonOm Bhaskar100% (1)

- Redefining LeadershipDokument15 SeitenRedefining LeadershipOm BhaskarNoch keine Bewertungen

- What Are Values, Morals, and Ethics - Business Ethics, Culture and Performance PDFDokument2 SeitenWhat Are Values, Morals, and Ethics - Business Ethics, Culture and Performance PDFOm BhaskarNoch keine Bewertungen

- Infosys Digital Transform Abstract 2017-03-24Dokument3 SeitenInfosys Digital Transform Abstract 2017-03-24Om BhaskarNoch keine Bewertungen

- Cash Flows 500Dokument41 SeitenCash Flows 500MUNAWAR ALI100% (2)

- Chapter 10Dokument8 SeitenChapter 10Om BhaskarNoch keine Bewertungen

- Cash Flows 500Dokument41 SeitenCash Flows 500MUNAWAR ALI100% (2)

- Work Done by M/S Soni Singh B/W 26Th Apr-25Th May Equipment ErectionDokument5 SeitenWork Done by M/S Soni Singh B/W 26Th Apr-25Th May Equipment ErectionOm BhaskarNoch keine Bewertungen

- New Doc 11Dokument1 SeiteNew Doc 11Om BhaskarNoch keine Bewertungen

- New Doc 12Dokument1 SeiteNew Doc 12Om BhaskarNoch keine Bewertungen

- Terms & Conditions For Security DepositDokument1 SeiteTerms & Conditions For Security DepositOm BhaskarNoch keine Bewertungen

- Design Projects in A PLCDokument10 SeitenDesign Projects in A PLCSam B.medNoch keine Bewertungen

- CNC Report1Dokument21 SeitenCNC Report1Prashant SharmaNoch keine Bewertungen

- r5210203 Pulse and Digital CircuitsDokument1 Seiter5210203 Pulse and Digital CircuitssivabharathamurthyNoch keine Bewertungen

- Service Manual Hrman Kardon AVR 430, AVR 630Dokument126 SeitenService Manual Hrman Kardon AVR 430, AVR 630aliarro100% (1)

- To Study The Characteristics of A Common Emitter NPN (Or PNP) Transistor & To Find Out The Values of Current & Voltage GainsDokument11 SeitenTo Study The Characteristics of A Common Emitter NPN (Or PNP) Transistor & To Find Out The Values of Current & Voltage GainsAman AhamadNoch keine Bewertungen

- Lampiran A1 SD A5Dokument466 SeitenLampiran A1 SD A5Irfansyah MaladiNoch keine Bewertungen

- Balanced To UnbalancedDokument4 SeitenBalanced To Unbalancedbvogeler4007Noch keine Bewertungen

- ENGN 2218 - HLab 1Dokument10 SeitenENGN 2218 - HLab 1varshav_4Noch keine Bewertungen

- Chemical Engineering Magazine 2017.08Dokument68 SeitenChemical Engineering Magazine 2017.08anizNoch keine Bewertungen

- Lab 1 - Ecm436Dokument12 SeitenLab 1 - Ecm436ewan0540% (5)

- Sierra 303B Frequency Selective Levelmeter Operation Manual (SOM-303B), January 1974.Dokument25 SeitenSierra 303B Frequency Selective Levelmeter Operation Manual (SOM-303B), January 1974.Bob Laughlin, KWØRL100% (1)

- Ac & DC CurrentDokument11 SeitenAc & DC CurrentAniketNoch keine Bewertungen

- 05 Askeland ChapDokument10 Seiten05 Askeland ChapWeihanZhang100% (1)

- Power Semiconductor DevicesDokument73 SeitenPower Semiconductor DevicesRajesh BhaskarlaNoch keine Bewertungen

- Sylvania ld320ssx Chassis fl9.4 PDFDokument96 SeitenSylvania ld320ssx Chassis fl9.4 PDFFernando GuerreroNoch keine Bewertungen

- Semiconductors: Energy Level Diagram of A SemiconductorDokument30 SeitenSemiconductors: Energy Level Diagram of A SemiconductorF2 - 57 Rahul Rajpurohit .MNoch keine Bewertungen

- EkekeDokument8 SeitenEkekeJeanCarlosCletoVazquezNoch keine Bewertungen

- Kirchof LawsDokument33 SeitenKirchof LawsZain SaleemNoch keine Bewertungen

- Design and Construction of LED Matrix DisplayDokument7 SeitenDesign and Construction of LED Matrix DisplayTseren TsekuNoch keine Bewertungen

- Electrical Engineering Text Listing - 2008Dokument2 SeitenElectrical Engineering Text Listing - 2008alikosNoch keine Bewertungen

- Icl3221, Icl3222, Icl3223, Icl3232, Icl3241, Icl3243Dokument28 SeitenIcl3221, Icl3222, Icl3223, Icl3232, Icl3241, Icl3243catsoithahuong84Noch keine Bewertungen

- EceDokument50 SeitenEcemandadi21Noch keine Bewertungen

- Be ManualDokument68 SeitenBe ManualSubhan50Noch keine Bewertungen

- Manual Equipo DanfossDokument60 SeitenManual Equipo Danfosscolive1100% (2)

- 2 N 7000Dokument7 Seiten2 N 7000Arturo SegovianoNoch keine Bewertungen

- 2he PDFDokument188 Seiten2he PDFnbr67sceNoch keine Bewertungen

- Cortinas GL r63fDokument3 SeitenCortinas GL r63fviernes06Noch keine Bewertungen

- DatasheetDokument4 SeitenDatasheetGrupo EpufmNoch keine Bewertungen

- Generator Automatic Voltage Regulator Operation ManualDokument6 SeitenGenerator Automatic Voltage Regulator Operation ManualchanlinNoch keine Bewertungen

- M45 Ceva ReprintDokument5 SeitenM45 Ceva ReprintAnonymous kg7YBMFHNoch keine Bewertungen

- 11 Electric Current PDFDokument2 Seiten11 Electric Current PDFDev RajuNoch keine Bewertungen

- Power Electronics: Thyristor Controlled Power For Electric MotorsDokument10 SeitenPower Electronics: Thyristor Controlled Power For Electric Motorsshahab moinNoch keine Bewertungen